4 THE ROLE OF TELEMATICS IN SMART CITIES

13 AUTOMATION24 EXPANDS THEIR PORTFOLIO WITH THE ADDITION OF NORGREN

14 THE FUTURE OF MOBILITY EVS, HYDROGEN AND E-FUEL

22 IDS IS THE FIRST INDUSTRIAL CAMERA MANUFACTURER TO OFFER THE SONY SENSOR IMX662 IN BOTH COLOUR AND MONO

24 BAKER HUGHES TO SUPPORT STRATEGIC GAS PROJECT IN ALGERIA TO ENHANCE ITALY, EUROPE’S ENERGY SECURITY

25 PIONEERING SOES IN THE ENERGY SECTOR, PERTAMINA PARTNERS WITH THE JAPAN COOPERATION CENTER FOR PETROLEUM & SUSTAINABLE ENERGY

26 GENERATIVE AI: TOOLS, MODELS, & APPLICATIONS

34 AXALTA LAUNCHES INDUSTRY FIRST RANGE OF ISCC PLUS CERTIFIED BIOBASED POWDER COATINGS

36 THE FOUR BUILDING BLOCKS OF THE INDUSTRIAL METAVERSE

40 ABB INVESTS IN NDUSTRIAL TO ACCELERATE DECARBONIZATION THROUGH AI-POWERED ENERGY MANAGEMENT TECHNOLOGIES

42 KOMATSU EUROPE LAUNCHES NEW SORTING AND DEMOLITION GRAPPLE RANGE

43 HILSCHER INTRODUCES SENSOREDGE IO-LINK MASTERS INSTANT MONITORING OF SENSOR DATA

44 AGGREKO: ENERGY INTENSIVE INDUSTRIES ACROSS EUROPE URGED TO CONSIDER DECENTRALISED ENERGY SOLUTIONS AMID FRENCH GRID ISSUES

45 VOLKERRAIL LIFE EXTENSION WORKS CONTINUE ON SHEFFIELD SUPERTRAM

46 EAST ANGLIA THREE OFFSHORE CONVERTER STATION TAKES TO WATER FOR FIRST TIME

48 ROHDE & SCHWARZ PRESENTS ITS TEST SOLUTIONS AT CCW 2024 THAT ENABLE A SUCCESSFUL MIGRATION TO MISSION-CRITICAL BROADBAND

50 IGUS HONORS ENERGY CHAIN APPLICATIONS AS PART OF ITS NINTH VECTOR AWARDS

51 INNODISK UNVEILS GROUNDBREAKING MIPI OVER TYPE-C SOLUTION FOR ENHANCED AI VISION APPLICATIONS

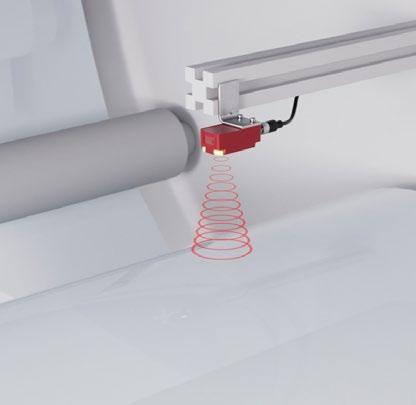

52 LEUZE: NEW ULTRASONIC SENSORS

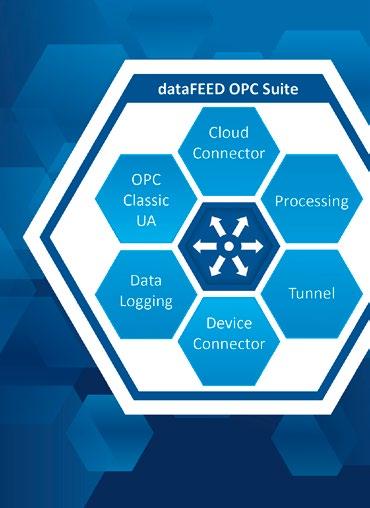

54 DATAFEED OPC SUITE FROM SOFTING INDUSTRIAL PROVIDES ACCESS TO SINUMERIC 840D CNC MACHINES

56 HARTING IS ON FIRE FOR THE SUBSTANCE OF THE FUTURE: ELECTRICAL ENERGY

57 NGK RECEIVES ORDER FOR NAS BATTERIES FOR LARGE-SCALE GREEN HYDROGEN PRODUCTION PROJECT

58 DELTA UNVEILS GROUNDBREAKING SOLUTIONS FOR SMART MANUFACTURING AND E-MOBILITY AT HANNOVER MESSE 2024

60 ADVANCING INDUSTRIAL COMPETITIVENESS THROUGH SOFTWARE, AUTOMATION, AND ELECTRIFICATION

62 DEVELOPING TAILORED INDUSTRIAL SOLUTIONS TOGETHER

64 NORD OFFERS OPTIMUM CONVEYOR FUNCTIONALITY WITH NORDAC ON/ON+ VFDS

66 COMAU’S DIGITAL TECHNOLOGIES TO IMPROVE BATTERY CELL PRODUCTION REACHING UP TO ZERO DEFECTS FOR THE BATTWIN PROJECT

68 COVAL LAUNCHES THE NEW GENERATION OF MULTI-STAGE MINI-VACUUM PUMPS: THE CMS M SERIES

70 SOUTHCO SECURING THE EV

73 HANNOVER MESSE 2024: SIEMENS ANNOUNCES A NEW GENERATION OF CONTROLLERS

74 EMERSON’S NEW MOTORIZED ACTUATOR AND SHUTOFF VALVE SOLUTION IMPROVES SAFETY AND RELIABILITY IN COMBUSTION SYSTEMS

75 DFI UNVEILS WORLD’S FIRST INDUSTRIAL MOTHERBOARD COMPATIBLE WITH INTEL CORE

76 AGGREKO UNVEIL MARKET-FIRST THREE-ENGINE GENERATOR WITH THE BRAND NEW POWERMX RANGE

78 ULMER SCHOKOLADEN AND CORETIGO ENHANCE CHOCOLATE MANUFACTURING WITH INDUSTRIAL WIRELESS AUTOMATION

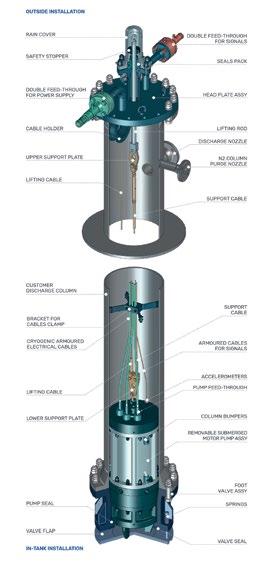

80 VANZETTI ENGINEERING PRESENTS NEW RETRACTABLE SUBMERGED PUMPS

81 KOLLMORGEN EXPANDS AKD2G VERSATILITY WITH THE LAUNCH OF NEW SYNCHRONIZED COMMUNICATION PROTOCOLS

Send your press releases to: editor@ipmediaonline.com

To receive ours newsletters, please subscribe online: https://induportals-media-publishing.com/

INDUSTRY is the magazine for engineers, published by InDuPORTALS MeDIA PuBLISHInG. It contains the latest product and company news for industrial markets. INDUSTRY edits its articles with the greatest of care, however we cannot guarantee the accuracy of the information presented in them. Our teams disclaim all responsibility concerning the content of this media or how it might be used.

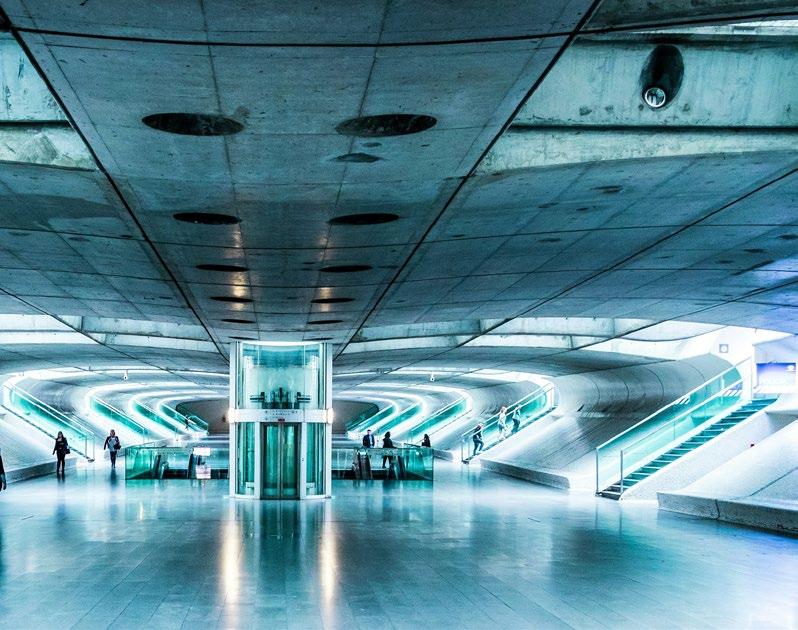

Milton D’Silva explores how telematics is helping in shaping the smart cities ecosystem.

Telematics is a portmanteau term formed by combining the words telecommunications and informatics. Originally used in French – télématique – it was coined by authors Simon nora and Alain Minc in a 1978 report that originally foresaw the use of telecommunications to exchange information with the science of computer processing. In simple terms, telematics is the process of transmitting information remotely over long distances, now over the internet. This is done in order to monitor, track and control various movements and activities, in conjunction with the use of sensors, GPS technology and other electronics to collect and transmit data. Today it is associated almost exclusively with vehicles and mobile machinery, though there are other applications as well. The exchange of information is central to the applications, the information gathered from multiple sources and devices and computed into useful bytes for specific applications. So widespread is the use of telematics today that it is just taken for granted with no thought to the technologies that go into it.

Like most other sensitive technologies, the use of telematics, even before the term was coined, had begun with the uS Defence Department that had developed the global positioning system (GPS), a network of satellites and receiving devices used to determine the location of combat vehicles and equipment in the field. Again as it often happens, it did not take long for the technology to become declassified and widely adopted for general applications, especially with the internet becoming available to the common man. By the early 1990s, GPS was made available for civilian use and the progressive growth in wireless communication technologies that enabled cellular networks made real-time data from vehicles available to central systems. This in turn resulted in the development of telematics systems for vehicle tracking, navigation, and emergency assistance. The earliest example of the effective use of telematics in the automotive field was when the government in South Africa used the technology to curb the widespread phenomenon of carjacking by remotely disabling the engine. However, the real boost to telematics was provided by the combination of mobile telephones and internet services with every successive generation of connectivity adding to the performance and efficiency.

Telematics – Not Just Automotive even as telematics is widely associated with automotive applications, it has also been adapted for various other sectors, especially in logistics, healthcare and agriculture. The following sectors make extensive use of telematics even as some relate invariably to the automotive part of these sectoral services:

• Fleet Management Services: For operators of large fleets of trucks, buses and delivery vehicles, telematics are of great help in planning and execution of schedules, selecting the optimum routes and monitoring driver conduct, which results in improving overall efficiency.

• Insurance: Insurance companies have been quick to use telematics to offer special incentives in the form of

customised insurance packages based on individual driver behaviour and vehicle data by assessing risk behaviour.

• Healthcare: Perhaps the best use case of telematics, in healthcare, it is used for remote patient monitoring and telemedicine. With wearable devices and sensors facilitating real-time monitoring and timely interventions, it is possible to treat patients remotely.

• Construction Equipment Monitoring: This is actually an extension of telematics in automotive applications but with a wider scope of tracking equipment usage, maintenance schedules and monitoring of idle time of the machinery. The result is optimum operations, reduced downtime and improved efficiency.

• Agriculture : With the increased mechanisation of agriculture telematics is the right tool for monitoring farm equipment, maintenance and usage, much like construction equipment. Optimising water use in irrigation is an added advantage.

• Utilities: This is an area which touches every citizen and the use of telematics by utilities – water, gas and electricity – goes a long way in billing, maintenance services and tracking and predicting failures.

• Logistics and Supply Chain: The memories of Covid and the disruption of supply chains is all too fresh in most minds even if a few have forgotten. Real-time tracking of shipments, locating lost consignments, and identifying

bottlenecks – telematics can play a critical role in the efficient movement of goods.

• Public Transportation: Those using public transportation can vouch for the efficacy of telematics in improving user experience in terms of schedules, arrival and departure times and much else, giving a seamless experience.

• Energy Management: If utilities take care of the consumer end, for energy companies, the added advantage of telematics is in monitoring of power generation or gas production and distribution, eliminating system inefficiencies, minimising distribution losses by plugging leaks, etc.

• Asset Tracking: For enterprises, logistics and supply chain is only part of the story. Tracking of assets – plant and machinery, static and mobile equipment is equally important and impacts the performance and profitability, with telematics binding operations together.

• Mining: This is a vast area literally and metaphorically, with assets spread across huge terrain that is often inaccessible. The use of telematics connects assets, monitors equipment and also tracks the movement of man and material, with real-time information always available.

• Telemetry in Sports: everyone today is aware of the extremely high competition in sports with split-second winning margins and consequent heartbreaks for those who fail to make the cut. Wearable sensors, health monitors, etc., facilitate the smooth and safe conduct of sporting events thanks to telematics.

The above examples make it obvious how telematics play a distinct role in various industry segments by making effective use of data for decision-making, which in turn leads to increased efficiency, safety and performance. Little surprise then, that telematics fits like a glove on the emerging smart cities ecosystem globally. Modern smart cities are driven by technology and telematics is right at the centre of this revolution, but more of that, later. At the moment, it would be of interest to understand the origins of the smart city concept.

The term smart city was coined by IBM in 2014, but the concept originated in the late 1960s in the uS when the citiesbased organisation Community Analysis Bureau began using computerised databases of citizens to serve them better. This was done to study the demographics, housing conditions and civic services in different cities and localities, in order to improve the quality of life in general, and provide emergency services and initiate relief measures in case of civic strife or natural calamities. Gradually, the concept evolved in tandem with increasing trends in urbanisation as cities attracted more and more people and there was a growing need for more efficient and sustainable urban development. Today, smart cities represent a paradigm shift in urban living, aided in no small measure by various digital technologies, data analytics, and connectivity solutions to address the many challenges that defy solutions by human intervention alone.

One of the key aspects of smart cities is the optimised use of available resources. In general, the traditional city administration with dated methods and distribution channels is largely ineffective due to the many deficiencies that have crept into the system. To optimise anything, the beginning has to be made by measuring all the parameters such as power quality and state of transmission and distribution networks, state of water pipelines, quality and accuracy of metering, etc. Once this is done with the help of advanced sensors and monitoring systems, the cities can manage energy and water supply more efficiently, plugging the leakages. For example, smart grids not only ensure better management of electricity distribution, it also minimises waste if not eliminating it altogether. The same is true of water supply, where proper monitoring and detection of inadequate pressure and leakages prevent unnecessary loss of a precious resource. Such optimisation not only conserves resources but also reduces the environmental footprint of cities, contributing to sustainability efforts. In the process, it also helps consumers by reducing the cost of utilities.

Another important aspect of modern cities is transportation – the road networks, metro infrastructure and various mobility options between private vehicles and public services. Traffic congestion and the resultant pollution are obvious bottlenecks made worse by inadequate public transportation services. Smart cities need smart

transportation solutions and many have evolved over the years. Gowing electrification of mobility – the metro services and tram carriages run on electricity as do an increasing number of private vehicles. Authorities today resort to intelligent traffic management with real-time information from the vehicles on the road to ease traffic congestion by keeping all drivers on a particular stretch informed about alternate routes, or caution them about delays. Another measure is encouraging carpooling, which is also aimed at reducing the number of vehicles on the road.

next in importance on the smart cities agenda is public safety and security, which is achieved by extensive electronic surveillance systems. extending far beyond the scope of traditional CCTV cameras, the smart city surveillance network encompasses smart lighting, advanced sensors, IoT devices, facial recognition systems, AI-powered analytics and predictive algorithms that form a seamless system of surveillance, enabling real-time data on traffic conditions, public places and environmental conditions, etc. This facilitates quick response in emergency situations. Besides contributing to safety measures, smart lighting also helps conserve energy by adjusting brightness levels to needbased requirements.

Perhaps the most significant part of the smart cities initiative is citizen engagement and the digitalisation of

administrative services in civic bodies. With systematic metering and billing of utilities, there is transparency and accountability. Online services with user-friendly interfaces on mobile devices empower citizens to access information without visiting any office and in general participate in decision-making by providing feedback to the municipal authorities. Such initiatives also inculcate a stronger sense of community participation and responsibility, taking ownership of the civic affairs in a way, contributes to the overall development of the city.

Finally, smart cities also encourage innovation and economic growth by wider community participation in civic activities. An empowered citizen also becomes a responsible, environmentally conscious citizen conserving resources and avoiding excesses.

With the proven efficacy of modern telematics – the amalgamation of advanced communication and information technologies – the technology plays a crucial role shaping smart cities that are enhancing various aspects of urban life. Following are the main areas where telematics provide the basic blueprint for the development of smart cities:

Traffic Management: Modern cities are thriving places of people engaged in business and commerce, and for that very reason travelling within the city for a myriad of reasons besides the basic need for commuting to respective places of work. While every city has a basic public transport system in place, a large number of people travel by own vehicles and growing urbanisation means traffic often becomes unmanageable. The smart city solution is twofold:

• Real-time Traffic Monitoring: Real-time data collection with the help of telematics of the number of vehicles on the road, the traffic hotspots causing congestion, providing information on alternate roads, etc., for optimised traffic flow.

• Predictive Analysis: With real-time analysis of current data and comparison with historical data for specific routes, smart cities are in a better position to predict traffic patterns and initiate measures to decongest the bottlenecks, easing the flow of vehicles.

Public Transportation : A long-established system of transport in urban areas for mass movement of people, public transportation is even more important in the smart city scheme of things to improve the quality of life. This is achieved by:

• Real-time Tracking: By providing accurate information on movements of metro trains and municipal buses, telematics allows for real-time tracking of public transportation, helping commuters plan their journeys more efficiently.

• Route Optimisation: Smart cities use data made available by telematics to rationalise public transportation routes, improve frequency of trips during peak hours and reduce overall travel times.

Parking Solutions: Vehicle owners driving around cities know how severe the space crunch for parking is with the limited slots already occupied. While dedicated mechanised parking facilities have sprung up in response, telematics help them connect with the motorists.

• Smart Parking: Smart parking systems that guide drivers with the help of telematics to the nearest available parking slots, avoiding traffic congestion and the resulting emissions from idling vehicles.

• Payment Integration: A seamless, integrated payment interface with mobile apps facilitates convenient and cashless parking payment solutions.

Emergency Services: Accidents, criminal activities, medical emergencies are routine happenings in city life. Instant action and remedial measures in what is described as ’the golden hour’ in medical parlance can save lives. This is exactly what telematics can provide in smart cities – a quick response that activates emergency services by providing real-time information about such incidents.

Environmental Monitoring: Air pollution in cities – mainly vehicular, industrial, construction and garbage disposal – is a serious health hazard. Besides air pollution, cities also suffer from noise pollution. Measuring pollution levels is the first step for initiating remedial actions:

• Air Quality Monitoring: While data of vehicular pollution and that of construction machinery is captured at source, sensors monitor pollution from other sources via telematics to help monitor and analyse air quality data, the results of which determine the course of action against pollution in order to improve environmental conditions.

• Noise Level Monitoring: Mainly a result of construction and building activity, here too sensors connected through telematics monitor noise levels, which in turn helps restrict the offending machinery from operating at all hours.

Infrastructure Upkeep: City infrastructure needs periodic maintenance, especially the state of the roads and bridges, for signs of unusual wear and tear and damage. For example, a study done by the Michigan Technological university in cooperation with the Center for Automotive Research and

the Michigan Department of Transportation, made use of remote sensing technologies to assess and monitor the condition of bridge infrastructure and improve the efficiency of inspection, repair, and rehabilitation efforts.

Smart Grids & Water Supply: Another important aspect of smart cities is energy and water supply and distribution, utilities that service the citizens. Telematics helps monitor and manage water and energy consumption, contributing to the development of smart grids that enhance energy efficiency in cities and supply metered water with appropriate conservation measures.

Waste Management : Mountains of trash is a serious side effect of modern lifestyles where everything comes packaged, mostly in plastic and other non-biodegradable materials, a serious problem for smart cities.

• Efficient Collection: Planning is the key to optimise waste collection by rationalising the routes to reduce vehicle use and fuel consumption in order to reduce the carbon footprint while raising the efficiency of waste management operations.

• Monitoring Fill Levels: Sensors are used to monitor the fill levels of waste containers, optimising collection schedules.

Public Safety: The importance of safety can never be overemphasized and the law enforcement agencies are always on the job. Technology plays an important role in this as public places are equipped with smart surveillance systems that continuously monitor streets and other public spaces for unusual activities. The footage is analysed by AI-based tools to detect unusual activities that trigger immediate response. Telematics plays an important role in bringing together all the areas under a common platform, facilitating quick decision-making that helps city administrators.

Traditionally associated with automotive applications, telematics, as seen in the preceding paragraphs, has applications beyond automotive in many other areas. While the primary focus of telematics remains the automotive sector which is witnessing rapid advances in the connected vehicles era, smart cities are emerging as a major user of telematics. This is obvious when comparing the growth of telematics exclusively in the automotive field versus the overall growth of telematics including other industry segments. A word of caution though – when it comes to market reports rarely do two agencies agree on the estimated numbers and at times the differences in figures are too far and wide raising doubts about the datasets used.

For example, according to a recent report by Market Research Future, the telematics market industry is projected to grow from uSD 42.6 billion in 2023 to uSD 133.2 billion by 2032, at a compounded annual growth rate (CAGR) of 13.5% during the forecast period (2023-2032). However, for the same period, Custom Market Insights puts the figure for 2023 at uSD 59.21 billion, which is projected to reach uSD 172.4 billion by 2032. Despite such variations, most agencies project a healthy market growth for telematics over the next decade.

When it comes to the use of telematics in smart cities, various players are involved from different sectors, which include government bodies that coordinate the various initiatives, technology companies, telecommunications providers, and infrastructure developers. Some of the major players in the smart city telematics field from the different sectors mentioned above include:

Government bodies and municipalities: Various municipal governments worldwide are investing in smart city initiatives, deploying telematics systems for transportation management, waste management, public safety, and more. Government agencies often collaborate with technology providers to implement smart city projects.

Technology companies

• IBM: A major player in developing software for smart cities, IBM provides various solutions including IoT platforms, data analytics, and cognitive computing. The Intelligent

Telematics is facilitated by the combination of smartphones and the internet.

Operations Center is part of the IBM Industry solutions software portfolio for smart cities.

• Cisco: As one of the pioneers of the smart city concept over the past several years, Cisco is partnering with cities, communities and governments around the world. It offers networking infrastructure and solutions for smart city initiatives, including IoT, security, and data management.

• Siemens : At the forefront in creating sustainable and efficient smart city infrastructure, buildings, and industries, Siemens provides smart city solutions ranging from transportation systems and building technologies to energy management, intelligent power distribution solutions, and SCADA systems for utilities management such as water, gas, and electricity.

• Microsoft: With a worldwide network of fast, efficient, and secure data centres, Microsoft ensures better performance through improved security and protection of city data, apps, and infrastructure. The company offers cloud-based platforms and services for smart city initiatives, including Azure IoT and data analytics solutions.

• Huawei : One of the key attributes of a smart city is efficient transportation, Huawei plays a significant role in optimising urban mobility. Through the use of IoT sensors and AI-driven analytics, Huawei’s solutions enable

intelligent traffic management, besides providing smart city solutions focusing on IoT, cloud computing, and digital transformation.

• Google: Despite the failed experiment of the large-scale project in Toronto, Google offers various technologies and platforms for smart city applications, including Google Cloud and Google Maps.

Telecommunications providers

Verizon: Offers IoT solutions and connectivity services for smart city applications, including smart transportation and public safety.

AT&T: Provides IoT platforms and connectivity solutions for smart city projects, including smart grid, traffic management, and environmental monitoring.

Vodafone: Offers IoT connectivity and solutions for smart city applications, including smart metering and urban mobility.

Infrastructure developers

Schneider electric: Provides infrastructure solutions for smart cities, including energy management, automation, and sustainable building technologies.

ABB: Offers technologies for smart grids, transportation systems, and industrial automation, contributing to smart city developments.

Bosch: Provides smart city solutions encompassing mobility, energy, and building technologies.

General Electric (GE): Offers smart city solutions focusing on energy management, lighting, and digital infrastructure.

Besides, there are a number of startups focusing on specific aspects of smart city telematics, such as urban mobility, environmental monitoring, and citizen engagement. These players often collaborate and compete in the smart city space, working together to create innovative solutions for urban challenges. Additionally, research institutions and academia play a role in advancing smart city technologies through research and development initiatives.

Automobiles – electric vehicles to be more specific – are going to be at the centre of the emerging smart cities ecosystem connected by telematics. Singapore, for example, is leveraging electric mobility as the key component of its urban transportation ecosystem with a widespread network of charging infrastructure integrated with smart grids, intelligent traffic management and smart parking. The smart

city infrastructure will be focused on sustainable transport solutions equipped with V2X technology where vehicles can communicate with each other, infrastructure, and even pedestrians, besides connecting with environmental monitoring and emergency response services. Above all, the smart cities ecosystem relies on a strong public-private partnership, with the involvement and close cooperation of all stakeholders.

References

1. https://www.norcomp.net/blog/outdoor-sensors-telematics-for-smart-city-initiatives

2. https://www.uffizio.com/blog/the-impact-of-vehicletelematics-on-next-generation-driving/

3. https://www.linkedin.com/pulse/fleet-solutionstelematics-paving-way-safer-smarter-more-bhoda2dg0c/

4. https://www.gtt.com/five-ways-telematics-makes-yoursmart-city-smarter/

More than 80 employees in 35 different countries, ensuring a strong relationship with main local media.

Mepax distinguishes itself through its extensive media knowledge and ability to select the best international online/print advertising options. PR can be translated into 35 languages.

50,000 published articles in 2023: EMEA: 48% - Asia: 31% - Americas: 21%. Most of the articles are published in the top 1000 media worldwide.

With a proven process set for more than 200 active customers, we can adapt to all specific client needs with the highest reliability. We have developed in house the most advanced PR dedicated ERP, enabling transparency and real-time full online reporting. International media management is then made easy, fast, and efficient for optimal results.

www.mepax.com

info@mepax.com

.Automation24 proudly announces the addition of Norgren pneumatic components to its portfolio, marking a significant milestone in the company’s journey. With this strategic move, Automation24 broadens its scope and capabilities to better serve its customers.

norgren air preparation products currently offered by Automation24 include regulators, filters, combination units (filter/regulator/lubricator), valves, and accessories. These proven air preparation products are built to overcome the common challenges of using compressed air.

The norgren excelon Plus 1/4” PTF combination unit, for example, combines several system-critical components: a 40 µm filter for particle and moisture removal, a highperformance pressure regulator, and a highly effective lubricator. The combination of these elements ensures efficient compressed air control while protecting sensitive equipment and extending the life of all system components.

Additional lines from norgren will be added throughout 2024, including pneumatic and electric actuators, control valves, vacuum generators, and air preparation solutions for process/food and beverage applications. With this expanded portfolio, Automation24 will ultimately be able to provide customers with a comprehensive suite of norgren compressed air solutions to meet the demands of applications that include factory automation, material handling, commercial vehicles, rail, life sciences, packaging, process control, and food and beverage.

For more information about Automation24 and its expanded portfolio www.automation24.com

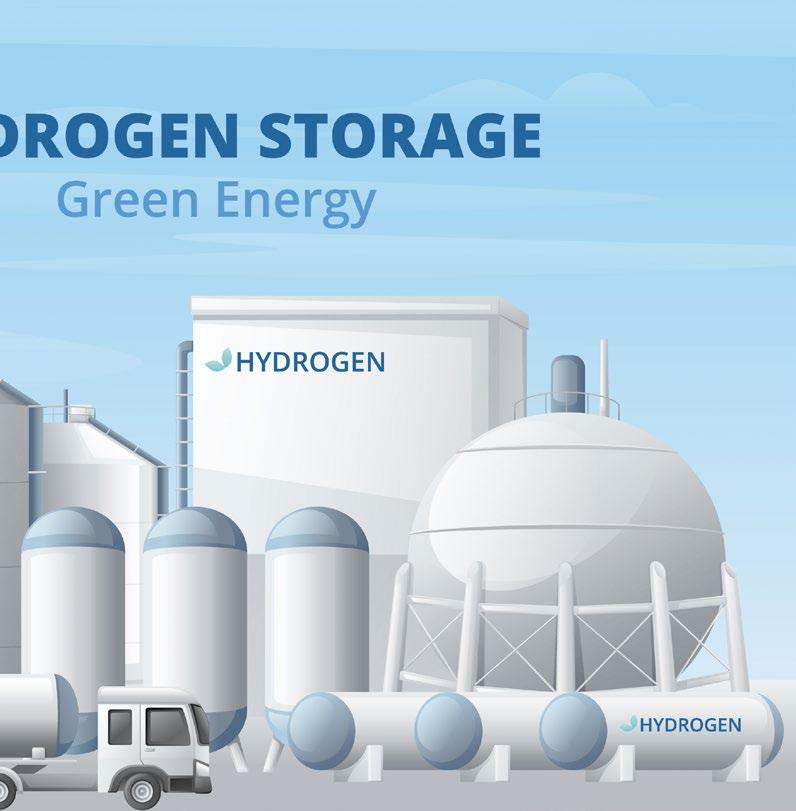

Milton D’Silva examines the pros and cons of mobility of the future with the three available options.

By most accounts, humans learned to light fire around 2 million years ago and set in motion the wheels of progress. The wheel, by the way, was invented much later, in the 4th millennium BC. ever since, the use of energy has been central to all human activity and has become the index of development – the more developed a nation, the more energy it uses. This unbridled use of energy has a side effect – the generation of greenhouse gases (GHGs) – which has today snowballed into a major crisis. While GHGs are essential to maintaining the right temperatures on earth, it is the excess caused by unbridled use of energy that has caused the crisis of global warming. The burning of fossil fuels, mainly hydrocarbons like coal and petroleum products, is today the largest contributor to global climate change, accounting for over 75 percent of GHG emissions and nearly 90 percent of all carbon dioxide emissions. The world is now warming faster than at any point in recorded history. The warmer temperatures are disrupting the usual balance of nature, changing the natural weather patterns the world has experienced for centuries. The year 2023, it may be noted, has turned out to be the hottest year in recorded history. This poses many risks to human beings and all other forms of life on earth.

At 28%, transportation is a leading contributor to GHGs. This is the direct result of the combustion of fossil fuels in the different types of engines used to power various modes of transportation like cars, trucks, ships, trains and aircraft. With over 90% of the energy sources used in transportation originating from fossil fuels, it is obvious the world must now have cleaner alternatives to them. It is not just transportation, but use of energy as a whole, because electricity generation contributes another 25% of GHGs. Although the proportion is slightly lower than transportation, the energy landscape is marked by its own challenge – more than 60% of electricity generation still relies on fossil fuels. This dual reliance on fossil-based energy in both transportation and electricity generation underscores the urgent need for transformative changes to address the environmental consequences.

Given the close relationship between energy and mobility, the world is today engaged in a massive exercise seeking to decarbonise transportation and electricity generation, which holds immense potential to address the burgeoning global climate crisis. By transitioning to cleaner and more sustainable energy sources, such as renewables and alternative fuels, there is significant potential to reduce GHG emissions, making a substantial and positive impact on the fight against climate change. To this end, there has to be a concerted effort with close coordination among policymakers, industries and individuals, to prioritise and invest in initiatives that promote the decarbonisation of these critical sectors to achieve a more sustainable and resilient future.

Alternatives to fossil fuels have always been there and some of the better known and also in use, though not as widely, are bio-diesel, bio-alcohol, bio-gas, chemically stored electricity, hydrogen, non-fossil methane and natural gas, vegetable oil, and in recent years, synthetic fuels or e-fuels.

Decarbonising transportation & energy

The early automobiles were actually battery-powered electric Vehicles (e Vs) and were doing reasonably well before the mass-produced Ford Model T gained immense popularity. The eVs of that era simply could not counter the performance of the IC engine, especially after they got the self-start feature. Thus went the early eV into a long period of hibernation, only to be woken up after the oil shocks of the late 1960s and early 1970s. The eV was further jolted into action by the climate crisis of recent years. The

renewed interest in eVs was ignited in part due to the Lunar Roving Vehicle ferried to the moon by the 1971 Apollo 15 mission, and research on the batteries had resulted in better capacities even as the cost remained high. The first serious boost to eVs was provided by the CARB mandate in the uS State of California in the 1990s, which specified that automakers sell a small number of lower-emission vehicles, with zero emission being the ultimate goal. In response, several mainstream automobile companies either converted an existing model, or developed a new one with an electric drivetrain. These were at best token attempts and no serious eV barring the General Motors eV1 and Toyota RAV4 eV resulted from it. However, the hybrid Prius launched by Toyota in 1997 attracted global attention and won several awards and accolades, clearing the path for a renewed interest in eVs. An important development during

the first decade of the new millennium was the founding of Tesla Motors, a Silicon Valley startup in 2003, as an electric mobility and clean energy company.

In the span of 20 years since, almost all global automakers have at least one eV on offer, if not a portfolio of models to choose from. Global e V sales have risen dramatically, crossing the 10 million mark in 2022. The total eV sales more than tripled in three years, going from 4% in 2020 to 14% in 2022. The momentum further accelerated in 2023 with the total eV sales including plug-in hybrids totalling a whopping 14.2 million, an increase of over 35% over the previous year, which adds to close to 16% of total light vehicle sales globally. The scale of eV adoption is far from uniform and varies from region to country. In general, China leads the eV adoption rate, followed by europe and the uS.

In the meanwhile, the decarbonisation of electricity is already happening as close to 30% of global electricity today is produced from renewable sources. The International Renewable e nergy Agency (IR en A) estimates that 90 percent of the world’s electricity can and should come from renewable energy by 2050. The best thing about electricity is its ability to integrate renewable sources like hydropower, which is a traditional source of clean energy, and now wind and solar, which are more recent renewable sources.

The un Climate Action Plan lists out five reasons the world should accelerate the pace of decarbonising the energy mix, primarily led by clean electricity.

1. Renewable energy sources are everywhere – With over 80% of the world’s population dwelling in countries that are net importers for fossil fuels, volatility in fuel prices and global flashpoints add to their energy anxieties. Time they exploit renewable energy sources in their own backyard to get rid of import dependency.

2. Renewable energy is cheaper – Growing adoption and economies of scale are causing prices of renewable energy sources drop dramatically. estimates suggest cheaper electricity from renewable sources could provide 65 percent of the world’s total electricity supply by 2030 and could decarbonise 90 percent of the power sector by 2050.

3. Renewable energy is healthier – Statistics from the World Health Organisation (WHO) indicate about 99 percent of people in the world breathe air that exceeds air quality limits and threatens their health, causing up to 13 million deaths. Clean energy sources help clean the atmosphere as well.

4. Renewable energy creates jobs – The International energy Agency (IeA) estimates that the transition towards netzero emissions will lead to an overall increase in energy sector jobs, outpacing the job losses caused by the decline in fossil fuel production and distribution channels.

5. Renewable energy makes economic sense –Governments across the world spend about $7 trillion annually subsidising fossil fuels. On the other hand, even conservative estimates suggest just about $4 trillion a year needs to be invested in renewable energy until 2030 –

Transportation is a leading contributor to greenhouse gas emissions.

including investments in technology and infrastructure – to allow the world to reach net-zero emissions by 2050.

How clean is the eV in terms of the environmental impact? At a time when the adoption of e Vs is showing healthy growth are there doubts raised in certain quarters about the viability of the model? Japanese automaker Toyota, one of the global leaders in automobiles, has always been sceptical of eVs being touted as the only solution for clean mobility. While critics are quick to point out that in its passion to promote hybrids Toyota has neglected research on eVs, the company has a more nuanced approach. In January 2024, Toyota chairman Akio Toyoda speaking at an industry event in Tokyo was emphatic that electric vehicles should not be developed to the exclusion of other technologies, such as hybrid and hydrogen-powered cars. According to him, eVs will only reach 30% market share at most with the rest taken up by hybrids, hydrogen fuel cell and conventional IC engine cars albeit with synthetic fuels.

Akio Toyoda may not be wrong. Car buyers in the uS are not as enthusiastic about eVs after the initial response and high initial cost and range anxiety are not the only reasons for that. Tesla is offering discounts on its vehicles; Ford is scaling back on production estimates for eVs and even German major Audi is having second thoughts. This comes within

months of most automakers on either side of the Atlantic declaring their intention to go total electric by 2035.

In the uS, for example, the national Automobile Dealers Association (nADA), the national voice of franchised newcar dealerships, their employees and their customers for over 100 years, is opposed to the Biden Administration’s proposed new emissions standards. In May 2023, the uS environmental Protection Agency (ePA) proposed a rule for model years 2027-2032 light- and medium-duty vehicles that call for 60% of new vehicles sold in 2030 and 67.5% of new vehicles sold in 2032 to be eVs. even the Alliance for Automotive Innovation, which represents automakers in the uS, has stated that the ePA rule is ’neither reasonable nor achievable in the time frame provided’.

More recently, the issue has assumed political overtones with the Republican-led House of Representatives voting in December 2023 to stall the Biden administration’s proposal. “While eVs may play a large role in the future of the auto industry, Washington should not discount other technologies like hydrogen, hybrids, and the internal combustion engine,” is what Republican Tim Walberg is reported to have said. Former President Donald Trump, a strong contender in the presidential race later this year, has also said he would reverse the electric vehicle rules.

Similarly, in March 2023, the european union approved a landmark law to end sales of new CO2-emitting cars in 2035, but not before Germany got an exemption for cars running on e-fuels. The other country that made common cause with Germany in seeking exemption for e-fuels is Italy. The eu law requires all new cars sold to have zero CO2 emissions from 2035, and 55% lower CO2 emissions from 2030, versus 2021 levels. The targets are designed to drive the rapid decarbonisation of new car fleets in europe. The european Commission has pledged, however, to create a legal route for sales of new cars that only run on e-fuels to continue after 2035, after Germany demanded this exemption, which offers a potential lifeline to traditional vehicles – although e-fuels are not yet produced at scale.

This only means that despite the popularity of eVs and their clearly demonstrated efficacy towards clean mobility, there are still efforts being made to explore other alternatives to fossil fuels.

The other clean alternatives – hydrogen and e-fuels

By now, the potential of hydrogen as an automotive fuel is well established. It was John Bockris, a chemistry professor who in the early 1970s described hydrogen as an economical and environmentally friendly substitute for fossil fuels to power automobiles. Today there are production vehicles from Toyota, Honda and Hyundai running on the roads

in California, uSA. German Group BMW is also testing Toyota fuel cells for its hydrogen cars, while Detroit major General Motors is doing the same with Honda technology. There are also hydrogen fuel cell-powered buses and trucks plying in many countries – the majority of them in China. Traditional manufacturers of heavy diesel and CnG engines like Cummins and FPT Industrial are also working on hydrogen-powered IC engines which are at trial stages and soon expected to be in series production. The emerging hydrogen economy has captured popular imagination and government support across the world.

The other alternative – synthetic fuels or e-fuels – is also relying on hydrogen basically. e-fuels are produced through a process known as the Fischer-Tropsch synthesis, where hydrogen is combined with CO2 extracted from the air and converted into a liquid energy carrier, which is a synthetic hydrocarbon fuel, or e-fuel. The hydrogen used to produce the e-fuel is generated by the electrolysis process that breaks down water into its components of hydrogen and oxygen, and to that extent, it is the same process that produces hydrogen for fuel cell electric vehicles (FCe Vs) or other industrial applications. Here it is important to understand that the electricity used to produce hydrogen must be renewable, because using electricity generated from fossil fuels defeats the very purpose of the exercise. The burning of e-fuel in IC engines results in emissions, but the carbon dioxide thus emitted is less that used in producing it, and hence considered carbon neutral, or better still, emitting less CO2 than fossil fuels.

Those who are espousing the cause of e-fuels have formed the eFuel Alliance, an interest group committed to promoting political and social acceptance of e-fuels and to securing their regulatory approval. The alliance represents more than 170 companies, associations and consumer organisations along the e-fuel production value chain.

At this point, one may ask why use hydrogen to produce e-fuels when the same can be used for FCeVs? Or for that matter why use FCeVs when eVs are already popular and serving the purpose well? To understand that, one must study the pros and cons of each of these alternatives – eVs, Hydrogen and e-fuels.

The case for and against EVs

Among the three options that form the theme of this article, electric vehicles or eVs are generally considered cleaner than traditional gasoline cars in terms of environmental impact. However, it’s important to note that the overall efficiency of an electric vehicle depends on various factors, including how electricity is generated, the manufacturing process, and the lifespan of the vehicle.

While zero tailpipe emissions during operation is the biggest advantage of eVs, the actual environmental impact of the eV depends on the source of the electricity used for charging. The full benefit accrues only if the electricity comes from renewable sources. If the electricity is generated from fossil fuels, some or most of the environmental benefits are lost. Another major point is the environmental footprint of the manufacturing process, which is believed to be less for eVs

than fossil fuel cars. But critics point out that the production of batteries for electric vehicles, in particular, involves mining and processing raw materials like lithium, cobalt, and nickel, and this is an area that has not been fully explored for its true impact. Add to that, the cost of battery replacement and the total lifespan cost with recycling.

In summary, while electric vehicles are generally cleaner in terms of direct emissions, the overall environmental impact depends on various factors. efforts are being made to make both electric vehicles and the electricity grid more sustainable, and advancements in technology and recycling practices are helping address some of the challenges associated with electric vehicle production and end-of-life management.

The comparison between hydrogen fuel cell electric vehicles (FC e Vs) and battery-operated electric vehicles (B e Vs) involves various factors, and the superiority of one over the other depends on specific circumstances and priorities. In comparison with eVs, FCeVs offer key advantages like a longer range and quick refuelling – it takes only a few minutes to fill a hydrogen tank, whereas charging an electric vehicle can take significantly longer. Hydrogen fuel cells can also be lighter than large battery packs, which can contribute to better efficiency and handling in some cases. Above all, hydrogen fuel cells are highly suitable for hard-

to-electrify mobility segments like heavy transportation, aviation and shipping.

However there are also challenges and concerns when it comes to the use of hydrogen, and these are mainly threefold:

• The infrastructure for producing, transporting, and dispensing hydrogen is currently limited compared to the widespread availability of electric charging stations.

• The production of hydrogen often involves energyintensive processes, which can impact the overall efficiency and environmental benefits of hydrogen fuel cells.

• Hydrogen fuel cell vehicles are generally more expensive to produce than electric vehicles, primarily due to the cost of the fuel cell technology and the materials involved.

At the heart of the argument in favour of e-fuels put forward by the eFuel Alliance are four main points:

• e-fuels have the potential to be carbon-neutral or even carbon-negative if the CO2 used in their production is sourced from the atmosphere or industrial processes

• e-fuels can be used in existing internal combustion engine vehicles with minimal modifications, and are ideal for hardto-electrify segments mentioned earlier in favour of the hydrogen fuel cell

• e-fuels can leverage existing infrastructure for storage, transportation, and distribution, making it potentially easier to integrate them into the existing energy and mobility systems, and

• e-fuels can serve as a form of energy storage, as they can be produced when there is an excess of renewable energy.

Against the potential benefits of e-fuels mentioned above, there are some real challenges associated with the production of e-fuels, including the efficiency of the conversion processes and the overall energy losses. The efficiency of converting renewable electricity into synthetic fuels needs improvement for these fuels to be a truly sustainable and scalable solution. Moreover, with the headstart enjoyed by eVs and the rapid scaling of charging infrastructure, it will be interesting to see whether there will be popular demand for e-fuels, if and when there is production with scale.

Summing up

In conclusion, the choice between battery-operated electric vehicles, hydrogen-powered fuel cell vehicles and e-fuels as the third alternative, shall depend on individual preferences, regional infrastructure, and specific use cases. All three technologies have their merits and challenges, and ongoing advancements may continue to shape the landscape of sustainable transportation. Above all, rapid decarbonisation of electricity is essential for the success of these options.

References

1. https://www.efuel-alliance.eu/

2. https://industry-india.com/market-overview/69893-arewe-really-done-with-ic-engines

3. https://pressroom.toyota.com/advanced-to-the-coretoyota-mirai-offers-an-electrifying-ride/

4. https://www.industryemea.com/marketoverview/75637-the-green-hydrogen-path-to-net-zero

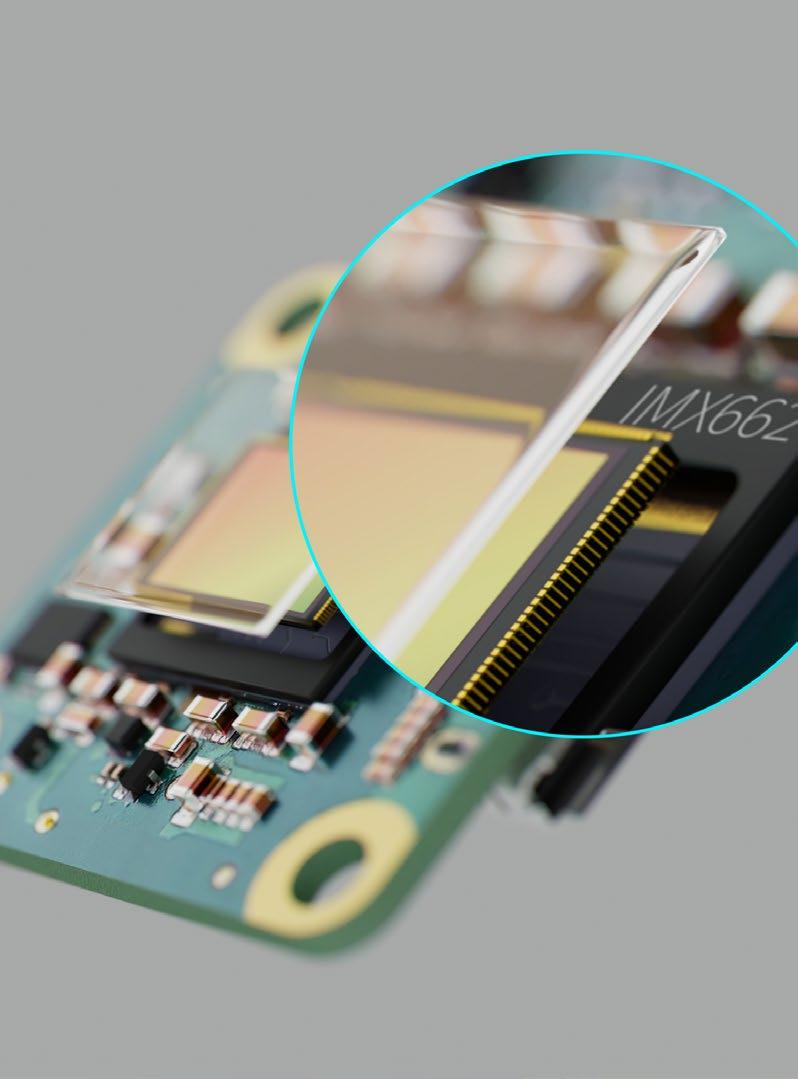

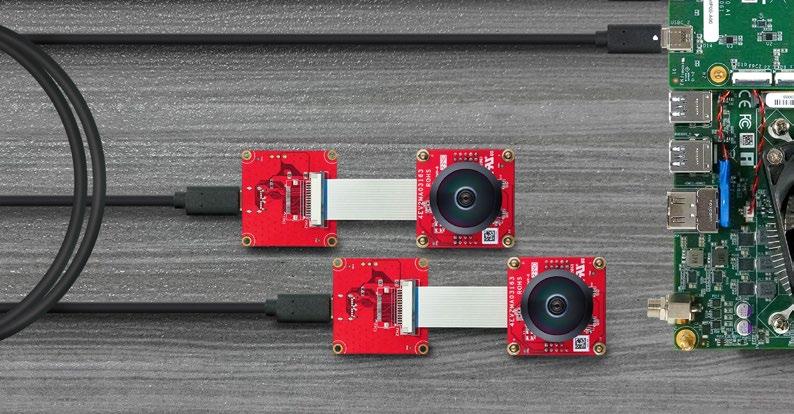

uEye+ XCP: Small industrial camera with outstanding low-light performance

The new uEye+ XCP and XLS cameras perform particularly well in low-light applications.

Compact, cost-effective and with exceptional image quality in low ambient light: IDS is the first industrial camera manufacturer to offer the 2 MP sensor IMX662 in both colour and monochrome versions. The sensors belonging to Sony’s Starvis 2 series are designed for maximum light sensitivity. They are now available either as compact ueye+ XCP models or as board-level versions in the ueye+ XLS series.

Both camera families are characterised by their compact design and are therefore suitable for embedded applications, for example. While ueye+ XCP models have a completely closed housing measuring 29 x 29 x 17 mm with a C-mount lens holder, the ueye+ XLS models measuring just 29 x 29 x 7 mm are available as board-level cameras with or without a C/CS- or S-mount lens holder. The new uSB3 industrial cameras deliver particularly impressive results when used in low-light conditions.

In addition to the special, highly sensitive pixel technology, customers benefit from another distinctive characteristic, as Jürgen Hejna, Product Manager ueye at IDS, explains: “We offer this rolling shutter sensor with anti-reflection coating, which further improves the image quality.” Thanks to this feature, disruptive reflections – known as lens flare – are reduced or completely avoided within the camera.

In addition, the new models offer excellent value for money, as Jürgen Hejna explains: “Customers can get the new models for well under 200 euros list price.” The company plans to make the entire range of Sony Starvis 2 sensors available in different camera families in the future. This will provide customers with the greatest possible flexibility when selecting these light-sensitive sensors.

www.ids-imaging.com

The uEye XLS board-level camera has a wide range of uses - e.g. in embedded applications

Project is critical to enhance the resilience of Algeria’s energy ecosystem, supporting Europe’s energy security by ensuring stable gas supplies.

Baker Hughes, an energy technology company, announced it was awarded a major contract from SOnATRACH for a gas-boosting project for the Hassi R’Mel gas field in Algeria. The contract is part of a broader order awarded to a consortium between Baker Hughes and Tecnimont, part of technology and engineering group MAIRe. The signing ceremony took place in Algiers in the presence of the three company CeOs: Rachid Hachichi of SOnATRACH, Lorenzo Simonelli of Baker Hughes, and Alessandro Bernini of MAIRe, as well as H.e. Mohamed Arkab, Minister of energy & Mines.

• Consortium with Tecnimont (MAIR e ) will supply SOnATRACH with 20 compression trains that are expected to boost gas production at the Hassi R’ Mel gas field in Algeria, one of the world’s largest.

• Agreement strengthens Italy-Algeria bilateral relations as Baker Hughes and Tecnimont will leverage their Italian industrial expertise to deliver on the project.

“The announcement marks a notable milestone in our historical collaboration with SOnATRACH for key energy projects in Algeria that have played a crucial role in supplying reliable energy to europe,” said Lorenzo Simonelli, chairman and CeO of Baker Hughes. “We have long believed that it is critical to increase gas within the overall global energy mix to help achieve a lower-carbon economy. This project helps to solve for energy producers’ multi-faceted challenge of driving sustainable energy development as energy demand increases. We are proud to support such a critical energy project in partnership with Tecnimont.”

Baker Hughes’ awarded scope includes the supply of 20 compression trains based on Frame 5 gas turbine and BCL compressor technology, which will be installed across three gas boosting stations within the Hassi R’ Mel gas field. Located 550 km south of Algiers, Hassi R’ Mel is the largest gas field in Algeria and one of the largest in the world, representing a key source of energy supply for Algeria and europe. Baker Hughes’ proven technology solutions are expected to play a central role in the project by boosting and stabilizing the pressure of natural gas and increasing production at site, which will enhance Algeria’s domestic energy system and economy as well as europe’s energy security.

The new gas-boosting stations are part of Algeria’s ambitious plan to strengthen its role in the global energy market and its commitment to natural gas as a key energy source for socio-economic development. According to Bloomberg neF, Algeria became the second-largest gas supplier to europe in 2023, further strengthening the country’s role in enhancing the energy security of the continent, particularly in Italy where Algeria represents the biggest single source of import. The Hassi R’ Mel Project is part of a broader strategic collaboration between Algeria and Italy, which includes recently signed agreements to foster bilateral cooperation and provide financial support for Algeria’s gas production as part of the Mattei Plan. The Mattei Plan seeks to promote cooperation between Africa and Italy along five main policy pillars: education and training, agriculture, health, water and energy. Packaging of the compressor trains, as well as manufacturing of the compressors and testing of the trains, will take place at Baker Hughes’ facilities in Italy.

www.bakerhughes.com

All these efforts align with Environmental, Social, and Governance implementation across all Pertamina’s business lines and operations.

Jakarta – Director of Finance of PT Pertamina, Emma Sri Martini, representing President Director of Pertamina, Nicke Widyawati, and Chief Executive Officer of the Japan Cooperation Center For Petroleum & Sustainable Energy, Tsuyoshi Nakai, signing the MoU Exchange for “Collaboration in the Field of Capability Development & Technical Cooperation in the Energy Sector”.

Pertamina and the Japan Cooperation Center For Petroleum & Sustainable e nergy have signed a Memorandum of u nderstanding regarding “Collaboration in The Field of Capability Development & Technical Cooperation in The energy Sector” in Jakarta. Director of Finance of Pertamina, emma Sri Martini, stated that the collaboration between Pertamina and JCCP is part of Pertamina’s efforts to address energy transition challenges, particularly the energy trilemma, through initiatives and cooperation with various parties. “One of the collaborations with JCCP involves three potential aspects; capacity development, which includes energy conservation and sustainable digitalization; women empowerment, focusing on career development and women empowerment; and technical assistance, which includes research initiatives supported by JCCP, such as studies on CO2 reform technology implementation in Indonesia, agroforestation development of rubber trees to produce carbon-neutral oil, and Sustainable Aviation Fuel development,” said emma.

Chief executive Officer of JCCP, Tsuyoshi nakai, appreciated the collaboration with Pertamina. “Pertamina and JCCP have had a long-standing business relationship, and this Mou is an initiative to enhance our cooperation. To strengthen the relationship, a cooperation dialogue forum has been established to discuss our collaboration achievements and plans,” he said. CeO of JCCP, Tsuyoshi nakai, added that this agreement’s signing is part of the Asia Zero emission Community event, which received full support from both the Indonesian and Japanese governments in December 2023.

At the same event, the Head of the Bureau of Communication, Public Information Services, and Cooperation of the Ministry of energy and Mineral Resources, Agus Cahyono Adi, said

the Ministry of energy and Mineral Resources supports this collaborative effort. This is important, as Pertamina is a major hope of the government to become a leader and pioneer, aiming towards the net zero emissions target in the future.

Vice President of Corporate Communication of Pertamina, Fadjar Djoko Santoso, added that this Mou is a significant milestone in the ongoing collaboration process. “This Mou signing signifies that we have reached a more solid level of collaboration and demonstrates both parties’ commitment to create innovation and make tangible efforts towards mutually beneficial cooperation for both Pertamina and JCCP, accelerating the energy transition in terms of human resource preparation and energy projects,” explained Fadjar.

The Mou exchange was conducted by the Director of Finance of Pertamina, emma Sri Martini, and the CeO of JCCP, Tsuyoshi nakai. It was witnessed by economic Minister - embassy of Japan in Indonesia - ueda Hajime, Special Counselor - Haruhiko Ando, and Head of the Bureau of Communication, Public Information Services, and Cooperation of the Ministry of energy and Mineral Resources - Agus Cahyono Adi. Senior leaders and executive board members from both parties also attended the event. Pertamina, as a leading company in the energy transition, is committed to supporting the net Zero emission 2060 target by continuously promoting programs that directly impact the Sustainable Development Goals achievement.

www.pertamina.com

K.A. Gerardino explores Generative AI, where precise engineering meets limitless creativity to reshape intelligent systems.

Generative AI is an interesting area of study that involves the creation of machines capable of producing content, such as images, text, or music, that is virtually indistinguishable from content created by humans. This technology relies on sophisticated algorithms and models to generate new, realistic data based on patterns learned from existing data.

In this comprehensive exploration, we discover the advanced tools, intricate models, and real-world applications propelling the evolution of Generative AI. Ready yourself for an in-depth analysis of algorithms and frameworks, uncovering the inner workings that position artificial intelligence at the forefront of innovation. Join us as we navigate the complexities of this transformative field, where precision engineering converges with boundless creativity to redefine the very fabric of intelligent systems.

The global generative AI market size reached uS$12.3 billion in 2023 and is expected to hit uS$58 billion by 2032, demonstrating a growth rate (CAGR) of 18.81% during the period of 2024-2032, according to IMARC Group. The increasing volume of generated data, the advancement of cutting-edge machine learning techniques, the expansion of the information technology (IT) sector, and the growing adoption of products across various industries are among the key factors driving the market forward.

embarking on a comprehensive exploration of Generative AI reveals a dynamic ecosystem teeming with innovation, where tools, models, and applications converge to redefine the very fabric of artificial intelligence. Let us delve into the intricate layers of each key aspect, unravelling the nuances that collectively contribute to the transformative nature of this growing field.

Here are some key aspects of generative AI, including tools, models, and applications:

Generative AI Tools

• OpenAI’s GPT (Generative Pre-trained Transformer): GPT-3, the latest version, is a powerful language model that has been widely used for various natural language processing tasks. It can generate coherent and contextually relevant text based on prompts provided to it.

• DeepDream: Developed by Google, DeepDream is an image generation tool that utilizes neural networks to enhance and modify images. It highlights and exaggerates patterns and features in images to create visually stunning and sometimes surreal results.

• StyleGAN (Generative Adversarial Network): StyleGAn is a popular model for generating realistic images. It excels in creating high-quality, diverse images with customizable styles. StyleGAn2, an improved version, has been widely adopted in the creation of deepfake images.

• GAns (Generative Adversarial networks): GAns are a class of algorithms where two neural networks, a generator, and a discriminator, are trained simultaneously through adversarial training. GAns are used for various generative tasks, such as image and video synthesis, as well as style transfer.

Generative AI Models

• BERT (Bidirectional Encoder Representations from Transformers): Although initially designed for natural language understanding, B e RT has been used for generative tasks as well. It understands the context of words in a sentence, making it suitable for generating coherent and contextually relevant text. Although initially designed for natural language understanding, BeRT has been used for generative tasks as well. It understands the context of words in a sentence, making it suitable for generating coherent and contextually relevant text.

• VQ-VAE-2 (Vector Quantized Variational Autoencoder 2): VQ-VAe-2 is an advanced model for image generation. It uses vector quantization and variational autoencoder techniques to produce high-quality and diverse images.

• Content Creation: Generative AI is used in the creation of digital content, including images, text, and music. This can be applied in various industries, from graphic design to entertainment.

• Deepfake Technology: GAns have been employed in the development of deepfake technology, enabling the creation of realistic-looking videos and images with manipulated content.

• Artificial Creativity: Generative AI is being explored as a tool for enhancing human creativity. Artists and designers use these models to inspire and assist in the creative process.

• Data Augmentation: In machine learning, generative models are utilized for data augmentation, creating additional training examples to improve the robustness and generalization of models.

• Drug Discovery and Molecular Design : Generative models are applied in pharmaceutical research to generate novel molecular structures for drug discovery.

While generative AI holds tremendous potential, it also raises ethical concerns, particularly in the context of deepfake technology and the potential misuse of generated content. Striking a balance between innovation and responsible use is crucial as this field continues to evolve.

Generative AI market growth factors

The generative AI market has witnessed significant growth in recent years, driven by several factors that contribute to its adoption across various industries. Here are some key growth factors for the generative AI market:

• Advancements in Deep Learning: Breakthroughs in deep learning architectures, such as Generative Adversarial networks (GAns) and Transformers, have significantly improved the capabilities of generative AI models. These advancements have led to the creation of more realistic and sophisticated content, driving demand in the market.

• Increased Computing Power: The availability of powerful GP u s (Graphics Processing u nits) and TP us (Tensor Processing u nits) has enabled the training of larger and more complex generative models. This increased computing power has played a crucial role in the development of state-of-the-art generative AI applications.

• Open-Source Frameworks and Tools: The availability of open-source frameworks and tools, such as TensorFlow and PyTorch, has democratized access to generative AI technology. This has lowered the entry barriers for developers and businesses, fostering innovation and expanding the overall market.

• Rise of Pre-trained Models: Pre-trained models, like OpenAI’s GPT and various versions of StyleGAn, have gained popularity. These models, trained on massive datasets, can be fine-tuned for specific applications, accelerating the development process, and making generative AI more accessible.

• Diverse Applications Across Industries: Generative AI finds applications in a wide range of industries, including entertainment, healthcare, finance, and manufacturing. This versatility has contributed to its market growth as businesses explore innovative ways to leverage generative AI for various use cases.

• Increased Data Availability: The abundance of digital data available for training generative models has been a crucial factor in their success. Large datasets allow models to capture diverse patterns, resulting in more accurate and realistic outputs.

• Creative Content Generation: The demand for creative content, including images, videos, and text, in industries such as marketing, design, and entertainment has fueled the growth of generative AI. Businesses are leveraging these technologies to streamline content creation processes and deliver engaging material.

• Research and Development Investments: Increased investments in research and development by both private companies and public institutions have driven innovation in generative AI. This ongoing research contributes to the development of more advanced models and applications.

• Growing Awareness and Adoption: As awareness of generative AI capabilities spreads, more businesses are recognizing the potential benefits of incorporating these technologies into their operations. The growing adoption across sectors further fuels market growth.

• Regulatory Support and Ethical Considerations: Clear regulatory frameworks and ethical guidelines around the use of AI technologies, including generative AI, provide a supportive environment for businesses to invest in and deploy these solutions. Addressing ethical concerns ensures responsible development and use of generative AI.

The convergence of these factors is driving the generative AI market, and its continued evolution is expected to bring about further innovations and applications across diverse industries in the coming years.

Restraining factors in Generative AI

While generative AI has experienced substantial growth and advancement, there are also several restraining factors and challenges that impact its widespread adoption.

Generative AI models often require large amounts of data for training, which raises concerns about data privacy and security. The use of personal or sensitive data in training sets may lead to privacy breaches and ethical issues. The potential for misuse of generative AI, especially in the creation of deepfakes or other malicious content, raises ethical concerns. Addressing the responsible and ethical use of these technologies is crucial to mitigate negative consequences.

Generative AI models can inadvertently learn and perpetuate biases present in the training data. This can lead to biased outputs, reinforcing existing societal prejudices and discrimination. ensuring fairness and addressing bias in generative models is an ongoing challenge.

Many generative AI models, especially complex neural networks, lack interpretability. understanding how these models generate specific outputs can be challenging, limiting their trustworthiness in critical applications where interpretability is essential.

Training and running sophisticated generative AI models often require significant computational resources, including powerful GPus and TPus. This resource intensiveness can be a barrier for smaller organizations or those with limited computing infrastructure.

The legal landscape surrounding generative AI, particularly in the context of intellectual property rights and ownership of generated content, is still evolving. Clear regulatory frameworks are needed to address legal challenges associated with generative AI.

Generative AI models may face challenges in generalizing well to diverse and unseen data. Overfitting to specific patterns in the training data may result in poor performance on new and varied inputs.

understanding and predicting the behaviour of generative AI models can be difficult. This lack of understanding may hinder the adoption of these models in critical applications where predictability is essential.

Building and maintaining state-of-the-art generative AI models can be expensive. This cost factor may limit the accessibility of generative AI technologies for smaller businesses and organizations with budget constraints.

Convincing users to trust outputs generated by generative AI models, especially in critical applications like healthcare or finance, can be challenging. e stablishing trust and acceptance is crucial for the successful integration of generative AI solutions.

Developing and deploying generative AI models often requires a combination of expertise in machine learning, computer science, and domain-specific knowledge. The need for interdisciplinary skills may pose challenges for organizations lacking diverse expertise.

Addressing these restraining factors requires a concerted effort from researchers, developers, policymakers, and industry stakeholders to ensure the responsible and ethical development, deployment, and use of generative AI technologies. Ongoing research and collaboration are essential to overcome these challenges and unlock the full potential of generative AI.

The generative AI landscape is undergoing rapid transformation, propelled by advancements from industry frontrunners, as highlighted by the IMARC Group. Presently, major market players are at the forefront of innovation, introducing novel models, refining existing ones, and employing avant-garde techniques to elevate the quality and diversity of generated content. notably, investments in research and development are directed towards enhancing image and video synthesis, with applications spanning virtual reality, gaming, content creation, and special effects.

In addition to pioneering technological advancements, key players in the generative AI arena are actively working towards democratizing access to this cutting-edge technology. Initiatives include the development of userfriendly tools, platforms, and APIs designed to empower developers, researchers, and businesses, ensuring seamless integration and utilization of generative AI capabilities. Furthermore, strategic collaborations through partnerships and mergers and acquisitions are a focal point for market leaders, strategically fortifying their positions in this dynamic landscape.

Among the notable entities shaping the generative AI market are:

• Adobe Inc. has been at the forefront of creative software and tools for decades. Their investment in generative AI is evident through products like Adobe Sensei, which leverages AI to enhance user experiences, automate tasks, and generate content. Its integration of generative AI into its suite of creative applications empowers designers, marketers, and content creators to produce personalized, high-quality content efficiently.

• Amazon Web Services Inc. (AWS) provides cloud-based infrastructure and services, including machine learning and AI capabilities. Their SageMaker platform enables developers to build, train, and deploy generative AI models. AWS democratizes access to AI tools, making it easier for businesses to adopt generative AI solutions without heavy upfront investments.

• D-ID specializes in privacy protection through AI. Their technology anonymizes facial images while preserving their utility. In an era of privacy concerns, D-ID’s generative AI solutions are crucial for safeguarding sensitive data, especially in industries like healthcare and finance.

• Google LLC’s research and development in generative AI have led to breakthroughs like DeepDream and BeRT. They also offer tools like TensorFlow and AutoML. Google’s opensource contributions and AI-driven products influence the entire industry. Their generative models enhance search, language understanding, and content creation.

• MOSTLY AI Inc. focuses on synthetic data generation. Their platform creates privacy-preserving synthetic datasets for training AI models. Synthetic data is essential for training robust generative models while protecting user privacy. MOSTLY AI’s approach addresses data scarcity and privacy concerns.

• OpenAI is renowned for its research in natural language processing (nLP) and generative models. Their GPT series (including ChatGPT) has transformed how we interact with AI-generated content.OpenAI’s democratization of largescale language models has sparked innovation across industries, from chatbots to content creation.

• Rephrase.ai specializes in video synthesis using AI. Their technology generates realistic video content from text descriptions. Video content is increasingly vital for marketing, entertainment, and communication. Rephrase. ai’s solutions streamline video production.

• Synthesia offers AI-driven video production tools. Their platform enables automatic video creation by converting text into lifelike videos.The company’s technology accelerates video content production, making it accessible to businesses and creators. Specific data related to Synthesia’s market share is not explicitly mentioned, but their impact aligns with the broader generative AI market trends.

Our exploration into the expansive domain of generative AI extends beyond the central focus on leading market participants, encompassing a broader spectrum of pivotal advancements. In this segment, we delve into ’Other Key Industry Developments,’ revealing a rich tapestry of fresh ideas, strategic partnerships, and emerging trends that are leaving an indelible mark on the trajectory of generative AI. From groundbreaking research projects to transformative alliances and technological milestones, the evolving landscape unfolds with each noteworthy endeavour.

In June 2023, Salesforce made a significant stride by introducing two generative AI products tailored for the commerce experience and personalized consumer engagement—Commerce GPT and Marketing GPT. The latter, Marketing GPT, harnesses real-time data from Salesforce’s cloud platform to generate innovative audience segments, personalized emails, and refined marketing strategies.

Similarly, in the same month, Accenture and Microsoft forged a collaborative effort to empower companies in transforming their businesses through the accelerated potential of generative AI driven by the cloud. This alliance is designed to guide customers in responsibly integrating and extending technology to suit their unique business needs.

May 2023 witnessed SAP Se joining forces with Microsoft to address fundamental business challenges through the incorporation of the latest enterprise-ready innovations. This strategic integration is poised to usher in new experiences, enhancing how businesses attract, retain, and optimize the quality of their workforce.

In the realm of startup acceleration, April 2023 marked a milestone as Amazon Web Services, Inc. unveiled the global Generative AI Accelerator. This initiative provides startups with access to impactful AI tools and models, optimization of machine learning stacks, customized go-to-market strategies, and more.

Lastly, the collaborative efforts of Adobe and n VIDIA in March 2023 stand as a testament to the industry’s commitment to advancing generative AI and fostering sophisticated creative workflows. This partnership aims to innovate advanced AI models seamlessly integrated into applications widely used by significant developers and markets, charting a course for the future of generative AI.

Generative AI in 2024

Let’s now cast our gaze into the crystal ball of generative AI and catch a glimpse of what the landscape holds for us in 2024.

In the ever-evolving landscape of artificial intelligence, the advent of advanced generative models marks a pivotal moment. As we stand on the cusp of innovation, GPT-4, the successor to the groundbreaking GPT-3, promises to propel us into uncharted territories of natural language understanding, creative expression, and interactive capabilities. GPT-4 is not confined to the realm of text alone. The upcoming generation of language models is set to transcend boundaries, seamlessly integrating multimodal inputs such as images, audio, and video. This expansion will usher in a new era of immersive and expressive interactions, pushing the boundaries of what AI can achieve.

The democratization of artificial intelligence is underway with the rise of fine-tuning tools. enabling users to tailor pretrained models to specific tasks, these tools are becoming commonplace. The ability to customize AI empowers businesses and individuals alike, fostering a new era of adaptability to unique needs. Domain-specific models will further enrich this customization trend, offering specialized solutions for fields such as law, medicine, and science. The fine-tuning of models for niche applications promises to enhance performance and relevance in specific domains.

As AI continues its ascent, the need for ethical considerations becomes paramount. efforts to mitigate bias in generative models will intensify, with a strong focus on fairness, transparency, and accountability. The interpretability of AI models will also see significant advancements, employing techniques like attention maps and rule-based explanations to demystify their decision-making processes.

The collaboration between human creativity and AI is set to reach new heights. Artists, musicians, and writers will join forces with AI to produce innovative works across various mediums. e xpect AI-generated music, paintings, and literature to grace galleries and concert halls, showcasing the symbiotic relationship between human ingenuity