Design and Development of Ackerman Steering System for Formula Student Vehicle

Shreyash Chougule1, Jotiba Avatade21Student, Department of Automobile Engineering, Rajarambapu Institute of Technology Islampur, Maharashtra, 415414 India

2Student, Department of Automobile Engineering, Rajarambapu Institute of Technology Islampur, Maharashtra, 415414 India

***

Abstract – In this paper, a steering system is designed for FORMULA BHARAT student vehicle, which adopts a rack-andpinion steering mechanism. Team planned to design and develop a custom steering design that not only provide high accuracy but also met our weight & budget norms. The theoretical modeling of the systems as well as the derivations of the optimal parameter values is presented here. By understanding the vehicle requirements first we finalized the Ackerman angle. Based on that angle the geometry of the Ackerman steering system and all the design calculations of the each component of the steering system are also presented.

Key Words: SteeringSystem,FormulaStudent,Ackerman Steering,RackandPinion

1. INTRODUCTION

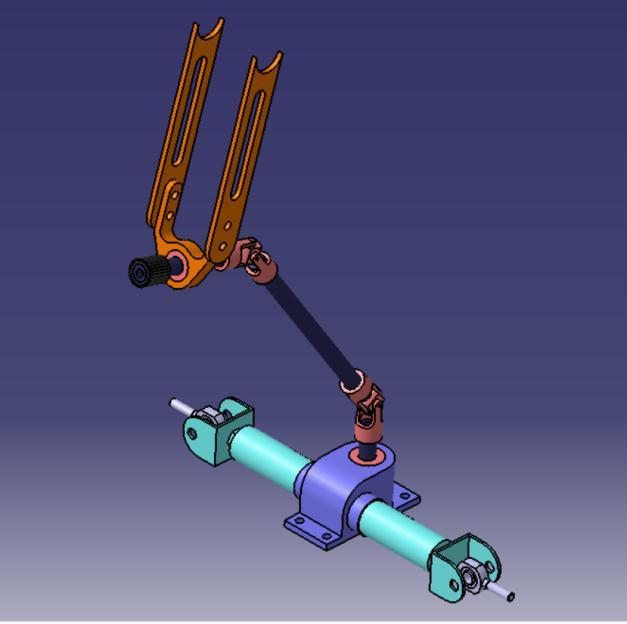

As we are working on a national level project named FORMULABHARATinwhichthedesignanddevelopmentof aFormulaStudentracecarwastobedoneandforthatwe had the task to design and develop a Ackerman Steering System thatfacilitated thedriverto takesharpturns with less efforts or with less revolutions of steering wheel. To achievethiswedecidedtomodifytheconventionalsteering mechanism that is used in the normal round cars. The steering system of the car is rack and pinion based mechanismthatconvertstherotationalmotiongeneratedat thesteeringwheelintoalinearmotionattheendoftherack. ThedesignisbasedontherulebookofFORMULABHARAT 2019,accordingtowhichdrivebywireforbiddenandhence wehaveselectedasimplerackandpinionsystemwith no additional electrical or hydraulic help. Though the tracks usedforsucheventsareflatinnature,onemustaccountfor thenaturalkinematicbehaviorofthesteeringsystemand henceitisessentialtonotonlyfactorstaticstressbutalso thedynamicaspectsofthesteeringsystem.

2. DESIGN PROCEDURE

Thesteeringsystemisafrontwheelbasedsteeringunit,asit inmostformulastudentcars,thedesigninvolvesformation ofmathematicalandgeometricalmodelfollowedbyCADand FEA procedure. The approach in designing said system involvesthefollowingsteps,

1. Identificationofthevehiclerequirements

2. Geometricalsetup

3. Geometricalvalidation

4. Designofmechanism

5. ModelingandAnalysisbyCADandFEArespectively

3. DESIGN SPECIFICATIONS

4. GEOMETRY DESIGN

4.1 Steering Geometry

The requirements are in accordance with the standard rulebookofFORMULABHARAT,butarealsomadesuretobe satisfactorytothedrivercomfortandalsotoensuresafetyto the driver. That’s why Ackerman steering geometry is chosen. Ackerman steering geometry is geometrical arrangement of linkages of the steering of vehicle. The kinematic condition between inner and outer wheel that allowsthemtoturnslip-freeiscalledAckermansteering.

Thefollowingparametersaresetup,

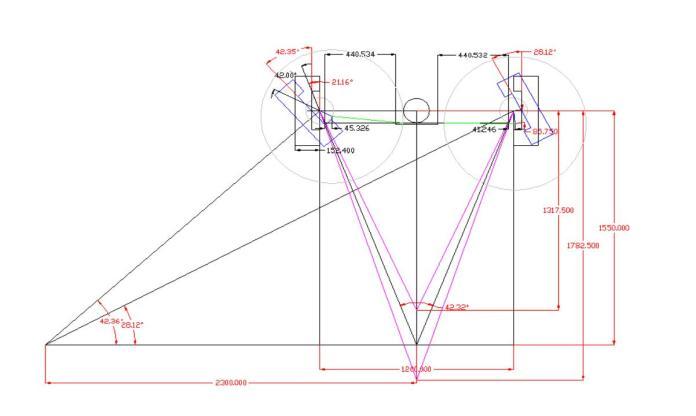

WheelTrack=1200mm

WheelBase=1550mm

RadiusofCurvature=2300mm

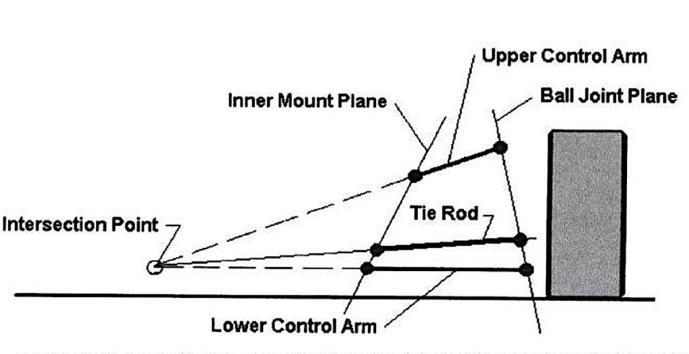

To avoid the lateral motion of wheel, while vehicle is in bump, a concept of bump steer geometry is implemented Conditionstoachievebumpsteerare:-

Instantaneouscenterofbothwishbonesandtierodmust besame.[2]

Tierodlengthissuchthat,itmustbeattachedtotheline ofintersectionofupperandlowerball joints.[2]

Thebelowfigureexplainsmoreaboutbumpsteergeometry.

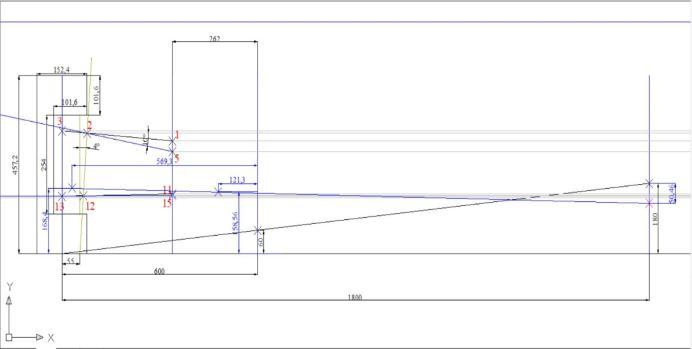

Soastoachievebumpsteerinourvehicle,steeringrackis place at 56 mm above floor. The following figure shows bumpsteergeometrydrawninAUTOCAD.Vehiclehassame instantaneousofbothwishbonesandsteeringrack.

5. DESIGN CALCULATIONS:

5.1 Steering System Design Calculations:

Assumptions:

Turningradius(R)=2300mm

Wheelbase(b)=1550mm

WheelTrack(t)=1200mm

VehicleWeight(W)=280Kg

TW=trackwidth

WB=wheelbase

R=radius

5.2 Ackerman geometry calculation: …….[3]

Value of the bump steer can be found from the below geometry.

AckermanAngle= ……….[3]

=42.32º

Steeringarmangle= ….[3] = =21.16º

Wheellocktolockrotation=θ+∅=42.35°+28.12°=70.47

%ofAckerman= = =100

5.3 Determination of Steering Ratio

ExistingSteeringratio = = …..[5]

ExistingSteeringratio=3.20

5.4 Determination of Steering Effort

Weightonfrontaxle=0.5×280=140kg

Weightoneachfrontwheel= kg=70 =686.6N

Friction force offers resistance to wheel rotations while negotiatingturn.

Frictionforce=μ×weightoneachfrontwheel=0.7×686.6= 480.7N

Torquerequiredatsteeringwheel=Frictionforce×radiusof pinion

Torquerequiredatsteeringwheel=480.7×20=9614N.mm

SteeringEffort= = =83.60N [3]

5.5 Calculation for M6 bolt:-

P=2kN–lateralforceontierod

Factorofsafety–2.5

Permissibletensilestrength=400N/mm²

σ= …….[1]

160= :d=3.98mm

5.6 Bending calculations for bolt: -

P=2000N

D=8mm

σb = …….[1] = =66.80N/mm^2

Doubleshearcalculations:

P=2000N

D=6mm

D= ……[1]

8= τ=21.21N/mm^2

Duringdoubleshearing,

τ=65.01N/mm^2

65>21.21N/mm^2:Designissafe.

5.7 Tie rod calculations:

θ= …..[1]

θ= =25.6kN/mm

τ(max)= 92.5=

Mb=25.8KN/mm

σb= …….[1]

σb=

σb= 131.3N/mm^2

Shearstress: τs= ……[1]

τs=

τs=65.1N/mm^2

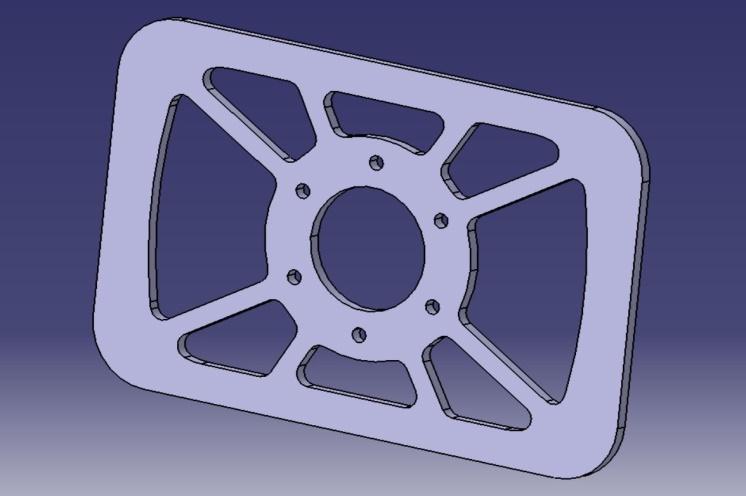

5.8 Steering Column Calculations:

RequiredData:

Lengthofcolumn(L)=200mm

Cfactor=di/d0=0.5

Permissibleangleoftwist=30

Diameterofsteeringwheel(D)=230mm

Modulusofrigidityofstainlesssteel=77200Mpa

Maximumtorqueonsteeringwheel(Mt) Forceonsteeringwheel(F)=83.6N

Mt=D*F=230*83.6

Mt=19228N-mm

Design of Hollow shaft on basis of Torsional Rigidity:

Θ=(584*Mt*L)/77200*d04(1-c4) …..[1]

3=(584*19228*200)/77200*d04 (1-0.54)

d0=12.09mmi.e.d0=14mm

Therefore di=7mm

Θ=(584*Mt*L)/77200*(14)4(1-0.54)

Θ=1.66840

Hence,FactorofSafety=3/1.66 =1.79

5.9

Ergonomics consideration for driver and as per the rule outerdimensionsofsteeringwheelsisdecided.

Fr =2000N

L10h=4000hrs.

N=750rpm

Bearinglife–

L10= ……..[1] =180millionrevolution

Dynamicloadcapacity–

P=Fr=2000N

C=P* …….[1]

=2000* =11292.43N

6.

5.10 Bearing calculations:

Fr =radialload

L10h=usedbearinglife

N=speedofrotation

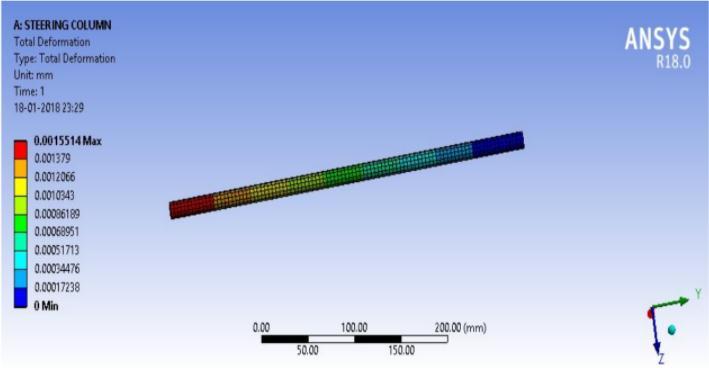

7. Analysis of components: -

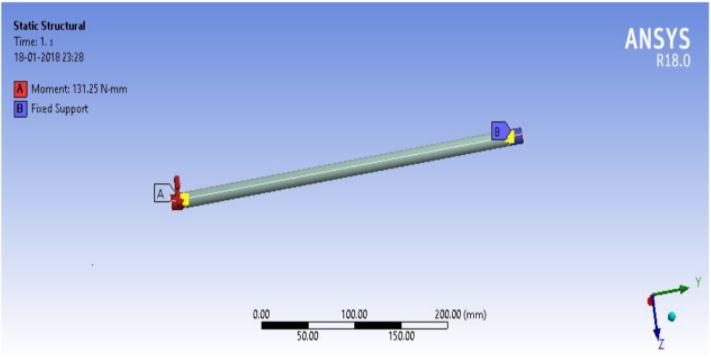

7.1 Tie rod analysis:-

Tierodloading[6]

8.2

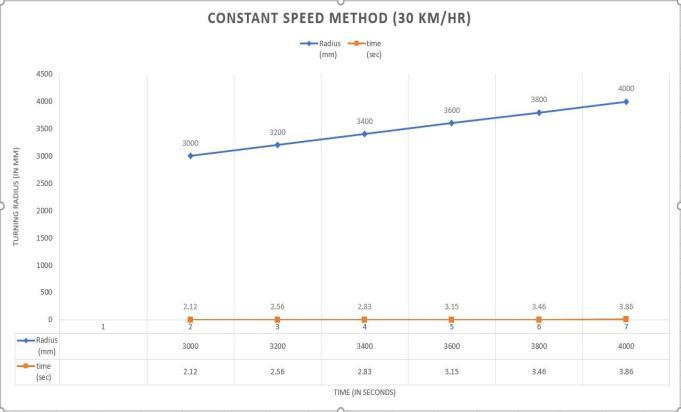

Hereturningradiusiskeptconstantandtimefordifferent speedtocompletethecircleiscalculated

-

Fortestingofsteeringsystem2methodsarefollowedand theyare:-

Constantspeedmethod.

Constantradiusmethods.

Time required in both the methods are calculated by stopwatchandtheresultsareplottedongraph.

Herespeedofthevehicleiskeptconstantat30km/hr.and time required to complete different turning radii are calculated.

While designing the vehicle the primary objective was to makethevehiclelight,compact,ergonomicandsafeforthe driver. While designing the system all the conditions of a racingenvironmentsuchasSpeedycornering,properturn and steering response were considered. Steering system functions desirably and the resulting vehicle is safe, attractive,reliable,economicalandfuntodrive

10.

Wewouldliketoexpressourspecialthanksofgratitudeto our team “Team Nequit” and “Automobile Engineering Department, RIT, Islampur” for guiding us throughout the process.

11. REFERENCES

[1] V B Bhandari, Design of Machine Elements, third edition,McGrawHillEducation,India,2010

[2] Thomas D. Gillespie, Fundamentals of vehicle dynamics, Society of Automotive Engineers, Inc. 400commonwealthdrive,Warrandale,PA150960001

[3] WilliamF.Milliken and DouglasL.Milliken,“Race Car Vehicle Dynamics”, Society of Automotive Engineers, Inc. 400 commonwealth drive, Warrandale,PA15096-0001

[4] Cristina Elena Popa, “Steering System and SuspensionDesignFor2005FormulaSAE-ARacer Car”, UniversityofSouthernQueensland,Facultyof EngineeringandSurveying,2005

[5] Caroll Smith, “Racing Chassis and Suspension Design”,societyofAutomotiveEngineers,Inc.400 commonwealth drive, Warrandale, PA 150960001,2004

[6] “Analysis and design of steering and suspension system by computer and mathematical methodology”AkashSood,AbhishekPandey,Savita Vyas,AvadeshK.Sharma,Internationaljournalof current engineering and scientific research (IJCESR), ISSN (PRINT): 2393-8374, (ONLINE): 2394-0697,VOLUME-3,ISSUE-1,2016

[7] RulebookFORMULABHARAT2019

12. Authors

Shreyash Satish Chougule TechnicalLead(TeamNequit) AutomobileEngineeringStudent, RIT,Islampur.

Jotiba Vinayak Avatade TeamCoordinator(TeamNequit) AutomobileEngineeringStudent, RIT,Islampur.