International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Rajani

Hardas1 , Atharv Nimbalkar2 , Abhijit Pawar3, Piyush Bhosale4

1Professor, Electrical Engineering, PES Modern College of Engineering, Pune, India 2,3,4Student, Electrical Engineering, PES Modern College of Engineering, Pune, India

Abstract - In modern sanitation systems, maintaining air quality in enclosed spaces such as restrooms/bathrooms is crucial for hygiene and user comfort. This paper presents an Intelligent Odor Management System Using PLC, which automates exhaust fan operation based on real-time occupancyandodor levels.ThesystemintegratesaPIRbeam sensorforoccupancydetectionandanammoniagassensorfor Odor assessment. A programmable logic controller (PLC) processessensorinputsandoptimallycontrolstheexhaustfan to ensure efficient ventilation while minimizing energy consumption. The proposed system enhances air quality management, reduces manual intervention, and promotes energy efficiency in public and commercial restrooms. Experimentalresultsdemonstratethesystem'seffectivenessin maintaining an odor-free environment. This research contributes to smart automation in sanitation, offering a scalable and cost-effective solution for improved restroom hygiene.

Key Words: PLC; fan, Odor Detection, Photoelectric Sensor, Ammonia Gas Sensor, Energy Efficiency, Realtime Performance.

In modern public and commercial infrastructure, maintaining air quality in restrooms is a critical yet often overlooked aspect of hygiene and energy management. Conventional ventilationsystemstypicallyrelyonmanual control or continuous operation of exhaust fans, which results in significant energy wastage, higher maintenance requirements, and accelerated equipment degradation. Theseinefficiencieshighlighttheneedforasmarter,more sustainablesolutiontoodorcontrol.

Thisresearchpresentsthedesignandimplementationofan IntelligentOdorManagementSystemusingaProgrammable Logic Controller (PLC). The proposed system aims to optimizeexhaustfanoperationbyintegratingreal-timedata from ammonia gas sensors, which detect odor levels, and infrared(IR)motionsensors,whichmonitoroccupancy.The PLCservesasthesystem’sbrain,processingsensorinputs and making intelligent control decisions to activate or deactivateexhaustfansonlywhennecessary

Byautomatingtheventilationprocessbasedonactualusage and air quality conditions, this system minimizes unnecessary energy consumption while ensuring a consistentlyhygienicrestroomenvironment.

The Intelligent Odor Management System is designed to reduceenergyconsumptionbycontrollingtheexhaustfan operation based on real-time odor detection and usage patterns.Unliketraditionalsystemswhereexhaustfansrun continuouslyoraremanuallyoperated,thissystemensures thefanfunctionsonlywhenrequired,thussavingenergyand reducingwearandtear.

The central component of this system is a Programmable LogicController(PLC),whichprocessesinputsfromtwokey sources:

1.AmmoniaSensor:Thissensorisresponsiblefordetecting the presence of odor in the restroom environment. Wheneveranyunpleasantsmell particularlyammonia is detected beyond a predefined threshold, the sensor immediatelysendsasignaltothePLC.Basedonthisinput, the PLC turns on the exhaust fan to clear the odor and improveairquality.

2.Infrared(IR)MotionSensor:Thissensorisusedsolelyfor counting the number of people entering and exiting the restroom.ItprovidesthePLCwithreal-timeoccupancydata, allowing the system to maintain a log of restroom usage throughouttheday.

Whatmakesthissystemmoreintelligentisitsabilitytolearn fromhistoricalusagepatterns.ThePLClogsdata fromthe last 7 days. Using this stored data, the systemcan identify peakusagehoursandadjustitsresponsiveness.

The intelligent odor management system is designed to automate the operation of restroom ventilation based on real-time detection of air qualityand restroom occupancy. The system primarily relies on a Programmable Logic Controller(PLC),whichprocessessignalsfromsensorsand controls the exhaust fan accordingly. The PLC acts as the central decision-making unit, programmed to respond to specificconditionsbasedonsensorinputandhistoricaldata.

Theammoniasensorplaysacriticalrolebydetectingodor levels within the restroom. When the concentration of ammonia crosses a predetermined threshold, the sensor sendsananalogsignaltothePLC,promptingittotriggerthe ventilation system. Simultaneously, the infrared motion

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

sensorcountsthenumberofindividualsenteringandexiting therestroom,allowingthePLCtologoccupancydata.This data is used to identify peak usage hours and adjust fan activation accordinglyto maintaina hygienic environment whileminimizingunnecessaryenergyconsumption.

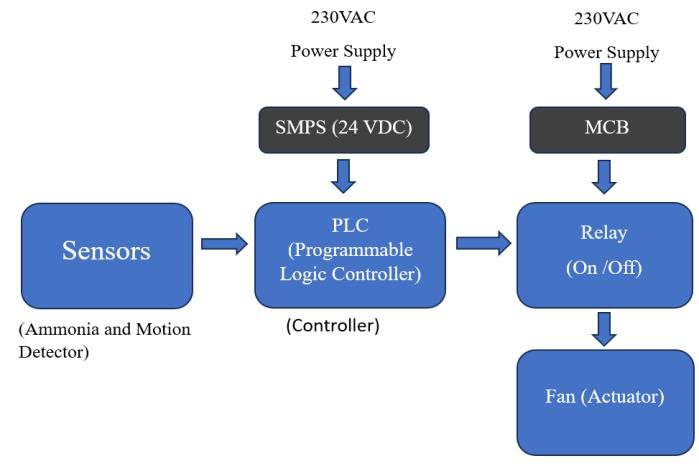

To operate in real-time, the system requires stable communicationbetweentheinputsensorsandthePLC,as wellasbetweenthePLCandtheoutputrelaycontrollingthe exhaustfan.Thesystem'spowersupplyismanagedthrough anMCBandaSwitchedModePowerSupply(SMPS),which convertsinputpowertoa 24VDCsupply suitableforPLC andsensoroperation.Therelaymoduleactsasaswitching device that enables or disables the exhaust fan based on commandsissuedbythePLC.

Theentireoperationaimstooptimizefanusagebyturningit ON only when Odor is detected or predicted during highoccupancy periods, and OFF when air quality is within acceptable limits. This reduces energy waste, lowers maintenancecosts,andensureseffectiveOdorcontrol.

A Programmable Logic Controller (PLC) is a crucial control unit that provides a communication interface and appropriate Input/Output (I/O) units to interact with hardwareformonitoringandcontrollingindustrialsystems. Itexecutessoftwareprogramsbasedonuserrequirements. Essentially, it functions as an industrial CPU, replacing traditional relay-based remote-control systems for maintenancetasks.Withtechnologicaladvancements,PLCs have become integral to industrial automation systems. Modern PLCssupport notonlylogic-based operations but also advanced mathematical functions, enabling the executionofmorecomplexmonitoringandcontroltasksas theircommandsetscontinuetoexpand.

EcoStruxure Machine Expert isusedforprogrammingthe PLC ladder diagram. The Schneider Electric PLC

(TM200CE40T) usedinthesystemincludes 24 inputs and 16 outputs.

A Photoelectric Sensor isanon-contactdevicethatdetects objectsormotionusingalightbeam.Inthissystem,weused a Self-reflective photoelectric sensor for reliable object detection.ItsendsadigitalsignaltothePLCwhenanobject interruptsorreflectsthebeam,enablingreal-timecontrolof deviceslikelightsorfans.Thissensoroffersfastresponse, highaccuracy,andeasyintegrationwiththePLC,improving systemautomationandhygienewithoutmanualswitches.

An ammonia (NH₃) gas sensor isachemicalsensorusedto detect the concentration of ammonia gas in the air. In bathroomapplications,ithelpsinmonitoringairqualityby sensing the presence of ammonia, which is commonly releasedfromurineandcleaningagents.Thesensoroutputs adigitalsignalproportionaltotheammoniaconcentration, which is processed by the PLC to trigger the exhaust fan whenapredefinedthresholdisexceeded.Commonlyused ammonia sensors, like the MQ-137 or MQ-135, are costeffective and highly sensitive. They help prevent Odor accumulationandmaintainafreshandhealthyenvironment by enabling automatic ventilation based on air quality parameters.

An exhaust fan is a critical component in bathroom ventilation systems, responsible for removing stale air, excesshumidity, andunpleasantOdortomaintaina clean and comfortable environment. In this automation project, theexhaustfanisactivatedandcontrolledbyaPLCbasedon inputsfromsensorssuchasmotiondetectorsandammonia gassensors.Forthisapplication,a KRUGER AMP315 axial flowexhaustfanisused,knownforitsreliableperformance andcompactdesign

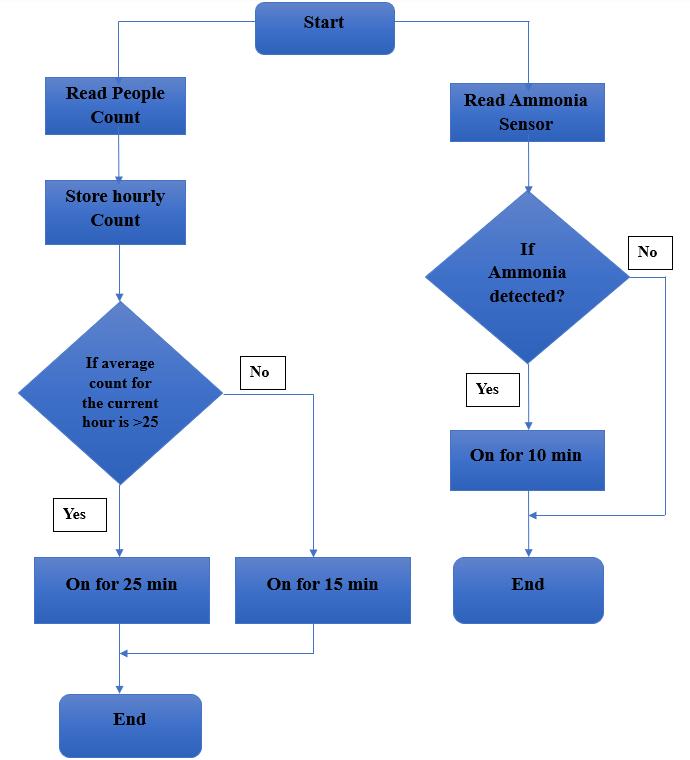

The logic for the intelligent odor management system is developed using EcoStruxure Machine Expert software, whichenablesthecreationofladderlogicdiagramsforthe SchneiderElectricPLC.Severalcorefunctionsareintegrated to automate the exhaust fan based on sensor inputs and time-basedanalysis.A counter isusedtodetectandcount the number of people entering and exiting the bathroom usingsignalsfrom Photoelectric Sensor motionsensors.

Tomanageandanalyzeusagepatternsovertime,a Shift Bit Register isimplementedtostorehourlypeople-countdata. Eachhour,thedatashifts removingtheoldestrecordand inserting the latest thus maintaining a live history of bathroom usage. This information helps categorize time periodsashighorlowusage.

A Real-Time Clock (RTC) module is used to synchronize operationsonanhourlybasis.Thisenablesaccuratelogging, real-time decision making, and identification of peak and

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

off-peak hours using another counter that evaluates historicaloccupancydata.

Inadditiontomotion-basedlogic,an ammonia gas sensor isusedtodetectelevatedodorlevelsinsidethebathroom. Whenthesensordetectsammoniabeyondasetthreshold,it sendsadigitalsignaltothePLC,whichimmediatelyactivates a timer.Thistimerkeepstheexhaustfanrunningforafixed duration regardlessofoccupancy toensurethattheodor isadequatelyventilated.Thisprovidesanadditionallayerof automation to maintain air quality even during low occupancyhours.

Thiscombinationofreal-timedataprocessing,sensor-based triggers,andhistoricalanalysisallowsforanintelligentand energy-efficientodormanagementsystem.Acorresponding flowchart illustrates the sequential steps and logic transitionsoftheentireprogram.

5.RESULT

With the integration of motion sensors, ammonia gas sensors, and a real-time clock (RTC), the exhaust fan responds dynamically to current conditions inside the bathroom.Thefanactivatesimmediatelyupondetectinga personorhighammonia concentrationandoperatesfora presetdurationbasedontimerlogic.Thisreal-timeresponse

ensures timely ventilation, better hygiene, and improved usercomfort,especiallyduringhigh-trafficperiods.

FAN ON DURATION OVER 24 HOURS ON TIME (MINUTES)

The system ensures significant energy savings by intelligentlycontrollingtheexhaustfanbasedonreal-time occupancy and ammonia levels. Instead of running continuously,thefanoperatesonlywhennecessary during peak hours or when high odor levels are detected. This targeted operation reduces unnecessary power consumption, extends the fan’s lifespan, and promotes efficientenergyusewithoutcompromisingairquality.

Afterimplementingtheoptimizationstrategy,asignificant reductioninbothenergyconsumptionandoperatingcosts wasachieved.Thereal-timecontrolofmotoroperationled toanenergysavingof240kWhpermonthandacostsaving of₹2880permonth.Thiscorrespondstoa66.67%reduction in the total monthly energy cost. The results highlight the effectiveness of the optimization in enhancing energy efficiencyandachievingsubstantialoperationalsavings.

An intelligent odor management control system for industrialexhaustfanshasbeendevelopedinthispaper.The system architecture, core functionalities, and implementation methods are presented along with the hardwareandsoftwaredesign.Usingaprogrammablelogic controller (PLC) as the central control unit, the system respondstoreal-timesensorinputstomanagefanoperation efficiently.Thecontrollogiceffectivelyreducesunnecessary fan runtime, thereby optimizing energy usage. The evaluation confirms that the intelligent control approach resultsinnotableenergysavings,improvesoverallsystem efficiency,andenhanceseconomicperformance.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

[1]TanyaBlank,IgorBrouk,SharonBar-Lev,GavrielAmar, Elie Meimoun, Shlomi Bouscher, Maxim Meltsin, Michele Vaiana,AmedeoMaierna,MariaEloisaCastagna,Giuseppe Bruno “Non-Imaging Digital CMOS-SOI-MEMS Uncooled PassiveInfra-RedSensingIEEE,2020

[2]Bj¨ornTimmer∗,WouterOlthuis,AlbertvandenBerg, “Ammoniasensorsandtheirapplications,Bj¨ornTimmer, WouterOlthuis,AlbertvandenBerg”

[3]MehmetFatihIIKHititUniversityElectrical-Electronic Engineering Çorum, Turkey mehmetfatih@hitit.edu.tr, “Monitoring and Control of PLC Based Motion Control SystemsviaDevice-Net

[4]JunaidyB.Sanger2021IEEE11thAnnualComputingand Communication Workshop and Conference (CCWC) “A Sensor-basedGarbageGasDetectionSystem

[5] Deepayan Das, Srinjoy Chanda,”Controlling and MonitoringofTrafficLightControlUsingSchneiderPLC”

[6]TiagoCoito,BernardoFirme1JoãoM.C.Sousa,MiguelS. E. Martins, Susana M. Vieira, João Figueiredo “Intelligent SensorsforReal-TimeDecision-Making”.

[7] G. Popovicsa,b, A. Pfeiffera, B. Kadara, Z. Véna,b, L. Kemenya, L. Monostori “Automatic Simulation Model GenerationBasedonPLCCodesandMESStoredData”

2025, IRJET | Impact Factor value: 8.315 |