A review on different process parameters in FDM and their effects on various required outputs

Aadesh R. Chaudhari1 , Om A. Sonawane2 , Mitali V. Dhivare3 , Sanket S. Chikshe41Student, Dept of Mechanical Engineering, PVG’s COET PUNE, Maharashtra, India

2 Student, Dept of Mechanical Engineering, PVG’s COET PUNE, Maharashtra, India

3 Student, Dept of Mechanical Engineering, PVG’s COET PUNE, Maharashtra, India

4Professor, Dept of Mechanical Engineering, PVG’s COET PUNE, Maharashtra, India ***

Abstract - FDM(Fuseddepositionmodelling)isthemanufacturingtechniqueinwhichproductisbuiltlayerbylayerwithhelp of3Dprintersbydepositionofheatedmaterialthroughanozzle.Itcanproducecomplexshapeswhicharenearlyimpossibleto buildthroughconventionalsubtractivemanufacturingprocesses,alsoitismoreefficient,economical,cheapandcanproduce widevarietyofproducts.Ontheotherhand,ithasseveralmajorlimitationslikelimitedoptionsofmaterial,dimensional accuracyandsurfacefinishing,poormaterialstrength,andslowrateofproduction.Numerousresearchstudiesareongoingon studytoenhancetheusageofFDMindifferentoperationalenvironments.Multipleresearchersconcentratedoncomposite materialssuchascarbonfibrecomposite,glassfibrereinforcedcomposite,metalcomposites,polymercomposites,andceramic composites.Thispaperaimstoprovideacomprehensivereviewofsubstantialprogresshasbeenmadeindevelopingarangeof samplesandoptimizationofprintingparametersforFDM.

Key Words: Additive manufacturing, process parameters, fused deposition modelling, composite materials, tensile and flexural strength

1. INTRODUCTION

The3DPrinting,arapidlyevolvingadditivemanufacturingtechnology,hasthepotentialtorevolutionizethemanufacturing industrybysignificantlyreducingproductiontimecomparedtotraditionalmethods.Withongoingadvancements,itisexpected that3Dprinterswillsoondominatethemarket,replacingtraditionalmanufacturingprocessesandinitiatinganewindustrial revolution[1] Additivemanufacturingalsoknownas3Dprintingisoneofthemostrevolutionarytechnologywhichpermits thefabricationofthephysicalobjectbyaddingthemateriallayerbylayertoformadesiredobjectwhichexactlysimilarto conventionalsubtractivemanufacturingprocesseslikelasercutting,CNCmachining,millingmachinecuttingwhichultimately facilitatestheuserwithseveralbenefitslikeDesignfreedom-3Dprintingallowsthetediousandintricategeometrieswhichare verydifficultormorelikelyimpossibletoaccomplishwithsubtractivemanufacturing.Materialefficiency-thesubtractive manufacturingprocessgeneratesremarkableamountofmaterialwastebecauseofeliminationofunwantedexcessmaterial, whereasadditivemanufacturingisverymaterialeffectivebecauseitconsumesonlyrequiredamountofmaterialtogeneratean endproduct.Costeffectivenessofcomplexparts-conventionalsubtractivemanufacturingprocessinvolvesmultiplesteps, specializedtoolsandlongerproductiontimewhicheventuallyresultsinhighcostsofproductbut,theadditivemanufacturing canmergemultiplecomponentsinthesingleprintedobjectwhichalsodecreasesassemblytimeaswellastime.CustomizationAdditivemanufacturingallowsthegenerationofexclusiveandpersonalizedpartsaspertheindividualrequirementsand preference.Reducedtoolingcosts-Additivemanufacturingeliminatestherequirementsofspecializedtoolsforcustompartsor batch production as it is needed in conventional manufacturing method. Vishal N. Patel et al. conducted a review on the parametricoptimizationoftheFusedDepositionModellingprocessinrapidprototypingtechnology,focusingondifferent parameterssuchaslayerthickness,airgap,rasterwidth,rasterorientation,andmechanicalproperties,andreviewingvarious studiesthatinvestigatedtheeffectsoftheseparametersonmechanicalproperties,surfaceroughness,buildorientation,and qualityofFDMparts[2].Themethodforcreatinghigh-qualityABSwireasafeedstockfilamentforFDMispresentedinthis paper by examining the effects of extrusion parameters. This method produces ABS wire with favorable mechanical and thermal properties, printability, and bed adhesion, indicating its potential for industrial applications in the automotive, aerospace,andmedicalsectors[3].

2. Additive Manufacturing Process:

AdditivemanufacturingistheclassoftechnologywhichautomaticallydesignthemodelusingCADdata. In recent years, additive manufacturing process has found various applications in many industrial as well as commercial sectors.ABSandPLAarethemost commonlyusedfilamentsin3Dprintingbothofthemprovidehighqualitymaterialsintheirownways[4].Wecanusevarious reinforcingmaterialstoenhancethemechanical,thermal,andflame-retardantpropertieslikeglassfiber-reinforcedmodeling

polymer(GFRP)usingthefuseddepositionmodeling(FDM)3Dprintingprocess[5].LeipengYangetal.investigatedtheimpact ofaddingCarbonNanotubes(CNT)toPolylacticAcid(PLA)inFusedDepositionModelling(FDM),focusingontheenhancement ofthermal,mechanical,andelectricalproperties,usingtwoapproaches:optimizingprocessparametersandutilizingnew materials,resultinginimprovedmechanicalproperties,electricalconductivity,andthermalstabilityasCNTcontentincreased inthePLA/CNTblend [6].A tableisformulated tocorrelatethevarious printingparametersandtheireffectson desired outputs.Fromthistable,itcanbeunderstoodthat,noneofthosehavesimilaritieswithinthemandtheycanbevariedasper therequirementsandavailabilityofresources.FDMisthemostpopularamongthedifferentadditivemanufacturingprocesses suchasstereo-lithography,fuseddepositionmodeling,binderjetting,directenergydepositionandsheetlamination. R.B. Kristiwanetal.conductedathoroughreviewonFDM3Dprinting,coveringfilamentprocessing,materials,printingparameters, andtheir impact on product quality.Theyhighlightedtheneed for printing parameter optimizationto achieve improved mechanicalpropertiesanddimensionalaccuracyanddiscussedcurrentissuesandpotentialfutureresearchdirections[7].

Table

Processparametersandtheireffectsonrequiredoutputs

FDMisthemostcommonlyusedadditivemanufacturingtechniquebecauseithasseveraladvantagesoverothertechniques suchasAccessibilityandaffordabilityofthe3Dprintersascomparedtootheradditivemanufacturingprocesses,itcanbeused withavarietyofmaterials,thismethodiseasytouseandevenbeginnerscanalsomakeobjectsbecauseofitsfriendlyinterface, and it has maximum flexibility by which one can control surface smoothness, mechanical and other strengths of the end product by varying its different printing parameters and their levels. Amir Rostami et al. demonstrated the influence of multiwalled carbon nanotubes (MWCNTs) on the rheological, thermal, and electrical properties of a PC/ABS blend, emphasizingthesignificantimprovementinphysicalandmechanicalpropertiesachievedthroughtheuseofnanofillers,aswell asthelocalizationofMWCNTsattheinterfaceofPCandABS,whichleadstoincreasedelectricalconductivity[8]. DineshYadav etal.successfullyusedanartificialneuralnetworktooptimizetheFDM3Dprintingprocessparametersformulti-material printing,leadingtobetterprintqualityandfewerdefects.Thisworkhaspotentialramificationsformanufacturingprocesses thataremoreeffectiveandeconomical[9].

3. Challenges in AM

Additivemanufacturingisreplacingthetraditionalmanufacturingprocessesbecauseofitsadvantageslikedesignfreedom, reducedtoolingcosts,productcustomization,sustainability,andwastereductionthoughAMhasahardpathaheadtoget acceptedforreal-timeproductapplication.SomeoftheimportantchallengesfacedbyAMarelimitedsizeofparttobeprinted, misalignmentsinthetoplayers,costoftheproduction,materialselection,lessaccuracy,costoftheproduction.DineshS.K.et al.studiedtheflexuralandtensilebehaviorofPLA,ABS,andPLA-ABSmaterialsin3Dprinting,evaluatingvariousprinting

parameters and proportions, and discovered that the sandwiching of ABS and PLA in 3D printed samples demonstrated promisingmechanicalproperties,indicatingitspotentialasafuturefilamentoptioninadditivemanufacturing[4].

3.1. Post-processing and finishing:

ItplaysaverycrucialroleinAMtofulfilldesireddimensionalaccuracy,surfacefinishing,andaestheticsoftheprintedparts.It increasesthecostandtimerequiredtomanufactureaspecificproductforenduse.Theprintingofoverhangsandcomplex geometries is facilitated by several AM techniques by use of support structures. This support must be taken down after printing,iscanbecarriedoutmanuallywiththeaidofcuttingimplementsorchemicalsolvents,orautomaticallyutilizing techniquelikewaterjettingorsupportsthosedissolves.BecauseAMisanadditivetechnique,partsfrequentlyhavelayered surfacetextures.Therearemanymethodsthatcanbeused,suchassanding,polishing,orabrasiveblastingtoenhancethe surfacefinishing.Thesetechniqueshelpinreducingsurfaceroughnessandapparentlayerlines,buttheyrequireresources, tooling,labors.H.Kursadetal.investigatedtheFDM3DprintingofMWCNTreinforcedABSnano-compositeparts,highlighting thesignificantimprovementinmechanicalandelectricalproperties,suchasincreasedtensilestrength,flexuralstrength,and electricalconductivity,demonstratingthepotentialforimprovedABSpartsintheelectronics,aerospace,andautomotive industries[10].

3.2. Emergence of Cavity

Itisalsoknownasvoidsordefects;theycanappearforavarietyofreasonsandhaveaneffectonthequalityandstructural integrityofprintedproducts.Cavitiesmaydevelopbetweendepositedlayersifthematerialflowisnotproperlycontrolledorif thereareproblemswiththematerial’sviscosity,temperature,orextrusionpressure.Duringtheprintingprocess,unevenor inconsistentheatdistributionmightresultinlocalizedcoolingorrestrictedmaterialmelting.Thismaycausegapsorweak interfacesbetweentheprintedlayersduetoinsufficientlayerfusion.PowderedmaterialisusedinseveralAMprocedures, suchaspowderfusionmethodsinwhichtheinternalcavitiesmaybecreatedintheprintedpartifgasesorairpocketsget trappedinthepowderbedorthematerialfeedstock.

4. Fused deposition modeling:

Theadditivemanufacturingprocessisthemanufacturingprocessinwhichwegetthedesiredshapeandsizeofanobject, efficientlywiththeleastusageofmaterialformingitlayerbylayerwhichultimatelygeneratesthedesiredoutcomeproductby anymaterial,frompolymerstometalsandfromceramicstoevenabiologicalmaterialtoosuchaslivingcells.Thefounderof Stratasys,ScottCrumpfirstintroducedtheFDMprocesstotheworldinthelate80s.Itiswellknownbysomeothernameslike FusedDepositionModelling(FDM),FusedFilamentFabrication(FFF),PlasticJetPrinting(PJP),MaterialExtrusion(ME),and ExtrusionDeposition(ED).Thestudyexaminestheflexuralandtensilebehaviorof3DprintedobjectsmadeofPLA,ABS,and PLA-ABSblends,emphasizingtheimpactofprocessingvariables,suchasprintingorientation,layerthickness,andinfilldensity, on the mechanical characteristics of the materials. The maximum flexural strength was found in PLA, the highest tensile strengthwasfoundinABS,andthequalitiesofPLA-ABSblendswereintermediate,highlightingthesignificanceofchoosinga materialandprocessingconditionsdependingondesiredmechanicalattributes.Inordertobetterunderstandandoptimizethe qualitiesof3Dprintedparts,thestudyalsohighlightsthemajorimpactofprintingorientationonmechanicalpropertiesand proposesmoreresearchonotherprocessingfactors[11].

In3Dprinting,themovingnozzleextrudestheheatedmaterialanddepositsitonthebedwhichcanmoveinaverticaldirection thatisthesameasthelayerthickness.Thenozzlecanmoveinbothdirectionsxandy,itmovesinx-ywhileprintingasingle layeranditcontinuestilltheentireobjectisprinted.ThematerialisheatedslightlyaboveitsglasstransitionorSoftening temperaturewhichbringsittoasemi-solidstate[13] Afterextrusionthroughthenozzle,thematerialimmediatelysolidifies andacohesivephenomenontakesplacewhichultimatelystrengthenstheobjecttobeprinted.Theadhesivephenomenontakes placebetweenthebottomlayerandthebedsurfacewhichensuresthattheobjectdoesnotshiftoutofposition.Dependingon theapplicationoftheobjecttheprintingparametersareselected.Inthe1990’s,FDMbecamecommerciallyavailable,andits basicoperationalprinciplesweredepictedindiagrambyH.K.Daveet.al.[12]isillustratedinfig.1

5. Process Parameters of FDM

InFDM,processparametersareveryimportantsincetheyhaveadirectimpactontheprecision,quality,andcharacteristicsof theprintedparts.Someofthemostimportantfactorsareorientation,infillpattern,infilldensity,layer thickness,printing speed,fiberangle,numberoffiberrings,extrusiontemperature[5,7,12].Dependingupontheparticularneedsoftheprinted part, the filament being used, and the desired quality of finished result, these process parameters can be modified and optimized.Toimproveprintquality,dimensionalaccuracyandmechanicalqualitiesinFDM,theseparameterscanbefinetuned. Vinaykumar S Jatti et al. investigated the effect of Fused Deposition Modelling process parameters such as layer thickness,printingspeed,infillpercentage,andextrusiontemperatureonthemechanicalpropertiesofprintedparts,where printingspeedaffectedmaterialdistributionandphysicalwear,infillpercentageinfluencedtensilestrength,impactstrength, flexuralstrength,andsurfaceroughnesswithmaximumvaluesobservedat100%infilldensity,andlayerthicknessinfluenced tensilestrength,impactstrength,flexuralstrength[13].AshishR.Prajapatietal.investigatedtheimpactstrengthof3Dprinted fiber reinforcement polymer composites and discovered that the number of fiber rings has a significant influence, with increasingimpactstrengthobservedin0°/90°fiberanglesamples,highlightingthe potentialof3Dprintingforproducing functionaldesignswithimprovedmechanicalpropertiesinvariousindustriessuchasaviationandautomotive[14].

5.1. Layer Thickness

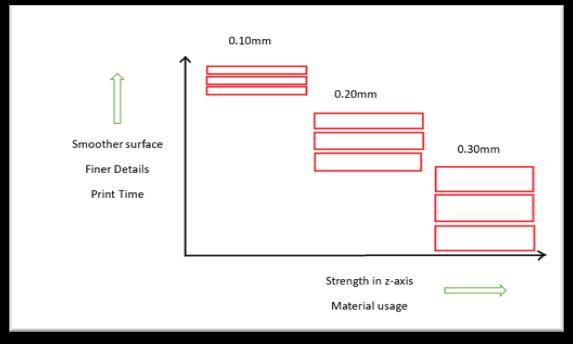

ThelayerthicknessistheheightofeachlayerthatisextrudedfromthenozzleanddepositedinFDM.Thisisoneofthemost importantparameterswhichplaysaroleindecidingtheprecisionlevelsharpnessofthe3Dprintedobject.Thesmallerthe layerthicknessmorewillbethesmoothnessofsurfacefinishingandgreatertheprecisionbutultimatelyitwillincreasethe printing time and material required for FDM whereas, the larger layer thickness prints the model in faster rate but compromisesinthesurfacefinishingquality.Fig2.illustratesthedifferentlayerorientations.Themechanical,surface,andpart qualitiesareallinfluencedbythelayerthickness.Thedensityofthecomponentandsurfacequalityrisewithlayerthickness [15].Highertensilestrengthisattainedatalowerlayerheightbecauseabiggerbondingareawithfewervacanciesisdetected atthelowerlayerheight,whichimprovestheperformanceofthetestspecimen[16].Withtheincrementofthelayerthickness, tensilestrengthfirstincreases,butafterafurtherincreaseinlayerthickness,tensilestrengthwasfoundtobedecreased[17].

5.2. Orientation

Theorientationreferstohowthespecimenisprintedalonganyaxisonthebead.Inthisstudywehavetakenthreedifferent orientationsviz.,flat,onlongedgeandonshortedge.Inflatorientationthespecimenisprintedalongthebottommostlayer andgraduallyprintstheupperlayers,whileinonlongedgeorientationthespecimenistobeprintedalongthelongestsideof thespecimen(horizontally)andsimilarlyforshortedgeitisprintedalongtheshortestsideofspecimen(vertically).The coolingrate,layerpackagingandtensilestrengthvariesasperthedifferentorientations.Fig3.referstodifferentorientation fordogboneshapedspecimen.

5.3 Infill Density

Infilldensityrefersofthepartisthepercentagevolumethatisbeingfilledwhileprintingthespecimenandtheremainingspace isvoid.Theinfilldensityaffectsthecharacteristicslikestrength,materialusage,weightofspecimen,timeofprint.Thelesser theinfilldensitythelesserwillbethevaluesofabovecharacteristicsandmorethevalueofinfilldensitymorewillbethevalue ofallcharacteristics.Fig4illustratesthevariouscombinationsofinfilldensityalongwithinfillpatterns[12].

5.4. Infill pattern

Theinfillpatternisthetechniquethathowtheinnerlayersareboundedtoeachother.Thesearenothingbutgeometrical patternswhicharebeingprintedintheinnerstructure.Therearemanyinfillpatternsavailableandthoseareselectedasper theapplicationrequirementsofanobject.Morethecomplexityrequiredintheinfillpatternmoretimeandmaterialitwilltake forprintingasshowninfig.4.

5.5 Printing speed

Therateatwhichtheprinterextrudesanddepositsthefilamentmaterialtoproduceathree-dimensionalobjectisreferredto asprintingspeedinFDM.Itisacriticalfactorwhichcanaffecttheoveralleffectiveness,productivity,andqualityofprocess. HighspeedcausesImproperDistributionofmaterial&wearofphysicalpartsVerylowspeedcauseslotoftimetoprintasingle specimen[13].

5.6. Extrusion Temperature

TheextrusiontemperatureinFDMisthetemperatureatwhichthethermoplasticfilamentismeltedanddepositedonelayerat atimetoproducea3Dprintedobject.TheextrusiontemperatureinFDMhasasignificantimpactonvarietyofprintingrelated factorsaswellasthefinalprintquality.Thefilamentmustconsistentlymeltattheextrusiontemperatureinorderforittoflow easilythroughtheprinter’snozzle.Thefilamentmaynotcompletelymeltifthetemperatureistoolow,whichcouldleadto blockagesorunevenextrusion.Theresolutionandgeneralprintqualityareimpactedbytheextrusiontemperature.Itaffects the deposition of material, flow rate, and filament viscosity. Although a higher temperature can make the material more flowable,itcanalsocauseproblemslikestringingorexcessivefilamentoozing.However,alowertemperaturemaycause under-extrusionorinsufficientlayerbondingwhileproducingprintsthataremoreaccurate.

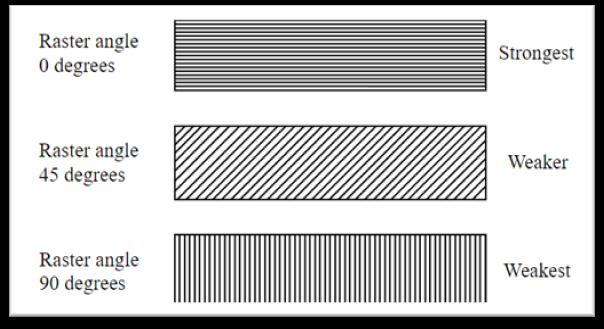

5.7. Raster Angle

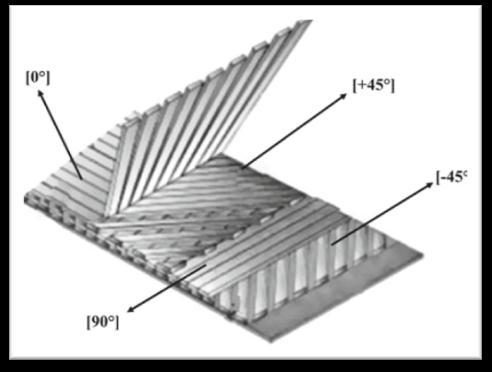

RasterangleistheanglecreatedbytheX-axisoftheplatformwherelayerdepositionoccursduringprinting.Themechanical characteristicsof3D-printeditemsaresignificantlyinfluencedbytherasterangle,whichdemonstratesthattensilestrength declineswithincreasingrasterangle.Arasterangleof0°mayoffergreatertensilestrengthbutalsomorebrittleness.Whilea 45°rasteranglelosesstiffnessandtensilestrength,itenablesforgreaterelongation.Thebestrasterangleshouldbechosen takingintoaccounttherequiredbalancebetweenstrength,flexibility,andotherimportantcharacteristicsfortheparticular application.Partsconstructedwitha90°rasteranglehaddecreasedstiffnessandtensilestrength[18].Thetensilestrengthis significantlyaffectedbyrasterangle.Astherasterangleischangedfrom0 -45 -90 thetensilestrengthgoesondecreasing.At 0°rasterangle,allfibersaredepositedparalleltotheloadingdirection,allowingthemtobearhigherloadsincetheimpactof fiberbondingisminimized.Whentherasterangleis90°,allofthefibersaredepositedperpendiculartothetensilestress, resultinginlesserstrength.Tensilestressandfailureoccurata45°rasterangleowingtoshearbetweenthefibersandfiber fracture[16].Whentherasterangleischangedfrom0°to90°level,thetensilestrengthfirstdecreasesandthenincreases[17].

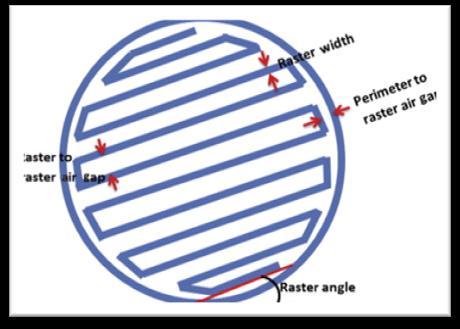

In3Dprinting,rasterwidthreferstothewidthofeachindividualline,or"raster,"depositedbytheprinternozzleduringthe printingprocess.Itisoftenreferredtoaslinewidthorextrusionwidth.Itdetermineshowmuchmaterialisextrudedand depositedwitheachpassoftheprintingnozzle.Agreateramountofmaterialisdepositedwithalargerrasterwidth,resulting inthickerprintedlines.Incontrast,a narrowerrasterwidthindicatesthatlessmaterialisdeposited,resultinginthinner printedlines[18].Itisobservedthatasrasterwidthincreases,tensilestrengthdecreases[17].Highertensilestrengthhasbeen obtainedwithahighervalueoftherasterwidth[16,20].Fig6showstherasterwidthalongwithrastertoairgap[19]

6. Composite material and reinforcements

SithiprumneaDueetal.performedresearchonthecreationanduseofABS/carbonnanotubes(CNTs)compositefilamentsin FDM3Dprinting,demonstratingthattheadditionofCNTsimprovesthethermalstability,modulusofelasticity,andmechanical propertiesofthecompositefilaments,suggestingtheirpotentialasmaterialsforFDM3Dprintingandhighlightingtheneedfor furtheroptimizationofprintingparametersandexplorationofotherpropertieslikeelasticmodulus[21].Thai-HundLeet.al. demonstratedthattheincorporationofMWCNTsintoABSfilamentsforFDM3Dprintingimprovedthethermalandmechanical propertiesofthecomposite,withuniformdistributionofMWCNTsobserved,suggestingtheirpotentialforhigh-performance functionalparts,althoughfurtherresearchisrequiredforprocessoptimizationandlong-termstabilityevaluation[22].The studydemonstrateshowaddingreinforcementmaterials,increasingreinforcementcontent,improvingpartorientation,and modifyinginfillpatternsanddensitiescanimprovethemechanicalpropertiesofcompositepartsmadeusingfuseddeposition modelling(FDM)technology.ThishighlightsthepotentialofFDMforcreatingcompositepartswithimprovedmechanical propertiesthroughprocessparameteroptimization[23].Thisstudyexamineshowprocessvariablesaffectthemechanical characteristicsofNylon-AramidcompositesmadeusingFDM.TheTaguchimethodisusedtooptimizevariableslikenozzle temperatureandinfilldensity,whichleadstoimprovedtensileandflexuralstrengthduetoimprovedinterfacialbondingand optimizedmicrostructure[24]. Thisreviewhighlightstheeffectsofprintingparameters,materialproperties,andcomposite

filamentsonproductstrength,stiffness,andothermechanicalpropertieswhilehighlightingtheneedforfurtheroptimization to improve the mechanical properties of FDM-printed parts. It also offers an overview of research on the production of metal/polymercompositefilaments[25].

7. Conclusion

Inthisreviewpaper,enhancedcomprehensionoftheeffectsofFDMprocessparametersandlinkedfeaturespartsprintedby FDMwereformed.Theseprocessparametersareregardedasessentialbecausetheprintedpartsurfacequality,strengths, aestheticsandoverallefficiencyoftheFDMprocessisdeterminedbythem.Variousprocessingparameter’seffectshavebeen evaluated,andoneofthem,itisnoticeablethatorientationofpartstobeprintedisconsideredtobeaninevitablefactorin determiningthemechanicalstrengthofpart.Itisobservedthatinfilldensityplaysadominatingpartindecidingtheweightand costofthematerialtobeprinted,thereisahugepossibilityfordoingresearchactivityintheseparametersasthepresent examinationaremainlyconductedforthevalue’sstandardvaluesandtypes.Itisseenthatinfillpatternplaysamainrolein decidingthemechanicalstrengthandgenerallyitismaximumforsymmetricalstructures.Itisevidentthatlayerheighthasa notableinfluenceonmaterialusageandqualityofprinting.Thefundamentalvariablesarereceivinggreatdealofattention fromresearchers,yetnumerousunknownfactorsmuststillbelookedintoastheyhavethepotentialtohaveabigimpacton boththeeffectivenessoftheprocedureandthequalityofthefinaloutput.Thelackofsubstantialliteraturesupportregarding theimpactofenvironmentalfactorsliketemperature,humidity,filamentmanufacturingconditionssuggestsaconsiderable opportunityforfurtherresearchinthisparticularfield.

REFERENCES

[1]LalitKumar,QamarTanveer,VineetKumar,MohdJavaid,AbidHaleem;Developinglow-costprinters

[2] Vishal N. Patel, Kamlesh P. Kadia; Parametric Optimization of The Process of Fused Deposition Modeling in Rapid PrototypingTechnology-AReview

[3]RupinderSinghSunpreetSinghKaranMankotia;DevelopmentofABSbasedwireasfeedstockfilamentofFDMforindustrial applications

[4]DhineshS.K.,ArunPrakashS.,SenthilKumarK.L.,MegalingamA.;StudyonflexuralandtensilebehaviorofPLA,ABSand PLA-ABSmaterials

[5] Ashish R. Prajapati, Harshit K. Dave, and Harit K. Raval; An Experimental Study on Mechanical, Thermal and FlameRetardantPropertiesof3D-PrintedGlass-Fiber-ReinforcedPolymerComposites

[6]LeipengYanga,ShujuanLia,,XingZhoub,JiaLiua,YanLia,MingshunYanga,QilongYuana,WeiZhangb;Effectsofcarbon nanotubeonthethermal,mechanical,andelectricalpropertiesofPLA/CNTprintedpartsintheFDMprocess

[7]RubenBayuKristiawan,FitrianImaduddin*,DodyAriawan,Ubaidillah,andZainalArifin:Areviewonthefuseddeposition modeling(FDM)3Dprinting:Filamentprocessing,materials,andprintingparameters

[8]AmirRostami,MoshenMasoomi,Mohammad.J.Fayazi,MehdiVahdati;Roleofmultiwalledcarbonnanotubes(MWCNTs)on rheological,thermalandelectricalpropertiesofPC/ABSblend

[9]DineshYadav,DeepakChhabra,RameshKumarGarg ,AkashAhlawat,AshishPhogat;OptimizationofFDM3Dprinting processparametersformulti-materialusingartificialneuralnetwork

[10] H. Kürşad Sezer⁎, Oğulcan Eren; FDM 3D printing of MWCNT re-inforced ABS nano-composite parts with enhanced mechanicalandelectricalproperties

[11] Vinaykumar S Jatti, Savita V Jatti, Akshaykumar P. Patel, Vijaykumar S. Jatti; A Study on Effect of Fused Deposition ModelingProcessParametersonMechanicalProperties

[12]HarshitKDave,NaushilHPatadiya,AshishRPrajapatiandShilpeshRRajpurohit;Effectofinfillpatternandinfilldensity atvaryingpartorientationontensile propertiesoffuseddepositionmodelling-printedpoly-lacticacidpart

[13]VinaykumarSJatti,SavitaVJatti,AkshaykumarP.Patel,VijaykumarS.JattiAStudyonEffectofFusedDepositionModeling ProcessParametersonMechanicalProperties

[14] Ashish R. Prajapati, Harshit K. Dave, Harit K. Raval;Influence of fiber rings on impact strength of 3D printed fiber reinforcementpolymercomposite

[15]HarshitK.Dave,BrijeshH.Patel,ShilpeshR.Rajpurohit,AshishR.Prajapati,DumitruNedelcu;Effectofmulti infillpatterns ontensilebehaviorofFDMprintedparts

[16]ShilpeshR.RajpurohitandHarshitK.Dave;TensileStrengthof3DPrintedPLAPart(AdvancesinAdditiveManufacturing and Joining)

[17]HarshitK.Dave,AshishR.Prajapati,ShilpeshR.Rajpurohit,NaushilH.PatadiyaandHaritK.Raval;Openholetensile testingof3Dprintedpartsusingin-housefabricatedPLAfilament

[18]HarshitK.Dave,AshishR.Prajapati,ShilpeshR.Rajpurohit,NaushilH.Patadiya&HaritK.Rava;Investigationontensile strengthandfailuremodesofFDMprintedusingin-housefabricatedPLAfilament

[19]ShilpeshR.RajpurohitandHarshitK.Dave;AdvancesinAdditiveManufacturingandTooling

[20]AshishR.Prajapati,ShilpeshR.Rajpurohit,NaushilH.Patadiya,HarshitK.Dave;AnalysisofCompressiveStrengthof3D PrintedPLAPart

[21] Sithiprumnea Dul, Luca Fambri and Alessandro Pegoretti; Filaments Production and Fused Deposition Modelling of ABS/CarbonNanotubesComposites

[22]Thai-HungLe,Van-SonLe,Quoc-KhanhDang,Minh-ThuyetNguyen,Trung-KienLe andNgoc-TamBui;Microstructure Evaluation and Thermal–Mechanical Properties of ABS Matrix Composite Filament Reinforced with Multi-Walled Carbon NanotubesbyaSingleScrewExtruderforFDM3DPrinting

[23] Filip Gorski, Wiesław Kuczko, Radosław Wichniarek and Adam Hamrol; Mechanical properties of composite parts manufacturedinFDMtechnology

[24] Nagendra,M. S. Ganesha Prasad ;FDM Process Parameter Optimization by Taguchi Technique for Augmenting the MechanicalPropertiesofNylon–AramidCompositeUsedasFilamentMaterial

[25]ÜmitÇevikandMenderesKam;AReviewStudyonMechanicalPropertiesofObtainedProductsbyFDMMethodand Metal/PolymerCompositeFilamentProduction