International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Dr. R Jayachitra1 , Balaji G K2 , Sudharsan C3

1Associate Professor, Department of Mechanical Engineering, PSG College of Technology, Coimbatore, India

2Department of Mechanical Engineering, PSG College of Technology, Coimbatore, India

3Department of Mechanical Engineering, PSG College of Technology, Coimbatore, India

Abstract - Theintegrationofnewproductlinesintoexisting manufacturing systems presents complex operational challenges, particularly in mixed-model assembly line environments. This study explores a comprehensive improvement initiative undertaken at a construction equipment manufacturing company, a leading Indian manufacturerofconstructionequipment,aimedatintegrating a new model SKT into its existing assembly line. Initial assessmentsrevealeda highDefectsPerMachine(DPM) rate of 424, along with systemic inefficiencies in documentation, facilities and quality control. The project employed a suite of industrial engineering methodologies and FlexSim-based simulation modeling. Data were collected across multiple stages of assembly, and the process flow was analyzed to identify bottlenecks and Non-Value-Added (NVA) activities. Corrective and Preventive Action (CAPA) measures were implementedtoaddresskeydefectareas.Projectilestudywas performed to calculate the average NVA percentage of the assembly line. Simulation results post-intervention demonstratedanullificationinDPM,takttimealignment,and currentprocessthroughput.Thestudyconcludesbyproviding facilities and Standard Operating Procedure (SOP), leads to cycle time reduction by 14.2%, states that engineering tools can significantly enhance efficiency, product quality, and readiness for new product integration in complex manufacturingsettings.

Key Words: Mixed-modelassemblyline,Lean,Simulation, Non-Value-Added (NVA) activities, Corrective and PreventiveAction,Newproductintegration

Indian manufacturing sector, particularly the constructionequipmentsegment,hasbeenevolvingrapidly tomeetdomesticandinternationalmarketdemands Aspart ofastrategicinitiativetoexpanditsproductportfolio,the companyintroducedanewmodelcalledSKT.Unlikelegacy models,SKTrequiredcustomizedassemblyprocessesdueto itsuniqueconfigurationanddesignconsiderations.

In high-mix, low-volume production settings such as construction equipment manufacturing, the integration of newproductsintoexistinglineswithoutdisruptingongoing

operationsisacriticalchallenge.Thiscallsforsophisticated planningandrobustprocesscontrolmechanisms.Industrial engineering provides a proven framework for achieving these objectives through data-driven analysis, workflow optimization,andimplementationofleanprinciples.

Despitecompany’sadvancedmanufacturingcapabilities, the pilot run of SKT resulted in a DPM count of 424 significantlyhigherthan industry-acceptable benchmarks. Thishighdefectratenotonlythreatenedproductqualitybut alsoindicatedsystemicissuessuchaslackofstandardized work procedures, insufficient operator training, and inadequate layout planning. Given these conditions, a comprehensiveimprovementprojectwasinitiatedwiththe followinggoals:

NullifyingtheDPMcountfromthecurrentlevel

Ensure defect-free integration of SKT into the existingline,

Optimize workflow and cycle time without additionalcapitalexpenditure.

Providefacilitiesandtheproperdocumentationfor theintegration.

Thispaperdetailsthestructuredmethodology,analysis, implementation,andoutcomesoftheproject,demonstrating howtheapplicationofindustrialengineeringprinciplescan revitalizeassemblyoperationsandenableseamlessproduct innovation.

The reviewed literature collectively emphasizes the importanceofproductivityenhancement,defectreduction, and assembly line optimization within manufacturing environments.

Several studies have explored lean manufacturing principles. The summary of the previous research papers with their objectives, Approach and outcomes are summarizedasshowninTable1.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

S.No

Objectives

[1] Tominimizeproductdefectsand provethehypothesisregardingthe impactoflaborperformanceon productquality

[2] Tosynthesizemethodologiesto minimizedefectsandidentify challengesanddirectionsindefect reduction

[3] Investigatehoworganizational interfacesmobilizeresourcesin productdevelopment

[4] Improvequalitycontrolfor assembledproductsusing predictivemodeling

[5] Adaptassemblylinebalancingand schedulingforflexible manufacturingandmarket demands

[6] DefineandpromoteZero-Defect Manufacturing(ZDM)for sustainableproduction

[7] Improveproductivityinsheet metalstampingsubassemblyarea

[8] Reducecycletimeinautomotive assemblylinetomeetproduction targets

[9] EnhanceproductivityusingMOST forstandardtimemeasurement

[10] Optimizehuman-robottask allocationusingcomplexity-based analysis

[11] ImproveoperationsthroughLean SixSigmaandVSM

[12] Reduceleadtimeinspoolcasing assembly

[13] Automatetimetrackinginmanual assemblyusingIoTandRFID

[14] Balancefanassemblylineand reducedelayusingRPWmethod

[15] Solvebottleneckissuesinsinglemodellinebalancing

[16] Addresstaskandworker assignmentbasedonskilland physicaleffortinALB

Approach

UsedOverallLaborEffectiveness (OLE),LinearRegression,andSix Sigma(DMAIC)

Literaturereviewusingdefined inclusion/exclusioncriteria

Casestudyofindustrialtool manufacturer(IndTool)

DevelopedDPU-chartbasedon defectpredictionmodels consideringproductcomplexity

Usedneuralnetworksand knowledgebaseforscheduling ruleselection

Literatureandindustryanalysis tocounterZDMskepticismand illustratebenefits

UsedLeantools(VSM,Kaizen, 5S);focusedondeburringand polishing

Mappedoperations,usedmethod studytoremoveNVAsand identifybottlenecks

Videostudy+MOSTanalysis; layoutandstorageredesignedto cutmovement

Assessedtaskcharacteristics; developedataskassignment methodology

AppliedDMAICwithSixSigma andLean(VSM);rootcause analysis

Simulatedcurrentandfuture VSMinFlexsim;applied5Sand Kaizen

Developedareal-timemethodtime-measurementsystemwith RFID-taggedtools

AppliedSALBandGALB;9 workstations,42tasksanalyzed viaRPW

Proposedamethodtoreduce standardtimeofnon-critical tasksusingslacktime

ProposedALWARBPintwo phases:long-termbalancingand short-termrebalancing

Outcome

Significantcorrelationbetween laborperformanceandproduct quality;FMEAshowedlaborwasa keydefectsource

Identifieddefectreduction methods;emphasizedemployee engagementandneedfor integratedframeworks

Highlightedimportanceof collaborationacrossorganizational boundariesforinnovation

Effectivereal-worldapplicationin defectmonitoringandcontrol

Simulationsvalidatedimproved schedulingandlinebalancing performance

ClarifiedZDMandemphasized standardizationforadoptionin Industry4.0

Processingtimereducedby62.5%; motionwastedroppedfrom1086 to261activities

Cycletimereducedfrom17.37to 15.02mins;improvedproduction andresourceutilization

Cycletimereducedby2mins; productionrateincreasedby 29.63%

Over70%tasksautomated; workloadbalanced;structured evaluationtooldeveloped

Timetomanufacturerodreduced by14.71%;WIPreducedby 17.76%;leadtimedownby14.88%

Leadtimereducedby5.7%(P3) and6.3%(P5);improvedstorage, lessmovement

Enabledaccuratetimetrackingand bettermanualprocessoptimization

Delayreducedfrom31%to5%; efficiencyupfrom69%to95%; outputincreasedto823units

Efficiencyimprovedfrom77%to 88%;balanceddelayreducedfrom 23%to12%

Improvedtaskassignment;better handlingofunskilledworkers; performanceenhanced

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Despite company’s excellency, it faced a critical challenge during the introduction of its new SKT product into the existing mixed-model assembly line. The SKT product,despitebeingastrategicadditiontotheportfolio, exposed numerous operational inefficiencies and inadequacieswithintheestablishedassemblyinfrastructure.

TheforemostissuewasasignificantlyhighDefects Per Machine (DPM) count recorded during the initial productionruns.ADPMlevelof424highlightedthesystem’s inability to absorb a new product variant without quality deterioration.Thesedefectswerenotisolatedbutspanned across multiple subsystems including electrical wiring, hydraulic integration, and chassis mounting indicating a breakdowninprocesscoherenceandstandardization.

Anotherkeyissuewasthelackofwell-documented procedures and graphics to support in operator training. Withoutwell-establishedstandardworkpractices,operators based on their actions extensively on verbal feedback, leadingtoinconsistenttaskcompletion.Thelackofasingle, centralized system for tracking defects only added to the problem, as it’s been a challenging one to study trends or enforcepreventiveactions.

Inthecurrentassemblyline,theproductsarelacked withthefacilitiessuchastheoperatingdesks(or)tablefor some of the operations and requires the specialized tools andfixturesforSKTintegration.Forthispurpose,theoverall assemblylinewasanalyzedwiththetools,fixtures,tables, trolleys, special tools, torque wrenches, etc., for all workstations.

The overall process of assembly doesn’t have a standardizedmethodforthechangeoverprocess,alsothere is a lack of documentation such as Standard Operating Procedures (SOP). The lack of these fundamental process controls defines that the launch of any new model was bound to bring difficulties instead of being smoothly integratedintotheproductionprocess.

As a summary, the current configuration was not well-suitedtohandlethecomplexityandaccuracyneededto

integrate SKT, resulting in performance deficits that requiredrapidcorrectiveaction.

The overall objective of this research was to facilitatethesmoothincorporationoftheSKTmodelintothe currentassemblylinewithoutcompromisingonqualityor efficiency. This objective was formulated into clear, measurablegoalstodirecttheinterventionprocess.

Themostimportantandinitialgoalwasto nullify thecountofDPMfrom424tozeroanimprovementof100%. Toaccomplishthisgoal,systemicprocessimprovements,the implementation of quality control checkpoints, and root causeeliminationwereneeded.

In order to make improvements maintainable, a standard work documentation is provided to all impacted stations.ThisinvolvedthedevelopmentofSOPs,visualwork aids,checklists,andoperatortrainingmodules.Thesewere intended to impose consistency and minimize reliance on individualknowledge.

Another one is to streamline the layout and movementoftheassemblyline.Byeliminatingnon-valueadded activities and redistributing work, the goal was to reduce cycle time by at least 10% and thus enhance throughputwithoutcapitalinvestment.

Finally, it was necessary to confirm all suggested improvementswithsimulationmodeling.UtilizingFlexSim,a virtualtwinofthecurrentandproposedassemblylineswas developed. This enabled the research team to simulate multiple configurations, forecast outputs, and choose the mosteffectiveprocessflowpriortoactualimplementation.

Together,thesegoalsshapedthestudy'sdesignand determineditssuccessmetrics.Thefollowingprojectwork explainshowtheintegrationofSKTwasperformedtothe assemblyline,tofinalvolumerampupbasedonthedemand fromthecustomers.

The approach taken for this project incorporates both conventional industrial engineering methods and contemporary computer simulation software. A thorough analysis of the existing assembly process was undertaken withemphasisondeterminingprocessinefficiencies,risky

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

operations, and non-value-added processes. The research commenced by gathering live data at four key assembly stages:chassis,tank,engine,andradiator.Timeandmotion studies were carried out at all the stages to standardize operationsandidentifydeviations.

RootCauseAnalysis(RCA)wasutilizedtotrackthe source of significant defects documented during the Pilot phaseprocess.SupportingthiswastheuseofFailureMode andEffectsAnalysis(FMEA),whichprioritizedthepossible risksrelatedtoeveryprocessactivityaccordingtoseverity, occurrence, and detection ratings. This allowed remedial measures to be prioritized and engineering resources allocatedaccordingly.

Tominimizemanualerrors,Poka-Yoke(or)errorproofing mechanisms were implemented at certain checkpoints. These measures were intended to prevent improper component assembly and sequence mistakes, especially in hydraulic connectors and wiring. Standard work processes were created and implemented at every workstation, with the result that operators consistently

applied similar and tested procedures. All of these instruments employed are in the industry-specialized CorrectiveandPreventiveAction(CAPA)formsothatitmay beseenthroughdigitalfactory.

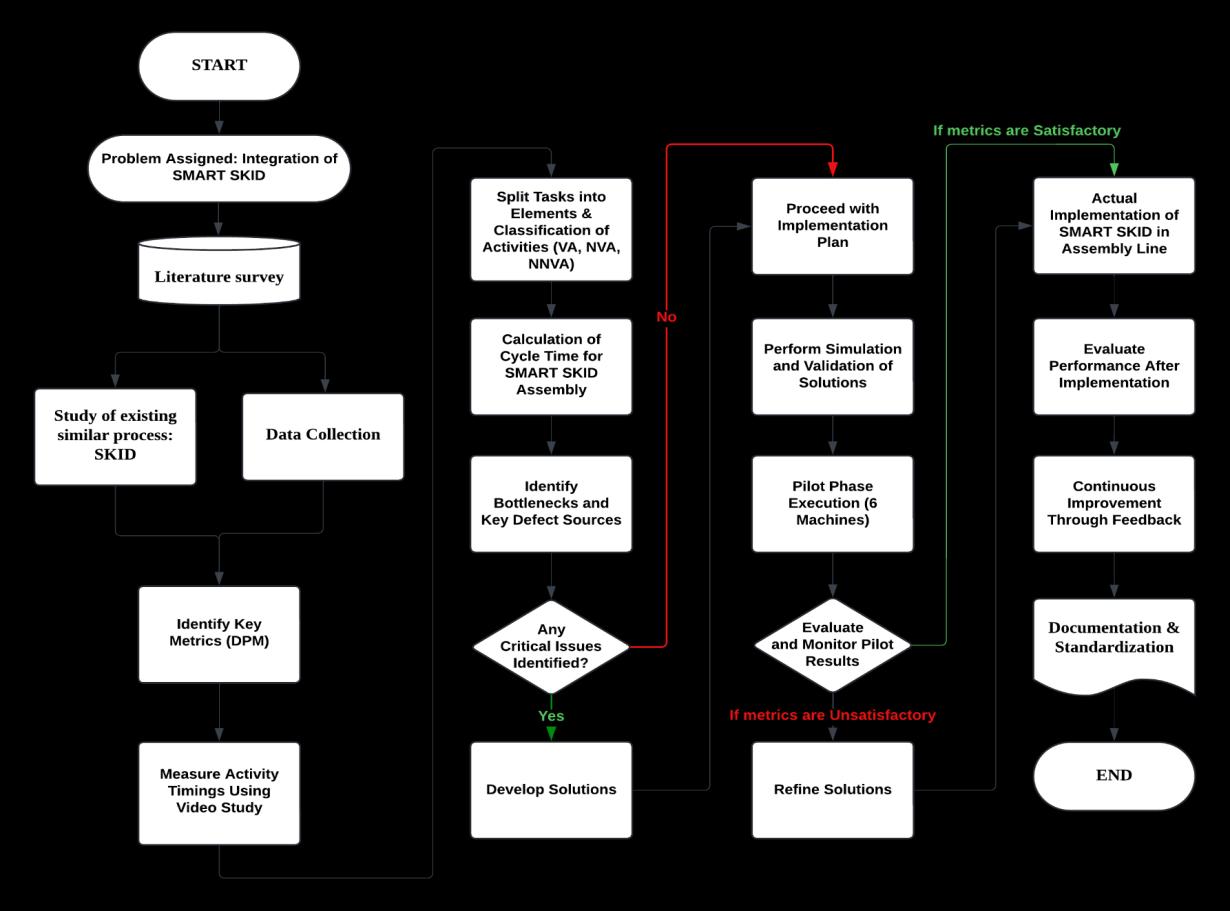

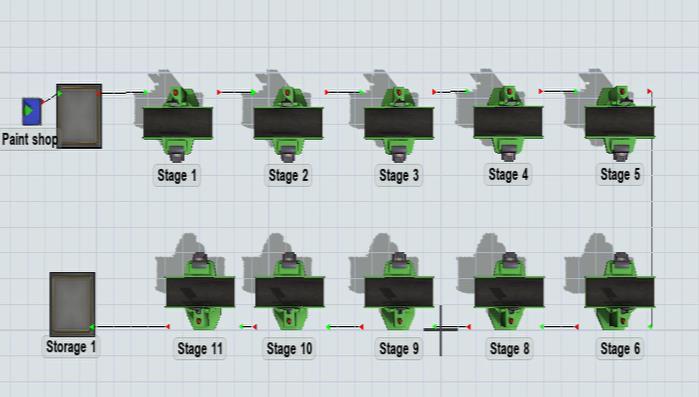

An important component of the methodology as showninFig-1wasthesimulationoftheassemblylineusing FlexSim software. The simulation model represented the existing workflow and layout, capturing cycle time variations, bottlenecks, utilization rates, work-in-progress levels,and throughput metrics.Aftervalidatingthemodel after simulating for a defined time frame, proposed improvements were incorporated and tested under simulated conditions. This dual-track methodology as an empiricalandvirtualtoensureacomprehensivediagnosis andinterventionprocess.

Theexistingassemblylineattheindustryfollowsa mixed-model configuration, allowing multiple product variants to be produced in tandem. While this provides

production flexibility, it also increases the complexity of operations,particularlyduringnewproductintegration.The analysis began with a detailed breakdown of defects recordedacrossdepartments,highlightingaDPMcountof 424duringtheSKTpilotphase.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

The total defects are classified based on the assembly and are established in the Table-02. This representednotonlyadeviationfromacceptablestandards butalsopointedtosystemicshortcomingsintheassembly environment.

Table-2: Defectcountsbasedonassembly

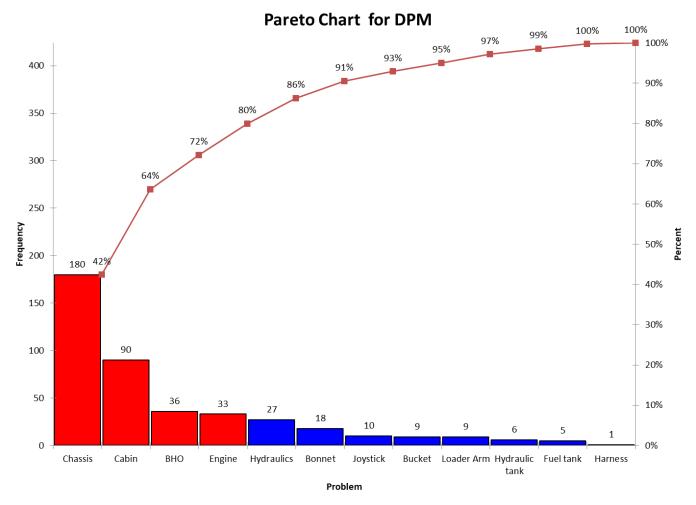

Thedefectsthatarecountedbasedontheassembly areincurredtotheParetochartasinFig-2toprioritizethe areasofmostdefectsfollowedbythesuccessiveonesbased onthat80%ofresultsarederivedfrom20%ofthecauses (or)reasons(or)roots.

Thetotal defects areassignedtothedepartments based on their cause. The defects in each department are shownusingthepivottableasinTable-03

Table-3: Defectcountsbasedondepartments

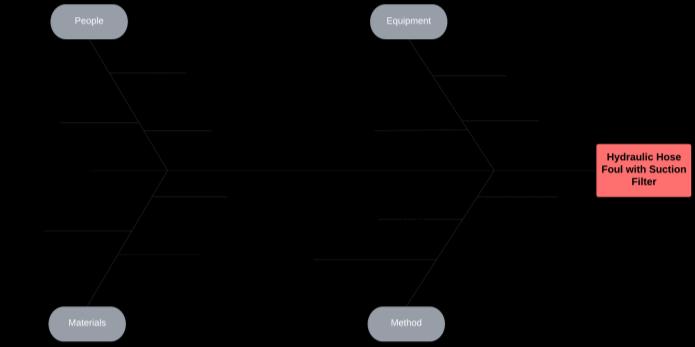

Acause-and-effectanalysiswascarriedouttoassign thedefectstotherespectiveonesacrossfivedepartments: Research and Development (R&D), Sourcing, Industrial EngineeringandDesign(IED),ManufacturingEngineering Department(MED),andHydraulics.Thediagramsrevealed recurringissuessuchasimpropercomponentspecifications, unclear instructions, sourcing delays, and unstandardized workstation setups. For example, the R&D department showedsignificantlapsesinversioncontrolofengineering drawingsasinFig-3

While IED lacked standardized methods for tool calibrationasinFig-4,sothatthedefectisassignedtothe IED.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Hydraulics, a department critical to SKT functionality,reportedfrequentleakagesduetoinconsistent torqueapplicationandsealalignmenterrorsasinFig-5.

Fig – 5: CauseandEffectDiagram(Dept.R&DHydraulics)

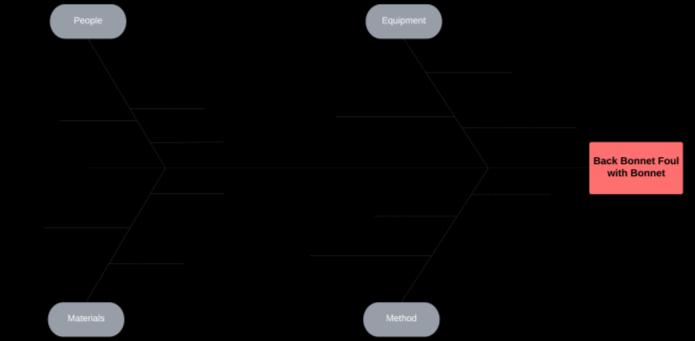

FortheSourcingdepartment,thetheeffectofpart not checked during the purchase leads to the foul of Back BonnetwiththeBonnet.Thecause-and-effectdiagramfor thisisshowninFig-6

Fig – 6: CauseandEffectDiagram(Dept.Sourcing)

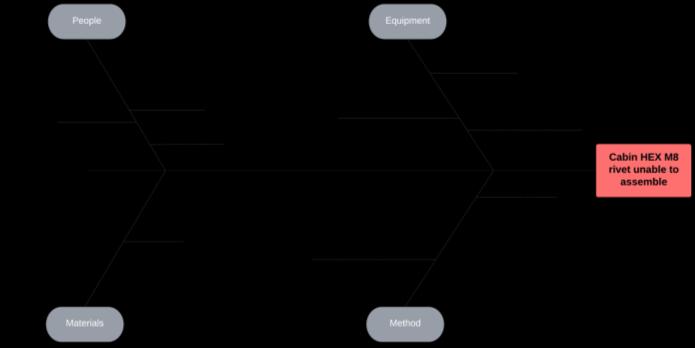

For the defect of Cabin HEX M8 bolt unable to assemble,thecauseisduetothedifferencetolerancesfrom thedifferentlasermachinesusedforcuttingtheplates.The cause-and-effectdiagramforthisisshowninFig-7.

Fig –7: CauseandEffectDiagram(Dept.MED)

Further,datafromtimeandmotionstudiesrevealed substantial non-value-added time, particularly in stages

involving material handling and tool fetching. Operators spent considerable time walking between stations due to suboptimallayoutdesign.Theseinefficienciesweremapped and consolidated into a table identifying non-value-added activities for each assembly stage, from chassis through radiatorinstallation.

Forthepurposeofsimulationofthemixedmodel assembly line in FlexSim software, the time study was performedandtheirstandardtimeswascalculatedforthe predominant4models,01to04.

The projectile study plays a crucial role in estimatingtheoverallcycletimeforthecompleteassembly process.SincethecurrentstudyhasprogresseduptoStage 04,thedatacollectedfromthesestageswasusedtopredict the non-value-added (NVA) activities for the remaining stages (Stage 05 to Stage 11). The video study was conducted, using that, the activities are classified into the elemental level and they are listed as Value-Added (VA), Non-Value-Added (NVA) and the Necessary-Non-ValueAdded(NNVA),basedonleanwastes.TheNVAdatawithan average NVA percentage of 24% and this value was then applied to estimate the NVA for Stages 05 to 11, as summarizedinTable-4.

Table-4: ConsolidatedNVAdataforStages01to11

Stage1 2395 575 1820

Stage2 3008 722 2286

Stage3 3658 878 2780

Stage4 4455 1069 3386

Stage5 2250 540 1710

Stage6 2741 658 2083

Stage8 2712 651 2061

Stage9 1689 405 1284

Stage10 4359 1046 3313

Stage11 1780 427 1353

Totaltime 29047 6971 22076

Average 4455 1069 3386

Cycletime withNVA 4455 74.25 Cycletime reducedis 1046 seconds or 17.4 minutes Cycletime withoutNVA 3386 56.43

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

The NVA percentage identified in the stage-1 is about 16.82%amongthe2395seconds,instage-2is26.29%from the3008seconds,instage03is30.42%from3658seconds comparingof1113secondsindicatingthemostamongthe other4stages,andinstage-04is22.85%from4455seconds The table also shows the motion included in them as

required by the industry to primary focus on the motion wasteandtoeliminatethem.

Thetimeanalysisforthesetasksfromthestages01 to 04 and their respective NVA percentage calculated is showninTable-5

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net

The table-6 presents an analysis of Non-ValueAdded(NVA)timeacrossfourdifferentstagesofaprocess. Eachstageliststhetotaltimetakeninseconds,alongwith thecorrespondingNVAtimeinsecondsanditspercentageof thetotal.InStage1,thetotaltimeis2519seconds,with403 secondsidentifiedasnon-value-added,resultingin16.82% NVA.Stage2hasatotaltimeof3008seconds,ofwhich791 secondsarenon-value-added,contributingto26.29%.Stage 3recordsthehighestNVApercentageat30.42%,with1113 secondsoutof3658beingnon-value-added.InStage4,1018 seconds out of 4455 are categorized as non-value-added, resulting in 22.85%. Overall, the average NVA percentage acrossallfourstagesiscalculatedtobe24.095%,whichis highlightedinredtoemphasizeitssignificance.

Table-6:

6.3 Standard time calculation after elimination of NVA for MODEL-1

ThestandardtimefortheModel-01,02,03,04was calculatedaftereliminatingtheNVAwithprovidedthetotal allowanceof14%,wasshowninTable-7.

Table-7: Standard

After the root causes and inefficiencies were identified, the proposed changes were modeled using FlexSimtotesttheirimpactbeforephysicalimplementation. Thesimulationincludedarepresentationoftheentireline over a 20-day operational window, equivalent to 28,080 minutes. The model established in FlexSim was shown in Fig-8.

Input data included takt time per stage, operator availability, and workstation configuration, all validated throughprimarydatacollection.

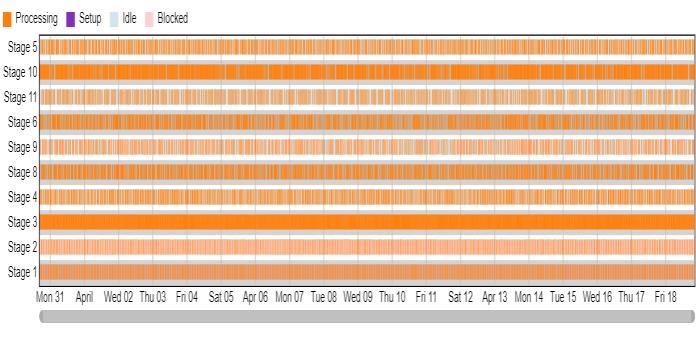

The Gantt chart obtained from the simulation representing the processing, idleness, blockage and the setupperiodsareshownintheFig-9.

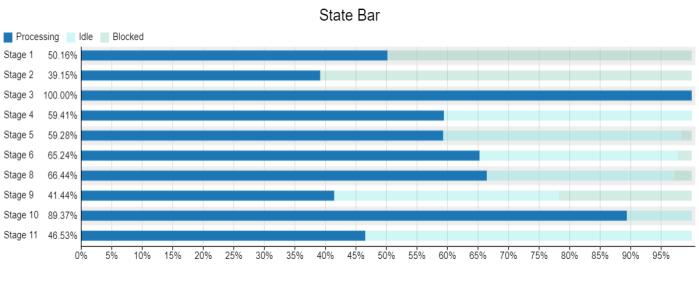

The software simulation exposed critical bottlenecksattheenginedropandradiatorassemblystages, withutilizationratesexceeding95%indicatingbottleneck pointsinthesystem.

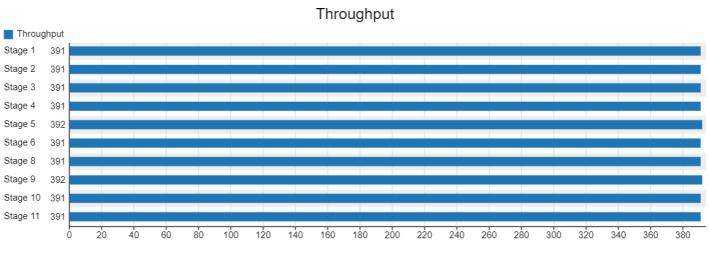

Also,throughputwasinconsistent,thethroughput amount acquired from the simulation for the assembly stageswasshownintheFig-10,whichiswaylessthanthe currentdemand.

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Fig –10: Assemblystages-throughputchart

The utilization of each stage with the idleness, blockageandprocessingperiodsareshowninFig-11,shows the100%utilizationinStgae-03leadingtotheblockagesin stages 01 and 02 also with the effect of idleness from the stages 05 to 11. This indicates the effect of the bottleneck stage (03) among the other stages, indicating the clear assessmentofrequirementofbalancingtheassemblyline.

Fig –11: AssemblyStages-Utilizationchart

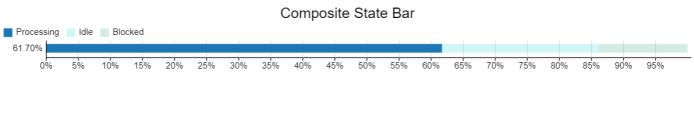

Theoverallutilizationoftheassemblylinefromthe simulation wasestablished asshowninthe Fig-12,shows the line utilization is 61.70% with the 24.3% of idleness alongwith14%ofblockagestage.

Fig –12: OveralllineUtilizationchart

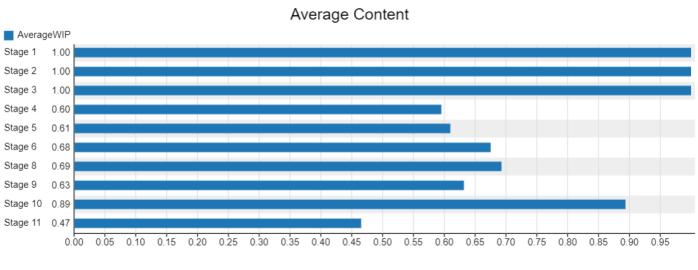

The WIP levels fluctuated due to uneven process balancing. The Fig-13, shows the average content of work (product)accumulatedineachstageoftheassemblyline.

The above charts describe the state of the mixed modelassemblylineforthecalculatedstandardtimeforthe 4 predominate models that are manufactured in larger quantitybasedonthecustomerdemand.

Thetimetakenforeachofthestagesandtheirstate arevisuallyseeninthecharts,belowintheTable-8,thetime takenforeachstateintheirrespectivestagesaredescribed for the 10 stages, from the stage 01-11. This table also indicatesthatthereisnoblockageandidlenessinstge-03, leading to the identification of the bottleneck stage. The stages01and02haszeroidlenessandleadstoblockageand processingstate.Followingthestage03,fromthestages04 to11,theidlenessstateisincreasedanddecreasedblockage comparedtothoseofstages01&02.

Table-8: Simulationsummaryofthestages

Simulation results corroborated real-world observations.TheFlexSimmodelpredictedthereductionin work-in-progress (WIP) inventory, primarily due to

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

improved task balancing and elimination of bottlenecks. Utilizationchartsillustratedmoreequitabledistributionof labor,avoidingoverburdenatspecificstations,andensuring optimaldeploymentofhumanresources.

Furthermore, theGanttchartfrom the simulation illustrated improved sequencing across all workstations. Operators no longer experienced delays due to tool unavailability or unclear instructions. Overall system throughputincreased,aligningwiththeplant’sproduction capacitytargetsforthenewSKTline.

The implementation of industrial engineering interventions and simulation-based validation yielded quantifiable improvements across multiple performance indicators. One of the most notableachievementswas the reductionoftheDefectsPerMachine(DPM)countfroman initial424tozero,translatingtoa100%improvement.This shows the targeted reduction threshold and brought the defectcountwithinindustry-acceptablelimits.

The reduction in DPM was attributed to several factors. Firstly, the introduction of standard operating procedures(SOPs)providedclear,step-by-stepguidanceto operators, thereby minimizing ambiguity and process deviations. Secondly, error-proofing systems (Poka-Yoke) preventedtherecurrenceoffrequentmistakes,especiallyin areas such as torque application, hydraulic fittings, and componentsequencing.Additionally,dailydefectchecklists andfeedbackloopsenabledcontinuousmonitoring,allowing supervisors to take immediate corrective actions. The percentagereductionisshowninTable-9.

The analysis of cycle time using simulation also showed a positive outcome. Prior to intervention, the average cycle time for SKT assembly was 92 minutes. Following the layout and workflow optimization, this was reducedto79minutes a14.2%reductionasaccumulated informofNVA.Thisimprovementshowstheunderscoring powerofprocessre-engineeringandtime-motionanalysisin achieving lean outcomes by means of proper training and awarenesstotheworkersandsequencingintheassembly line.

These results shows that the application of lean tools, combined with data collection and simulation, can significantly enhance assembly line performance both qualitativelyandquantitatively.

From the analysis, it was observed that the time taken before the elimination of Non-Value-Added (NVA) activitieswas56minutesperstation.Aftereliminatingthese non-value-addedactivities,thetimereducedto48minutes per station. This results in a reduction of 8 minutes per station. In terms of percentage, this corresponds to about 14.2% reduction in time per station, indicating a notable improvementinoperationalefficiency.

Based on the findings of this project, several recommendations are planned to ensure the long-term sustainability of improvements and to adopt continuous improvement(Kaizen)oftheassemblyline:

Step1:Itisrecommendedthatallproductvariants:current andfuturecanbeaccompaniedbydocumentationincluding processflowcharts,SOPs,defectchecklists,andFMEAtables. This will create a standardized knowledge base for the organizationandreducethelearningcurveduringproduct transitions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Step 2: The plant should adopt a culture of continuous improvement(Kaizen)throughregularauditsandfeedback loopsinternally.Evenafterinitialsuccess,processesshould be periodically reviewed to identify new bottlenecks, inefficiencies,ordefectpatternsthatmayariseasproduction rampup

Step3: Thereisastrongcasefordigitalintegrationofquality controlsystems.Theimplementationofbarcodescanning, digitaldefectlogging,andoperatordashboardscouldfurther reduce manual errors and improve traceability across the productionlineasaimprovementindigitalfactory.

Step 4: Another recommendation pertains to workforce training. While SOPs can standardize operations, crosstrainingandupskillingwillensureoperatorsremainagilein adaptingtodesignchanges, layoutmodifications,andtool enhancements.

Step5: TheFlexSimsimulationmodeldevelopedduringthis project should be maintained and updated with real-time data.Thisdigitaltwincanbeusedtosimulatefutureproduct introductions,productionramp-ups,orlayoutchanges,thus servingasastrategicdecision-supporttool.

The present study successfully demonstrates the applicabilityandimpactofindustrialengineeringtechniques inimprovingaliveconstructionequipmentassemblyline. ThroughacomprehensivecombinationofRCA,FMEA,PokaYoke, time and motion study, and FlexSim simulation, the integrationofthenew SKT productintotheassemblyline wasaccomplishedforfurthervolumeramp-up

TheDPMcountwasnullified,averagecycletimewas shortened by 14.2%, and WIP levels were effectively stabilized. Prominently, the interventions were implemented, highlighting the strength of analytical problem-solvingandleanmethodologiesinmanufacturing systems.

Thisprojectnotonlyresolvedimmediatechallenges relatedtoproductintegrationbutalsoestablishedascalable framework for future improvements. The success of the initiative confirms the critical role of organized manufacturingmethodsinincreasingproductivity,quality, andoperationalexcellenceforthemanufacturingfirm

[1] Mukti Ali Sadikin (2023), Defect Reduction in The ManufacturingIndustry:SystematicLiteratureReview, International Journal of Industrial Engineering and EngineeringManagement,pp.73-83

[2] Filscha Nurprihatin, Yayang Nadistya Ayu, Glisina Dwinoor Rembulan, Johanes Fernandes Andry, Tika EndahLestari(2023),MinimizingProductDefectsBased onLaborPerformanceusingLinearRegressionandSix Sigma Approach, Management and Production Engineering,pp.88-98

[3] Viktoria Sundquist, Lisa Melander (2020), Mobilizing resources in product development by organizational interfacesacrossfirms,unitsandfunctions,Journalof Business&IndustrialMarketing.

[4] Elisa Verna, Gianfranco Genta, Maurizio Galetto, FiorenzoFranceschini(2022),TheInternationalJournal ofAdvancedManufacturingTechnology,pp.2835-2846

[5] Wen Hou and Song Zhang (2024), Assembly line balancing and optimal scheduling for flexible manufacturingWorkshop,JournalofMechanicalScience andTechnology,pp.2757-2772.

[6] FoivosPsarommatis,JoãoSousa,JoãoPedroMendonça & Dimitris Kiritsis (2022), Zero-defect manufacturing theapproachforhighermanufacturingsustainabilityin theeraofindustry4.0:apositionpaper,International JournalofProductionResearch,pp.73-91

[7] Ali Ahmad Malik, Arne Bilberg, (2019), Complexitybased task allocation in human-robot collaborative assembly,IndustrialRobot:theinternationaljournalof roboticsresearchandapplication.

[8] Ashish Kalra, Sachin Marwah, Sandeep Srivastava, Rajesh Bhatia (2020), Productivity Improvement in Assembly Line of Automobile Industry by Reducing CycletimeofOperations,IJERT,pp.28-31

[9] Chansiri,Singhtaun,Veerawit,Pipattanapoonsin(2023), Applying Line Balancing to Improve Production Line Efficiency: A Case Study of an Automotive Company, 13th International Conference on Information CommunicationandManagement,pp.21-25

[10] George Kanawaty, (1992), Time study: Selecting and timingthejob,Introductiontoworkstudy,International LabourOffice,Geneva,pp.281-294

[11] Gualtiero Fantoni and Salam Qaddoori Al-Zubaidi (2020), Automating the process of method-timemeasurement,InternationalJournalofProductivityand PerformanceManagement,pp.958-982

[12] Haritha Malika Dara, Ashwin Raut (2024), Reducing non-valueadded(NVA)activitiesthroughleantoolsfor theprecastindustry,Heliyon.

[13] Ibeh Matthew Imagwuike, Nwankwojike Bethrand Nduka & Nwadinobi Chibundo Princewill (2020), Assembly line balancing implementation in

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

manufacturing industry, International Journal of MechanicalandProductionEngineeringResearchand Development(IJMPERD),pp.5683–5692

[14] Jagdeep Singh, Harwinder Singh, Amandeep Singh, Jashanpreet Singh, (2019), Managing industrial operationsbyleanthinkingusingvaluestreammapping and six sigma in manufacturing unit: Case studies, ManagementDecision.

[15] McDermottO,KevinODwyer,JNoonan,AnnaT,Angelo Rosa(2023),Thedevelopmentofaleansixsigmaand BIM framework for enhancing off-site manufacturing, InternationalJournalofLeanSixSigma,pp.50-69

[16] Maha A. Alrawi (2023), Proposing a new method to solve line balancing bottleneck problem in the singlemodelline,EmeraldOpenResearch2023,5:8

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.226 | ISO 9001:2008

|