International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

1B. Tech, Final Year Student, Goel Institute of Technology & Management, Lucknow, U.P, India

1B. Tech, Final Year Student, Goel Institute of Technology & Management, Lucknow, U.P, India

1 B. Tech, Final Year Student, Goel Institute of Technology & Management, Lucknow, U.P, India

2 Assistant Professor, Department of Mechanical Engineering, Goel Institute of Technology & Management, Lucknow, U.P, India ***

Abstract - This project involves the innovative design and construction of a supercar structure, built over an old car chassis using clay for the initial modeling phaseandfiberglass as the primary material for the final car body. The aim of the project is to create a lightweight, functional, and visually stunning supercar, leveraging the flexibility of clay modeling for precise design and the strength-to-weight benefits of fiberglasscomposites. Theprojectemphasizessustainabilityby repurposing an old car chassis, promoting material efficiency, and applying cutting-edge techniques in car body design.

Key Words: Supercar design, Chassis repurposing, Clay modelling, Fiberglass composites, Lightweight materials, Functional design, Visual aesthetics, Sustainable automotive engineering.

1.INTRODUCTION

The automotive industry is driven by the quest for innovation, performance, and sustainability. This project merges traditional modelling techniques with modern materialstocreateauniquesupercardesign.Theuseofclay formodellingallowsforflexibilityandprecisioninshaping the car’s exterior before transitioning to the durable fiberglassmaterial,whichprovidesstructuralintegrityand lightness.Byusinganoldcarchassisasthefoundation,the project also emphasizes the importance of reusing and repurposing materials, reducing waste, and promoting sustainableengineeringpractices.

1.1 Objectives: -

1. Sustainable Design: - Torepurposeanoldcarchassis andcreateanewsupercarbodyusingsustainablemethods andmaterials.

2. Precision in Design: - To use clay modelling for detailed and accurate shaping of the car’s exterior design, ensuringbothaestheticappealandaerodynamics.

3. Lightweight Supercar: - Toconstructasupercarbody using fiberglass composites, reducing weight while maintainingstrengthanddurability.

4. Aerodynamics and Performance: - To design a supercar body that optimizes aerodynamics for better performance,fuelefficiency,andhandling.

5. Cost-Effective Innovation: - Toexplorethefeasibility andcost-effectivenessofcombiningtraditionalandmodern techniquesforcreatinghigh-performancevehicles.

Thedesignandfabricationofasupercarstructureusingclay modellingandfiberglasscompositematerialoveranoldcar chassis is an innovative project that combines traditional and modern techniques to create a high-performance vehicle. This approach has several potential applications acrossdifferentsectors,bothwithintheautomotiveindustry and in related fields. Below are the key application areas wherethisprojectcanhavesignificantimpact:

1. AutomotiveDesignandCustomization

2. MotorsportsandPerformanceRacing

3. SustainabilityandEnvironmentalImpact

4. AerospaceandIndustrialDesign

2.1 PREVIOUS WORK: -

[1] V.D. Libera Junior et al. (2022)

Title: Processing, Thermal and Mechanical Properties of CompositeLaminateswithNaturalFibersPrepregs Journal: PolymerPolymers&Composites

DOI: 10.1177/09673911221087591

Elaboration:

This research evaluates the use of natural fiber-based prepregs (pre-impregnated materials) in composite laminates.Thestudysystematicallyanalyzestheprocessing parameters, thermal behavior (via TGA/DSC), and mechanicalproperties(tensile,flexural,andimpactstrength) of these laminates. The results reveal that natural fiber prepregs offer decent thermal resistance and mechanical strength, making them suitable for semi-structural applications, while also reducing environmental impact comparedtosyntheticalternatives.

[2] N. Fuentes Molina et al. (2021)

Title: Recycling of Residual Polymers Reinforced with NaturalFibersasaSustainableAlternative:AReview

Journal: Polymers(Basel)

DOI: 10.3390/polym13213612

Elaboration:

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Thisreviewexploressustainablewastemanagementthrough recycling natural fiber-reinforced polymers (NFRPs). It discusses mechanical, chemical, and thermal recycling techniques and evaluates their efficiency, environmental footprint,andeconomicviability.Thereviewemphasizesthat recycling NFRPs not only reduces landfill waste but also promotes circular economy practices, especially in automotiveandpackagingsectors.

[3] C. Jaiswal (n.d.)

Title: BiocompositeMarketResearchReport

Source: MarketResearchFuture.com

Link: BiocompositeMarketReport

Elaboration:

This industry report presents a global analysis of the bio composite market, highlighting trends, drivers, restraints, andregionalgrowthpatterns.Itidentifiesincreasingdemand in automotive and building materials due to eco-friendly regulations and consumer preferences. Key materials discussedincludewood-plasticcompositesandnaturalfiber composites. The reportalsodiscusses investmentsin R&D andforecastssteadymarketgrowththrough2028.

[4] A. Meraldo (2016)

Title: IntroductiontoBio-BasedPolymers

Book: MultilayerFlexiblePackaging

DOI: 10.1016/B978-0-323-37100-1.00004-1

Elaboration:

Thisbookchapterintroducesbio-basedpolymers polymers derivedfromrenewablebiomasslikestarch,cellulose,and polylacticacid(PLA).Itdescribestheirchemicalstructure, processing challenges, and advantages such as biodegradability and low carbon footprint. Applications in multilayer packagingare discussed, where these materials areusedasbarrierlayers,improvingbothenvironmentaland functionalperformance.

[5] M. Avella et al. (2009)

Title: Eco-ChallengesofBio-BasedPolymerComposites

Journal: Materials(Basel)

DOI: 10.3390/ma2030911

Elaboration:

Thisarticlereviewstheecologicalandtechnicalchallengesin producingandusingbio-basedpolymercomposites.Topics includerawmaterialsourcing,performancelimitations(e.g., moisture absorption), and end-of-life scenarios. It also outlines strategies for improving composite properties through hybridization, coupling agents, and advanced manufacturingtechniques.

[6] Y.K. Kim (2012)

Title: NaturalFiberComposites(NFCs)forConstructionand AutomotiveIndustries

Book: HandbookofNaturalFibers

DOI: 10.1533/9780857095510.2.254

Elaboration:

This chapter provides a comprehensive overview of NFCs, focusing on their adoption in construction (e.g., roofing, panels) and automotive sectors (e.g., interior trim, dashboards).ItcomparesthemechanicalpropertiesofNFCs withsyntheticfibercomposites,discussescost-effectiveness, and addresses challenges like water absorption and processingvariability.

[7] G. Wiedemann & H. Rothe (1986)

Title: ReviewofPrepregTechnology

Book: DevelopmentsinReinforcedPlastics 5

DOI: 10.1007/978-94-009-4179-3_3

Elaboration:

A foundational work detailing the development and applicationofprepregtechnology.Itexplainsthebenefitsof usingpre-impregnatedfibersforenhancedcontroloverresin distribution,leadingtoconsistentmechanicalproperties.The chapteralsodiscussescuringcycles,storageconditions,and applicationsinaerospace,wherehighprecisionandstrength arecrucial.

[8] M. Jabbar & A. Nasreen (2021)

Title: CompositeFabricationandJoining

Book: CompositeSolutionsforBallistics

DOI: 10.1016/B978-0-12-821984-3.00013-9

Elaboration:

Covers fabrication methods such as filament winding, vacuum-assistedresintransfermolding(VARTM),andresin infusion. It also explores joining techniques for composite parts,suchasmechanicalfastening,adhesivebonding,and hybridmethods.Thechapteremphasizestheimportanceof proper joining methods to ensure structural integrity in ballisticanddefenseapplications.

[9] A. Bhatnagar et al. (2006)

Title: PrepregBallisticComposites

Book: LightweightBallisticComposites

DOI: 10.1533/9781845691554.2.272

Elaboration:

Focuses specifically on the use of prepreg composites in ballistic protection. It discusses materials like aramid, UHMWPE,andcarbonfibersimpregnatedwiththermosetor thermoplasticresins.Thechapterexplainstheadvantagesof prepreg processing in achieving uniform fiber-resin ratios and enhancing impact resistance, making them ideal for armorsystems.

[10] V.M. Karbhari (2007)

Title: Fabrication, Quality, and Service-life Issues for CompositesinCivilEngineering

Book: Durability of Composites for Civil Structural Applications

DOI: 10.1533/9781845693565.1.13

Elaboration:

Addressesconcernsrelatedtotheuseofcompositematerials in civil engineering structures like bridges, pipelines, and retrofits.Itcoverscommondefects(voids,delamination’s),

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

quality control techniques (NDT methods), and environmental degradation (UV, moisture, fatigue). The author emphasizes the need for long-term performance monitoringandproperdesignconsiderations.

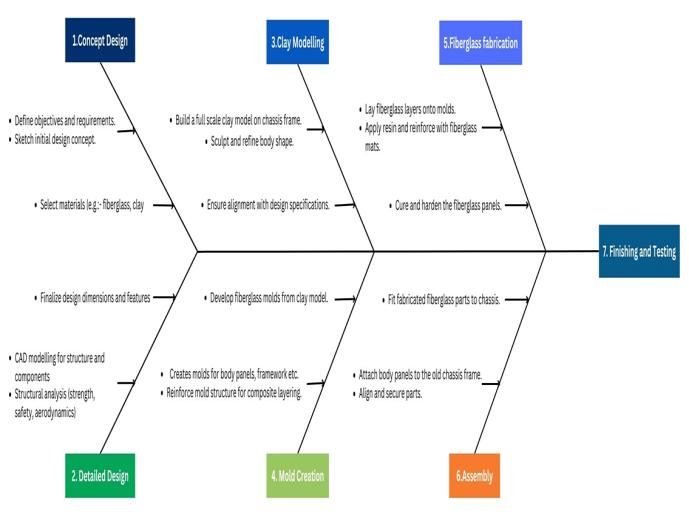

ProposedWorkfortheProject:DesignandFabricationofa Supercar Structure Using Clay Modeling and Fiberglass CompositeMaterialOveranOldCarChassis

Theproposedwork outlinesthedetailedstepsrequiredto achieve the design and fabrication of a supercar structure usingclaymodelingandfiberglasscompositematerialsover an old car chassis. This approach combines the art of automotive design with modern materials engineering, leveragingclayforaestheticsandfiberglasscompositesfor performanceanddurability.

3.1 Phases of the Project

Theprojectisdividedintofivekeyphases,eachfocusingon differentaspectsofdesign,development,andfabrication.

Phase 1: Design & Conceptualization (Weeks 1-3)

Objectives:

Definethevisualandfunctionalaspectsofthesupercar. Develop a concept that incorporates aerodynamics, aesthetics,andperformance.

Tasks:

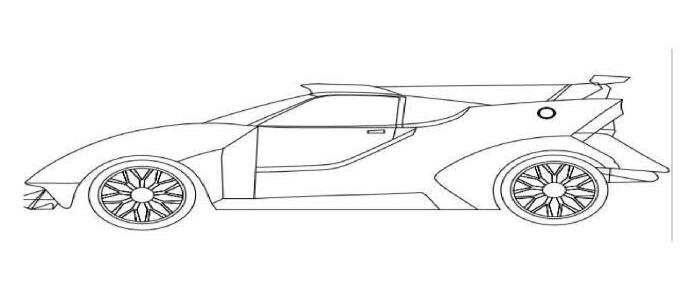

Initial Sketches and CAD Modelling:

Sketchandconceptualizethedesignofthesupercar,focusing onthebodyshape,aerodynamics,andintegrationwiththe oldchassis.

UseCADsoftware(AutoCAD,Rhino,orSolidWorks)tocreate 3D models of the supercar body. These models will help visualizethedesignbeforephysicalmodellingbegins.

DesignConsiderations:

Analyze the old car chassis to determine its compatibility withthenewdesign.

Evaluate weight distribution, engine placement, and clearance to ensure the new body fits the existing components.

Plan for aerodynamics, emphasizing drag reduction, downforce,andairflowaroundcriticalareaslikethefront grille,reardiffuser,andsidepanels.

Phase 2: Clay Modelling (Weeks 4-6)

Objectives:

Createafull-scalemodelofthesupercarbodyusingclayfor ergonomicandaestheticvalidation.

Refine the design based on both functional and aesthetic requirements.

Tasks:

Clay Modelling Setup:

Build a framework over the old chassis or a mock-up structure to support the clay modelling process. This will serveasthefoundationforsculptingthebody.

Usehigh-qualityautomotiveclay,whichcanbeeasilyshaped andsmoothedfordetailing.

Sculpting the Design:

Begin sculpting the body using hand tools and sculpting knives, ensuring precision in key areas like the front end, roofline,wheelarches,andrearend.

Use clay to model the aerodynamic contours and design features,ensuringthattheproportionsareaccurateandthe surfacesaresmooth.

Refinement and Testing:

Continuously refine the design by adjusting based on aestheticgoalsandaerodynamicfunctionality. Consider testing aerodynamic principles like airflow dynamics using CFD (Computational Fluid Dynamics) simulationsinparallelwiththephysicalmodel.

Objectives:

Createmoldsfromtheclaymodeltobeginthefabricationof thefiberglasscompositebody.

Ensurethatthemoldscapturethedetailsandsurfacefinish oftheclaymodel.

Tasks:

Mold Preparation:

Applyareleaseagenttotheclaysurfacetoensurethatthe fiberglassmoldcanbeeasilyseparatedlater.

Build a mold frame around the clay model to hold the fiberglasslayersinplace.

MoldingProcess:

Lay fiberglass fabric onto the clay model, layer by layer, applyingepoxyresintoeachlayer.Thefiberglassmaterial willformtheexternalmoldforthebody.

Use multiple layers of fiberglass to achieve the desired thicknessandstrength.

Oncethefiberglassisset,carefullyremovethemoldfromthe clay model, ensuring all details are captured without damage.

Objectives:

Fabricate the supercar body using fiberglass composite materials.

Ensurethebodyislightweight,strong,anddurable.

Tasks:

Fiberglass Layup:

Begintheprocessoflayingfiberglasssheetsintothemolds createdfromtheclaymodel.

Eachlayeroffiberglasswill becoatedwithepoxy resin to bondthelayerstogether.Theresiniscarefullyappliedusing brushes,rollers,orspatulastoensureevencoverage.

Reinforcehigh-stressareassuchasthedoorframes,wheel wells, and front/rear sections with additional layers of fiberglass.

Curing:

Allow the fiberglass body to cure for the required time (typically24-48hours)toensurethatithardenscompletely.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Duringthecuringprocess,monitorthemoldtoensurenoair bubblesordefectsforminthecompositematerial.

TrimmingandRefining:

Oncethefiberglassbodyisfullycured,removeitfromthe moldandbegintrimmingexcessmaterial.

Sand and smooth the surfaces to remove imperfections. Additional coats of resin and gel coat can be applied to improvefinishqualityanddurability.

Phase 5: Assembly and Integration (Weeks 14-16)

Objectives:

Assemblethefiberglassbodyontotheoldcarchassis. Integrate all necessary mechanical and electrical components.

Tasks:

Chassis Integration:

Fitthefiberglassbodyontotheoldchassis,ensuringprecise alignment with the drivetrain, suspension, and other key components.

Secure the body to the chassis using custom brackets or mountinghardware.

Engine and Drivetrain Integration:

Install the engine, transmission, suspension, steering, and othermechanicalcomponentsfromtheoldchassisintothe newbodystructure.

Ensure the engine compartment has sufficient space for coolingandairflowrequirements.

Interior Design and Ergonomics:

Design and install the interior components, including the dashboard, seating, controls, and other comfort or performancefeatures.

Ensurethattheergonomicsoftheinteriorareoptimizedfor drivercomfortandeaseofuse.

Testing and Final Adjustments:

Conductinitialstaticteststocheckforstructuralintegrity, alignment,andfitmentofcomponents.

Perform dynamic testing (if possible) to evaluate the handling,aerodynamics,andperformanceofthecar. Makeanynecessaryadjustmentsbasedontestingoutcomes, suchasimprovingaerodynamicsorrefiningthesuspension setup.

Design Documentation: CAD models, design sketches, and concept drawings.

ClayModel: A full-scale, hand-sculpted model of the supercar body.

Fiberglass Molds: Molds created from the clay model, including detailed surface finishes.

Fiberglass Body Panels: The final composite body panels, ready to be integrated with the chassis.

Assembled Supercar: A fully assembled supercar using the repurposed chassis, custom fiberglass body, and functional mechanical components.

Testing Reports: Aerodynamic testing, structural integrity reports, and performance evaluation.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

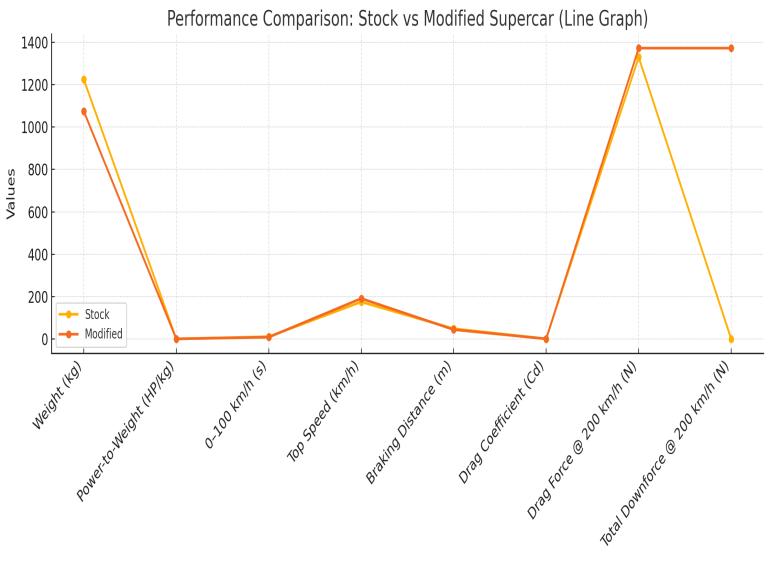

4.Calculation and Result

4.1 Improvement Table (Stock v/s Modified Car)

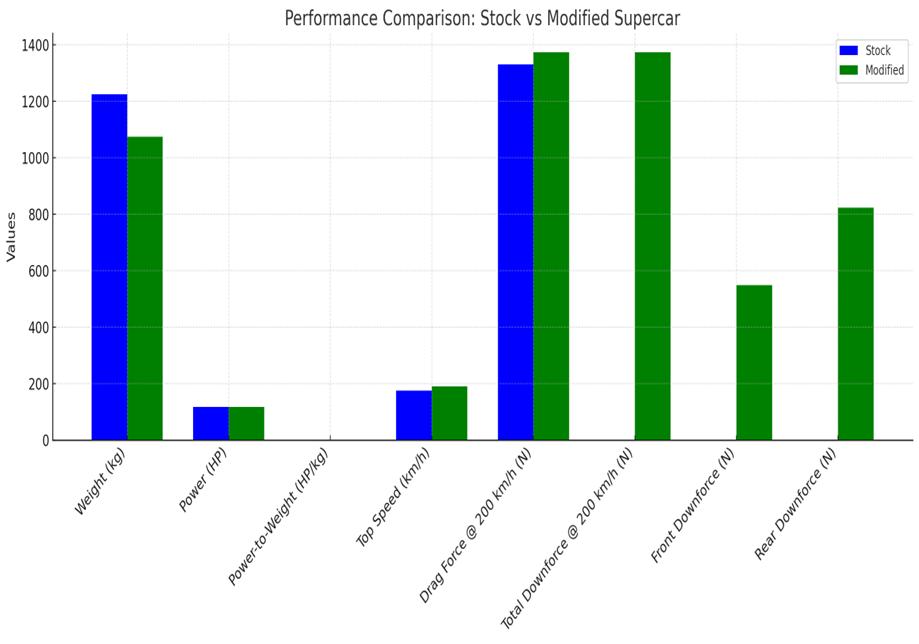

Metric Stock Honda City (2008) Modified Supercar (Fiberglass Body) Difference / Impact

Weight ~1225 kg 1075 kg 150 kg lighter

Power (HP) 118 HP 118 HP No change

Power-toWeight Ratio (HP/kg) ~0.096 0.11 +15% improvement

Acceleration (0–100 km/h)

~10.5 sec ~8.15 sec ~2.35sec faster

Top Speed ~175 km/h ~191 km/h +16km/h increase

Braking Distance (100–0 km/h)

Drag Coefficient (Cd)

~0.31 0.32 (optimized with downforce) Slightly higher due to downforce

Drag Force @ 200 km/h ~1330 N (estimated) 1373 N Small increase due to added width

Total Downforce @ 200 km/h Minimal 1373 N Significantly increased, improvesgrip

Front/Rear Downforce Split - 549 N / 824 N Balanced 40/60 split for stability

Table-1 PARAMETRIC EVALUATION

4.2 Performance Chart (Stock v/s Modified Car)

Graph-1: Line Graph

Graph-2: Bar Graph

5. COST AND MATERIAL PURCHASING

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net

Table-2 COST ESTIMATION

6.CONCLUSION AND RECOMMENDATIONS

6.1 Summary of Findings

The aerodynamic modifications significantly improved drag reduction and downforce generation, as validated through CFD simulations andwindtunneltesting.

Structural reinforcements using composite materials enhanced the vehicle’s durability and crash resistance while maintaining a lightweight design.

Costandsustainabilityanalysisdemonstratedthe feasibilityofusingrecycledandcompositematerials forhigh-performancevehiclefabrication.

Despite challenges in fabrication and testing, the overallresultsindicatethesuccessfulexecutionof theproject’sobjectives.

6.2 Conclusion

The project successfully demonstrated that a lightweight supercar structure can be fabricated using clay modelling and fiberglass composite materialsoveranexistingchassis.

The integration of advanced aerodynamics and structural reinforcements resulted in improved performance characteristics, including enhanced stabilityandhandling.

Thefindingssuggestthatcompositematerialsoffer a viable alternative to conventional metal bodies, balancingweight,strength,andsustainability.

6.3 Future Work and Recommendations for Further Research

Furtherrefinementofmaterialselection,including the incorporation of next-generation composites like graphene-based materials for enhanced strengthanddurability.

Advanced aerodynamic studies using AI-driven optimization techniques to refine airflow and efficiency.

Implementation of active aerodynamics for realtimeadaptabilityinvariousdrivingconditions.

Extended real-world testing to assess long-term durability,wearresistance,andenergyefficiency.

Exploringautomatedfabricationtechniquessuchas 3D printing of composite materials to improve productionefficiencyandprecision.

This chapter provides a final assessment of the project’s feasibilityandsuccesswhileoutliningpotentialdirections for future advancements in composite automotive design andaerodynamics.

[1]

V.D.LiberaJunior,L.A.Teixeira,S.C.Amico,S.MariadaLuz Processing,thermalandmechanicalpropertiesofcomposite laminateswithnaturalfibersprepregs

Polym. Polym. Compos.,30(2022), Article096739112210875,10.1177/09673911221087591 Viewatpublisher GoogleScholar

[2]

N.FuentesMolina,Y.FragozoBrito,J.M.PoloBenavides Recyclingofresidualpolymersreinforcedwithnaturalfibers asasustainablealternative:areview

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 05 | May 2025 www.irjet.net p-ISSN: 2395-0072

Polymers (Basel),13(2021), p.3612,10.3390/polym13213612

ViewatpublisherGoogleScholar

[3]

C. Jaiswal, Market research report, (n.d.).https://www.marketresearchfuture.com/reports/bio composite-market-4433(accessedOctober23,2023). GoogleScholar

[4] A.Meraldo

IntroductiontoBio-BasedPolymers,in:MultilayerFlexible Packaging

Elsevier(2016), pp.47-52,10.1016/B978-0-323-371001.00004-1

ViewPDFViewarticleViewinScopusGoogleScholar

[5]

M.Avella,A.Buzarovska,M.Errico,G.Gentile,A.Grozdanov

Eco-challengesofbio-basedpolymercomposites

Materials (Basel),2(2009), pp.911925,10.3390/ma2030911

ViewatpublisherViewinScopusGoogleScholar

[6]

Y.K.Kim

Natural fibre composites (NFCs) for construction and automotiveindustries,in:handbookofNaturalFibres Elsevier(2012), pp.254279,10.1533/9780857095510.2.254

ViewPDFViewarticleGoogleScholar

[7]

G.Wiedemann,H.Rothe

Review of Prepreg Technology, in: Developments in ReinforcedPlastics 5 Springer Netherlands,Dordrecht(1986), pp.83119,10.1007/978-94-009-4179-3_3

ViewatpublisherViewinScopusGoogleScholar

[8]

M.Jabbar,A.Nasreen

CompositeFabricationandjoining,in:CompositeSolutions ForBallistics

Elsevier(2021),pp.177-197,10.1016/B978-0-12-8219843.00013-9

ViewPDFViewarticleViewinScopusGoogleScholar

[9]

A.Bhatnagar,B.Arvidson,W.Pataki

Prepregballisticcomposites

LightweightBallisticComposites,Elsevier(2006),pp.272304,10.1533/9781845691554.2.272

ViewPDFViewarticleViewinScopusGoogleScholar

[10]

V.M.Karbhari

Fabrication,qualityandservice-lifeissuesforcompositesin civil engineering, in: durability of composites for civil structuralapplications

Elsevier(2007),pp.13-30,10.1533/9781845693565.1.13

ViewPDFViewarticleViewinScopusGoogleScholar

Bibliography

AMAN KUMAR SHAHI

B. TECH, FINAL YEAR GITM, LUCKNOW

HARSH YADAV

B. TECH, FINAL YEAR GITM, LUCKNOW

DEEPAK KUSHAHA

B. TECH, FINAL YEAR GITM, LUCKNOW

MR. ASHISH KUMAR SRIVASTAVA ASSISTANCE PROFESSOR DEPARTMENT OF MECHANICAL ENGINEERING GITM, LUCKNOW

© 2025, IRJET | Impact Factor value: 8.315 |