International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Kartik Patel1, Rubina Chaudhary2, Rakesh Maheshwari3

1Senior Project Associate, 2Head, 3Scientist E and Head

1’3Value Addition Research and Development (VARD) and Intellectual Property Rights Management (IPM)Engineering

1’3National Innovation Foundation-India (NIF), an autonomous Institute of Dept. of Science and Tech. Govt. of India

2Devi Ahilya Vishwavidyalaya, Indore, Madhya Pradesh

Abstract - Incorrect drying of cardamom significantly impacts quality, quantity, and economic viability, resulting in a 10-20% loss in quality and quantity and a 5-10% loss in market value. Causal factors include inadequate techniques, insufficient training, and poor handling and storage practices. Implementing optimal drying technologies and proper training can mitigate these losses. Cardamom drying is a crucial step in preserving the quality and aroma of this valuable spice. Various drying technologies are employed in India, but their efficiency, capacity, quality retention, and cost- effectiveness vary significantly. This review evaluates cardamom drying technologies to bring to light the potential of current technologies and future direction for growth. The results indicate that Solar and Heat Pump dryers offer the fastest drying times, ranging from 6 to 12 hours, and superior quality retention. In contrast, Biomass dryers demonstrate low energy consumption and moderate drying times of 14-19 hours. Conversely, Electric dryers and Traditional Bhattis exhibit high energy consumption and compromised quality retention. A comprehensive cost analysis reveals Solar dryers as the most economical option, closely followed by Biomass dryers. This review provides critical insights for cardamom stakeholders, policymakers, and researchers, underscoring the potential of energy-efficient and cost-effective drying technologies to enhance the competitiveness of India's cardamom industry. To boost both quality and productivity in cardamom production, India must prioritize the adoption of efficient and cost-effective drying technologies.

Key Words: Cardamomdrying,energyefficiency,qualityretention,cost-effectiveness,solardrying,heatpumpdrying,biomass drying

Cardamom(Elettaria cardamomum (L.)Maton)(Fig1),aptlyreferredtoasthe"QueenofSpices,"isahighlyvaluedspicecrop nativetothetropicalregionsofIndiaandSoutheastAsia[1][2].Thisaromaticcropiswidelycultivatedforitsseeds,whichare enclosedinagreen,pod-likefruit,prizedfortheiruniqueflavour,aroma,andmedicinalproperties[3].Cardamomproduction inIndiasignificantlycontributestotheglobalmarket,accountingforapproximately40%ofworldwideproduction[4].India producesaround40,000-50,000tonsofcardamomannually,withmajorproducingstatesincludingKarnataka,Kerala,Tamil Nadu,andNEregion[4][5].

ThemaincardamomvarietiescultivatedinIndiaareAlleppeyGreen,CoorgGreen,andNagaJhaal[1]alongwithNjallani variety [6][7]. However, the industry faces several challenges, including climate change, diseases, and pests [3]. Rising

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

temperaturesandchangingrainfallpatternsaffectyieldandquality,whilefungaldiseasesandinsectinfestationsresultin significant losses [8]. To address these issues, the Government of India (GoI) has initiated programs like the National HorticultureMissionandtheSpiceBoardofIndia[9].

India'scardamomexportsarepredominantlydirectedtotheMiddleEast,Germany,Europe,theUSA,andSoutheastAsia[10] [11].Whiletheseestablishedmarketsremainstrong,therearesignificantopportunitiesforgrowthinemergingmarketsanda risingdemandfororganicandspecialtycardamom[12].Domestically,thecardamomindustryiswitnessingincreaseddemand forcardamom-basedproducts[13],alongsidethepotentialforvalue-addedproductslikecardamomoilandpowder[1],which offerpromisingavenuesformarketexpansion.

Tograbtheseopportunities,theIndiancardamomindustryneedstoprioritize improvementinproductivity,quality,and sustainabilitythroughfocusedresearchanddevelopment,farmers’training,andtheadoptionofinnovativetechnologies.One suchareaofinnovationliesinpost-harvestprocessing,particularlydryingtechnologies.Forinstance,thebenefitsofsolar dryingsystemsshouldbehighlighted,whichreducedryingtimebyapproximately50%comparedtotraditionalopensun dryingmethods,[14].Similarly,acomprehensiveperformanceanalysisofsolarandheatpumpdryers,demonstratingtheir effectivenessinpreservingthegreennessandessentialoilcontentofcardamom[15].Furtheremphasizestheimportanceof adoptingadvanceddryingtechniquestoaddressinefficienciesintraditionalmethodsandreducetheexcessiveconsumptionof fuelwood[16].

ThisintegratedapproachforenhancingboththemarketstrategiesandprocessingtechnologiescanhelpensurethatIndia remainscompetitiveinboththeglobalanddomesticcardamommarketswhileadheringtosustainablepractices.

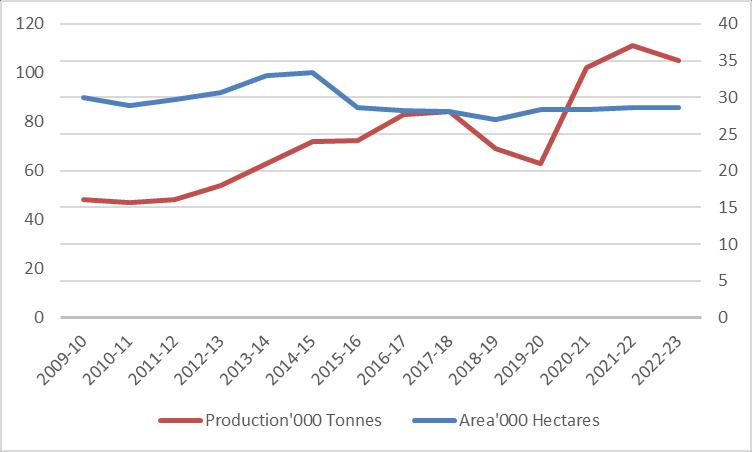

CardamomcultivationinIndiahasseenfluctuatingtrendsinareaandproductionovertheyears(Chart1).From2009–10to 2014–15,bothareaandoutputgenerallyincreased,withapeakof100,000hectaresand24,000tonnesin2014–15.Althoughthe areadeclinedinsubsequentyears,productioncontinuedtorise,reaching28,000tonnesby2017–18.Adipoccurredin2018–19, withbothareaandproductionfalling.However,from2019–20to2022–23,thecultivatedarearemainedstablearound85,000–86,000hectares,whileproductionshowedsignificantgrowth,peakingat37,000tonnesin2021–22.Thesetrendsreflectthe adaptabilityofcardamomfarminginIndia,withproductionimprovingdespitevaryingcultivationareas.

CardamomharvestingtypicallyoccursbetweenAugustandNovember,dependingontheregionandvariety[1][17].The idealharvestingstageiswhenthecapsulesaremature,green,andslightlysofttothetouch.Hand-pickingandstem-cuttingare thetwoprimaryharvestingmethods,withhand-pickingbeingmorelabour-intensivebutresultinginminimaldamagetothe capsules.Afterharvesting,cardamomundergoesaseriesofpost-harvestprocessestopreserveitsqualityandflavour.Cleaning isthefirststep,whichinvolvesremovingimpurities,dirt,anddebrisfromtheharvestedcapsules[3].Thiscanbedonethrough hand-sorting, air-jet cleaning, or mechanical cleaning. Drying is a critical step in the post-harvest process, reducing the moisturecontentto10-12%topreventspoilageandMoldgrowth[8].Variousdryingmethodsareemployed,includingsun drying,solardrying,electricdrying,andfuel-baseddryinglikebiomassandfossilfuel[17].Curingisanotheressentialstep, whichinvolvestreatingthecardamomcapsuleswithheat,steam,orchemicalstoinhibitMoldgrowth,preservecolourand

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

flavour,andreducemoisturecontent[9].Gradingandpackagingfollow,withcardamomsortedbysize,colour,andquality, thenstoredinairtightcontainersorbags.Properstorageisessential,typicallyinacool,dryplace(temperature:10–20°C, humidity:60–70%)foruptotwoyears[10].However,post-harvestlossesremainasignificantchallengebothinthefieldand themarket,withestimatedlossesrangingfrom30%to50%[13][18].

Dryingisacriticalstepinpreservingcardamom'squality,ensuringitslongevityandviabilityforstorageandexport.Fresh cardamompodshaveahighmoisturecontentofaround80%,makingthemsusceptibletospoilage,Moldgrowth,andinsect infestation[1][19].Topreventtheseissues,itisessentialtoreducethemoisturecontentto10-12%throughproperdrying. Proper drying prevents spoilage by inhibiting microorganism growth, minimizing yeast fermentation, and preserving cardamom'snaturalflavourandaroma[3].Reducedmoisturecontentcreatesanunfavourableenvironmentformicroorganisms, reducing the risk of mycotoxin production, contamination, and spoilage [8]. Drying also plays a vital role in maintaining cardamom's distinctive flavour and aroma by retaining its essential oils [1]. Proper drying preserves cardamom's sweet, pungent,andaromaticflavour,maintainingitsdistinctivearomaandenhancingtheoverallsensoryexperience[3].Furthermore, properdryingextendscardamom'sshelflife,enablingstorageforextendedperiodswithoutsignificantqualityloss[9].Reduced moisturecontentpreventsre-absorptionofmoisturefromtheenvironment,minimizesoxidation,andpreservescardamom's naturalcolourandflavour[8].Finally,driedcardamommeetsinternationalqualitystandards,enablingexporttoglobalmarkets [10].Compliancewithinternationalregulations,suchasISOandASTM,enhancesmarketaccessandcompetitiveness.

InIndia,thequalitystandardsfordriedcardamomarespecifiedbytheBureauof IndianStandards(BIS).AccordingtoIS 1907:1984,largecardamomshouldhaveamaximummoisturecontentof10%andaminimumvolatileoilcontentof5%[20]. Forsmallcardamom,IS13446:2009stipulatesamaximummoisturecontentof12%andaminimumvolatileoilcontentof6% [21].Additionally,IS1797:1985providesgeneralspecificationsforcardamom(Elettariacardamomum(L.)Maton),including requirements for colour, flavour, and aroma [22]. Furthermore, IS 13145:1993 outlines standards for dried cardamom capsules,coveringaspectssuchaspackagingandlabelling[23].Adherencetothesestandardsensuresthatdriedcardamom meetstherequiredqualityparametersfordomesticconsumptionandexport.

Lossesincurredduetoincorrectdryingofcardamomcanbesubstantial,affectingquality,quantity,andeconomicviability. Incorrect drying can lead to flavour and aroma degradation, colour changes, texture changes, and reduced shelf life [1]. Additionally, moisture content fluctuations can result in weight loss, shrinkage, or breakage during drying, leading to inconsistent quality [3]. The economic implications of incorrect drying are significant, with reduced market value due to inferior quality, decreased export potential, and increased energy costs associated with re-drying or re-processing [9]. Estimatessuggestthatincorrectdryingcanresultina10-20%lossinqualityandquantity[9],witha5-10%lossinmarket value due to inferior quality [9, 24]. Factors contributing to incorrect drying include inadequate drying techniques or equipment,insufficienttrainingorexpertise,inconsistenttemperatureandhumiditycontrol,andpoorhandlingandstorage practices[8].Tomitigatetheselosses,implementingoptimaldryingtechnologies,trainingfarmersandprocessorsonproper dryingtechniques,monitoringtemperature,humidity,andmoisturelevels,andimprovinghandlingandstoragepracticesare essential.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

FollowingsixtypesofdryingmethodsareusedfordryingcardamomFig.2showsthesemethods.

Traditionaldryingmethods,suchassundryingandsmokehouses,remainwidelypracticedduetotheirsimplicityandlow initialcosts[1].Sundryinginvolvesspreadingcardamomonmatsorconcretefloorsunderdirectsunlight.Althoughsimpleand cost-effective,thismethodishighlyweather-dependent,labour-intensive,andsusceptibletocontamination.Itoftenresultsin inconsistentdryingqualityandquantitylossesduetobirdsandpestinfestations.Smokehouses,ontheotherhand,usesmoke from burning wood or biomass to dry cardamom. Although this imparts a distinctive flavour and aroma to the spice, it introduceshealthrisksandenvironmentalconcernsduetosmokeexposure.Despitewidespreaduse,thesemethodsexhibit severalinefficiencies.Highenergyconsumption,unevendrying,andthelossofessentialoils crucialforcardamom'sflavour andmarketvalue arecommondrawbacks.Asemphasizes,thesetraditionalpracticesoftenfailtomeetmodernefficiencyand qualitystandards,highlightingtheneedforinnovativeandsustainabledryingtechnologies,[14].

Solar drying is an effective method that utilizes natural sunlight to evaporate moisture from cardamom, offering energy efficiencyandlow-costbenefits.Solardryerscanbecategorizedintodirect,indirect,ormixed-modetypes,eachdesignedwith componentssuchassolarcollectors,dryingchambers,aircirculationsystems,andtemperaturecontrolmechanisms.Thisecofriendlyalternativesignificantlyreducesdryingtimeby approximately50%comparedtotraditional opensundrying.As demonstrationonsolardryersareparticularlyeffectiveinpreservingthegreennessandessentialoilcontentofcardamom, makingthemasustainableandpracticaloptionfordryingprocesses[25].

Electricdryingoffersadvantages,suchasenhancedproductqualityandreducedenergyconsumption.Thismethodensures thatcardamomretainsitsnaturalgreencolour,acriticalfactorforitsmarketvalue.Studies,emphasizetheeffectivenessof electricdryinginovercomingtheinefficienciesoftraditionalmethods,particularlyunevendryingandcontamination,which oftencompromisethequalityofthefinalproduct,[24]. Theprocessofelectricdryingreliesonelectricheatsourcestoremove moisturefromcardamomefficiently[12].Commontypesofelectricdryersincludecabinetdryers,tunneldryers,androtary dryers.Thesesystemsare designedfor easyoperationandprovideuniformdrying conditions,addressingthechallenges

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

associatedwithtraditionalpractices.Keycomponentsofelectricdryerstypicallyincludeelectricheatingelements,drying chambers, air circulation mechanisms, and temperature control systems, ensuring a controlled and consistent drying environment.

Fuel-baseddryingusesfuelslikegas,diesel,orbiomasstogenerateheatfordryingcardamom[13].Fuel-baseddryingsystems forcardamomrelyonenergysourcessuchaswood,diesel,gas,orbiomasstoproduceheatforthedryingprocess.These systemsarewidelyusedinregionswhereelectricityorsolarenergyislessaccessible.Withcomponentsincludingaheating chamber,dryingchamber,andaircirculationsystem,fuel-baseddryersensureuniformandefficientdryingconditions.

Hybriddryingtechnologiesintegratemultipledryingmethods,suchassolar-electric,solar-gas,andelectric-fuelsystems,to achieveoptimaldryingresults[10].Thesesystemsofferdistinctadvantages,includingimprovedenergyefficiency,reduced operationalcosts,andenhancedflexibilityinadaptingtovaryingenvironmentalconditions.Bycombiningsolarandauxiliary energysources,hybriddryingsystemsensureconsistentperformanceevenduringadverseweatherconditions,suchascloudy days. A notable example is the hybrid mixed-mode solar dryer, which efficiently utilizes solar energy supplemented by auxiliarypowersources.Thesedryersoptimizeenergyuse,maintainingconsistenttemperaturelevelscrucialfordryinghighqualityproducts.Asaresult,theynotonlyreduceenergyconsumptionbutalsopreservetheproduct'sessentialproperties, ensuringsuperiorquality[16].

Innovative drying employs advanced technologies to dry cardamom efficiently [13]. Innovative drying technologies for cardamom are transforming traditional practices by enhancing efficiency, quality, and sustainability. Among these advancements,theMicrowaveCardamomDryingMachinestandsoutasarevolutionarysolution[26].Thistechnologyuses microwaveradiationtoexpeditethedryingprocesswhilepreservingtheessentialoilsandvolatilecompoundsthatcontribute tocardamom'sdistinctivearomaandflavour.Unlikeconventionalmethods,itensuresuniformdryingandsignificantlyreduces processing time. Innovative dryers include microwave, radio frequency, heat pump, freeze, and vacuum dryers, with advantagessuchasfastdryingratesandenergyefficiency.

Overahundredresearchpapersandarticleswerereviewed,ofwhichapproximatelythreedozenwerefoundtoberelevant. Thefindingsonvarioustypesofdryersusedforcardamom,alongwiththeircomparativeanalysis,arepresentedinTable1.

largecardamom curing chambers (Bhattis) in Sikkim

ICRI Improved Bhattiforlarge cardamom curing

perbatch EnergySource:Firewood andBiomass PowerConsumption:NA

Small Bhattioperates withverypoor operatingthermal efficiencyofthe order5-15% resultingin wastageofhuge quantities [35]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

LPGfiredsmall cardamom drier

22-23 hours NA

Abraham Low Pressure Cardamom Drying Chamber 6-8 hours

Cardamom Dryer developed By UAS, Bangalore 10hours

50-100kg perbatch

Low- Cost portable biomass fired dryer for cardamom drying 14-19 hours 20-30 kg perbatch

Solar-biomass hybrid dryer (SBHD) for small cardamom 19hours NA

Solardryerfor large cardamom 24hours(3 sunny days)

20-50kg perbatch

Solarandheat pumpdryerfor small cardamom 10-15 hours (Solar)

20-50kg perbatch

12-15 hours(heat pump dryer) 50-200 kg pe rbatch

EnergySource:LPG Fuel: LPG (Liquefied PetroleumGas)Energy Consumption: 1.43 kg LPG/kg cardamom(approx.) Moisture content: 8%(w.b.)

Energy Source: ElectricityandLPG

Colour retention: Good

Power Consumption: 1 HP(0.75kW) motor Moisture

NA

Good

EnergySource:Biomass (firewood)

10%

Energy Consumption (SEC):0.67kg firewood/kgcardamom (average)

Good

EnergySource:Solarand Biomass (hybrid) Specific EnergyConsumption (SEC):NA

Moisture content: 9.1%(w.b)

Colour retention: Good (better in SBHDthanbiomass mode) Highest percent of oilcontent.

Energy Source: Solar Energy

Moisture content: 10.1%(w.b)

Power Consumption: 0

kW (Passive solar drying)

Colour retention: Excellent

Energy Source: Solar Energy

Moisture content: 10-12%

Power Consumption: 0

kW (Passive solar drying)

Colourretention: Poor (greenness value:-0.8to-3.25)

Energy Source: Electricity PowerConsumption:NA

Moisture content: 10-12%

Colour retention: Excellent (greennessvalue: higher)

28.63% and 23.98% were obtained for the SBHDandbiomass mode [30]

Collectorefficiency of solar dryer for drying large cardamom was 40.02 % in the month of December [31]

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

Indirect type flat plate collector solar dryerforblack cardamom

24hours 20-50kg perbatch Energy Source: Solar Energy Power Consumption: 0 kW (passive solar drying)

Medium Daily energy efficiency of the solar energy accumulator reached 35.8%, while the daily exergy efficiency reached 13.84%. Exergyefficiencyof thedryingchamber wasintherangeof 47–97%

Hot air convective drying for small cardamom

6-12hours50-200 kg pe rbatch

Note:'NA'indicatesinformationnotavailable.

Cardamomdryingtechnologiesvarysignificantlyintermsofdryingtime,capacity,energysource,energyconsumption,costs, spacerequirements,andefficiency,cateringtodifferentneedsandscalesofproduction(Table1).TheLPG-firedsmallcardamom dryer,forinstance,operateswithin22-23hours,consumingapproximately1.43kgofLPGperkgofcardamomwithathermal efficiencyof75.74%.Thismethodachievesgoodcolorretention,an8%moisturecontent(w.b.),andcostsRs.2.10perkg, makingitaviableoptionforsmalltomediumspaces.Ontheotherhand,theAbrahamLowPressureDryingChamberisfaster, requiringonly6-8hourstodry50-100kgbatchesusingelectricityandLPG.Itisidealforsmallspaces,ensuringgoodcolor retention,andcostsRs.20,000perunit.Similarly,thecardamomdryerdevelopedbyUASBangalore,whichalsocaterstosmallscaleoperations,takes10hourstodry50-100kgbatches,maintainsa12%moisturecontentwithgoodcolorretention,andis pricedatRs.0.3Lakh.Forlower-costoptions,theportablebiomass-fireddryerprocesses20-30kgofcardamomwithin14-19 hoursbyconsuming0.67kgoffirewoodperkgofcardamom,ensuring10%moisturecontentandgoodcolorretention.

Thesolar-biomasshybriddryer(SBHD)exemplifiesahybridapproach,dryingcardamomin19hourswithimprovedcolor retention,amoisturecontentof9.1%(w.b.),andthehighestoilcontent,thoughitsdryingefficienciesstandat28.63%forSBHD modeand23.98%forbiomassmode.Thesolardryerforlargecardamomreliessolelyonsolarenergy,requiring24hours(three sunnydays)forabatchof20-50kg.Thismethodachievesexcellentcolorretention,a10.1%moisturecontent(w.b.),anda collectorefficiencyof40.02%duringDecember.Forsmallcardamom,thesolarandheatpumpdryersoffertwodistinctmodes. The solar mode, although eco-friendly, requires 10-15 hours, processes 20-50kg batches, and yields poor color retention (greennessvalue:-0.8to-3.25).Incontrast,theheatpumpmodeismoreefficient,handling50-200kgbatchesin12-15hours, ensuringexcellentcolorretentionandamoisturecontentof10-12%.

Theevolutionaryjourneyofdryersusedforcardamomdryinghasundergonesignificanttransformationsovertheyears(Figure 2).Initially,traditionalmethodssuchassundrying,smokedrying,andBhattidryingwereemployed.However,withtheadvent ofmechanization,electricdryers,gasdryers,andhotairdryersemerged,improvingdryingefficiency.Advanceddryerswere developed,includingsolardryers,heatpumpdryers,andbiomassdryers.Theseinnovationsenhancedenergyefficiencyand sustainabilityincardamomdrying(Table1).Recently,moderndryerssuchashybriddryers,freezedryers,microwavedryers, andautomateddryershaverevolutionizedtheindustry.Lookingahead,futuredirectionsforcardamomdryingtechnologies includedevelopingenergy-efficientdryerslikegasifiers,sustainabledryingsolutions,advancedautomationandmonitoring systems,andintegratingartificialintelligenceandIoT.Byembracingtheseinnovations,thecardamomindustrycanenhance quality,productivity,andprofitability.

Thecomprehensiveanalysisofvariouscardamomdryingtechnologiesrevealedsignificantvariationsindryingtime,capacity, energyconsumption,quality,cost,andspacerequirements.Thestudydemonstratedthatsolarandheatpumpdryersofferedthe shortest drying time (6-12 hours), while traditional bhattis required the longest time (24-48 hours). In terms of energy consumption,solardryersshowedzeroenergyconsumption,whileLPGfiredandelectricdryersconsumedsignificantamounts. Heatpumpandsolardryersretainedexcellentcolorandmoisturecontent(10-12%).Solardryerforlargecardamomachieved

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

(40.02%)collectorefficiencyand(35.8%)dailyenergyefficiency.ICRIImprovedBhattishowed(5-15%)thermalefficiency, whilehotairconvectivedryingandAbrahamLowPressureCardamomDryingChamberdemonstratedhighefficiencyindrying timeandenergyconsumption.Thecostanalysisrevealedthatsolardryersofferedthelowestcostperkg(Rs.0.3-2.10),while traditional bhattis incurredhighcostsduetofirewoodconsumption.Tooptimizecardamomdrying,adoptingsolarandheat pumpdryingtechnologiesisrecommended.Additionally,promotingbiomassdryersasasustainablealternativetotraditional bhattis anddevelopingcost-effectiveandscalabledryerdesignsarecrucial.Futureresearchshouldfocusoninvestigatinghybrid dryingtechnologies,developingenergy-efficientandcost-effectivedryerdesignsforsmall-scalecardamomproducers,and studying the impact of drying methods on cardamom's nutritional and medicinal properties. The future research may be divertedtowardsestablishinggasifier-baseddryersowingtoitspotentialuseinregionswhereelectricityandadequatesunlight isnotavailable.Byadoptingefficientandsustainabledryingtechnologies,thecardamomindustrycanenhanceproductquality, reduceenergyconsumption,andcontributetoamoreenvironmentallyfriendlyfuture.

TheauthorswouldliketoacknowledgeNationalInnovationFoundation-Indiaforsharingthedetailsofgrassrootstechnology titled“AbrahamLowPressureCardamomDryingChamber”whichwasdeemedusefulfromcomparativeperspective.

TheAuthorsdeclarenoconflictofinterest.

[1] Ambiga,S.,Pandian,R.S.,Saratha,V.,Ashokkumar,K.,Ramasubbu,R.,Lawrence,L.V.,andPandian,A.(2021).Phytochemical analysisandpharmacologicalpotentialofcardamom. Cardamom,227-256.

[2] Ajmera,P.,Singh,A.,ChauhanSharma,L.,andSingh,M.(2018).Cardamomcropproductionandharvesting:Areview. InternationalJournalofFoodScienceandNutrition,3(2),174-178.

[3] Surendran,S.,Prasannan,P.,Jayaram,Y.,Pandian,A.,andRamasubbu,R.(2021).Ethnopharmacologyandphytochemistryof cardamom.Cardamom[Elettariacardamomum(L.)Maton]:Production,breeding,management,phytochemistryandhealth benefits,285-317.

[4] MinistryofAgricultureandFarmersWelfare.(2020).HorticultureStatisticsataGlance.

[5] Aloysius,O.C.(2020).ProductionandpricebehaviourofsmallcardamominIndia:Anevaluation. International Journal of Science and Research (IJSR),9(12).

[6] NationalInnovationFoundation.(2001).Indiainnovates:Firstnationalgrassrootstechnologicalinnovationsandtraditional knowledgeawards.

[7] Anisha,C.S.,Mathew,K.M.,Sasidharan,S.,Jose,S.,Varghese,R.C.,Ranjanan,R.,Geethu,M.,Rao,Y.S.,andRemashree,A.B. (2020).DiversityanalysisofreleasedvarietiesofIndiancardamomusingISSRmarkersrevealnarrowinggeneticbase. Indian Journal of Biotechnology,19,311–322.

[8] Wangchuk,C.,Dem,K.,Nidup,K.,Pelden,T.,Wangdi,D.,andDorji,K.(2023).ImpactofClimateChangeontheProductionof CardamominoneoftheChiwogunderSamtseDzongkhag,Bhutan, International Journal of Scientific Research in Engineering and Management,7(12):1-16.

[9] SpiceBoardofIndia.(2020).AnnualReport2019-2020.

[10] Export-ImportBankofIndia.(2020).India'sSpiceExportPerformance.FoodandAgricultureOrganization,2017

[11] Anbuchelvi,M.(2018).EconomicanalysisofIndiancardamomanditsexporttrends. Economic Analysis, 6(2).

[12] OrganicMarketResearch.(2020).GlobalOrganicSpiceMarketReport.

[13] FoodProcessingIndustryMinistry.(2020).AnnualReport2019-2020.InternationalFundforAgriculturalDevelopment, 2019

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072

[14] Ranjan,P.,Achom,J.,Prem,M.,Chettri,S.,Lepcha,P.T.,andMarak,T.B.(2018).Studyofdifferentdryingmethodseffecton qualityoflarge-cardamom(AmomumSubulatumRoxb.)capsules. An International Refereed, Peer Reviewed & Indexed Quarterly Journal in Science, Agriculture & Engineering, VII,182-186.

[15] Jayakumar,J.,Jeevarathinam,G.,Sudagar,I.P.,Prasath,V.A.,Singh,P.,Kumar,S.D.,andPandiselvam,R.(2024).Performance analysisofsolarandheatpumpdryerofsmallcardamom(ElettariaCardamomumMaton)usingenergyanalysis,drying kinetics,andquality. Biomass Conversion and Biorefinery,14(17),20807-20821.

[16] Afzal,A.,Iqbal,T.,Ikram,K.,Anjum,M.N.,Umair,M.,Azam,M.,Akram,S.,Hussain,F.,AmeenulZaman,M.,Ali,A.,andMajeed, F.(2023).Developmentofahybridmixed-modesolardryerforproductdrying. Heliyon, 9(3),e14144.

[17] Bhutia,K.C.,Bhutia,S.O.,Chatterjee,R.,andPariari,A.(2017).Post-harvestprocessingandmarketingoflargecardamom inIndia. Journal of Crop and Weed,13(3),56-63.

[18] Sharma,A.,andSharma,A.(2019).PostharvestLossesduringtheMarketingofLargeCardamonandGingerSpicesCropsin EastDistrictofSikkim.InternationalJ.ofCurrentMicrobiologyandAppliedSciences,8(5),1274-1282

[19] Singh,R.,andB.K.Yadav(2018)."DevelopmentofLow-CostPortableBiomassFiredDryerforCardamomDryinginHilly Areas." Journal of Environmental and Biological Sciences,5(6):118-24.

[20] BureauofIndianStandards(2020)."IS1907:1984-SpecificationforLargeCardamom."1984.CardamomAssociationof India.IndustryReport.

[21] BureauofIndianStandards(2009)."IS13446:2009-SpecificationforSmallCardamom".

[22] BureauofIndianStandards(1985)."IS1797:1985-SpecificationforCardamom(ElettariaCardamomumMaton)".

[23] BureauofIndianStandards(1993)."IS13145:1993-SpecificationforDriedCardamomCapsules".

[24] Bag, J., and Singh, N. (2024). Traditional and Contemporary Drying Methods an Overview. Journal of Ayurveda and Integrated Medical Sciences, 9(6),111-121.

[25] Ambrose,D.C.P.,andS.J.K.Annamalai(2013)."PerformanceevaluationofLPGfiredsmallcardamomdrierincardamom plantation, International Journal of Agricultural Engineering.6(1):162-165.

[26] LoyalFoodProcessingLine.(n.d.)(2024). Fully automatic microwave cardamom dryer: Revolutionizing spice preservation. LoyalFoodProcessingLine.

[27] National Institute of Food Technology Entrepreneurship and Management. (2022) Reading manual for cardamom processing under PM FME scheme.NIFTEM.

[28] Tyagi,S.K.,Bashir,A.A.,Chandrasekar,V.C.,tiNimesh,A.N.,andKhatkar,A.B.(2019).DryersDevelopedinAICRPon PHETelopedinAICRPonPHET. Technical Bulletin

[29] Mandal,M.,Sharma,R.,andTamang,B.(2018). Development of low-cost portable biomass-fired dryer for cardamom drying in hilly areas. Journal of Environmental Biology,39(6),1255-1260.

[30] Shreelavaniya, R., Kamaraj, S., Subramanian, S., Pangayarselvi, R., Murali, S., and Bharani, A. (2021). Experimental investigationsondryingkinetics,modelingandqualityanalysisofsmallcardamom(Elettariacardamomum)driedinsolarbiomasshybriddryer. Solar Energy,227:635-644.

[31] Seveda,M.S.,andJhajharia,D.(2012).Designandperformanceevaluationofsolardryerfordryingoflargecardamom (Amomumsubulatum). Journal of Renewable and Sustainable Energy,4(6):063129(2012)

[32] Dash, S., Choudhury, S., and Dash, K. K. (2022). Energy and exergy analyses of solar drying of black cardamom (Amomumsubulatom Roxburgh) using indirect type flat plate collector solar dryer. Journal of Food Process Engineering, 45(4),e14001.

[33] Mishra, S., Sahu, J. K., Sanwal, N., and Sharma, N. (2021). Hot air convective drying of small cardamom (Elettaria cardamomumMaton):Evaluationofdrying,color,andaromakinetics. Journal of Food Process Engineering,44(4),e13649.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

[34] Mande,S.,Kumar,A.,andKishore,V.V.N.(1999).Astudyoflarge-cardamomcuringchambersinSikkim. Biomass and Bioenergy, 16(6),463-473.

[35] Deka,T.N.,Biswas,A.K.,Gopakumar,B.,andPotty,S.N.(2003).LargecardamomcuringthroughICRIimprovedbhatti. Journal of Hill Research,16(1):57-60.

Volume: 12 Issue: 04 | Apr 2025 www.irjet.net p-ISSN: 2395-0072 © 2025, IRJET | Impact Factor value: 8.315 | ISO 9001:2008 Certified Journal | Page1472