International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

S. Jyothi Rani1, J. Niranjan2, T. Shyam praneeth3 , Y. Venkatakameswara Rao4, R. Girish5

1Assistant Professor, EEE, Visakha institute of engineering & technology, Visakhapatnam, Andhra Pradesh, India 2,3,4,5UG Student, EEE, Visakha institute of engineering & technology, Visakhapatnam, Andhra Pradesh, India ***

Abstract - In order to keep operations safe and extend the lifeofbatteries,thefast-expandingelectricvehicle(EV)sector needs dependable solutions for managing batteries and preventing fires. Through the use of simulation and prototypingtechniques,thisprojectaimstoprovideanelectric vehicle (EV) fire safety solution and battery management system (BMS). The system's central processing unit is an ATmega328 microcontroller based on the Arduino platform.

A voltage sensor, a current sensor, and a DHT11 temperature sensor are used to continually monitor critical metrics including battery voltage, current, and temperature, respectively.Thedataisevaluatedinreal-timetoevaluatethe battery'shealthand identifyanydangerslikeoverchargingor overheating.Theprototypehastemperaturedetectionandan emergency cutoff mechanism to provide basic fire safety measures, in addition to monitoring. To avoid thermal runaway or fire situations, the device may instantly separate the battery if it detects excessive temperature spikes. Prior to prototyping, the design was validated using simulation models. The results show that the system can quickly detect problems and fix them, offering a cheap and scalable way to make EVs safer.

Key Words: ElectricVehicle,Batterymanagementsystem, Arduino,DHT11sensor,Voltagesensor,Currentsensor

1.INTRODUCTION

A reliable and secure battery system is crucial to the operationofelectricvehicles(EVs).Dangerousconsequences like thermal runaway and fires can occur if batteries, especially lithium-ion ones, are not properly protected againstchangesintemperature,voltage,andcurrent.Thatis why it is critical to incorporate fire safety measures into Battery Management Systems. The history ofBMS, electric vehiclefiresafetysolutions,andtheintegrationofsensors with inexpensive microcontrollers like the Arduino ATmega328arealltopicscoveredinthisliteraturestudy[1]

To keep electric vehicle batteries safe, run for as long as possible, and function at their best, battery management systems are essential. A BMS keeps an eye on important characteristicsliketemperature,voltage,andcurrenttomake sure the battery doesn't become damaged or fail [2]. In additiontomonitoringandactivelybalancingcellvoltages,

modernBMSdesignsalsoincludefaultdetectiontechniques, stateofcharge(SOC)andstateofhealth(SOH)prediction. ThehighcostandcomplexityoftraditionalBMSsolutionshas promptedstudiestofindsimpler,cheaperalternativesthat maybeusedforeducationalandprototypingpurposes[3-5]

For lithium-ion batteries, thermal runaway poses a significant threat. Overcharging, overheating, or physical damagecansetoffunpredictablereactionsthatresultinfires Automatically disconnecting or activating suppression systemsand early detectionof temperatureanomalies are essential components of effective fire protection systems. While more sophisticated electric vehicles have fire suppressionsystemsandintegratedsensors,solutionssuch as temperature-triggered cut-offs work well for basic prototypes[6].

The ATmega328 microcontroller, which is part of the Arduinoplatform,hasprovenpopularforcreatingadaptable, low-cost battery monitoring devices. Patel and Modhera found that systems based on the Arduino platform can accurately monitor battery characteristics for small-scale applications[7].TheATmega328isperfectforeducational and prototype projects because to its processing power, numberofanalog-to-digitalconversion(ADC)channels,and ease of programming. It can perform simple control operationsandreal-timedataacquisition.Tokeepabattery in good working order, it is crucial to monitor its temperature, voltage, and current: A cheap digital way to measurethesurroundingtemperatureandhumidityisthe DHT11temperaturesensor.Themethodisnotperfect,butit mayidentifydangeroustemperatureincreases aprecursor tobatteryoverheating[8-9] TheArduinocansafelymonitor batteryvoltageswiththeuseofvoltagesensors,whichare usually constructed using voltage divider circuits. These sensorsscaledownthevoltagewithinthe0-5VADCrange.In ordertoidentifyinstancesofdeepdischargeorovercharging, voltage monitoring is useful [10].Itiscommon practiceto employcurrentsensorsthatarebasedontheHalleffectto monitorthecharginganddischargingcurrentsofthebattery. Predicting battery health and usage trends is much easier withaccuratecurrentmonitoring[11].

Section1providesanintroductiontotheimportanceof battery management and fire safety systems in electric vehicles,highlightingcurrentchallenges.Section2explains the Battery Management Systems (BMS), fire safety

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

mechanisms, and the use of Arduino-based platforms and sensorsformonitoringkeybatteryparametersandproposed system. Describing the design and development of the prototype using the Arduino ATmega328 microcontroller alongwithDHT11temperaturesensor,voltagesensor,and current sensor. Section 3 presents the results and discussions, including system performance, response to critical conditions, and validation through simulation and testing. Finally, Section 4 concludes the paper by summarizingkeyfindingsandemphasizingthepotentialof low-cost, sensor-based solutions for improving EV battery safety.

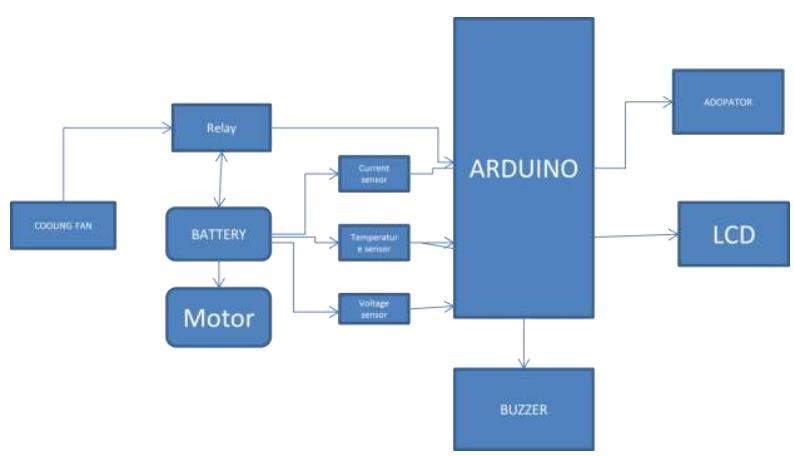

2.1 Block diagram

TheblockdiagramasshowninFigure1,representsthe Development of a Battery Management and Fire Safety SolutionforElectricVehiclesusingArduinoATmega328and varioussensors.AtthecenterofthesystemistheArduino, whichactsasthemaincontroller.Batterypowersthemotor andismonitoredcontinuouslybythreesensors:ACurrent Sensor measures the charging and discharging current. A Temperature Sensor (likely DHT11) checks for abnormal risesintemperature.AVoltageSensormonitorsthebattery voltage to prevent overcharging or deep discharging. The Arduino receives data from all these sensors and makes decisionsinrealtime:Ifanyparameterexceedsthesafelimit (e.g.,hightemperatureorovercurrent),theArduinotriggers aRelay.TheRelaycandisconnectthebatteryfromthemotor and simultaneously activate a Cooling Fan to reduce the temperatureandpreventthermalrunaway.Additionally,the ArduinocommunicateswithaBuzzer,whichsoundsanalarm toalertuserstopotentialhazards.Thesystemalsodisplays real-timebatterystatus(voltage,temperature,current)onan LCD screen for easy monitoring. Power is supplied to the ArduinothroughanAdaptor.

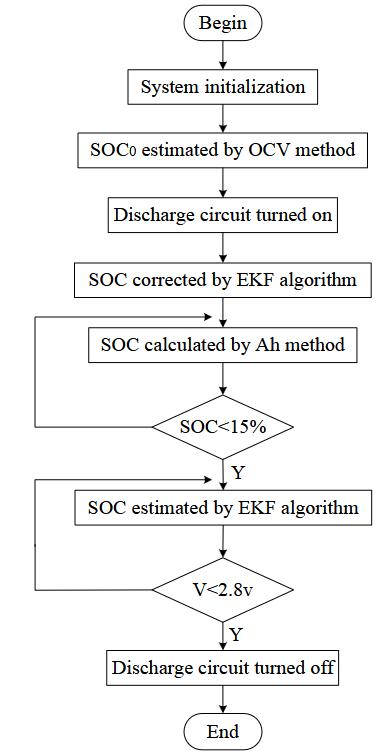

other algorithms in terms of computing efficiency on SOC. Bothoftheseapproaches,however,arenotsuitableforusein EV due to the more complex nature of the working environment; in fact, they are likely to provide inaccurate estimatesandpoorjudgments.Whenabatteryislefttorest foranextendedperiodoftime,itsvoltagestabilizesandis referredtoastheopencircuitvoltage.However,duetothe extreme conditions experienced by electric vehicle batteries including rapid charging and discharging, irregularstarting,andlargechangesincurrent thevoltage of the batteries does not stabilize quickly, and the exact amountoftimeittakesforindividualcellsinthepacktodo so might vary. These findings suggest that OCV has a significant measurement error, leading to inaccurate estimatedresults.

TheAhcountingmechanismshouldbeprovidedanexact SOC beginning value, as is well known. This criterion is seldomsatisfiedinEVapplications,whichisashame.Getting thecurrentbatterystatuswhilethecarisabouttostartwas notpossible.Additionally,thebatterypackundergoesagreat number of intense electrochemical reactions in an electric vehicle setting. So, the SOC estimate results would increasinglydepartfromtheactualvalueduetothepresence of some not-so-minor disturbances in the sample data. In light of the limitations of these two approaches and the unique working conditions in EV, the research proposes a combinationalgorithmasanefficientestimatingmethod.A simplified flow diagram is shown in Figure 1, and a brief explanationfollows.

WhenitcomestoEVapplications,theopencircuitvoltage (OCV)andamperehour(Ah)countingmethodsoutperform

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

TheflowchartasshowninFigure2,outlinestheprocess forestimatingandmanagingtheStateofCharge(SOC)ofa batterysystem.Initially,thesystemundergoesinitialization whereallcomponentsandparametersareset.ThefirstSOC value (SOC₀) is estimated using the Open Circuit Voltage (OCV) method, which involves measuring the battery’s voltage at rest. Once the initial estimation iscomplete, the discharge circuit is turned on to allow the battery to discharge.Toimproveaccuracy,theSOCiscorrectedusing theExtendedKalmanFilter(EKF)algorithm,whichaccounts fornoiseandsystemvariations.Asthebatterydischarges,the SOC is continuously updated using the Ampere-hour (Ah) countingmethod,trackingtheamountofenergyused.The system then checks whether the SOC has dropped below 15%. If it has, the SOC is re-estimated using the EKF algorithm to ensure better accuracy at low charge levels. Followingthis,thebatteryvoltageismonitored,andifitfalls below 2.8V, the system turns off the discharge circuit to prevent battery damage. The process then ends after ensuringthatthebatteryoperatessafelywithinitslimits.

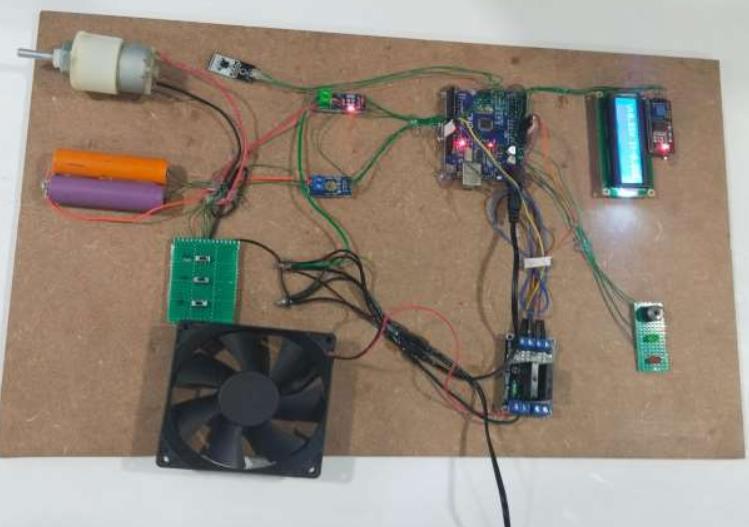

Using an Arduino ATmega328 microcontroller and a numberofsensors,thisprototypeshowsthedevelopmentof asolutionforelectricvehiclebatterymanagementandfire safety.Amotorthatmimicsthetorqueofanelectriccaris linked to rechargeable battery cells in the configuration. Attachedtothebatteryaresensorsthatmeasurethecurrent flowingthroughitandthevoltagelevels,respectively,inreal time. For the purpose of fire safety, a DHT11 temperature sensorisemployedtoidentifyinstancesofoverheatinginthe vicinityofthebatterypack.Theprototypeoftheproposed systemshowninFigure3.

AnArduinoreceivesdatafromthesensorsinrealtime, analyzesit,andthenshowstheresultsonanLCDscreenfor convenient viewing. In response to data collected by the sensors, an external relay module is wired to operate the motor and cooling fan. The system's fan will turn on automaticallytoreducetemperatureifitbecomestoohot. Thetechnologyisdesignedtoimmediatelyinformusersby buzzerifhazardoussituationsaredetectedandcontinue.To illustratehowtheBMSandfiresafetydeviceswouldoperate in an actual electric vehicle, the entire assembly is placed neatlyonawoodenfoundation.Thedesignguaranteesthat electricvehiclesaresafe,reliable,andhaveeffectivebattery management.

The temperature, current, and voltage sensors, among others, collect data on the battery's properties in the suggested system and transmit it to the Arduino microcontroller for analysis. This aids in regulation compliance, improves safety by reducing the likelihood of battery fires, promotes electric vehicle economy, and lengthens the life of the battery. Battery failure can be avoided, life can be extended, maintenance costs can be reduced,safetycan be increased, and planned purchaseof

batteries can be done instead of emergency replacements withasmartersystemthatmanagesbatteries.Themethodis usefulinmanydifferentfields,includingmanufacturing,the home,andtheautomobileindustry.AnLCDpanelshowsthe current, temperature, voltage, State of Charge (SOC), and StateofHealth(SOH)ofthebatteryatalltimes.Furthermore, in accordance with the established protocols for the safe management of electric and hybrid vehicle batteries, the power is promptly disconnected and an audible alarm is sounded if the temperature rises above a certain point. In addition,NodeMCUcontinuallyuploadsallthegathereddata to an IoT web page, allowing for remote management and monitoring.

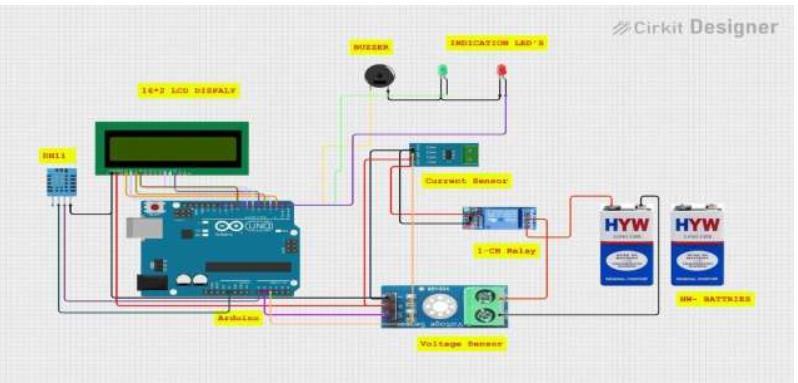

Thecircuitshownina Figure4 isaBatteryManagement SystemandFireSafetySystemdesignedusingArduinoUNO and several sensors, built in Cirkit Designer software. The main components include a DHT11 temperature and humidity sensor, a current sensor, a voltage sensor, a 1channelrelaymodule,a16x2LCDdisplay,abuzzer,andtwo indicatorLEDs(redandgreen).Two9Vbatteriesareusedas thepowersource.TheArduinoreadsreal-timedatafromthe voltage sensor to monitor battery voltage and from the currentsensortomonitorloadcurrent.Simultaneously,the DHT11sensormonitorsambienttemperatureandhumidity. ThesystemdisplaysallmeasuredvaluesontheLCDscreen. Under normal conditions, the green LED remains ON,

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

indicatingsafeoperation.Ifanabnormalvoltage,current,ora suddenriseintemperature(suggestingfire)isdetected,the system immediately triggers the relay to disconnect the battery, sounds a buzzer, and switches the red LED ON to signaldanger.

This project ensures battery protection by cutting off powerduringovervoltage,overcurrent,orfireconditionsand providesbothvisualandaudioalertsforusersafety.Itactsas an automatic safety shield for battery-powered devices by combiningbatterymanagementandfiresafetyinasimple and efficient way. The real-time display, immediate fault detection,andquickshutdownmechanismmakeitidealfor DIY projects, portable electronics, and energy storage systems.Overall,thecircuitisasmart,compactsolutionthat enhancesthesafetyandreliabilityofbatterysystems.

Monitoring the Battery Life and Displaying Battery CharginginCompliancewithAllMandatoryInputBoundaries Monitoringtemperaturewithautomaticshutoff.Thissystem reliesonalithium-ionbattery,achargingandscreensystem, buttons,anLCDdisplay,acurrentsensor,avoltagesensor, and a temperature sensor to function. The system continuously monitors and protects an electric vehicle's battery.

Inthisarticle,wedevelopthesysteminaccordancewitha 3S lithium-ion battery. The system we set up will prevent accidents from occurring in addition to monitoring the battery and charging it safely. When activated, the system makesuseofitschargingandmonitoringtechnology,letting the user charge the 3S battery in a secure location. The voltage sensor isusedtomonitor the voltageandstopthe currentfromflowingtothebatterywhileitisbeingcharged. Additionally, the LCD display shows the current battery voltage.Afterthebatteryisfullycharged,theframeworkwill removethestockanddisplay"Batteryfullycharged"onthe LCDdisplay.

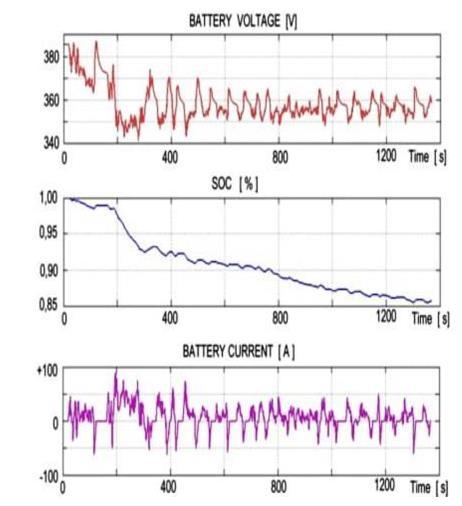

Fig -5:Batteryparameters

ThreecrucialgraphspertainingtotheArduino-basedFire SafetyandBatteryManagementSystemaredisplayedinthe image: Battery voltage (V) as a function of time (s) is displayed in the first graph. The voltage is higher at the beginning(around5.8V),butitlowersdownandfluctuates between 5.4 and 5.6V over time, which means that the batteryisdischarged.Thebattery'sStateofCharge(SOC%) as a percentage is displayed in the second graph. As the battery is being utilized, its charge is progressively decreasingfromitsinitialnear-100%level.Graph3asshown in Figure 5 displays the current (A) in the battery as a functionoftime(s).Charginganddischargingprocesses,or variations in the load associated with the battery, could explain the current's positive and negative fluctuations. In sum,thegraphsshowhowthesystemkeepsaneyeonthe battery'svoltage,current,andstateofcharge(SOC)inreal time to prevent fires and abnormalities and manage the batteryproperly.

TheBatteryManagementandFireSafetySystemusing Arduinoensuressafeoperationofbattery-powereddevices. It continuously monitors battery voltage, current, temperature, and humidity. The system disconnects the battery automatically during abnormal conditions like overvoltage, overcurrent, or fire. Visual (LEDs) and audio (buzzer)alertsprovideimmediatewarningstousers.RealtimedataisdisplayedonanLCDscreenforeasymonitoring.

Thisprojectenhancesthesafety,reliability,andlifespanof batteries.Itisasimple,efficient,and effectivesolutionfor modernbatterymanagementneeds.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

[1] A.Chaudhury,V.Sonti,A.Hota,A.R.SaxenaandS.Jain, "ANewSingle-PhaseFive-LevelNeutralPointClamped Cascaded Multilevel Inverter for Minimization of Leakage Current in PV Systems," 2021 International ConferenceonSustainableEnergyandFutureElectric Transportation(SEFET),Hyderabad,India,2021,pp.15.

[2] G.K,"ImplementationofFiveLevelMultilevelInverter with Reduced Leakage Current," 2022 IEEE InternationalConferenceonDistributedComputingand Electrical Circuits and Electronics (ICDCECE), Ballari, India,2022,pp.1-6.

[3] R.Selvamuthukumaran,A.GargandR.Gupta,"Hybrid MulticarrierModulationtoReduceLeakageCurrentina Transformerless Cascaded Multilevel Inverter for PhotovoltaicSystems,"inIEEETransactionsonPower Electronics,vol.30,no.4,pp.1779-1783,April2015.

[4] S.Asapu,N.Chilaka,N.S.Pantham,N.Sakalabattula,K.S. Tejitha and R. Lakkabattula, "High-Gain DC-DC ConverterImplementedwithanImprovedSlidingMode MPPT Control for Solar PV Applications," 2024 InternationalConferenceonInnovationandNoveltyin Engineering and Technology (INNOVA), Vijayapura, India,2024,pp.1-6,doi:10.1109/INNOVA63080.2024. 10846995.

[5] S. Asapu, L. Juttiga, D. Bhuvaneswari, S. S. Adabala, P. Apireddi and A. Bale, "Implementation of Seven-Level Asymmetrical Multilevel Inverter for Solar PV Application," 2024 International Conference on Distributed Computing and Optimization Techniques (ICDCOT), Bengaluru, India, 2024, pp. 1-5, doi: 10.1109/ICDCOT61034.2024.10516167.

[6] V.Madhurima,C.Raju,S.ManojandT.GuruRagini,"EV's Battery Monitoring and Emergency Suppression System," 2023 IEEE Fifth International Conference on Advances in Electronics, Computers and Communications(ICAECC),Bengaluru,India,2023,pp. 1-5,doi:10.1109/ICAECC59324.2023.10560094.

[7] S.K.Tripathi,S.Maurya,A.Dubey,P.PalandA.Tiwari, "IoT Based Electrical Vehicle Battery Management SystemwithChargeMonitorandFireProtection,"2024 3rdInternationalconferenceonPowerElectronicsand IoTApplicationsinRenewableEnergyandits Control (PARC), Mathura, India, 2024, pp. 444-448, doi: 10.1109/PARC59193.2024.10486414.

[8] L.Chitra,K.K.K.S,S.Prakash,R.N,V.PradeepandM. Safal, "Innocuous Design of Battery Management Systems For Electric Vehicles," 2023 Second InternationalConferenceonAugmentedIntelligenceand

Sustainable Systems (ICAISS), Trichy, India, 2023, pp. 1770-1775,doi:10.1109/ICAISS58487.2023.10250714.

[9] T.R.PalleswariYalla,A.Siva,K.P.Swaroopg,G.Durga Prasad,M.DeenakondaandR.Banothu,"Comprehensive AnalysisandPerformanceInvestigationofNon-Isolated DC-DCConvertersinSolarPhotovoltaicApplications," 2024 International Conference on Computational Intelligence for Green and Sustainable Technologies (ICCIGST), Vijayawada, India, 2024, pp. 1-6, doi: 10.1109/ICCIGST60741.2024.10717523.

[10] M. Safril, S. Hasan and M. D. J. Siburian, "Battery ManagementSystemonCompetitionElectricCar,"2024 8th International Conference on Electrical, Telecommunication and Computer Engineering (ELTICOM),Medan,Indonesia,2024,pp.176-182,doi: 10.1109/ELTICOM64085.2024.10864777.

[11] O.F.GOKSUandR.ACARVURAL,"BatteryManagement ModulewithActiveBalancingandCellSwitching,"2018 6thInternationalConferenceonControlEngineering& InformationTechnology(CEIT),Istanbul,Turkey,2018, pp.1-6,doi:10.1109/CEIT.2018.8751773.