International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

David Atadious1, Onyekachi Tochukwu Dennar 2 , Ibrahim Adebayo Alamutu3 , Ikechukwu Patrick Onwuamaeze4

1,2,3,4Mechanical Engineering Department, Petroleum Training Institute, Effurun, Delta State, Nigeria. ***

Abstract

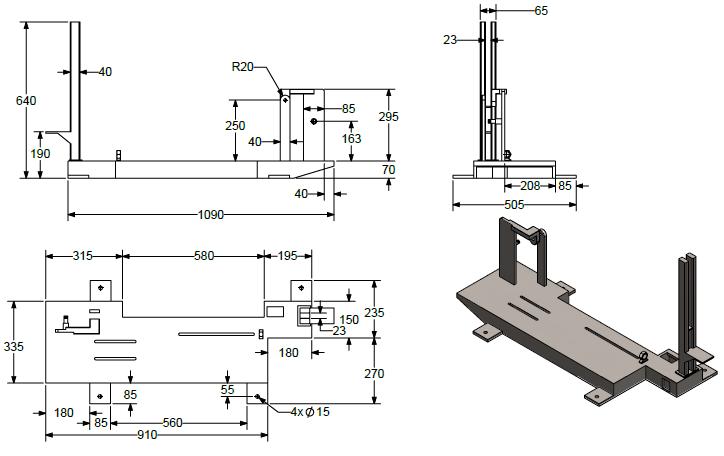

This project introduces the development and assembly of an automated power hacksaw, engineered tocut metalmaterials into a range of sizes and lengths with precision. The central purpose is to streamline the metal cutting process, reducing the need for manual labour and saving valuable time, which ultimately leads to greater productivity. Throughthis series of connections, the rotary motion generated by the motor is converted into the reciprocating movement of the hacksaw blade which drives the cutting stroke of the hacksaw blade in the cutting operation. The Machine fabrication was executed according to the designed parameters developed and presented in the CAD model, yieldingthefollowingdimensions: 1167mm overall height, 1240mm overall length and 536mm overall width. The machine test was conducted at 502.32 rpm which produces an average cutting speed of 54(m/min) and Cutting force of 88.47N. In comparison to an already existing machine in the school workshop, the designed machine is proven to be approximately 23.8% more efficient on bases of energy consumption. All machine components were thoughtfully designed and constructed. The finished device was tested on various metals to assess its performance and reliability.

Ahacksawisacommontoolforfitters,whichcancutsmaller round steel, angle steel, flat steel, plastic, wood and work piece [1]. A Hacksaw consists of basically two main elements: A frame with a handle and a blade [2]. Mainly therearetwotypesofhacksawframes;thefixedhacksaw frameandtheadjustablehacksawframe;thehandlesonthe framescanbestraighthandle,pistol-typehandleandtubular typehandle[2][3] Astandardhacksawbladelengthis10to 12inches(250to300mm) orcanbeassmallas 6inches (150mm)[4].

Poweredhacksawsgenerallyuselargebladesinavarietyof sizes,orsmallmachinesusethesamehandbladesforsmall operations[5].Thepitchoftheteethcanbefrom6to14TPI (teethperinch)forahandbladeandwithnearly6TPIfora largepowerhacksawblade[5].

Thisprojectistailoredtowardthedesignandconstructionof an auto electric power reciprocating hacksaw, to ease the manual labor(stress)andtosavetimetowardthecutting operationinaworkshop[6].ThePowerHacksawMachineis

a type of Automatic Machine Tool whereas; the whole purposeiscuttingthematerials(metalornon-metal)that consistslessandevenhighthicknessordiameter[4].Power hacksaw have an arm section which is the reciprocating portionofthemachinethatcutsthematerialonaforwardor backwardstroke[6].Thetoolisequippedwithaclamping vicethathashandlesonecanturntotightenorloosenthe gripontheworkpiece;itisapowerfulpartofthehacksaw that lock the object in position for cutting [3]. A Flywheel transmitstheenergytothehorizontalguideandalsostores theenergyaccordingtotherequirement[6].

Themanualusedofhacksawinaworkshopisverystressful andtimeconsuming,especiallyiftheworkpiecetobecutis hardandwithalargediameter.Asaresult,specialtoolswith specialprecautionareneededtocarryoutthistask;hence theideabehindthiswork

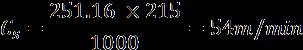

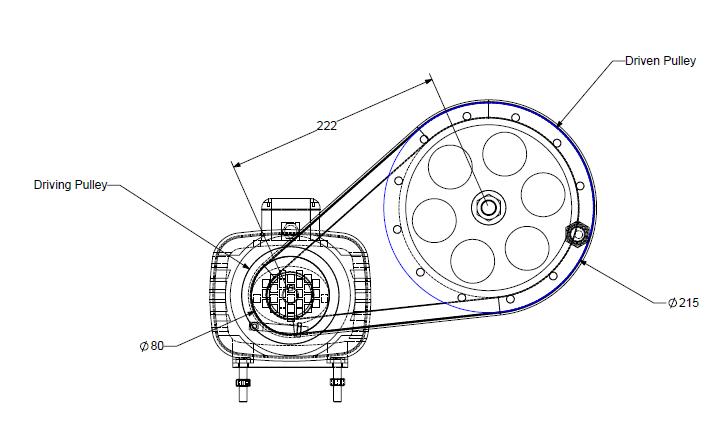

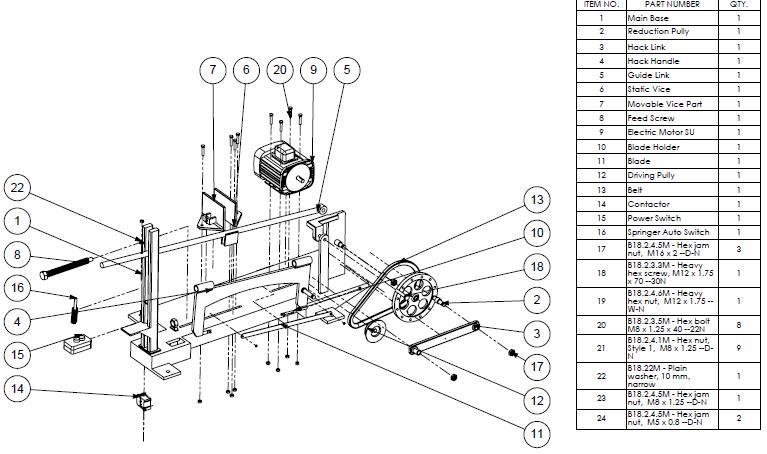

Severalpartsofthemachineweredesignedwhichincludes the electric motor, saw blade, power switch, saw frame, bottom plate and pulley connected with flat belt, brass busheswithshaftpassingthroughit.Thedesigndetailsare showninthediagramsofFig.1–5

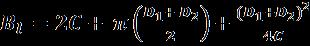

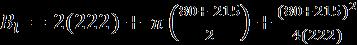

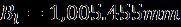

Length of Belt Calculation

=Lengthofbelt in mm, C=centerdistancebetweentwo pulleys, D1 =pitchdiameterofthedrivingpulley,D2 =pitch diameterofthedrivenpulley

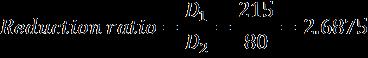

Speed Reduction via Pulley

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

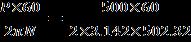

where D1 = diameter of driving pulley (215mm), D2 = diameterofdrivenpulley80mm),N1=rpmofdrivingpulley (motorrpm=1350rpm),N2 =rpmofdrivenpulley

= Bending Moment Analysis

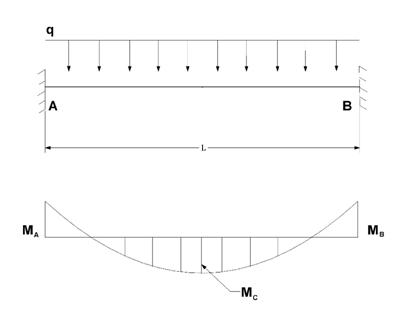

Thebendingmomentwhichisthereactioninducedinthe structural frame when an external force (in this case, the weightoftheauto-reciprocatingmachine)isappliedtoitis considered and treated as a beam fixed at both ends with uniformlydistributedload.

To determine bending moment, the bending moment diagramisestablishedbelow:

Fig.1:BendingMoment

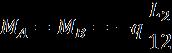

WhereM=momentatthefixedends(Nm)

q=uniformload(N/m)

L=lengthofbeam

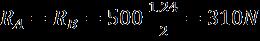

There (taking measuredweightofauto-reciprocatinghacksawmachineto be500N)

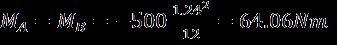

SupportReactions

whereR=supportforcesatthefixedends(N)

Therefore

Torque Calculation

Power=500W(specificbyproducer)

Power=

TorqueT=

T(Driven)=9.51����

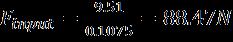

Cutting Force WhereFisthecuttingforcegenerated,ristheradiusofthe pulley

Cutting Speed Calculation

Cuttingspeedreferstothespeedatwhichthecuttingtoolor blademovesacross the work pieceduringa machiningor cuttingoperation(Ronan,2024).Itistypicallymeasuredin surfacefeetperminute(SFM)ormetersperminute(m/min) and is a critical factor in determining the efficiency and qualityofacuttingprocess(Ronan,2024)

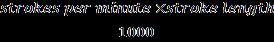

For one rotation of the driven pulley, the hacksaw moves two times linearly with only one effective cutting stroke. Therefore,thecuttingspeediscalculatedusingthefollowing formula:

����=

where���� istheCuttingspeedinm/min

Strokes per Minute:Thenumberofstrokesmadebythe hacksawmachineperminuteandisgivenas ������������ ����������ℎ = 2 × ������������ ������i���� = ������������ ������������ ����������������=215����

Therefore

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page78

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

The construction details that were followed in other to fabricationtheelectricpowerreciprocatinghacksawwereas follow:

i. Theoperationofamanualhacksawwasfirst put into consideration, which produce a reciprocating(toandfrom)movement.

ii. Thehacksawframewasthenconstructedfrom a mild steel plate with the shape of the English Alphabet C. The frame is 567mm, 250mm and 12mmthick.

iii. Asmoothstraightshaftof1100mmlongwas constructedwitha spider(hollow)weldedatone end of the rod, and two sleeve of 1½ inch by 100mmwasweldedontopoftheframe.

iv. Anelectricmotorwasthenmountedonthe baseofthemildsteelplateof912mm,355mmand 8mmthick.

v. Apostwasconstructed,whichwasattachtoa pulleythathasbeenmachinewithabrassbushatit centered through a shaft that passes through the center of the hole of the pulley, thereby creating room for the pulley to be driven by the electric motorthroughanattachmentofflatbelt.

vi. Ahacklinkwasconstructedof345mm,40mm and 10mm thick, in which a brass bushes were fabricatedatbothends. Thehacklinkisattachedto thepulleyatoneendandthehacksawframeatthe otherendthroughtheconnectionofashaft,these connection help to create the reciprocating movement.

vii. Aclamping(vice)devicewasconstructedfrom an angle bar of 10mm thick. This device helps to holdtheworkpiecefirmlyduringcuttingoperation.

viii. Thesittingpositionforthecontractionwas constructed, which serve as a circuit breaker and suppliedcurrenttotheelectricmotorforoperation tobegin.

ix. Asittingforanemergencyswitchwasalso constructed.Thisdevicehelpstostartthesystem and also put off the system after operation is terminatedorcompleted.

x. Anelectricwireof2.5by4mmwasusedtotap currentfromthepowersupplysource. Theelectric motorisathree-phaseelectricmotorthatwhythe wireis2.5by4mm.

theworkingdrawing.

xi. Alongboltwasattachedtothelong110m shaftthathelpstostoptheemergencyswitchafter theworkpiecehasbeencutoffcompletely.

i. The hacksaw frame was constructed from a rectangularplateof12mmofthickness.

ii. Thetensionedknobandbladepinwereconstructed with the used of 11 bolts and nuts. And a filing machine was used to smooth the rough surfaces thatoccurduringcuttingoperation.

iii. Theclampingvice wasconstructedfromanangle bar of 10mm thickness. Two isosceles triangle shapeswasproducedfromit,whichare142mmby 80.3mm.Oneofthetwopiecesisconnectedtothe baseplatewiththehelpof14boltsandnutstohold itfirmlytothebaseoftheprojectwork.Thesecond piecepassesthroughaslottedcenterlinethatallow movementfromoneendwiththeaidofascrewbolt when been tightening or loosing. A U shape pivot was drill on the center and welded with a 14bolt passingthroughthecenterholeandweldedtothe screwbolt.Thisenablesthemovementofthejaw.

iv. Thehacklinkwasconstructedfrommildsteelplate, producing345mmby40mmfrom10mmthickness. Twoholesweredrilledatbothendsinwhichtwo brassbushesof25mmofdiameterweremachineon the holes in other to create space for shaft to go throughit.

v. The post bar was constructed from a mild steel plate of 358mm by 85mm.A hole was drill at the center from a distance of 170mm, and a shaft of 15mmofdiameterispassedthroughtheholeand weldedfirmlythroughtheoppositesurface

vi. The main base was constructed from a mild steel plateof8mmthick.Arectangularlineof1098mm by596mmwasmarkoutandcuttingoperationwas carryout.Adistanceof119mmwasmarkoutfrom bothendsofthe1098mmplate.2/3ofthemarkout linewascutwithfilingmachineinothertoenable bendingofthemildsteelplatetomakeprovisionfor the height of 119mm at both sides. A plate of 202mm by 197mm was also mark out from the frontoftheplateinothertohavetheshapein

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net

Industrial Machine (3000W) Designed Machine (500W) Manual Handsawing

Table1: Results Material

(mm)

Hollow SquarePipe (3mmThick) 26mmHollow SquarePipe (3mmThick)

Hollow SquarePipe (3mmThick)

From Table 1, we obtain the energy dissipated by both machinestoestablishacomparisoninefficiencybetweenthe designedmachineandtheindustrialmachineattheschool workshop.Thiscanbededuceusingtheformula

ForDesignedmachine,Energy=500X32=16,000J

Fortheindustrialmachine,

Energy=3000X7=21,000J

Theenergyefficiencyofthedesignedmachinecomparedto the already existing industrial machine is calculated as follows:

��������������������=23.8%

Therefore, the designed machine is approximately 23.8% moreefficientthantheexistingindustrialmachine,basedon energyconsumption.

Table1,emphasizestheimportantofcuttingforceinpower hacksawcuttingoperation.Evenwhenthecuttingspeedof thedesignedmachinewasmorethanthatoftheindustrial machine,thecuttingdurationoftheindustrialmachinewas lessthanthedesignedmachine.Thisisduetotheenormous cuttingforceoftheindustrialmachine.However,fromthe deductionsoftheenergydissipated,thedesignedmachineis

approximately 23.8% more efficient than the industrial machine.

Itisknownthatmanuallyoperatedhacksawcanbereplaced with an electric powered reciprocating hacksaw machine. Electricpowerhacksawmachinegiveshighproductivityin shorttimeperiod,reducedlaborforce,andminimizestress whichareveryimportantinthesedaysproductionprocess.

Theelectricpowerhacksawmachinecanbemadeuseofin smallscaleindustries.Therangeofsizeofwork-piecesthat canbecutusingelectrichacksawmachinecanbevariedby changingthebladesize.

Themachineisefficientandproductioncostisrelativelylow iftheywillbemassproduced.

[1] Ronan,Ye.“FeedRateandCuttingManufacturing: Differences, Connection and Calculations.” 26 October, 2024. 3ERP. 21 June 2025 <https/www.3ERP.com>.

[2] Siddhartha, N. S., Vishakaraj, S., Alphin, M. S., Vigneshwar,M.,Vijayakumar,L.“DesignofaCrank Operated Reciprocating Hacksaw.” Journal of AppliedMechanicsandMaterials852(2016):564567.

[3] Kumar, A.S., Manikanta, P., Lokeshwar, B., Kumar, S.S.,Reddy,S.V.K.,Rahul.M.“DesignandFabrication of Four Way Hacksaw.” International Research JournalofModernizationinEngineeringTechnology andScience4.5(2022):4246-4253.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

[4] Kohale, U., Adhao, S., Thakare, D., Panchawate, A., Dalvi,S.andAkarte, P.“DesignandFabrication of MotorizedHacksawMachine.”InternationalJournal for Research in Applied Science and Engineering Technology10.5(2022):3697–3703.

[5] Anon. “Types of Hacksaw Blades and Hacksaw Frames.” 26 June 2025. Engineering Learn. <https://engineeringlearn.com/types-of-hacksawblade-hacksaw-frame/>.

[6] Nazar, M., Singh, K. K., Mahato, P. K., Kumar, R. Automatic Power Hacksaw Machine using Slider Crank Mechanism. Unpublished B. Tech. Project Repor.Phagwara-India:DepartmentofMechanical Engineering,LovelyProfessionalUniversity,2015.

|