International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Anuj Soni1 , Rahul Satbhaiya2

1M.T.ech Research Scholar, Infinity Management and Engineering College

2Assistant Professor and Head of Civil Department, Infinity Management and Engineering College

Abstract - This study presents a comparative structural analysis of Cold-Formed Steel (CFS) and Hot-Rolled Steel (HRS) for a mid-rise industrial building (12 m × 35 m × 13 m) using STAAD software. The performance of both materials is evaluated under identical loading conditions, focusing on bending moments, shear forces, axial forces, deflections, support reactions, andseismic loads. Results indicatethatCFS exhibits lower bending moments, shear forces, support reactions, and deflections compared to HRS, along with superior seismic performance (36% lower base shear) and approximately 24% cost savings. Despite higher axial force capacity, CFS proves to be a more efficient and economical choice for industrial applications, offering practical advantagesforsustainableconstructioninbudget-constrained regions.

Keywords: Cold-formed steel, Hot-rolled steel, Structural analysis,Industrialbuildings,Seismicperformance,STAAD, Costefficiency

1.INTRODUCTION

1.1 Background

The demand for efficient, cost-effective, and structurally soundindustrialbuildingshasledtogrowinginterestinthe use of different steel sections primarily Hot-Rolled Steel (HRS) and Cold-Formed Steel (CFS). These structures require large, unobstructed spaces capable of supporting dynamicloads,makingsteelthepreferredmaterialduetoits highstrength-to-weightratioanddurability.WhileHRShas traditionallydominatedthe industry foritssuperiorloadbearingcapacity,CFSisincreasinglybeingconsideredforits lightweightproperties,materialefficiency,andcostbenefits.

1.2 Research Significance

Despite advancements in steel construction, limited comparativeresearchexistsontheperformanceofHRSand CFS in industrial buildings. As industries seek more sustainableandeconomicalsolutions,evaluatingthesetwo materialsunderstructuralandseismicconditionsbecomes crucial.Thisstudyaddressesthisgapbyanalyzingamid-rise industrial building using both HRS and CFS, focusing on parameters such as bending moments, shear forces, axial forces,deflection,andseismicbehavior.

Theprimaryobjectivesofthisresearchare:

Tocomparethestructural efficiencyandload-bearing capacityofHRSandCFSsections.

To assess the material and weight efficiency of both steeltypes.

To evaluate cost implications across fabrication, transportation,anderectionphases.

To analyze seismic performance using Time History AnalysisinSTAADsoftware.

This study aims to provide engineers and designers with data-driveninsightstosupportmaterialselectioninmodern industrialconstruction.

2. Literature Review

2.1 Steel Structures in Industrial Buildings

Steelisapreferredmaterialinindustrialconstructiondueto itshighstrength-to-weightratio,modularity,andresistance toenvironmentalloads.Itenableslargeunobstructedspans essential for warehouses, factories, and other industrial operations. The adaptability of steel also supports faster constructionandreducedlaborcosts(Chenetal.,2017).

Hot-rolled steel sections are manufactured at high temperatures, allowing for ductile and strong structural members like beams and columns. Their resistance to bucklingandabilitytohandleheavyloadsmakethemideal forprimarystructuralcomponentsinlarge-scaleindustrial buildings(AISC,2018).However,theyareheavierandmore energy-intensive to produce, increasing costs and environmentalimpact(Smith&Brown,2017).

Cold-formedsteelisshapedatroomtemperature,producing lightersectionswithhighyieldstrength.Itiscommonlyused forsecondarymemberssuchaspurlins,girts,anddecking. CFS is advantageous in terms of weight reduction,

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

transportation ease, and customization (Mandal & Chakraborty, 2021). Limitations include lower buckling resistance under compression and potential for corrosion overtime(Zhouetal.,2022).

2.4 Design Standards for Steel Structures

Steeldesignisgovernedbynationalandinternationalcodes. HRSdesignfollowsIS800(India),AISC(USA),andEurocode 3(Europe),whileCFSiscoveredunderIS801andAISIS100. Thesestandardsaddresskeyaspectslikestrength,stability, serviceability, and connection detailing (Sharma & Gupta, 2016).

2.5 Comparative Studies on HRS and CFS

Previousstudieshaveexploredseveralperformanceaspects:

Fire Resistance:Crostietal.(2009)emphasizedtheneed foradvancedfiremodeling,particularlyforCFSdueto itsthin-wallednature.

Joint Behavior:Bayanetal.(2011)andLeeetal.(2014) identifiedjointweaknessesinCFSstructures,especially underload.

Seismic Performance: Petruzzelli et al. (2012) and Ragavanetal.(2018)showedthatbothHRSandCFScan performwell underseismicloading,providedbracing andconnectiondetailingareoptimized.

Buckling Analysis: Garifullin & Nackenhorst (2015) reportedthatinitialimperfectionssignificantlyinfluence CFScolumnbehavior.

Applications and Cost: Shabari & Prasad (2017) demonstratedthecost-effectivenessofCFSinhousing systems,whileThande(2014)highlightedkeystructural componentsinwarehousedesign.

2.6 Research Gap

Although individual performance studies exist, few works offeradirect,comprehensivecomparisonofHRSandCFSin mid-rise industrial buildings. There is a particular lack of studiesinvolvingdynamicloadanalysisusingtoolslikeTime History Analysis. This research aims to fill this gap by evaluatingthestructuralandeconomicperformanceofboth steeltypesunderidenticalloadingconditionsusingSTAAD software.

3. Methodology

3.1 Overview

Thisstudyadoptsacomparativeapproachtoevaluatethe structural behavior and cost-effectiveness of industrial buildingsconstructedusinghot-rolledsteel(HRS)andcold-

formed steel (CFS) sections. Using STAAD PRO software, both structural systems are modeled and analyzed under identical geometric, material, and loading conditions, including seismic analysis, to assess their overall performance.

A mid-rise industrial building is designed with consistent geometry for both HRS and CFS models. Keyspecificationsareasfollows:

Table 3.1Geometric Parameters of Model

Parameter

Details

BuildingType Rectangularcladdedbuilding

SectionType ISsections(HRSandCFS)

SupportCondition Fixed

Length 35meters

Width 12meters

Height 13meters (10meave+3mtrussrise)

TrussType Howetype

NumberofTrusses 10

Span 12meters

OpeninginWallArea 10%

LifeofStructure 50years

TerrainCategory 2

ClassofStructure A

Topography Flat(<3°slope)

RoofCovering Corrugatedmetalsheets (5kg/m²)

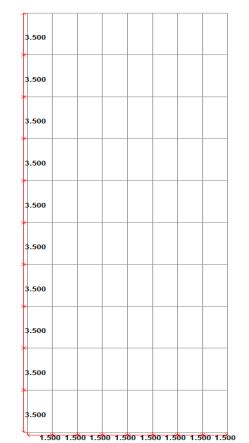

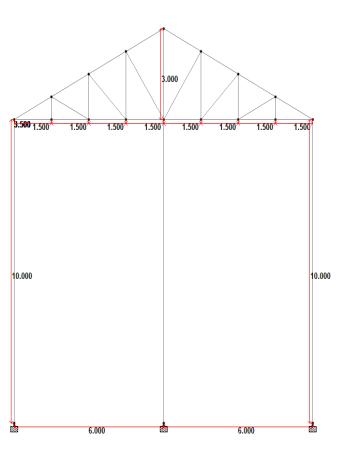

a) TopView b) FrontView

Figure 3.1 Top view abd front view of geometric layour

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Thebuildinglayoutincludestypicalbeam-columnframing for industrial use. Load combinations are based on IS 800:2007 for limit state design, including dead load, live load,andseismicloadcases.

3.3 Material Selection

Material selection emphasizes structural performance, availability,andeconomicfeasibility:

Hot-Rolled Steel (HRS): Standard I- and H-sections selectedfortheirhighstrengthandstiffness,commonly usedinindustrialframeworks.

Cold-FormedSteel(CFS): C-andZ-sectionschosenfor their lightweight and cost-effective characteristics, suitableforefficientloadtransferwithreducedmaterial usage.

MaterialoptimizationisperformedviaSTAADPROtoensure codecomplianceandstructuraladequacy.

3.4 Structural Analysis Using STAAD PRO STAADPROisusedfor:

Modeling: Accurate 3D models including geometry, boundaryconditions,sectionproperties,andloading.

Analysis: Linear static and dynamic (Time History) analysisforperformanceevaluationundervariousload conditions,includingdead,live,wind,andseismicloads.

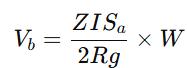

3.5 Seismic Analysis

Seismic behavior is evaluated as per IS 1893:2016 using parameterssuchas:

SeismicZoneFactor,ImportanceFactor,andResponse ReductionFactor

BaseShearCalculationusingtheISformula

Time Period Evaluation based on empirical and analyticalmethods

Base Shear Distribution across the height based on stiffnessandmass

Dynamic response parameters such as base shear, time period,storydrift,andsupportreactionsarerecordedand comparedforbothHRSandCFSmodels.

3.6 Comparison Parameters

The comparison is based on the following structural and economiccriteria:

Axial Forces: Abilitytoresistverticalloadsincolumns andtrussmembers

SeismicResponse: Timeperiod,baseshear,andmode shapes

Deflection: Maximumdisplacementunderserviceloads

Shear Forces and Bending Moments: Resistance to lateralandflexuralloads

Support Reactions: Impact on foundation loads and design

Cost Analysis: Material,fabrication,anderectioncosts

Thismethodologyprovidesaframeworkforevaluatingthe suitability of HRS and CFS in industrial buildings, offering insightsformaterialselectionandstructuraloptimization.

4. Modelling and Calculations

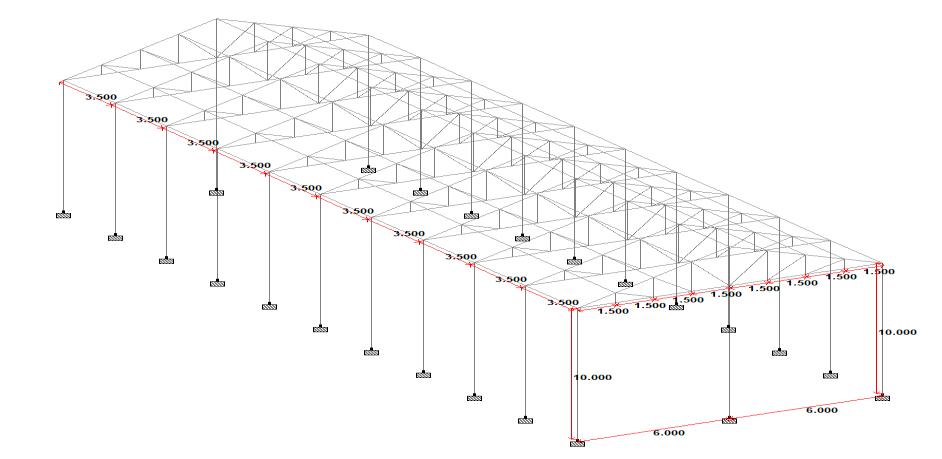

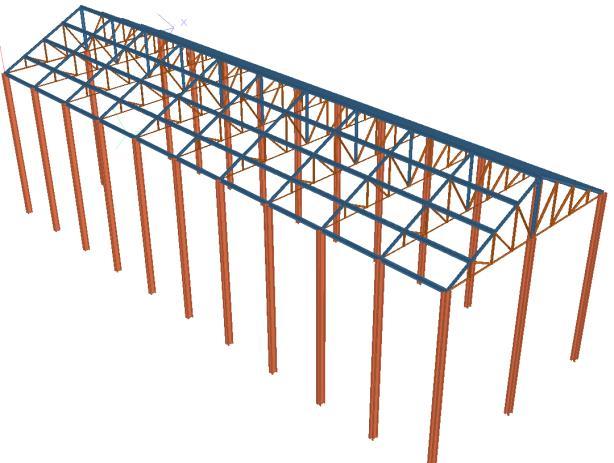

ModelGeometry: FollowingGeometryispreparedwith thehelpofstructuralwizardtoolinstaadPro.

Figure 4.1 Isometric view of geometric layout

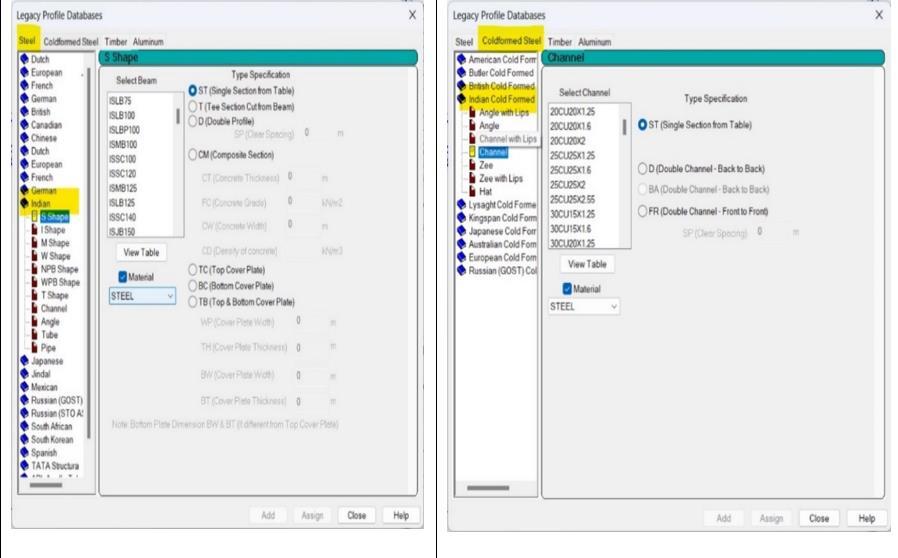

MaterialProperties: MaterialPropertiesforbothtypes ofstructuresareassignedformStaaddatabaseascold formedsteelIndiansectionandHotrolledsteelIndian section.

© 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page99

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

Figure 4.2 Assignment of Material Properties

AfterAssignmentofgeometricandmaterialproperties structurewilllooklikeasfollows:

Figure 3.3 Material propert Assigned modal

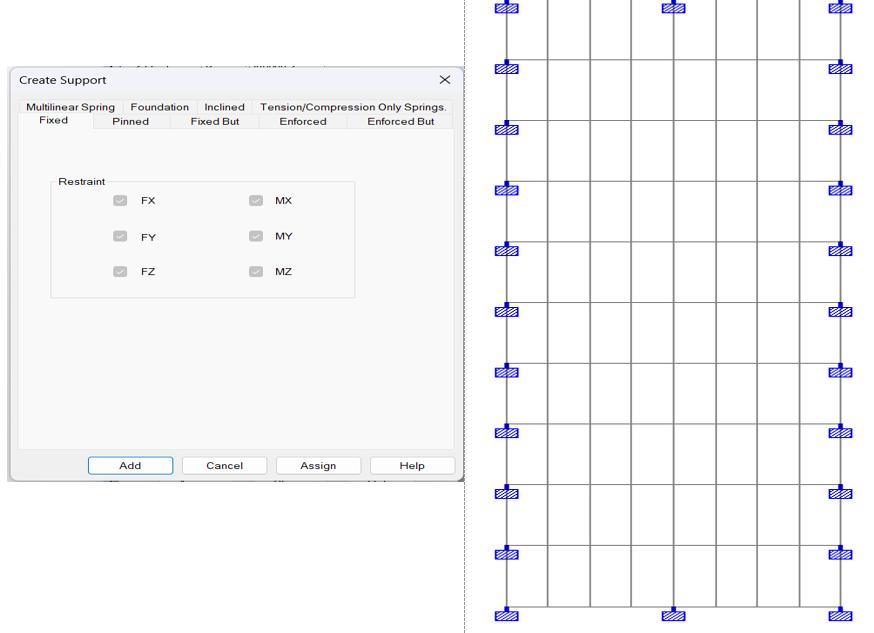

Support Conditions: Fixed Support is used at all columnsasshowninfigurebelow

Figure3.4Assignmentofsupports

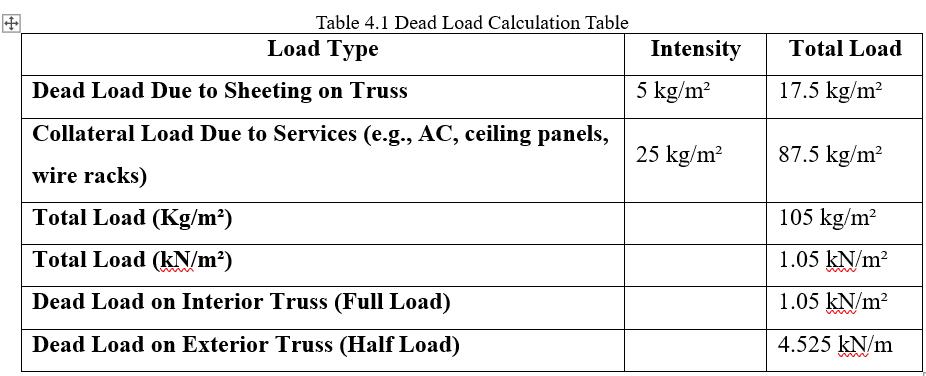

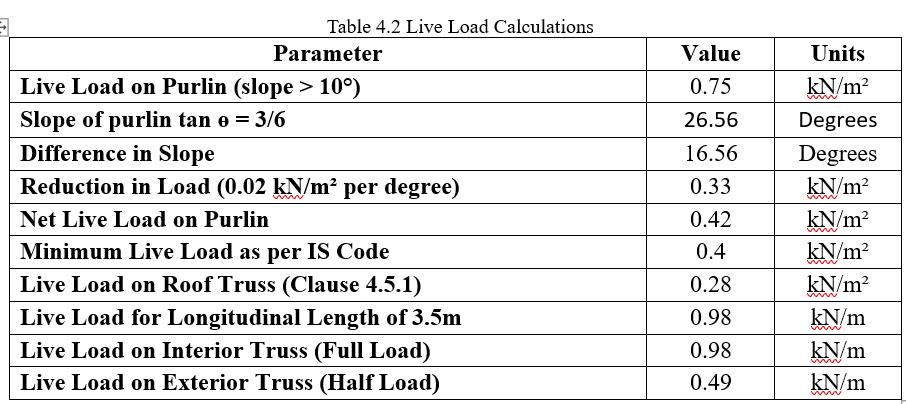

Load Calculation

The"PerformAnalysis"commandinstructuralanalysis softwaresuchasSTAADisusedtoexecutetheanalysis of a structural model based on the defined geometry, loads, load combinations, boundary conditions, and material properties. By running this command, engineers can determine the structure’s response, including deflections, stresses, and support reactions. Theanalysiscancover static,dynamic,linear, ornonlinearmethods,dependingontheproject’scomplexity. This step is essential for evaluating the structure’s safety,stability,andserviceability,allowingdesignersto identifyandaddressissueslikeexcessivedeflectionsor overstressingbeforeconstructionbegins.

5.1 Seismic

The seismic analysis reveals that cold-formed steel (CFS) structures demonstrate improved seismic efficiency compared to hot-rolled steel (HRS) structures. The CFS frame,withasignificantlylowerseismicweight(290.27 kN vs.457.88 kNforHRS),experiencesabout36%lowerbase shear(-11.33 kNvs.-17.83 kN).Thisreductionismainlydue tothelighternatureofCFS,whichreducesseismicforces.

The time period of the CFS structure is longer (0.68 s vs. 0.58194 s), indicating lower stiffness and resulting in reducedspectralacceleration(1.956 gvs.2.337 g).Minimum base shear is also lower for CFS (-1.93 kN compared to3.21 kNforHRS).

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

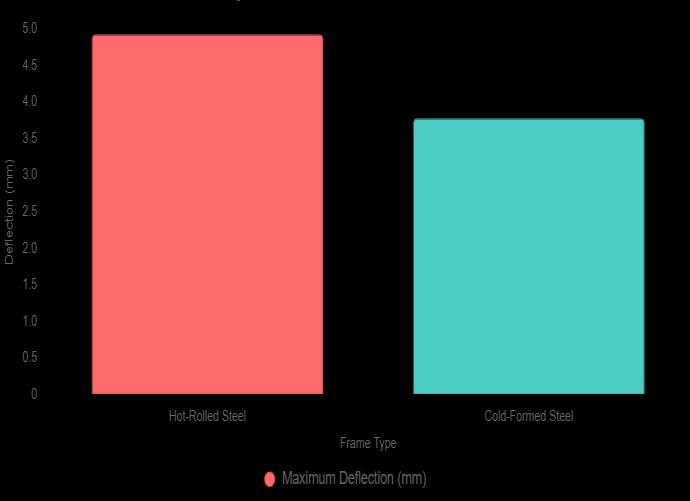

5.2 Maximum Deflection

Thehot-rolledsteelframeexhibitsamaximumdeflectionof 4.93 mm, while the optimized CFS frame shows a lower deflectionof3.78mm.Thisreductionindeflectionhighlights thesuperiorstructuralstiffnessandperformanceoftheCFS frameunderload,enhancingitsserviceabilityandaesthetic appeal.

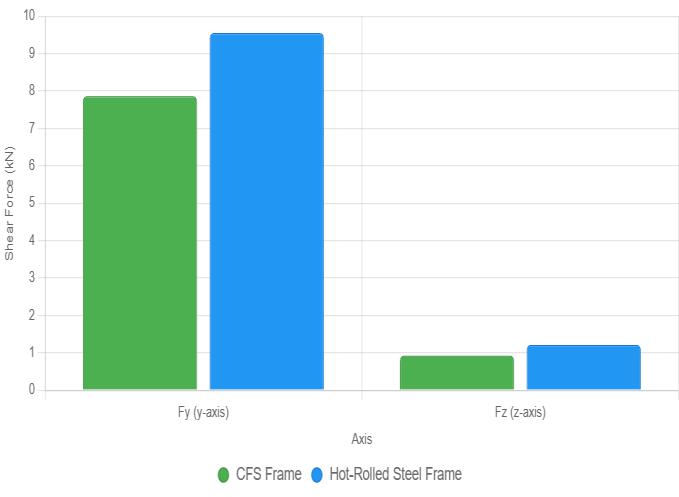

5.3 Maximum Shear Forces

Thecomparisonofmaximumshearforcesrevealsthatthe optimized cold-formed steel (CFS) frame exhibits lower shearforcesthanthehot-rolledsteelframe.Specifically,the CFSframeshowsmaximumshearforcesof7.863 kNabout they-axis(Fy)and0.928 kNaboutthez-axis(Fz),compared to 9.551 kN and 1.211 kN, respectively, for the hot-rolled steelframe.

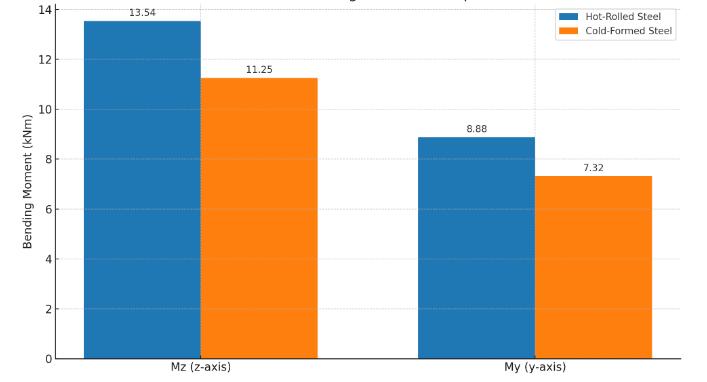

5.4 Maximum Bending Moments

Cold-formedsteel(CFS)showslowerbendingmoments(Mz =11.254 kNm,My=7.321 kNm)thanhot-rolledsteel(Mz= 13.539 kNm, My = 8.876 kNm), indicating better loadhandlingefficiencyandreducedflexuralstress makingCFS acost-effectivechoiceforconstruction.

5.5 Maximum Axial Force Comparison

Cold-formed steel (CFS) shows a higher axial force (47.315 kN) than hot-rolled steel (HRS) (40.280 kN), indicatingHRShandlesaxialloadsmoreefficiently.However, CFS offers benefits like lower weight and cost, making it suitable where overall efficiency and economy are priorities.

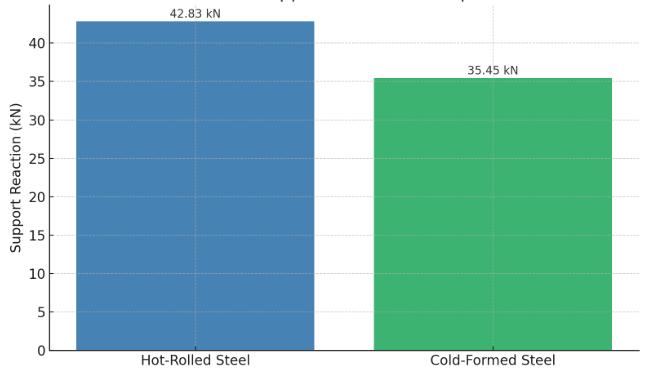

5.6 Maximum Support Reaction

The maximum support reaction for cold-formed steel (35.45 kN)isapproximately17.2%lowerthanthatofhotrolled steel (42.833 kN). This indicates better load distributionefficiencyinCFS,resultinginreducedstresson foundations, cost savings, and faster, easier installation, makingitamorepracticalandeconomicalchoiceformodern construction.

2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

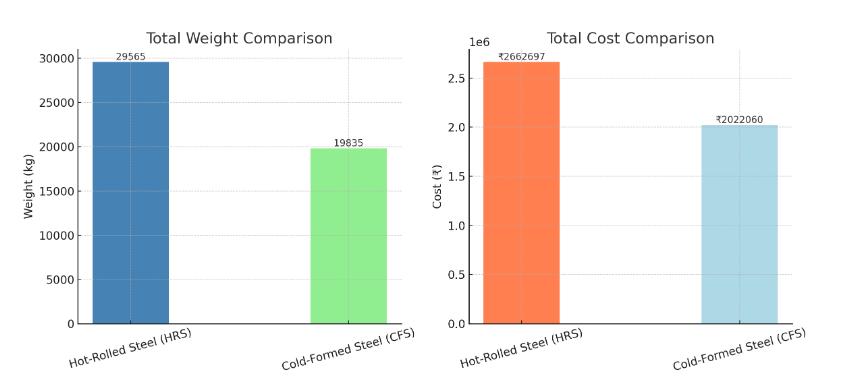

5.7 Cost Comparison

Thecostanalysisbetweenhot-rolledsteel(HRS)andcoldformedsteel(CFS)revealsasignificanteconomicadvantage infavorofCFS.Thedatapresentedbelowsummarizesthe total material weight, overall cost, and cost savings associated with using CFS in place of traditional HRS sections. This analysis confirms that CFS can lead to approximately24%costsavingscomparedtoHRS.

5. Conclusions

Thisstudyconductedadetailedcomparisonbetweenhotrolled and cold-formed steel sections for a 3D mid-rise industrialbuildingframe,underidenticaldesignandloading conditions.

Cold-formed steel (CFS) sections exhibited lower bending moments (11.254 kNm and 7.321 kNm) compared to hot-rolled steel (HRS) sections (13.539 kNm and 8.876 kNm). This implies improved flexural efficiencyinCFSframes,whichmayallowformaterial optimization.

CFS structures demonstrated lower maximum shear forces(7.863kNand0.928kN)thanHRS(9.551kNand 1.211 kN). This reflects better handling of lateral stressesandimprovedinternalforcedistribution.

The axial force capacity in CFS was slightly higher (47.315kN)comparedtoHRS(40.28kN).Althoughthis may indicate slightly less axial load efficiency, the advantages in weight and cost still favor CFS in most scenarios.

Maximumsupportreactionswere35.450kNforCFSand 42.833kNforHRS,showingabouta 17.2% reduction withCFS.Thishighlightsimprovedloaddistributionand apotentialforlighterfoundationdesign.

CFSframesexperiencedamaximumdeflectionof 3.78 mm,comparedto 4.93mm inHRS.Thisindicatesbetter stiffnessandserviceabilityperformanceforcold-formed sections.

Duetoitslighterweight,CFSgenerated 36%lessbase shear compared to HRS in seismic conditions. The longer time period due to reduced stiffness further contributestolowerseismic forces,makingCFSmore favorableinearthquake-proneareas.

CFSprovidesanestimated 24%costsavings overHRS. Thisis attributed toreducedmaterial weight,simpler handling, and faster construction. In cost-sensitive regions like India, CFS offers a significant economic advantage.

Overall, the study concludes that cold-formed steel is a superior alternative for industrial steel frames, especially where weight, cost, and seismic performance are critical factors. Its availability, cost-effectiveness, and structural efficiency make it an excellent choice for modern constructionapplications.

WhilethecurrentresearchestablisheskeybenefitsofCFS over HRS, several areas remain open for further investigation:

AnalysisofTallandHeavyStructures: Futurestudies could evaluate the scalability of CFS in high-rise buildings or heavy industrial structures, where additionaldesignconsiderationsareinvolved.

Seismic and Wind Load Studies: More detailed assessmentsareneededtoexploreCFSbehaviorunder dynamic loads in high seismic zones or regions with intensewindactivity.Thiswillhelprefinedesigncodes andguidelines.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 07 | Jul 2025 www.irjet.net p-ISSN: 2395-0072

ConnectionBehavior: Structuralperformanceishighly influenced by connection behavior. Research should focusontestingvariousCFSconnectiontypes(bolted, welded,etc.)underdifferentloadconditionstodevelop efficientjointdesigns.

Hybrid Structural Systems: Exploringhybriddesigns thatcombineCFSwithreinforcedconcrete,timber,or other materials could offer performance and sustainability benefits. These systems may be particularly valuable in mixed-use or modular construction.

By addressing these areas, future research can further strengthenthecaseforcold-formedsteelasasustainable, economical, and high-performance solution in modern structuralengineering.

Reference

[1]. Kalyanshetti,M.G.,&Mirajkar,G.S.(2012).Comparison between Conventional Steel Structures and Tubular Steel Structures. International Journal of Engineering ResearchandApplications,2(6),1460-1464.Retrieved fromwww.ijera.com

[2]. IS 800:2007. General Construction in Steel – Code of Practice.BureauofIndianStandards.

[3]. IS801:1975.CodeofPracticeforUseofStructuralSteel in Overhead Transmission Line Towers. Bureau of IndianStandards.

[4]. IS875:2015,Part1.CodeofPracticeforDesignLoads (OtherthanEarthquake)forBuildingsandStructures. BureauofIndianStandards.

[5]. IS875:2015,Part2.CodeofPracticeforDesignLoads (OtherthanEarthquake)forBuildingsandStructures. BureauofIndianStandards.

[6]. IS875:2015,Part3.CodeofPracticeforDesignLoads (OtherthanEarthquake)forBuildingsandStructures. BureauofIndianStandards.

[7]. IS806:2009.CodeofPracticeforUseofSteelTubesfor BuildingsandStructures.BureauofIndianStandards.

[8]. Dubina, D., et al. (2007). Analysis and Design of Steel Structures.

[9]. GaryS.(2010).AnalysisandDesignofSteelStructures. Retrieved from http://raselpics.ru/steel-designstructures-practice.pdf

[10]. IIT-Kharagpur.(2023).Designof Steel Structures. NPTELOnlineMaterialfortheStudents.Retrievedfrom www.scribd.com

[11]. Subramanian,N.(2014).DesignofSteelStructures. OxfordUniversityPress.

[12]. Ghersi, A., Landolfo, R., & Mazzolani, F.M. (1994). Bucklingmodesofdoublechannelcold-formedbeams. Thin-WalledStructures,19.

[13]. Calderoni,B.,DeMartino,A.,Ghersi,A.,&Landolfo, R.(1994).Ontheseismicresistanceoflightgaugesteel frames. In Proceedings of the 1st International Conference on the Behaviour of Steel Structures in SeismicAreas(STESSA’94),Timisoara,Romania.

[14]. Calderoni,B.,DeMartino,A.,Ghersi,A.,&Landolfo, R. (1997). Influence of local buckling on the global seismic performance of light gauge portal frame. In Proceedingsofthe2ndInternationalConferenceonthe BehaviourofSteelStructuresinSeismicAreas(STESSA ’97),Kyoto.

[15]. Fiorino,L.,DellaCorte,G.,&Landolfo,R.(2004).An experimental study on seismic behavior of sheathed cold-formedsteelstudshearwalls.InProceedingsofthe XICongressoNazionale“L’ingegneriaSismicainItalia” (ANIDIS2004),Genova.