International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

Ms. Chinmayee Jadhav*1 , Mr. Raju Narwade*2

*1ME Student, Civil Engineering Department Pillai HOC College of Engineering and Technology Pillai HOCL Educational Campus, HOCL Colony Rasayani, Tal: Khalapur, Dist: Raigad-410207

*2 Head of Department, Civil Engineering Department, Pillai HOC College of Engineering and Technology Pillai HOCL Educational Campus, HOCL Colony Rasayani, Tal: Khalapur, Dist: Raigad-410207.

Abstract

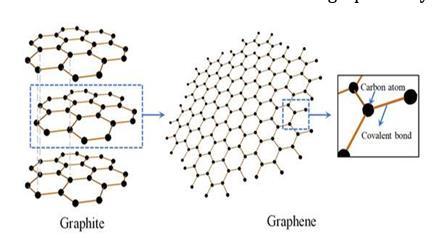

Graphene,atwo-dimensionalcarbonallotrope,possessesexceptionalmechanical,electrical,andthermalproperties,makingit a promising material for enhancing traditional building materials. This study investigates the integration of graphene-based materialsinto building designusing advancedcomputational tools,suchasBuildingInformationModeling(BIM)andenergy analysis software. These tools are employed to model, simulate, and optimize the use of graphene in construction materials likeconcrete,insulation,andcoatings.Themethodologyincludesselectingappropriategraphenederivatives,creatingdetailed digital models, optimizing material placement, and evaluating performance through simulations. ANSYS and Avogadro softwareareusedtoanalyzegraphene-basedmaterialsatvaryingscales,frommolecularstructurestomacroscopicbehaviors. The study reveals that graphene can improve the strength, durability, and sustainability of buildings, particularly by reinforcing concrete, enhancing thermal properties, and enabling self-healing capabilities. Despite its potential, challenges related to cost, scalability, and regulatory standards are also addressed. The research highlights the importance of computational tools in facilitating the integration of graphene-based materials into building design, ensuring safer, more efficient,andenvironmentallyresponsibleconstruction.Thisstudycontributestothegrowingbodyofknowledgesurrounding graphene'sroleinconstructionandemphasizesitstransformativepotentialinsustainablebuildingdesign.

Keywords: Graphene, building materials, computational modeling, Building Information Modeling (BIM), energy analysis, concrete reinforcement, thermal properties, self-healing materials, ANSYS, sustainability.

Graphene, a single layer of carbon atoms arranged in a honeycomb lattice, was first isolated in 2004 by Andre Geim and KonstantinNovoselov,whoreceivedtheNobelPrizeinPhysicsin2010forthisdiscovery.Graphene'sexceptionalmechanical, electrical, and thermal properties, including high tensile strength, outstanding electrical conductivity, and thermal conductivitygreaterthancopper,havemadeitavaluablematerialforconstruction.In2024,theglobalgraphenemarketwas valuedatUSD1.1billion,withconstructionapplicationsexpectedtodrivemarketgrowth,predictedtoexceedUSD2.5billion by 2030. Graphene can enhance traditional building materials like concrete, steel, and glass, creating lighter, stronger, and more durable structures. Its electrical conductivity enables the development of smart materials, paving the way for energyefficient and responsive smart buildings. Advanced software tools, including Building Information Modeling (BIM), finite element analysis (FEA), and computational fluid dynamics (CFD), play a crucial role in optimizing the design of grapheneenhanced materials. These tools allow precise simulations of graphene's interaction with construction materials, predicting performance under various conditions. Despite its promise, challenges such as high production costs and scalability remain, but with ongoing research and development, graphene is poised to revolutionize the future of construction, fostering sustainable,technologicallyadvancedinfrastructures.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net

p-ISSN:2395-0072

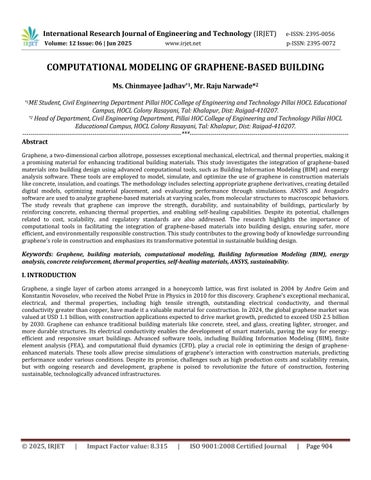

Graphene,ahexagonallyarrangedsheetofsp²-bondedcarbonatoms,isasingleatomthickandcanvaryinlateraldimensions from nanometers to microscale. The international editorial team of Carbon recommended a standard nomenclature for graphene,givenitsnoveltyandtheconfusionsurroundingitsterminology.Monolayergraphene,withasinglelayerofatoms, is the purest form known and is ideal for high-frequency electronics. The properties of bi-layer and tri-layer graphene, with two and three layers, respectively, change as the number of layers increases. Graphene is renowned for its exceptional electronic,mechanical,andopticalproperties,makingitpromisingforvariousapplications.

Electrically,grapheneexhibitsextremelyhighconductivity,makingitidealforelectronicapplicationssuchastransistors and sensors. Its electron mobility is stable across temperatures, ensuring consistent performance. Mechanically, graphene is the strongestmaterialtested,withatensilestrengthof130GPaandanimpressiveYoung'smodulus of1TPa,makingitsuitable for lightweight, high-strength applications. Optically, graphene can manipulate light at the atomic scale, with applications in photodetectors, modulators, and ultrafast optics. These properties make graphene a transformative material in multiple industries,includingelectronics,telecommunications,andconstruction.

The integration of graphene into building design relies on advanced software tools for optimizing its performance in realworldapplications.Thesetools,suchasBuildingInformationModeling(BIM)andFiniteElementAnalysis(FEA), areessential for simulating the behavior of graphene-based materials under various loads, stresses, and environmental conditions. BIM helps create detailed digital representations, allowing designers to visualize how graphene composites interact with the overall structure, such as reinforcing concrete or steel. Software tools ensure optimized safety, performance, and costefficiency by predicting the flexural strength and crack resistance of graphene-reinforced materials. Additionally, simulation software aids in material optimization, testing how graphene interacts with other construction materials like cement or polymers.Byadjustingparameters,softwarepredictsoptimalmaterialmixtures,ensuringmaximumstrength,durability,and energy efficiency. Furthermore, software plays a vital role in environmental impact analysis, assessing the sustainability of graphene-based materials throughout their lifecycle. This includes evaluating carbon footprints, energy consumption, and long-term ecological impact, ensuring that graphene's incorporation enhances building performance without compromising environmentalgoals.Insummary,softwaretoolsarecrucialinmakinggrapheneagame-changingmaterialinconstruction.

Somnath Bharech et al. (2015) reviewed the fundamental properties, types, production processes, and applications of grapheneasone ofthe"futurematerials."Givenits exceptional mechanical,thermal,andelectrical properties, graphene was

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

identified as a revolutionary material for use in aerospace, automotive, electronics, and construction. M. Devasena et al. (2015) conducted an experimental investigation to determine the optimal concentration of graphene oxide in concrete for maximumstrengthperformance.Theyvariedgrapheneoxidecontentat0.05%,0.1%,and0.2%ofcementcontentandtested samplesat7,14,and28days.Resultsshowedimprovementsincompressive,tensile,andflexuralstrength,demonstratingthe effectivenessofgrapheneoxideasaconcreteadditive ZHOU Ding et al. (2012) reviewedthedevelopmentofgraphene-based hybrid materials by integrating inorganic or organic species. These hybrids exhibited superior performance in various applications, especially in energy storage and conversion, due to graphene’s thermal, mechanical, and electrical properties. Aungkan Sen et al. (2017) described graphene as the smartest material in materials science due to its combination of extraordinaryphysico-chemicalproperties.Thereviewevaluatedthelatesttrendsingrapheneresearchandvarioussynthesis methods,aimingtoidentifyscalablecommercialtechniques.

Houxuan Li et al. (2023) presentedadetailedsummaryofexperimentalfindingsontheimpactofgrapheneoncement-based materials.Theydiscussedhowvariablessuchasmassratio,curingtime,andmaterialtypeinfluencemechanicalstrengthand durability. The paper also covered advanced applications like improving interfacial adhesion, thermal and electrical conductivity,absorptionofheavymetals,andenergyharvestinginbuildings.Itconcludedbyidentifyingexistingresearchgaps and suggesting directions for future studies. Abergel et.al (2010) This paper provides a theoretical perspective on the properties of graphene, discussing its unique electronic structure, strength, and potential applications in various fields. It highlights the exceptional conductivity and mechanical properties of graphene, which make it a promising material for construction and energy applications. Understanding these properties is essential for designing buildings and infrastructure that can leverage graphene’s strengths, enhancing performance and sustainability. The paper emphasizes graphene’s future roleinthedevelopmentofadvancedmaterialsforconstruction. Adamu, M., Trabanpruek (2022) Thisstudyinvestigatesthe compressive behavior and durability performance of high-volume fly ash concrete incorporating plastic waste and graphene nanoplatelets.Usingresponse-surfacemethodology,theresearchshowshowgraphenecanimprovethemechanicalproperties anddurabilityofconcrete, whichiscritical forsustainable building design. Theinclusionof graphene enhancesstrengthand extends the material’s lifespan, reducing maintenance costs and environmental impact, making it an ideal material for sustainableinfrastructureintheconstructionindustry. Asim, N. (2022) Thisreviewprovidesanoverviewoftheapplication ofgraphene-basedmaterialsindevelopingsustainable infrastructure.Theauthors highlighthowgraphenecan beintegrated into various building materials, including concrete, to improve performance and contribute to environmental sustainability. Thereviewdiscussesthepotentialofgraphenetoreplacetraditionalmaterials,reduceenergyconsumption,andenhancethe durability of infrastructure. It is an important resource for understanding how graphene can support the construction of sustainable,energy-efficientbuildings.

Bheel, N et.al (2023) This research examines the effects of graphene oxide on the properties of engineered cementitious composites(ECC)usingamulti-objectiveoptimizationtechnique.Thestudyrevealsthattheincorporationofgrapheneoxide significantly enhances the mechanical properties of ECC, including tensile strength and resistance to cracking. The paper highlightsthepotentialofgrapheneoxidetoimprovethesustainabilityofconcretematerials,makingthemmoredurableand resistanttoenvironmentalstress,akeyaspectforconstructingresilientbuildings. Bianco, A. (2013) Thispaperaddressesthe safety concerns associated with graphene and its potential toxicity, providing a comprehensive review of the health risks related to its widespread use. Although graphene has remarkable properties, the paper raises important questions about its environmental and health impact, particularly in applications involving construction materials. It emphasizes the need for further research to understand these risks, ensuring that the benefits of graphene in building materials do not come at the expenseofhumanorenvironmentalsafety.

Graphene, a two-dimensional material made of a single layer of carbon atoms, has emerged as a revolutionary building material due to its exceptional strength, durability, and versatility. It is ten times stronger than steel while being lighter and more flexible. Graphene-based materials hold great potential in enhancing building performance, improving structural integrity, reducing environmental impact, and increasing longevity. To incorporate graphene effectively, advanced software tools like Building Information Modeling (BIM), finite element analysis (FEA), and molecular dynamics simulations are essential. These tools help model, simulate, and optimize graphene's behavior in real-world conditions, enabling sustainable andinnovativebuildingdesigns.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

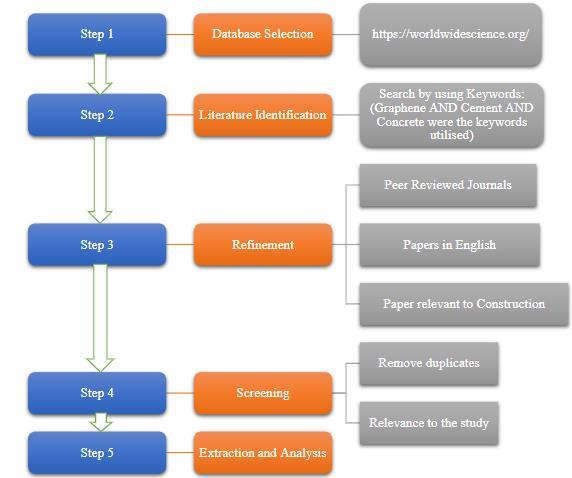

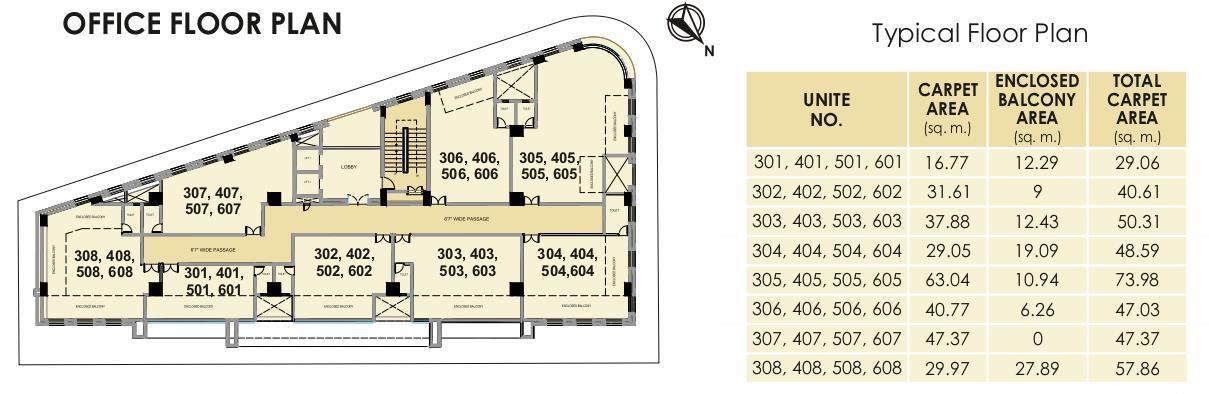

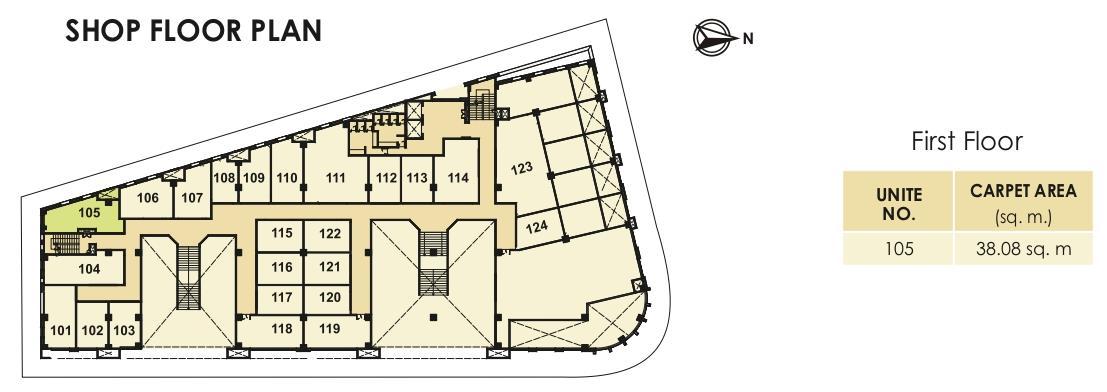

ThePridePurple projectinvestigatesintegratinggraphenecompositesintocommercial construction.Itcomparestraditional concrete with graphene composites in terms of cost, performance, durability, and environmental impact. While concrete is morecost-effectiveinitially,grapheneofferssuperiorstrength, reducedstrain energy,andlonger servicelife, makingitideal for premium infrastructure. Despite higher upfront costs, graphene promises lower maintenance, enhanced durability, and sustainability. The study advocates for strategic use of graphene in critical components and recommends scaling production andoptimizingcomputationalmodelingforbettercost-efficiencyinfuturebuildings.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

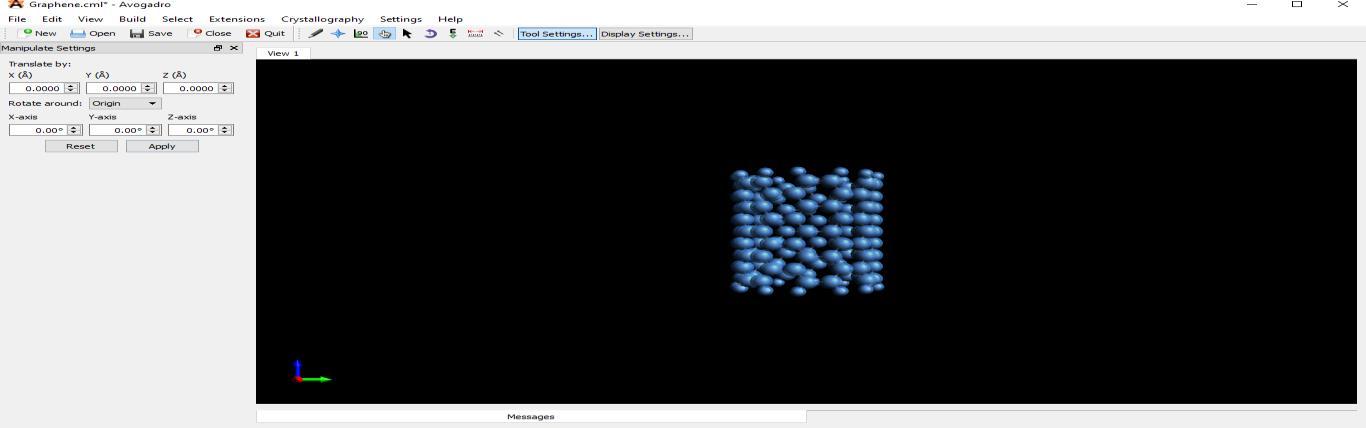

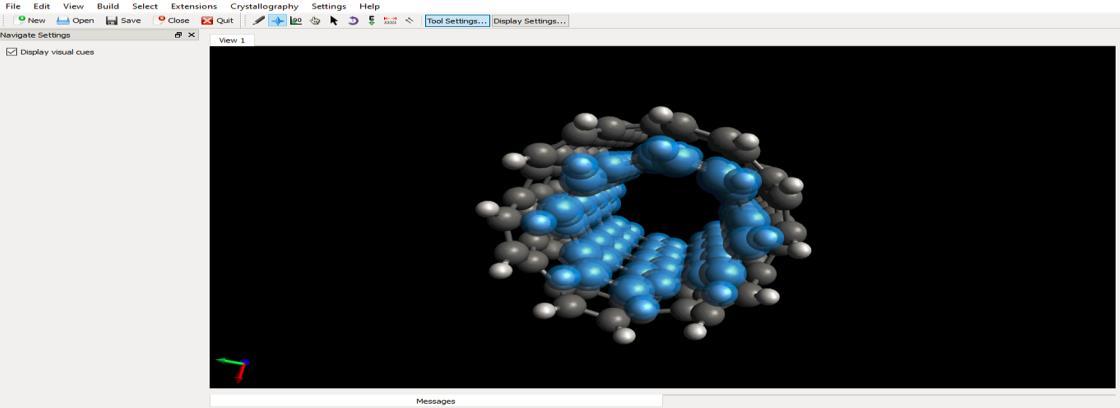

The figure shows a side view of the atomic arrangement in graphene, visualized using Avogadro software. The blue spheres represent carbon atoms arranged in a hexagonal lattice, forming a single layer of graphene. The atoms are closely packed, demonstrating the two-dimensional nature of graphene sheets. This structure is fundamental for understanding graphene's exceptional electrical, mechanical, and thermal properties. The 3D perspective helps in appreciating the uniformity and planarityofthegraphenelayer.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

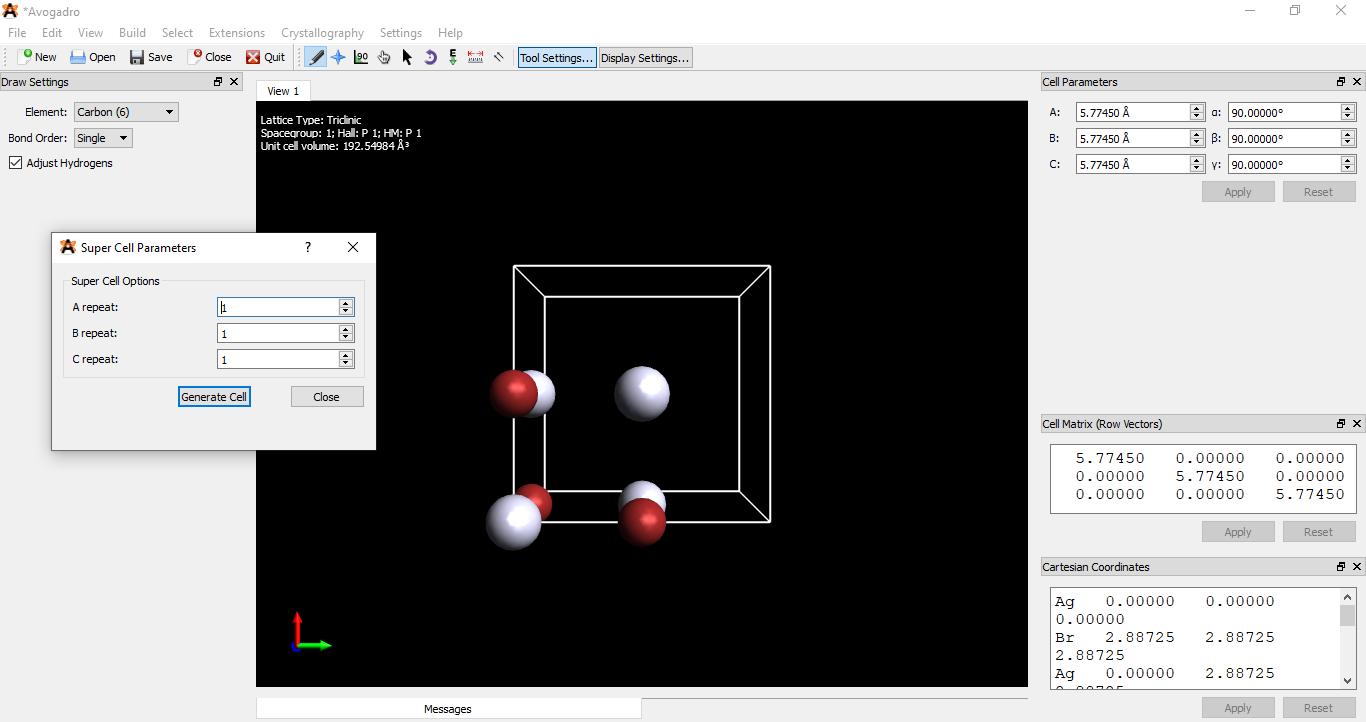

The figure representsa 3D ball-and-stick model of a carbon nanotubesegment,visualizedthroughcrystallographysoftware. The blue spheres represent carbon atoms forming a hexagonal lattice rolled into a cylindrical shape, characteristic of nanotubes.Thewhitesphereslikelydepicthydrogenatomscappingtheopenendsofthenanotubetostabilizethestructure. This model illustrates the tubular arrangement of carbon atoms that endows nanotubes with their unique mechanical, electrical,andthermalproperties.

The figure shows a segment of a carbon nanotube visualized using crystallography software. Blue spheres represent carbon atoms arranged in a hexagonal lattice, while white spheres indicate hydrogen atoms capping the nanotube ends for stabilization. The model highlights the tubular structure of carbon atoms, which is crucial for the nanotube's exceptional mechanical strength, electrical conductivity, and thermal properties. This visualization aids in understanding the atomic arrangementandsurfacechemistryofcarbonnanotubes.

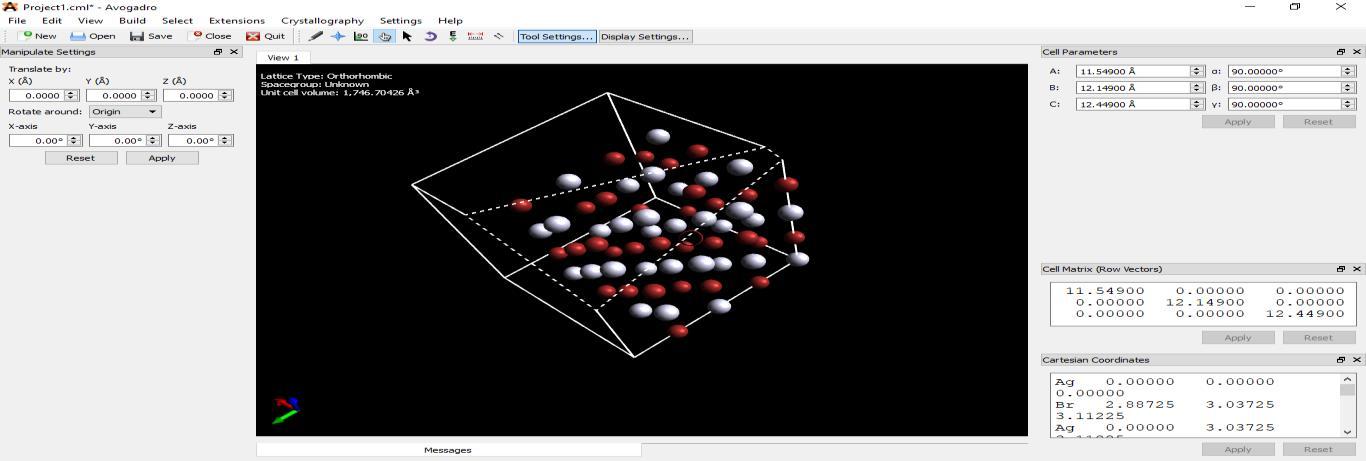

The figure displays a 3D visualization of an orthorhombic crystal lattice, showing atoms arranged within the unit cell boundaries. The white and red spheres represent different atomic species or positions within the lattice. The lattice parameters (a, b, c) and angles (all 90°) indicate the unit cell dimensions and confirm the orthorhombic symmetry. The arrangementandconnectivityreflecttheatomicpackingandstructureofthecrystallinematerial,usefulforunderstandingits physicalandchemicalproperties.

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

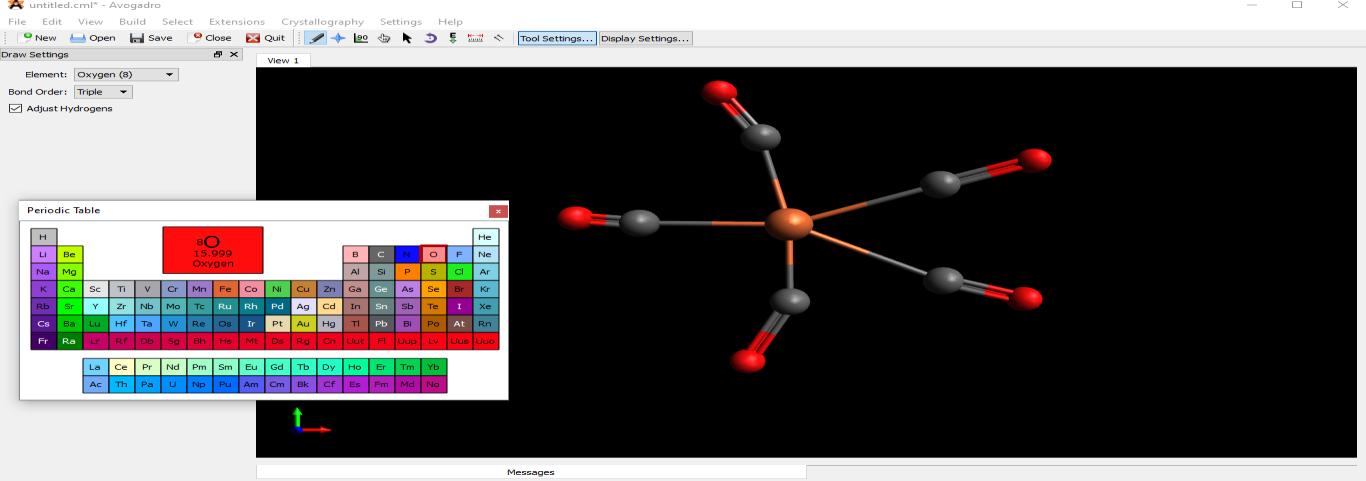

Thefiguredepictsa3Dmolecularstructureofametalcoordinationcomplex,visualizedusingAvogadrosoftware.Thecentral atom(likelyametalion)isshowninbrown,surroundedbymultipleoxygenatoms(red),formingcoordinationbonds(orange lines).Theoxygenatomsappearto bepartofligandscoordinatedtothemetal center,illustratingthegeometry andbonding arrangement typical in coordination chemistry. The periodic table on the left highlights oxygen, indicating its elemental identityinthestructure.

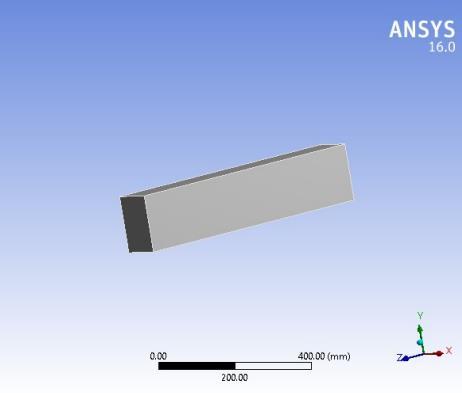

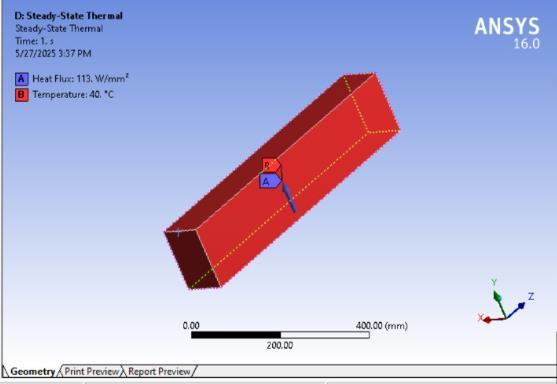

The figure shows a 3D rectangular beam model created in the ANSYS 16.0 simulation environment. The beam is oriented in space with the X, Y, and Z axes shown at the bottom right corner for reference. The scale bar below the beam indicates the length dimensions in millimeters, suggesting the beam is approximately 400 mm long. This model is likely prepared for structuralanalysissuchasstress,strain,ordeformationunderappliedloadsorboundaryconditions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

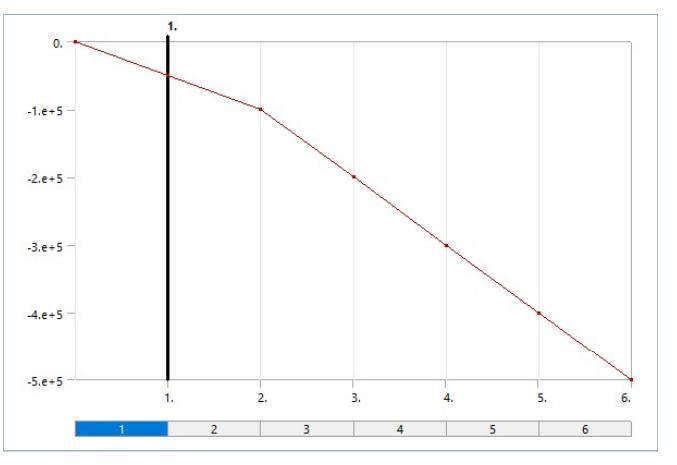

Thegraph5.7showsasteepdeclinein eigenvaluesfromthefirsttothesecondprincipalcomponent,indicatingthatthefirst principal component accounts for the majority of the data's variance. Subsequent components contribute progressively less. Thispatternsuggeststhatdimensionalityreductioncouldbeeffective,withmostofthemeaningfulinformationretainedinthe firstoneortwocomponents.Thescreeplotconfirmsthatonlythefirstfewcomponentsaresignificantforanalysis.

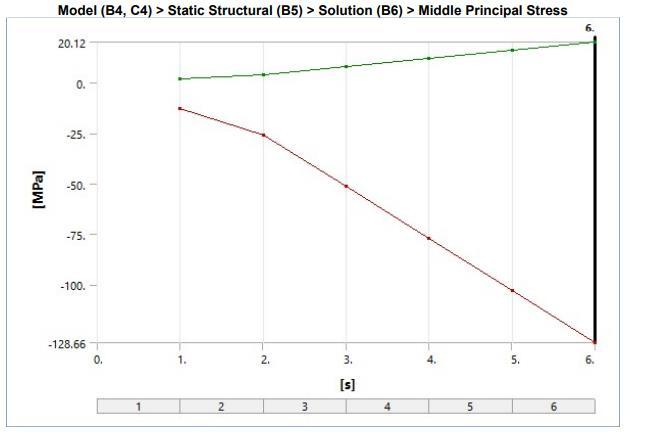

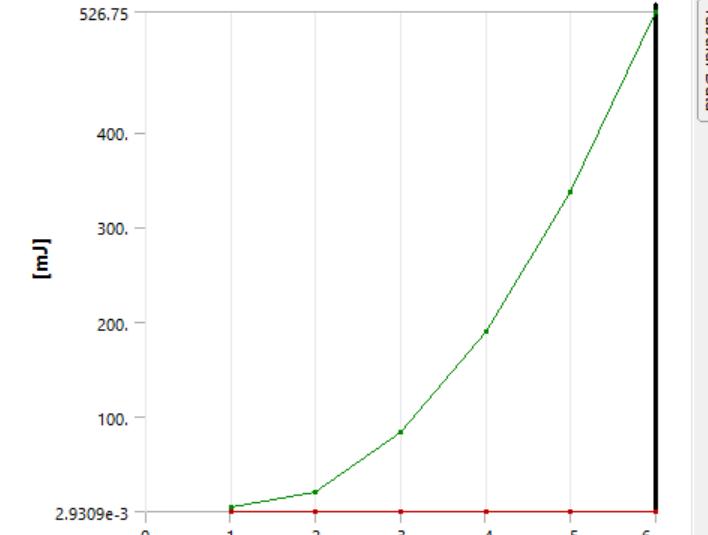

Thegraphdisplaysthevariationofmiddleprincipalstress(inMPa)overatimeintervalfrom0to6seconds.Thestressvalues are split into two trends: one increasing slightly (green) and the other decreasing significantly (red), indicating tensile and compressive stress behavior, respectively. The decreasing trend reflects increasing compressive stress in the structure over time.Thisanalysisispartofastaticstructuralsimulation,whichhelpsassessmaterialstabilityunderappliedloads

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

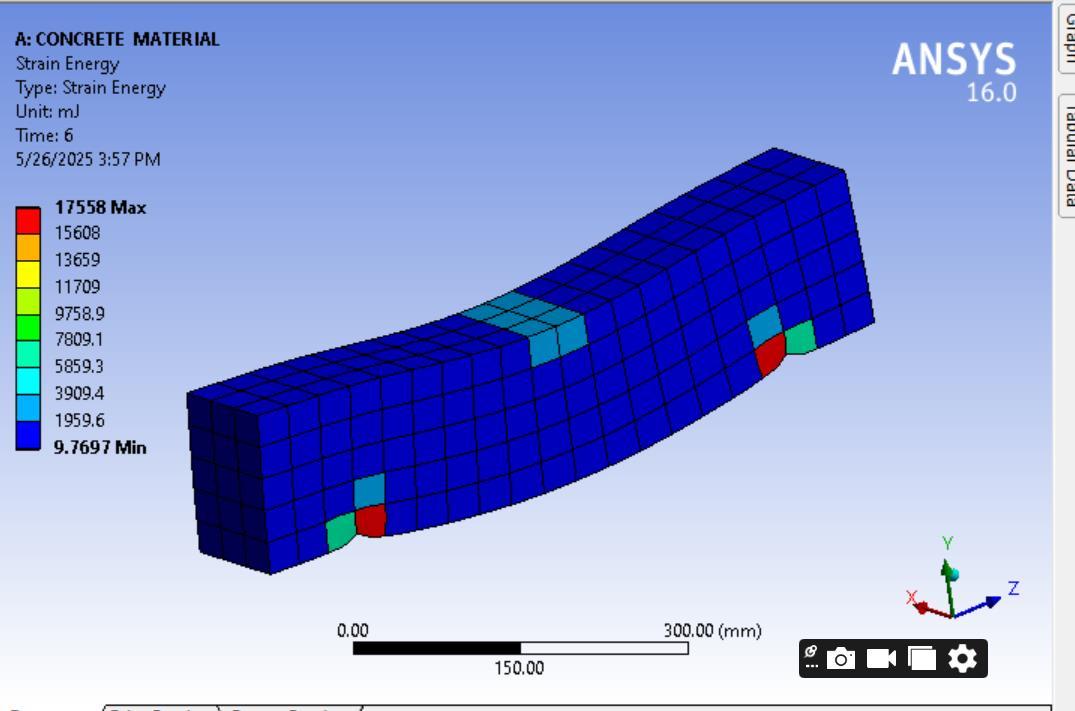

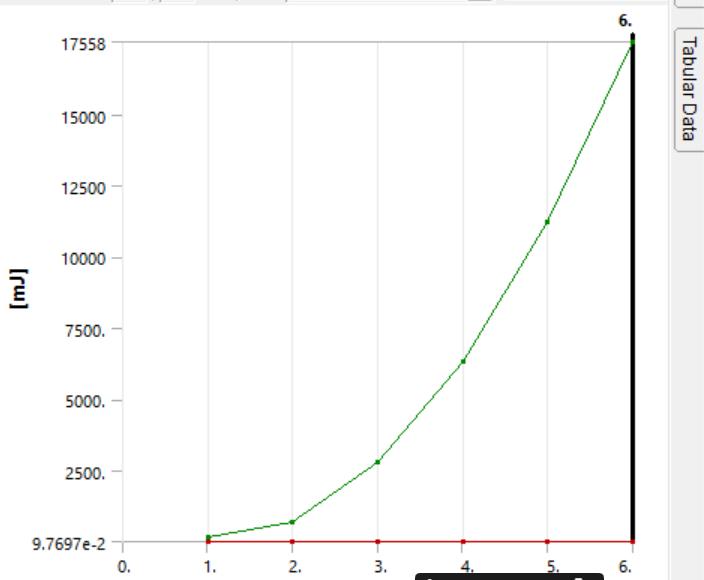

The figure shows the strain energy distribution in a concrete beam analyzed using ANSYS software. The color gradient represents the strain energy levels, with red areas indicating maximum strain energy concentrations (up to 17,558 mJ) and blueareasshowingminimalstrainenergy(around9.77mJ).Higherstrainenergyzonessuggestregionsexperiencinggreater deformationandpotentialstress,oftencriticalforfailureanalysis.Thebeamexhibitsnoticeablestrainenergyconcentrations nearthesupportsandthemid-span,indicatingtheseareasaremoststressedunderloadingconditions.

Thegraphshowsarapidincreaseinthevariablemeasuredinmilliliters(ml)fromstep1tostep6.Initially,thevalueis very low, but it grows exponentially or sharply as the steps progress. This suggests an accelerating trend or process leading to a substantial increase by the final step. The steep rise at the end indicates that the system or phenomenon being measured is experiencingrapidexpansionorgrowth.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

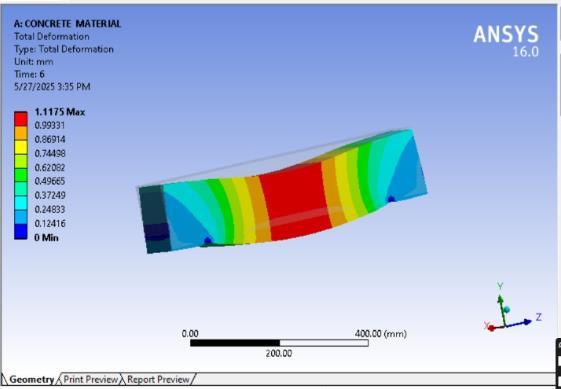

The figure illustrates the total deformation distribution of a concrete specimen under load, analyzed using ANSYS software. The color gradient indicates the magnitude of deformation, with red areas showing the highest deformation (up to 1.1175 mm)andblueareastheleast(near0mm).Thissuggeststhatthecentralregionexperiencesthemaximumdisplacement,likely duetoappliedloadingconditionsorstructuralconstraints.

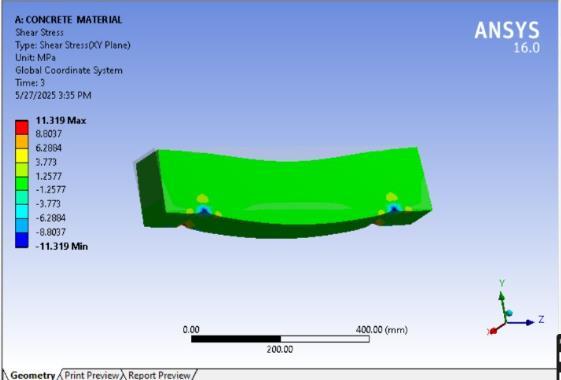

The figure shows the shear stress (XY plane) distribution in a concrete beam under load, with stress values ranging from11.319MPato11.319MPa.Thecentralregionofthebeamexperienceslowershearstress(greenzone),whiletheareasnear the supports show higher stress concentrations (yellow to red zones). This indicates typical shear stress patterns where maximumshearoccursnearsupports.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

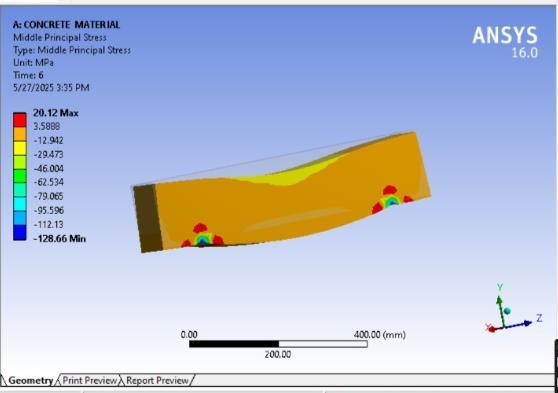

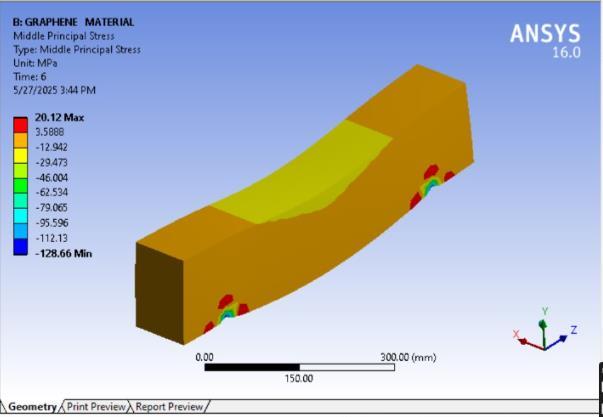

Thefigureshowsthedistributionofmiddleprincipalstressinaconcretebeamunderload,withstressvaluesrangingfrom128.66 MPa (blue, compressive) to 20.12 MPa (red, tensile). High compressive stresses are concentrated near the bottom edges,whiletensilestressesappearnearthetopsurface.Thisindicatesbendingstresstypicalinaloadedbeam.

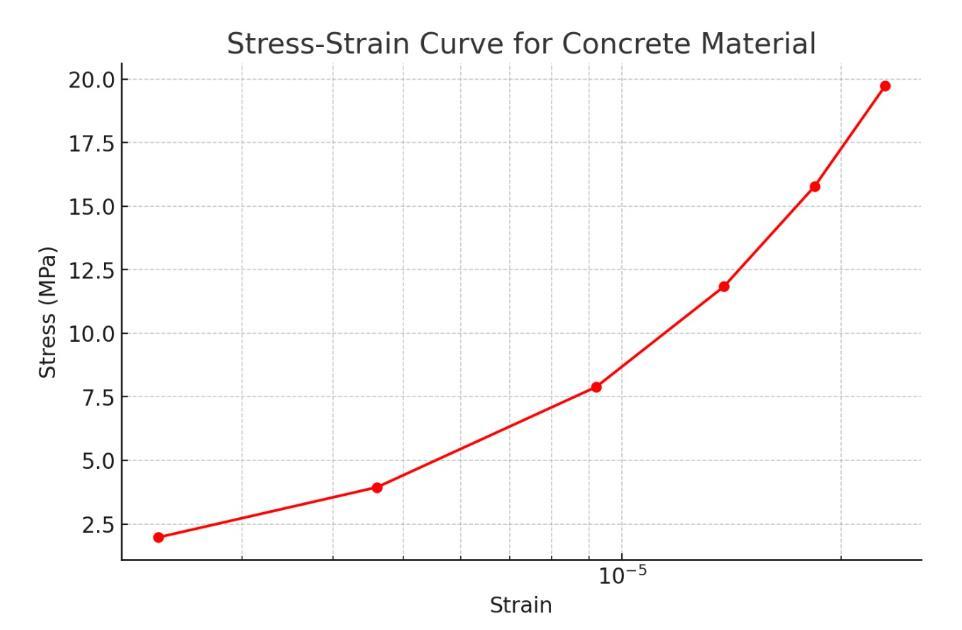

Thisgraphillustratestherelationshipbetweenstressandstrainforconcretematerial.Asthestrainincreases,thestress also increases, indicating the material's resistance to deformation under load. The curve shows a nonlinear behavior, typical of concrete,withstressrisingmorerapidlyafteracertain strain,reflectingthematerial'sincreasingstiffnessorapproaching its failurepoint.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

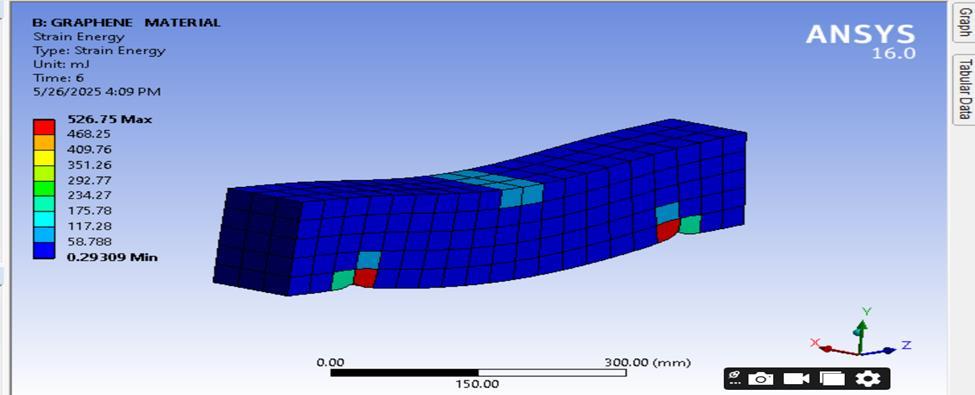

Thefigureshowsthestrainenergydistributionina graphenematerialmodel analyzedusingANSYS16.0.Thecolorgradient indicatesthevariationinstrainenergy,withredrepresentingthemaximumstrainenergy(526.75mJ)andbluetheminimum (0.29309 mJ). Higher strain energy concentrations appear near the supports and the bent region, indicating areas of greater deformation and potential stress concentration. This helps identify critical regions for failure or design optimization in the graphenestructure.

Thegraphshowsthevolumechangeoftwosamplesovertime.Thegreenlineexhibitsa rapidincreaseinvolume,indicating significant expansion or growth. In contrast, the red line remains almost flat, suggesting negligible or no change in volume throughout the observed period. This could indicate differences in the properties or behaviors of the two samples under similarconditions.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

19. MiddlePrincipalStressDistributioninGrapheneMaterialunderLoad(ANSYS16.0Simulation)

The figure illustrates the distribution of middle principal stress (in MPa) within a graphene material sample under applied load,analyzedusingANSYS16.0.Thecolorgradientshowsstressconcentration,withredregionsindicatingmaximumstress (20.12MPa)andblueregionsrepresentingminimumstress(-128.66MPa).Thestressvariesalongthelengthofthespecimen, highlightingpotentialareasoffailureordeformation.

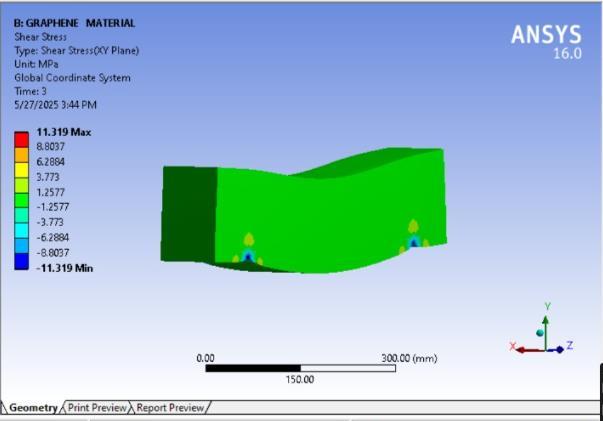

The figure displays the shear stress (XY Plane) distribution in a graphene material analyzed using ANSYS 16.0. The color gradient represents varying shear stress magnitudes, with red indicating maximum shear stress (11.319 MPa) and blue indicating minimum (-11.319 MPa). The stress appears concentrated near the ends or specific points, which could indicate regionspronetomaterialfailureorhighdeformationunderload.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

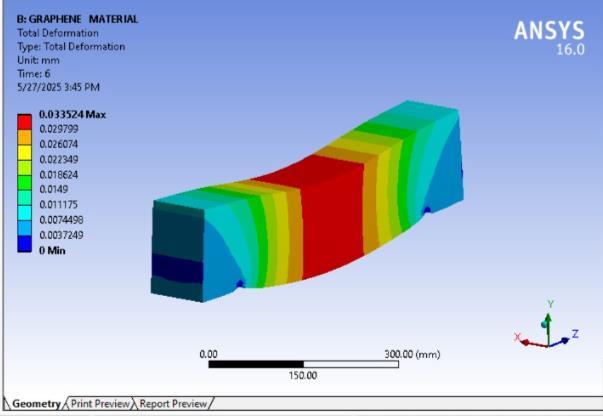

The figure shows the total deformation of a graphene material subjected to a load or force, with deformation measured in millimeters.Thecolorgradientindicatesdeformationmagnitude,whereredrepresentsthemaximumdeformation(~0.0335 mm) and blue represents minimal or no deformation. This suggests the central region experiences the highest strain, with deformation gradually decreasing towards the edges, highlighting the material's response to applied stress under the given conditions.

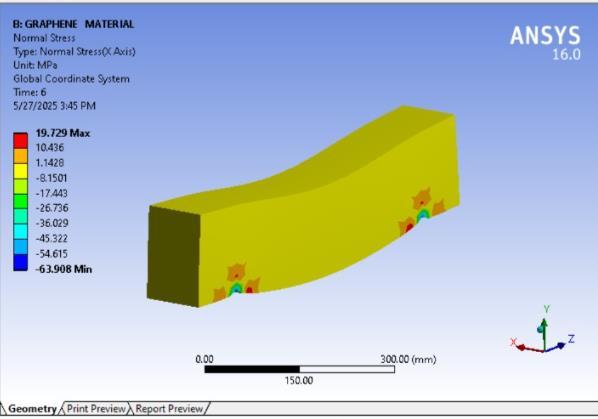

Thefigureillustratesthenormalstressdistributionalongagraphenespecimensubjectedtobendingortensileloading.Stress values range from a maximum of 19.729 MPa (red regions) to a minimum of -63.908 MPa (blue regions), indicating areas undertensionandcompression,respectively.Thestressconcentrationnearthefixedendssuggestscriticalpointsforpotential failure or material yielding. This simulation helps in understanding mechanical behavior and optimizing the graphene structureforpracticalapplications.

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

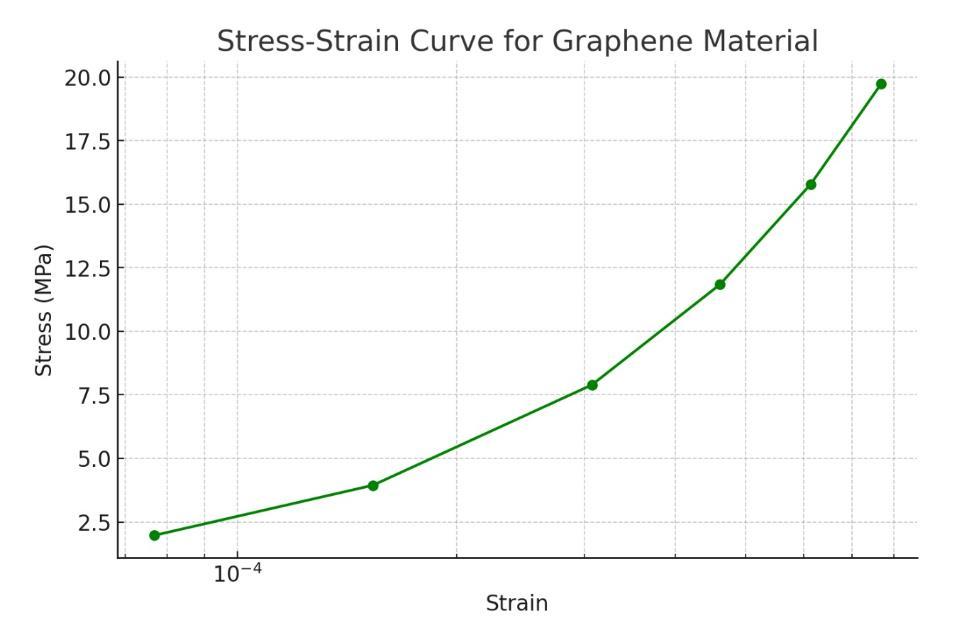

Thefigureshowstherelationshipbetweenstress(inMPa)andstrainforgraphenematerial. Asthestrainincreases,thestress also increases non-linearly, indicating that graphene exhibits strong mechanical strength and stiffness. This curve helps understandhowgraphenedeformsunderappliedstress,essentialforitsapplicationsinmaterialsscienceandengineering.

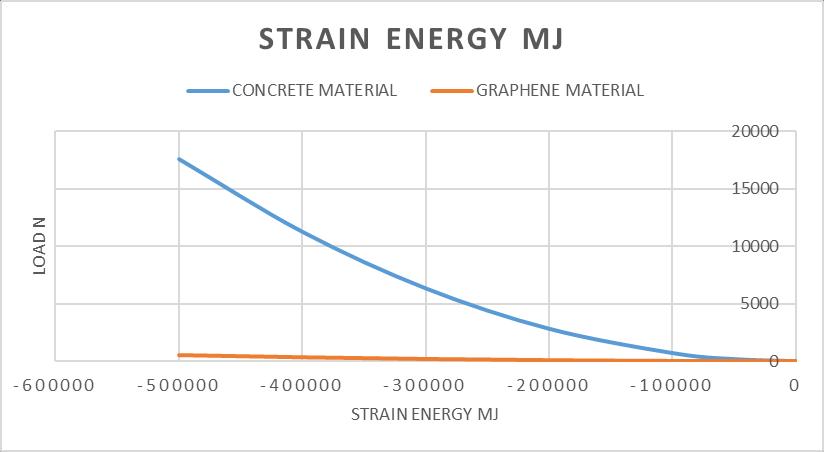

The comparison of load versus strain energy in the two materials reveals a stark contrast in their mechanical performance. Theconcretespecimenexhibitsaveryhighenergy‐absorptioncapacity stillsustainingroughly17000Nofloadataround–500 000 MJ of stored strain energy and then steadily releases that energy as the load decays toward zero. By contrast, the graphenematerialshowsa nearlyflat,low‐magnituderesponse,peakingatonlyabout1000Nandstoringverylittleenergy before unloading. In practical terms, concrete can absorb and release orders of magnitude more mechanical energy under load,whereasthegraphenecompositeinthistestunloadsalmostimmediatelyandcontributesnegligibleenergyabsorption.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

Thefigureshowsthesteady-statethermaldistributioninarectangularbarsimulatedinANSYS16.0.Theheatfluxisappliedat oneendwithamagnitudeof113W/mm²,andthetemperatureissetto40°Cattheoppositeend.Thecolorgradientindicates thetemperaturedistributionalongthebar,highlightingthethermalconductionpathandtemperaturegradientunder steadystateconditions.

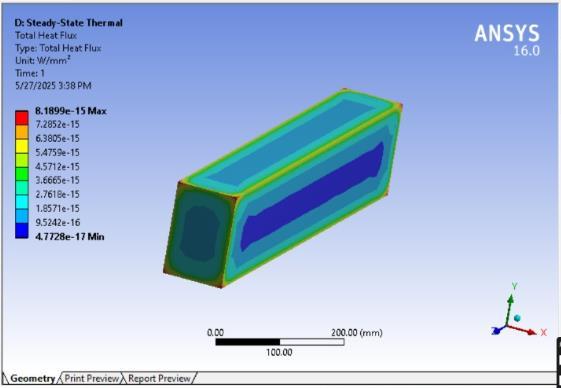

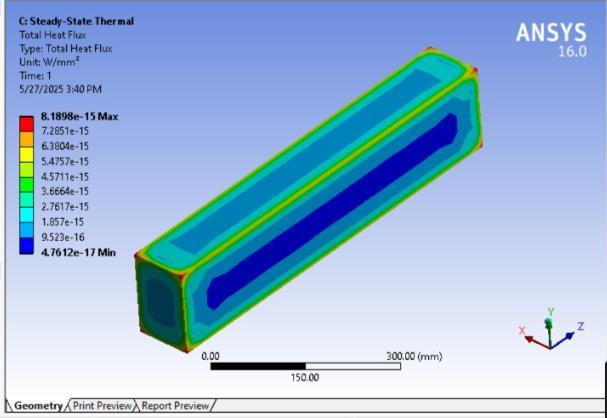

The figure shows the distribution of total heat flux on a 3D object simulated using ANSYS 16.0 under steady-state thermal conditions.Thecolorgradientrepresentsvaryingmagnitudesofheatflux,withredindicatingthemaximumfluxandbluethe minimum.Thisvisualizationhelpsidentifyregionsofhighandlowthermalactivity,whichiscriticalforassessingheattransfer efficiencyandpotentialthermalstresszonesinthematerial.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

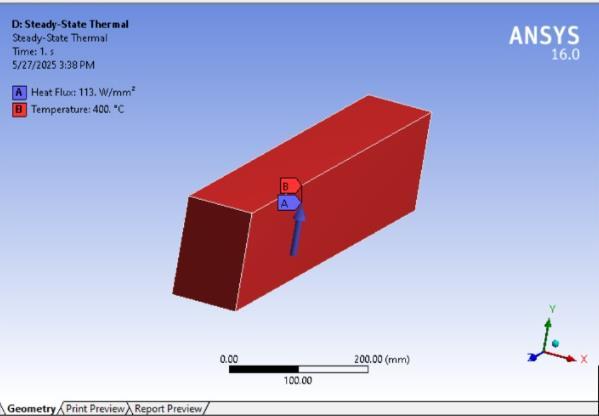

Thefigureshowsasteady-statethermalsimulationofasolidobjectusingANSYS16.0.Thetemperatureatthemarkedpointis 400°C, with a heat flux of 113.94 W/mm² applied. The color and arrow indicators depict the direction and intensity of heat transfer,andthescalebarprovidesthephysicaldimensionsinmillimeters.Thisanalysishelpsinunderstandingtemperature distributionandheatflowwithintheobjectundersteadyconditions.

The figure shows the total heat flux distribution within a rectangular conductor under steady-state thermal conditions, simulatedusingANSYS16.0.ThecolorscaleindicatesthemagnitudeofheatfluxinW/mm²,withredareasrepresentingthe highestheatfluxandblueareasthelowest.Theheatfluxisconcentratedneartheedgesandsurfaces,suggestingheattransfer predominantlyoccursattheseregions,whiletheinnercorehasminimalheatflux.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072

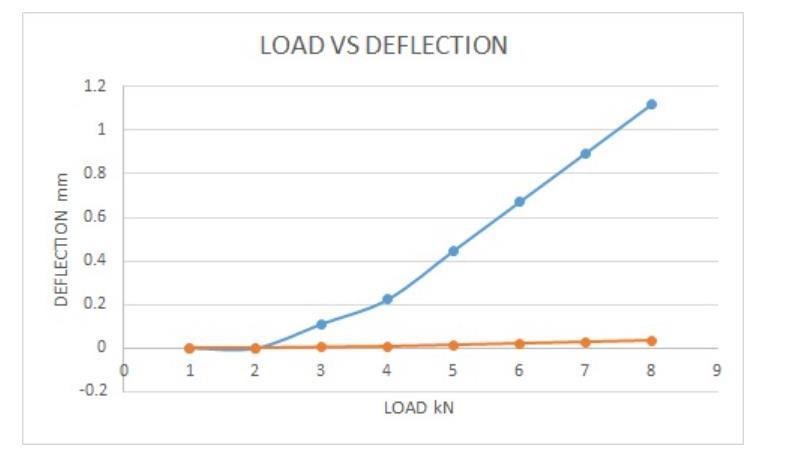

Thegraphillustratestherelationshipbetweentheappliedload(inkN)andtheresultingdeflection(inmm)fortwodifferent cases,representedbytwolines.The bluelineshowsaclearpositivecorrelation,wheredeflectionincreasessignificantlywith load,indicatingaflexibleorlessstiffmaterial.Theorangelineremainsalmostflat,suggestingminimaldeflectionregardlessof theincreasingload,indicatingastifferormorerigidmaterial.

This study conducts a comparative analysis of graphene and concrete materials using ANSYS software, focusing on both thermal and static structural performance in the context of the Indian climate. Thermal analysis reveals graphene’s high thermal conductivity, enabling rapid heat dissipation, while concrete acts as an effective thermal insulator, reducing indoor heatgain anadvantageinIndia’shotclimate.Structurally,grapheneshowssignificantlylower deflectionandstrainenergy absorption compared to concrete, indicating its superior stiffness and efficiency in handling mechanical stresses. Concrete remains more suitable for general construction due to its insulation properties, whereas graphene excels in specialized applications requiring high thermal dissipation and strength. Graphene's sustainability benefits include reduced material weight and energy-efficient coatings, and its optical transparency could optimize natural light through smart glazing. Avogadro software, combined with ANSYS, offers molecular-level insights into graphene’s properties, enabling the developmentofefficient,durablebuildingcomponentsformodern,sustainablearchitecture.

1. Abergel, D.S.L., Apalkov, V., Berashevich, J., Ziegler, K. and Chakraborty, T., 2010. Properties of Graphene: a theoretical perspective.AdvancesinPhysics,59(4),pp.261–482.https://doi.org/10.1080/00018732.2010.487978

2. Adamu, M., Trabanpruek, P., Limwibul, V., Jongvivatsakul, P., Iwanami, M. and Likitlersuang, S., 2022. Compressive Behavior and Durability Performance of High-Volume Fly-Ash Concrete with Plastic Waste and Graphene Nanoplatelets by UsingResponse-Surface Methodology.Journal of Materials in Civil Engineering, 34(9),p.04022222. https://doi.org/10.1061/(ASCE)MT.1943-5533.0004377

3. Asim, N., Badiei, M., Samsudin, N.A., Mohammad, M., Razali, H., Soltani, S. and Amin, N., 2022. Application of Graphene-based materials in developing sustainableinfrastructure: An overview.Composites Part B: Engineering, 245, p.110188.https://doi.org/10.1016/j.compositesb.2022.110188.

4. Bheel, N., Mohammed, B.S., Abdulkadir, I., Liew, M.S. and Zawawi, N.A.W.A., 2023. Effects of Graphene Oxide on the Properties of Engineered Cementitious Composites: Multi-Objective Optimization Technique Using RSM. Buildings, 13(8), p.2018.https://doi.org/10.3390/buildings13082018

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

5. Bianco,A.,2013.Graphene:SafeorToxic?TheTwoFacesoftheMedal.AngewandteChemieInternationalEdition,52(19), pp.4986–4997.https://doi.org/10.1002/anie.201209099.

6. Bianco,A. and Prato,M., 2015. Safetyconcernson Graphene and 2D materials: aFlagship perspective.2DMaterials, 2(3),p.030201. https://doi.org/10.1088/2053-1583/2/3/030201

7. Britannica, 2023. Graphene | Properties, Uses & Structure | Britannica. [online] Available at: <https://www.britannica.com/science/graphene> [Accessed 15 August 2023].[8].Bussy, C., Ali-Boucetta, H. and Kostarelos, K., 2013. Safety Considerations for Graphene: Lessons Learnt from Carbon Nanotubes. Accounts of Chemical Research,46(3),pp.692–701.https://doi.org/10.1021/ar300199e

8. Cai,W.,Wang,B.-B.,Wang,X.,Zhu,Y.-L.,Li,Z.-X.,Xu,Z.-M.,Song,L.,Hu,W.-Z. and Hu, Y., 2021. Recent ProgressinTwodimensionalNanomaterialsFollowingGrapheneforImprovingFireSafetyofPolymer(Nano)composites.ChineseJournal ofPolymerScience,39(8),pp.935–956.https://doi.org/10.1007/s10118-021-2575-2.

9. Chintalapudi, K. and Pannem, R.M.R., 2022. Enhanced chemical resistance to sulphuric acid attack by reinforcing Graphene Oxide in Ordinary and Portland Pozzolanacement mortars. Case Studies in Construction Materials, 17, p.e01452.https://doi.org/10.1016/j.cscm.2022.e01452

10. Choi,J.,Wang, M.C., Cha, R.Y.S., Park, W.I. andNam,S.,2013. Graphenebioelectronics.BiomedicalEngineeringLetters, 3(4),pp.201–208.https://doi.org/10.1007/s13534-013-0113-z.

11. Du,S.,Tang,Z.,Zhong, J., Ge, Y. and Shi, X., 2019. EffectofadmixingGrapheneoxideonabrasionresistance of ordinary portland cement concrete.AIPAdvances,9(10),pp.105110–9.https://doi.org/10.1063/1.5124388

12. Al-mashhadani,A.M.R.(2021).ConcreteModificationUsingGrapheneandGrapheneOxideAM&T.January2020,46–56. https://doi.org/10.17277/amt.2020.02.pp.046-056

Volume: 12 Issue: 06 | Jun 2025 www.irjet.net p-ISSN:2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified

| Page923