International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Shidhi swarupa Nayak1 , Snehal Ramdas Kshirsagar2 , Sangita Nayak3

Assistant Professor, Dept. of Civil Engineering, Sanghavi college of Engineering, Maharashtra , India

Assistant Professor, Dept. of Civil Engineering, Sanghavi college of Engineering, Maharashtra , India

Assistant Professor, Dept. of Civil Engineering, Spintronic Technology & Advance Research,Odisha,India

Abstract-

Bituminousconcrete(BC)mixesaremostcommonlyusedall overtheworldinflexiblepavementconstruction.Itconsists of asphalt or bitumen (used as a binder) and mineral aggregatewhicharemixedtogether,laiddowninlayersand thencompacted.Undernormalcircumstances,conventional bituminous pavements if designed and executed properly perform quite satisfactorily but the performance of bituminous mixes is very poor under various situations. Today’s asphaltic concrete pavements are expected to performbetterastheyareexperiencingincreasedvolumeof traffic,increasedloadsandincreasedvariationsindailyor seasonaltemperatureoverwhathasbeenexperiencedinthe past.Inaddition,theperformanceofbituminouspavements is found to be very poor in moisture induced situations. Considering this a lot of work has been done on use of additives in bituminous mixtures and as well as on modification of bitumen. Research has indicated that the additionofpolymerstoasphaltbindershelpstoincreasethe interfacialcohesivenessofthebondbetweentheaggregate andthebinderwhichcanenhancemanypropertiesofthe asphaltpavementstohelpmeettheseincreaseddemands. However,theadditivethatistobeusedformodificationof mixorbindershouldsatisfyboththestrengthrequirements aswellaseconomicalaspects.

The quantity of plastics used throughout the world is increasing every year. Municipal solid wastes (MSW), manufacturingprocessesandserviceindustriesproducea lotofwasteplasticmaterials.Thegrowingnumberofplastic materialseveryyearandlimitedlandfillconditionscauses manyalternativesexistforthedisposalofplasticwaste.This paperprovidesasummaryofthestudyontheutilizationof plastic wastes in road construction. Data from researcher showthatplasticcanimprovesomepropertiesofmodified asphalt mixture. Having considered the economic and environmentalprudentangles,utilizationofwasteplasticas anadditivetoasphaltmixtureissuitabletobeusedforroad pavement.Utilizationofwasteplasticinbituminousblends hasdemonstratedthattheseenhancethepropertiesofblend not withstanding diminishing transfer issues. Waste polyethylenewhichisisolatedandcleanedisslicedwiththe endgoalthatitgoesthroughthesievehaving2mm-3mm size utilizing shredding machine. The measurements of

plastic of 0%, 2%,4%,6%,8% utilized as substitution of bitumen. The utilization of this advancement won't just fortifythedevelopmentofroadsadditionallyincrementthe lifeexpectancyofroadsandinadditionhelptoenhancethe naturalconditions.Plasticroadswouldbeanadvantagefor India'shotandstickyatmosphere,wheretemperaturesas often as possible cross 50 °C and downpours make extraordinary devastations, leaving a large portion of the asphalts with enormous pot gaps. Plastic road provides a solutiontotheproblemofeffectivedisposalofplasticwaste atthesametimeincreasesthestrengthanddurabilityofthe road, addresses the environmental, economic and most importantsafetyissue.

KEYWORDS: Bituminous concrete (BC), Polypropylene Plastic,Bitumen,ModifiedBitumen,MarshallProperties

Roadinfrastructureformsthebedrockofmodernsocieties, facilitatingeconomicgrowth,trade,andsocialconnectivity. Bituminousconcrete,a widelyadoptedpavingmaterial,is criticalforconstructingdurableandefficientroadnetworks globally.However,conventionalbituminousmixesareoften susceptible to various forms of distress, including fatigue cracking,rutting,andmoisturedamage,particularlyunder increasingtrafficvolumesanddiverseclimaticconditions, leading to frequent maintenance and rehabilitation costs. Simultaneously,theburgeoningglobalissueofplasticwaste, specifically polypropylene (PP) plastics, presents a formidable environmental challenge. The accumulation of thesenon-biodegradablematerialsinlandfillsandnatural ecosystemsnecessitatesinnovativeandsustainabledisposal solutions. While extensive research has focused on improving the performance of bituminous pavements through various modifiers, and considerable efforts have been directed towards managing plastic waste, the synergisticpotentialofincorporatingplasticwasteintoroad constructionasaperformanceenhancerremainsanareaof criticalinvestigation.Thisresearchaimstobridgethisgap by exploring the feasibility and efficacy of utilizing polypropyleneplasticasamodifierinbituminousconcrete mixes.Thejudiciousintegrationofplasticwasteinpavement constructionnotonlyoffersaviablepathwayforsustainable waste management but also holds significant promise for

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

enhancingthemechanicalanddurabilitycharacteristicsof bituminousconcrete,therebycontributingtomoreresilient and long-lasting road infrastructure. Specifically, this experimental study focuses on investigating the impact of varyingpercentagesofpolypropyleneplasticontheMarshall Stability and flow, volumetric properties, and moisture susceptibility (through indirect tensile strength ratio) of bituminous concrete mixes. The findings from this laboratory-basedstudy will be instrumental incomparing theperformanceofconventionalmixeswithpolypropylenemodifiedmixesanddetermininganoptimumplasticcontent forimprovedpavementperformance

2. OBJECTIVES:

Basic intention is to efficiently utilize the nonbiodegradable plasticina constructivewaysothatit canbe beneficialto society.Mainobjectiveof presentprojectwork are:-

Toevaluatethepropertiesofpolymermodifiedbitumen fordifferentratiosofpolypropylene(varyingfrom2%8%).

Determination of Optimum Binder Content (OBC) throughMarshallAnalysis

Toidentify the optimumproportionof plastic(OPC)to beadded inthe bitumenmix for getting the required strength.

3.

1.Sangita et al. (2011),“suggested a novel approach to improve road quality by utilizing plastic waste in road construction. According to them India spends Rs 35,000 croresayearonroadconstructionandrepairs,includingRs 100,000 crores a year just on maintenance and roads by bitumenmodificationlasts2-3timeslonger,whichwillsave usRs.33,000croresayearinrepairs,plusreducedvehicle wearandtear.”

2. R. Vasudevan and Dr.Samuvel (2013),“utilized waste plasticforintegrateddevelopmentofRuralandArterialroad network for socio-economic Growth. He studied both dry andwetmixingprocessbyaddingpolymerwithrespectto theweightofbitumenused.Authorreportedthatpolymer bitumenblendisabetterbindercomparedtoplainbitumen resulting higher Marshall Stability and decreasing the possibilitiesofpotholesformation.”

3.Sabinaetal.(2009),“evaluatedtheperformanceofwaste plastic/polymermodifiedbituminousmixandobservedthat the results of marshal stability and retained stability of polythenemodifiedbituminousconcretemixincreases1.21 and1.18timeshigherthanthatofconventionalmixbyusing 8%and15%(byweightofbitumen)polythenewithrespect to 60/70 penetration grade of bitumen. But modified mix

with15%polyethyleneshowedslightlydecreasedvaluesfor MarshallStabilitythanthatofthemixwith8%modifierin theirresults.”

4. P.O. Awoyera,A. Adesina,“stated that the use of Plastic wasteforconstructionapplicationswillsolveboththesolid wasteproblemanddepletingdepositsofrawmaterialsused for plastic waste in different construction applications supportsthesustainabilitytrendofacirculareconomy.The useofPlasticwasteforconstructionapplicationscreatesa pathway to use these wastes for long term applications compared to short term ones such as recycling into new productswhichwillendupaswastewithinashortperiodof time. The use of plastic waste for various construction applicationwillleadtovariousrevenuegeneration.”

5. A.S. Sandbhor and J.K Patil(2019),“studied how plastic waste in mix will help reduction in need of bitumen by around10%,increasethestrengthandperformanceofroad, avoiduseofantistrippingagent,avoiddisposaloftheplastic wastebyincinerationandlandfillingandultimatelydevelop atechnology,whichiseco-friendly.Plasticroadsaremeans ofthepreventionandultimatelythecure.”

6.R.AnandandSathya.S(2012),“carriedoutexperimental study on conventional bitumen and polymer modified bitumenandobservedasignificantimprovementincaseof ruttingresistance.Thepolymercoatedonaggregatereduces the voids and moisture absorption. This results in the reductionofrutsandthereisnopotholesformation.”

7.AzmatShaikhetal, “investigated thatMarshall Stability valueincreaseswithplasticcontentandMarshalFlowvalue decreasesuponadditionofpolythenei.e.theresistanceto deformations under heavy wheel loads increases. They concluded that the addition of plastic waste enhances the variouspropertiesofanordinarybituminousroad.”

8.A.Adesinaetal.(2016),“statedthattheroadwillservethe tenureofits constructionforthebettermentofthepeople residing in the vicinity of the road. And serve a good property value for the future projects proposed by the constructionagenciessharingtheroute.”

9.A.Krishna(2018)Concludedthatthequalifierwhenused in 2% by weight of bitumen can improve the stability of pavement,bestamongthembeingLDPE.

10.KotreshK.M etal(2016),“reportedthattheutilizationof wastematerialinasphaltpavementwouldbebeneficialin ordertofindanalternativesolutiontoincreaseservicelifeof asphalt pavement and reduce environmental pollution as well. Form their study it is concluded that Polyethylene Terephthalate (PET) reinforced mixtures possess higher stability value, flow, fatigue life in comparison with the mixtureswithoutPET.”

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

11.SubhamBansaletal.(2017),“statedthatdiscardedwaste plastic materials in bituminous concrete mix may aid in minimizingtheconstructioncostoftheroads.Moreoverit may also contribute in preventing the environmental pollution cause by dumping of such waste materials in ground”.

12.V. Sabdra(2017),“Gaveapotentialsolutiontostrength lossofbituminouspavementunderwater.Theycompared performance of bituminous mix under water with and withoutpolyethyleneadmixtureandconcludethatbitumen mixes with polyethyleneperformedwell under waterand showed even better Marshall Stability than normal bituminous mix under normal condition Keeping the environmentsafefrompollutionwillbeanaddedbonus.”

13. Science Tech Entrepreneur (2008),“proposed that the durability of the roadslaid withshreddedplasticwaste is muchmorecomparedwiththosewhichasphaltedwiththe ordinarymix.Whileanormalhighwayroadlasts4to5years itisclaimedinthispaperthatplastic-bitumenroadscanlast upto10years.Accordingto thispaper rainwaterwill not seep through because of the plastic in the tar. So, this technologywillresultinlesserroadrepair.”

14. P. K Gangwar(2010),“stated that application and performance of polyethylene as modifying additive in asphaltmixture.Theyaddedpolyethyleneasadditivetohot mineral aggregate for few minutes, and then added the asphalt mixing together which simplifies the construction process and reduces the cost of construction. They concludedthatthereisimprovementonhightemperature stability, low temperature cracking resistance and water resistance on modification and evaluate polyethylene as additive in the technical, economic and environmental aspects.”

15. Murphy et al. (2001),“examined the possibility of incorporating waste polymer into bitumen as a modifier, evaluatedtheperformanceofrecycledmodifiedbitumenand compare their properties with those of standard bitumen and polymer modified bitumen. They concluded polypropylenesarenotusefulinimprovingthepropertiesof bitumenand displayedpractical difficulties during mixing andtesting,suggestingpoorcohesionwithbitumen.”

From the above study of the behavior of plastic waste modified BC, it was observed that the modified mix improvedMarshallCharacteristics.Marshallstabilityvalue increases with plastic content and Marshall Flow value decreases upon addition of plastic i.e. resistance to deformations under heavy wheel loads increases. Plastic enhancesthevariouspropertiesof anordinary bituminous road.Consideringthesefactorswecanassurethatwecan obtainamorestableanddurablemixfor thepavementsby polymermodifications.

4. METHODOLOGY:

a) Test on physical Properties of conventional and modifiedbitumen

b) PreparationofMarshallsamples

c) TestonMarshallsamples

Voidanalysis

5. EXPERIMENTAL WORK

5.1Determination of specific gravity of polypropylene

Specific gravity of polypropylene was found by following guidelinesofASTMD792-08.

Theprocedureadoptedisgivenbelow;

1) Theweightofthepolypropyleneinairwasmeasuredby abalance.Letitbedenotedby“a”.

2) Animmersionvesselfullof waterwaskeptbelowthe balance.Apieceofironwirewasattachedtothebalance suchthatitissuspendedabout25mmabovethevessel support.

3) Theplasticwasthen tiedwitha sink bytheiron wire andallowedtosubmergeinthevesselandtheweight wasmeasured.Letitbedenotedas“b”.

4) Then plastic was removed and the weight of the wire andthesinkwasmeasuredbysubmergingtheminside water.Letitbedenotedas“w”.

Thespecificgravityisgivenby:

S=a/(a+w-b)

Where:

a=19gm

b=24gm

w=26gm

s=19/(19+26-24)=19/21=0.90476

Takes=0.905

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

5.2 Tests on Modified Bitumen:

TABLE 1: Physicalpropertiesofmodifiedbitumen:-

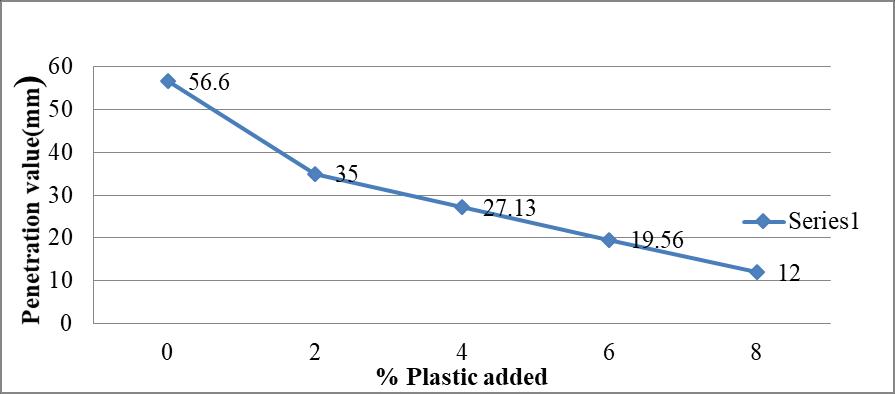

(Variation of penetration value of bitumen with the increase in % of plastic)

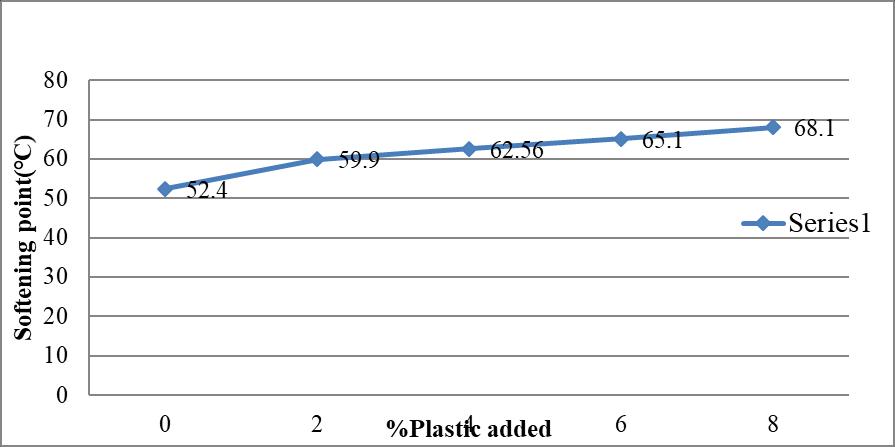

5.2.2Effect of plastic on Softening point of Bitumen

It was observed that withincrease inplasticcontent the value of softening value increases. Higher the value of softening point shows thebitumen issuitableforhigher climatic region.

(Variation of Softening point of bitumen with the increase in % of plastic)

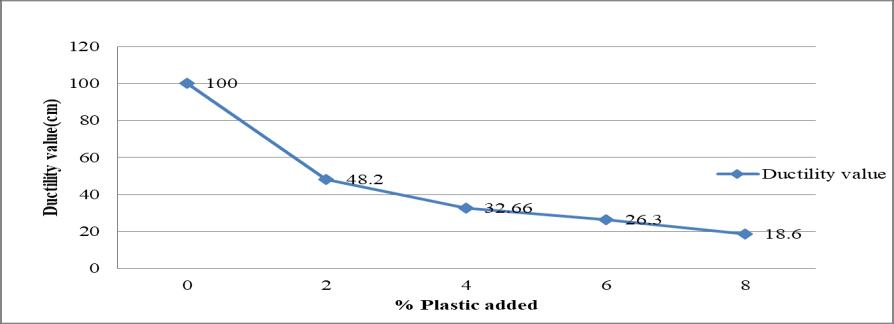

5.2.3 Effect of Plastic on Ductility value of Bitumen

5.2.1 Effect of Plastic on Penetration value of Bitumen

Withincreaseinpolypropyleneplastic,itwasobservedthat thepenetration valueofbitumenisdecreases,indicatethe improvementintheirtemperaturesusceptibilityresistance characteristics.

Theductilityvaluesdecreasewithincreaseinpercentageof polypropyleneplastic.Bitumenwithlowductilityvaluemay getcrackedespeciallyincoldregions

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Figure 2: Variation of ductility value of bitumen with the increase in % of plastic

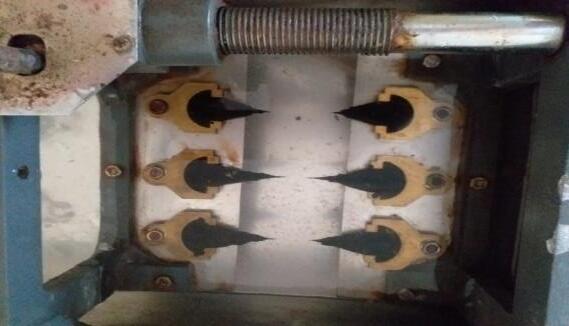

(Ductility value test on Bitumen Vs. Plastic Modified Bitumen)

6. Preparation of Marshall samples:

The mixes were prepared according to the Marshall procedure specified in ASTM D1559.For BC mixes the coarseaggregate,fineaggregateandfillerweremixedwith bitumen and polypropylene plastic according to the gradation given in Table 3.2. Here the Optimum polypropylenecontent(OPC)wasfoundby Marshall test. The mixing of ingredients was done as per the following procedure

1)Requiredquantitiesofcoarseaggregate,fineaggregate& mineralfillersweretakeninanironpan.

2) This was kept in an oven at temperature 160℃ for 2 hours.Thisisbecausetheaggregateandbitumenaretobe mixedinheatedstatesopreheatingisrequired.

3)Thebitumenwasalsoheateduptoitsmeltingpointprior tothemixing.

4)Therequiredamountofplastic wasweighedandkeptin aseparatecontainer.

5)Wasteplasticsbydirectmixingwithhotbitumenat176) Theaggregatesinthepanwereheatedonacontrolledgas stoveforafewminutesmaintainingtheabovetemperature.

7)Nowplasticmodifiedbitumenwasaddedtothismixand the whole mix was stirred uniformly and homogenously. Thiswascontinuedfor15-20minutestilltheywereproperly mixed which was evident from the uniform colour throughoutthemix.

8)Thenthemixwastransferredtoacastingmould.

9)ThismixwasthencompactedbytheMarshallHammer.

10)75no.Ofblowsweregivenpereachsideofthesample sosubtotalof150no.ofblowswasgivenpersample.

11)Thenthesesampleswithmouldswerekeptseparately andmarked0℃

Inthismethod,theresistancetodeformationofacompacted specimen of bituminious mixture is measured when the specimen is loaded diametrically at a deformation rate of 50mm/min.Hereare two majorfeaturesof theMarshall method ofmixdesign.

a) Stability,flowtestsand b) Voids analysis

The Marshall stability ofthemixisdefinedasthemaximum loadcarriedbythespecimenatastandardtesttemperature of 60℃ .The flow value is the deformation that the test specimen undergoes during loading up to the maximum load.InIndia,itisaverypopularmethodof charecterization of bituminous mixesduetoitssimplicityandlowcost.Inthe present study Marshall properties such as stability,flow value,unit weight and air voids were studied to obtain optimum binder content(OBC) and the optimum plastic content(OPC).

ThevolumetricanalysisincludescalculationofBulkDensity ,Percent Air voids in Mineral aggregates (VMA), Percent VoidsFilledwithBitumen(VFB).TheMarshalltestinclude findingtheMarshallStability and Flowvalueof Marshall specimen.This has been carried out at different binder content.At each binder content three specimen are made .Theaveragebulkdensityofthreespecimensisfoundoutin terms of gm/cc.The OBC was calculated as the average of asphalt content for maximum stability,maximum unit weightand 4%airvoids.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Table-2 Results for Finding OBC of BC grade- II with binder content VG -40.

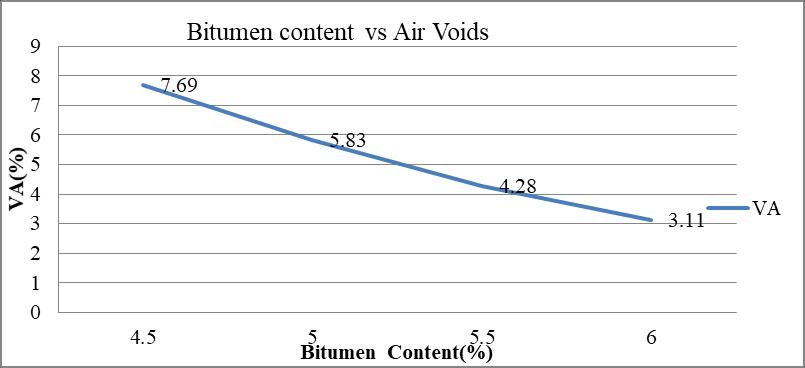

6.2.1Voids in paving mix(VA)

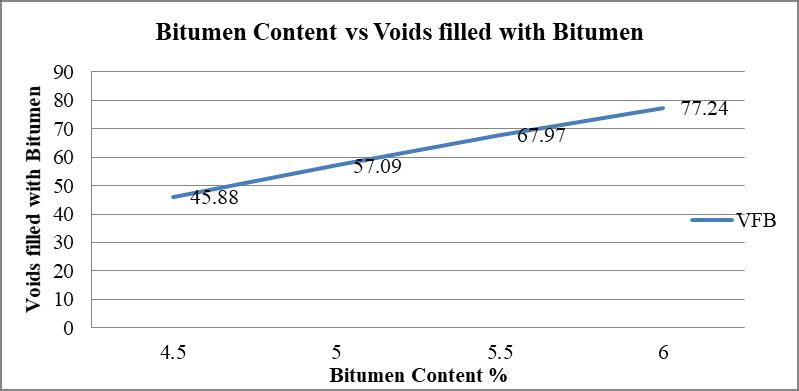

6.2.2Voids Filled With Bitumen(VFB)

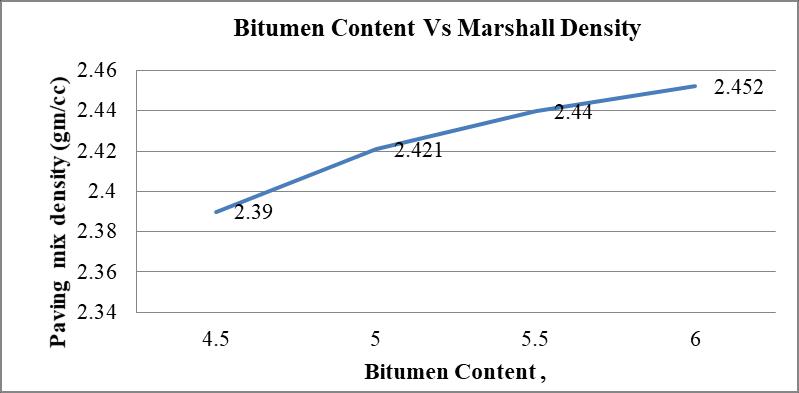

6.2.3Bitumen Content vs Marshall Density

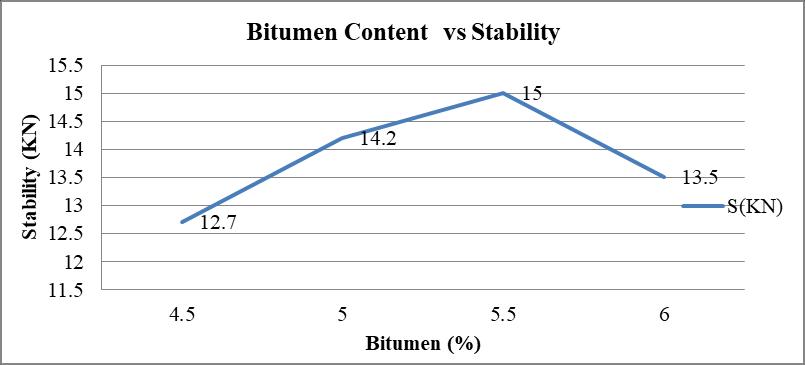

6.2.4Marshall Stability Value

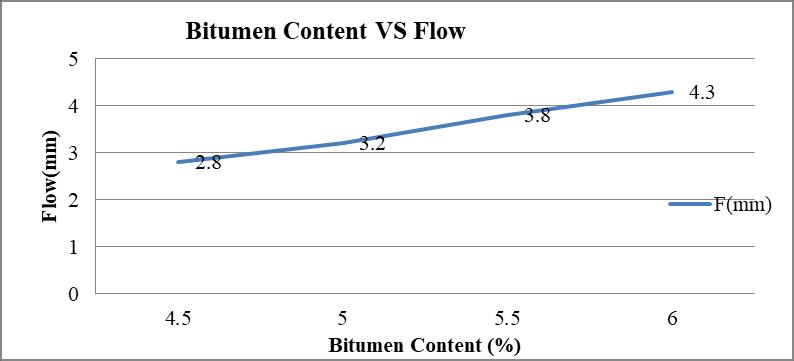

6.2.5Marshall Flow Value

6.3 Determination of Optimum Bitumen Content(OBC):-

The Optimum binder content for the mix design is the binder,contentusuallythemosteconomicalandsatisfyallof theestablishedMORTHSpecifications.Thedesignoptimum bitumencontentshouldbecompromiseselectedtobalance allthemixproperties.

Optimumbindercontentofthemix(OBC)fortheBCis 5.7% byweightofmix.

Calculation Involved

Totalweightofsample=1200gm

OptimumBitumenContent=5.7%

SoweightofBitumen=68.4gm

Thepolypropylenecontentwas varied from2to 8% and for each polypropylene content ,3 samples were prepared.

Thesampleswerenamed ,theweight of polypropylene & bitumenfor each samplewere calculated and shown in Table 3 and 4

International Research Journal of Engineering and

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net

TABLE 3

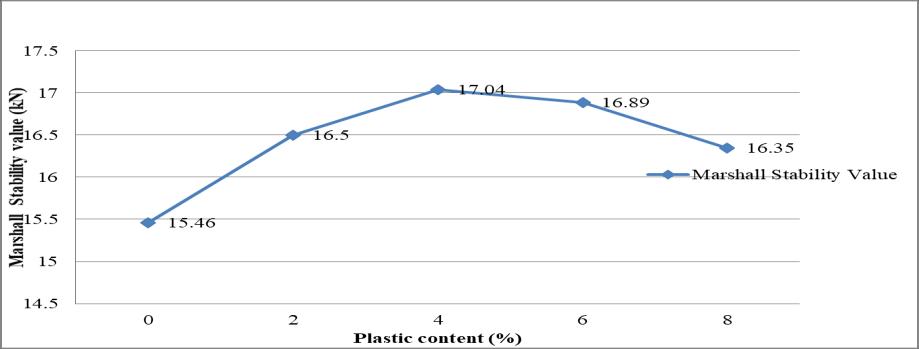

Variation of Marshall Stability of BC mix with different Plasticcontent

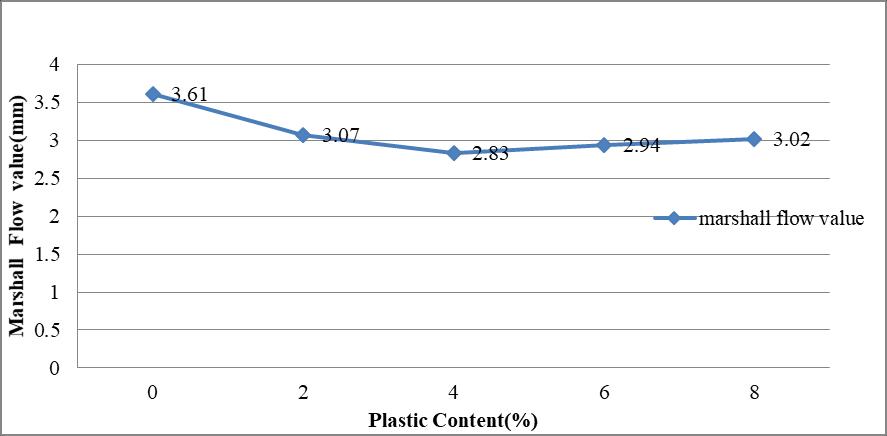

6.6 Flow value:

Itisobservedfromgraphsthatbyadditionofpolypropylene plasticflowvaluedecreasesthanthatofconventionalmixes, againfurtheradditionofpolypropyleneafterOPCtheflow valuestartstoincrease.

TABLE 4

6.4 Effect of polypropylene plastic on Marshall properties of BC with Cement as Filler:

Here result in variation of Marshall properties with 5% bindercontentwherepolypropylenecontentistakenas 0%, 2%,4%,6%,8%for BCareexplainedbelow.

6.5 Marshall Stability:

From the graphs it can be analyzed that with addition of polypropylene stability value also increases up to certain limitsandfurtheradditiondecreasesthestability.Thismay beduetoexcessamountofpolypropylenewhichisnotable tomixinasphaltproperly.

(VariationofFlowValueofBCwithdifferentPlastic Content )

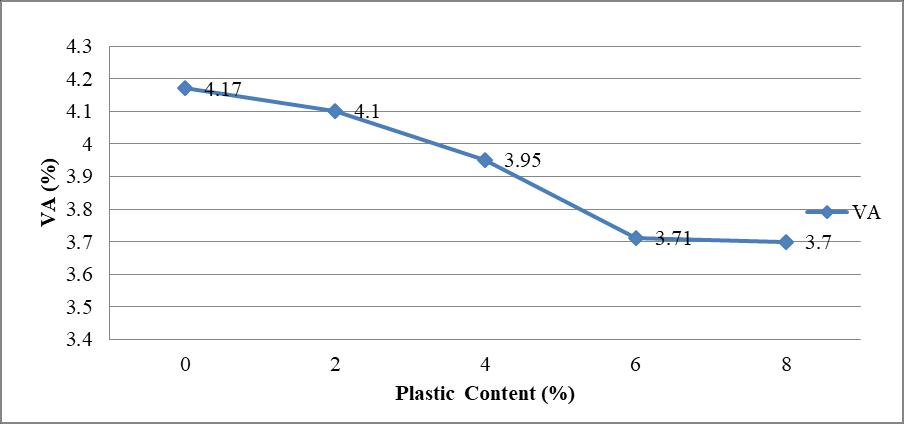

6.7 Air void(VA)

Itisobservedthatwithadditionofpolypropyleneplasticto mix the air void is decreasing than that of conventional mixes.

(Variation of Air Voids of BC mix with different Plastic Content)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

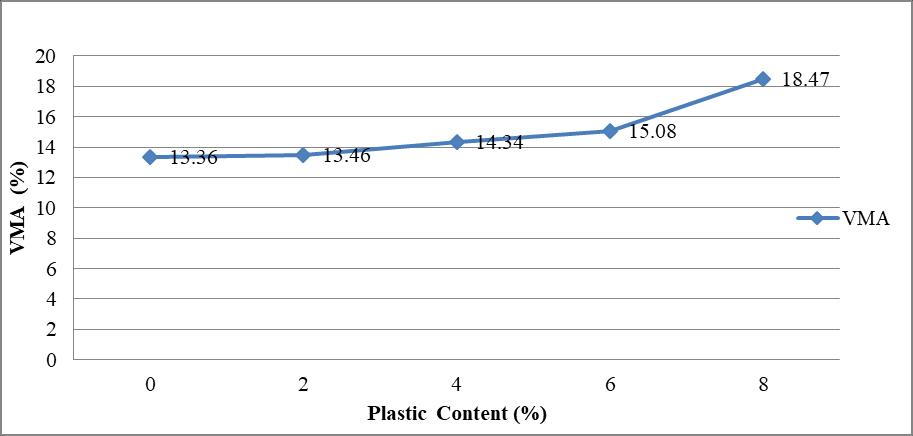

Variation of VMA values with different polypropylene contents are shown in graphs below. Form the graphs it shownthatadditionofpolypropylenetomixtheVMAvalues increasesthanthatofconventionalmixes

Variation of Vma Of BCMixWithdifferentPlasticContent

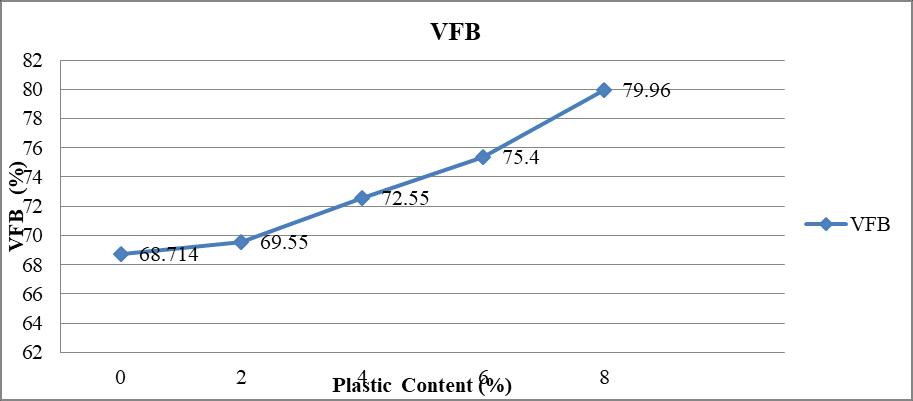

6.9 Void filled with bitumen(VFB)

Variation of VFB with different polypropylene content is showningraphsbelowfromthisgraphsitisobservedthat with addition of polypropylene plastic to mix the VFB increasesthanthatofconventionalmixes.

Variation of VFB of BC mix withdifferentPlasticContent

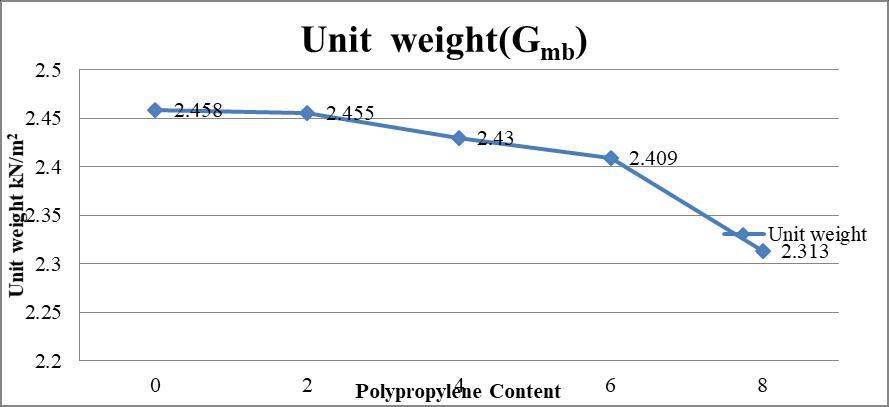

6.10 Unit weight

ItisObservedthatwithincreaseinpolyethyleneplasticin the BC mix its value decreases than conventional mix. It happensduetolighterweightofpolypropyleneascompared tobitumen.

Variation of Unit weight of BC mix with different Plastic Content

Theoptimumplasticcontent(OPC)wascalculatedbytaking theaverageofthreevaluesgiven below:-

The plastic content corresponding to the maximum stabilityofthe Marshallsample.

TheplasticcontentcorrespondingtotheMaximum unit weightofthespecimen.

Designed limits of percent air voids in the total mix(4%).

Table5–Optimum bitumen content based on the mix parameters Parameters

The Optimum value of plastic added from the experimentalresultsis 3.03%byweight

Thevolumetricparametersi.e.Airvoids,Voidfilledwith Bitumen, Voids in Mineral aggregates(VMA) and Marshall Stability and Flow value at OPC are given in Table-5.1.And all properties Satisfies the MORTH Specification.

Hence,itreducesthequantityofbitumenupto3.03% by weight and reduces the cost of construction of flexiblepavement

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Fromthestudyofthebehavior of polypropylenemodified BCitwasfoundthatthemodifiedmixpossessesimproved MarshallCharacteristicsas mentionedbelow:-

The optimum value of plastic waste added from the experimental result is 3 .03% by weight. Reduces the quantityof bitumenupto3.03%byweightandreducesthe costofconstructionofflexibleconstruction.

It is observed that Marshall stability value increases with polypropylenecontentupto 4% andthereafterdecreases. We observe that the marshall flow value decreases upon additionofpolypropylene, i.etheresistancetodeformations under heavy wheel loads increases. Also the values of parameters like VMA,VA ,VFB are within the required specifications.

Consideringthesefactorswecanassurethatwecanobtaina morestableanddurablemixforthepavementsbypolymer modifications. This small investigation not only utilizes beneficially, the waste non –degradable plastics but also providesusanimprovedpavementwithbetterstrengthand longerlife period.

PolymermodifiedpavementswouldbeaboonforIndia’shot and extremely humid climate, where temperatures frequentlyrisespast50℃andtorrentialrainscreatehavoc, leaving most of the roads with heavy distresses. This adversely affects the life of the pavements. The polymer modifiedbitumenshowimprovedpropertiesforpavement construction. This also can reduce the amount of plastics wastewhichotherwiseareconsideredtobeathreattothe hygieneoftheenvironment.

In this modification process plastic is mixed with hot bitumen.Thispolymermodifiedbitumenalsoreducesthe voidspacespresentinthemix.Thispreventsthemoisture absorptionandoxidationofbitumenbyentrappedair.The roadcanwithstandheavytrafficandshowbetterservicelife. Itwillnotonlyaddvaluetoplasticwastebutwilldevelopa technology,whichiseco-friendly.

However,itisrecommendedthatmoreresearchregarding thetopicshouldbedoneandmoretrial sectionshould be laidandtheirperformanceshouldbestudied.

1.H. shafiq,A. Hamid,(2016),“Plastic Roads:A Recent AdvancementinWasteManagement”.Internationaljournal ofEngineeringReserchandTechnology.

2.S. Rajasekaran, Dr. R. Vasudevan and Dr. Samuvel Paulraj,(2013),“ReuseofWastePlasticCoatedAggregatesBitumen Mix Comosite For Road Application-Green

Method,”AmericanJournal ofEngineering Reserche-ISSN: 2320-0847.

3.S.Bansal,AnilK.MisraandP.Bajpai(2017),“Evalutionof modifiedbituminousconcretemixdevelopedusingrubber and plastic waste materials”.International Journal of SustainableBuiltEnvironment”.

4. A. Raut, W. Dhengare,Ajay L. Dandge,Harshal R.(2016),“Utilization of Waste Plastic Materials in Road Construction”,JournalofAdvanceReserchinMechanicaland CivilEngineering”.

5.S. Azmat(2017), “Use of Plastic Waste in Road Constuction”,InternationalJounalofAdvanceResearchAnd Development’vol2.

6.R.Manju,Anand,Sathya.S(2017),“Use ofPlasticWastein Bituminous Pvement”,International Journal of ChemTechReserch.

7.S. Laxman Hake,Prashant R.P Awsarmal ,“Utilization of Plastic Waste in Bitumen Mixes for Flexible Pavement.”Journalsfrom ResearchGate.

8..SabinaRivankar,H.Hanurmesh,“Plastic Bitumen Mix Road”,International Journal of Innovations in Engineering ResearchAndTechnology”Volume3.

9.N. Thakre, D. Mangrulkar, M. Janbandhu, and J. Saxena ,“Polymer Modified Bitumen”,IOSR Journal of Mechanical and Civil Engineering,Volume 13,Issue 6 ver. VI(Nov-Dec 2016).

10.KotreshK.M,Y.BayuKebede,“AStudyonUseofPlastic WastesinRoadPavementConstruction,”AStudyonUseof PlasticWastesinRoadPavementConstruction.”vol.5,issue 4,April2016.

11.M.SubrahmanyaSarma,B.Srikanth,(2018),“StudyonUse of Waste Polythene in Bituminious Paving Mix Design,” International Journal for Modern Trench in Science and Technology”,ISSN;2455-3778,Volume4.

12. A. Biswas, A. Goel and S. Potnis (2020),“Performance comparisionofwasteplasticmodifiedversusconventional bituminiousroadsinPunecity:Acasestudy”,casestudyin constructionmaterials13(2020)e000411.

13.AkileshYadav, R . Chandrakar,(2017),“Construction of plastic roads: An effective way to utilize wastes,” International Research of Engineering and Technology, Volume04Issue-11.

14.Y.Menaria,RupalSankhla(2015),“UseofWastePlasticin Flexible Pavements-Green Roads”,Open Journal of Civil Engineering,5,299-311.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

15.ShirishN.NemadeandPrashantV,“UtilizationofPolymer Waste For Modification Of Bitumen In Road Construction”,Sci.Revs.Commun:2013,198-213,ISSN22772669.

16.Neeraj K. Chaubey,(2016), “A Study of Effective Utilizationof WastePlasticinBituminousMix”,International JournalofEngineeringandTechnology,Volume:03Issue:07.

17.A.S Sandbhor, J.K Patil,(2019), “Use of Plastic Waste in Construction of Road”,International Research Journal of EngineeringandTechnology”,Volume:06Issue:04.

18.Sangita, G. Reena and K.Verinder,(2011), “A Novel ApprochToImproveRoadQualityByUtilizingPlasticWaste InRoadConstruction”,JournalofEnvironmentalReserchAnd Development,Vol.5,pp.1036-1042.

19.IRC:SP:98(2013), “Guidelines For The Use Of Waste PlasticInHotBituminousMixes(DryProcess)”.

20.M.Nayak(2017),“StudyonUtilizationofPlasticWastein BituminousConstructionMixes”,VolumeNo06,ICITTESE17.

21. A Radadiya,G. Swami(2018), “Comparative Study of Recycled polypropylene Plastic using in Construction of Flexible Pavement”,International Journal Of Innovative Researchinscienceengineering andTechnology,Vol.7,Issue 4,ISSN:2319-8753.

22.R.MahmoodRaouf(2018),“RecycledPolypropyleneTo ImproveAsphaltPhysicalProperties”,InternationalJournal ofCivilEngineeringandTechnology,Vol.9,Issue12,Article ID:IJCIET_09_12_128

23.MohitAkshayHS(2018),“BituminousMixDesignStudies UsingHighDensityPolyethyleneonBCLayer”,ISSN:22780181,Vol.7Issueo6.