IN DUSTRY

INTERNATIONAL

INDUSTRIAL MARKET MAGAZINE

OLYMPIC SHOWS AND ARTIFICIAL MOONS

32

ACOUSTIC IMAGERS TO DETECT COMPRESSED AIR LEAKS, PARTIAL DISCHARGES, MECHANICAL FAULTS, AND QUANTIFY GAS LEAKS

12

HUTCHINSON LAUNCHES FIRE-RESISTANT, HALOGEN-FREE EPDM MATERIAL FOR SEALING BATTERY PACKS IN ELECTRIC VEHICLES

28

WEARIN PROVIDES ADVANCING POLICE SAFETY WITH IOT AND AI-ENABLED TACTICAL VESTS

20

03 | April 2024 WORLDWIDE

4 LEUZE PRESENTS NEW ODT3CL1-2M LASER DIFFUSE SENSOR

8 IDS JOINS THE INNOVATION PARK ARTIFICIAL INTELLIGENCE (IPAI)

10 ROBODK AND COMAU PARTNER TO OFFER IMPROVED ROBOTIC SIMULATION AND OFFLINE PROGRAMMING

12 FLIR ANNOUNCES SI2-SERIES OF ACOUSTIC IMAGERS TO DETECT COMPRESSED AIR LEAKS, PARTIAL DISCHARGES, MECHANICAL FAULTS, AND QUANTIFY GAS LEAKS

14 HAIMER TOOL ROOM NOW WITH WINTOOL AND TOOLBASE SYSTEM

18 REVOLUTIONISING CABLE LABELLING: A CALL TO ACCELERATE YOUR PRODUCTION WITH BRADY’S AUTOMATED SOLUTIONS

19 ELECTRO RENT ANNOUNCES DISTRIBUTION AGREEMENT WITH VIAVI SOLUTIONS

20 WEARIN PROVIDES ADVANCING POLICE SAFETY WITH IOT AND AI-ENABLED TACTICAL VESTS

22 EMERSON’S NEW COMPACT, RUGGED PC BUILT TO CONNECT INDUSTRIAL FLOOR TO CLOUD

23 NEW MINI LEVER ACTUATED PLUNGER SAVES TIME AND SPACE

24 NEW LEMO PRODUCT FAMILY PORTFOLIO SIMPLIFIES SELECTION PROCESS

26 SECO NANOJET REAMERS OPTIMIZE

CHIP CONTROL TO ELIMINATE SCRAPPED PARTS

NEW PRODUCTION SITE: FEINTOOL CONTINUES SUCCESS STORY IN ASIA WITH PLANT IN INDIA 28 HUTCHINSON LAUNCHES FIRE-RESISTANT, HALOGEN-FREE EPDM MATERIAL FOR SEALING BATTERY PACKS IN ELECTRIC VEHICLES 30 TWO OFFERS FOR WAREHOUSE LOGISTICS 32 OLYMPIC SHOWS AND ARTIFICIAL MOONS 36 FASTER ACCESS TO DEVICE DATA 38 EMERSON INTRODUCES ULTRASONIC METAL WELDERS WITH ADVANCED CONTROLS FOR FAST-CYCLING, HIGHPRECISION WELDS 40 THE FUTURE OF AUTONOMOUS TRUCK SAFETY AND USABILITY 42 NEW IGUS SMART FIXED FLANGE BEARINGS UNLOCK PREDICTIVE MAINTENANCE 43 ORBEX GROUP NOW OFFERS TWO FIBER OPTIC ROTARY JOINT (FORJ) SOLUTIONS INTERNATIONAL INDUSTRIAL MARKET MAGAZINE 03 • INDUSTRY | April 2024 www.magazine-industry-usa.com ADVERTISERS: • MEPAX 7

27

Send your press releases to: editor@ipmediaonline.com

To receive ours newsletters, please subscribe online: https://induportals-media-publishing.com/ INDUSTRY is the magazine for engineers, published by iNDUpOrTAlS MEDiA pUBliSHiNG. it contains the latest product and company news for industrial markets. INDUSTRY edits its articles with the greatest of care, however we cannot guarantee the accuracy of the information presented in them. Our teams disclaim all responsibility concerning the content of this media or how it might be used.

INDUPORTALS MEDIA PUBLISHING

Find our publications on iSSUU.

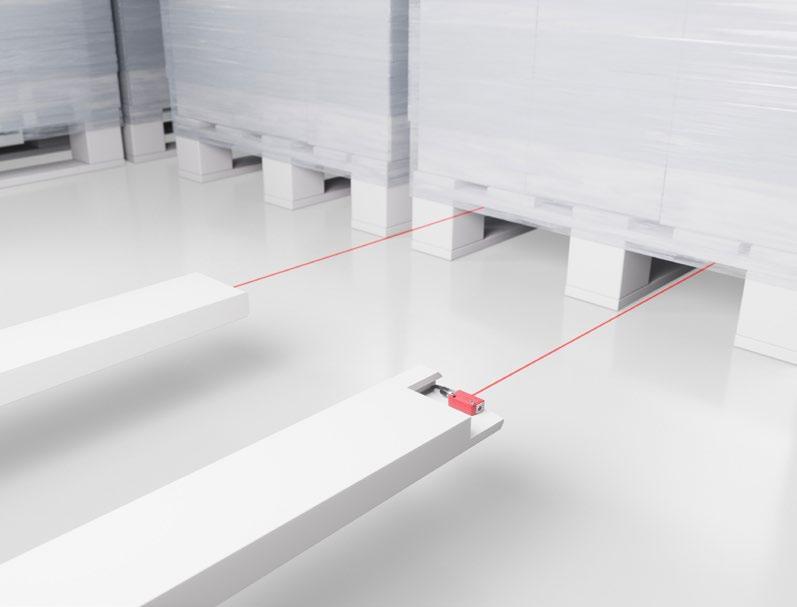

LEUZE PRESENTS NEW ODT3CL1-2M LASER DIFFUSE SENSOR

Thanks to the extremely small and space-saving housing (11.4 mm x 34.2 mm x 18.3 mm), the ODT3CL1-2M can be used in many different applications.

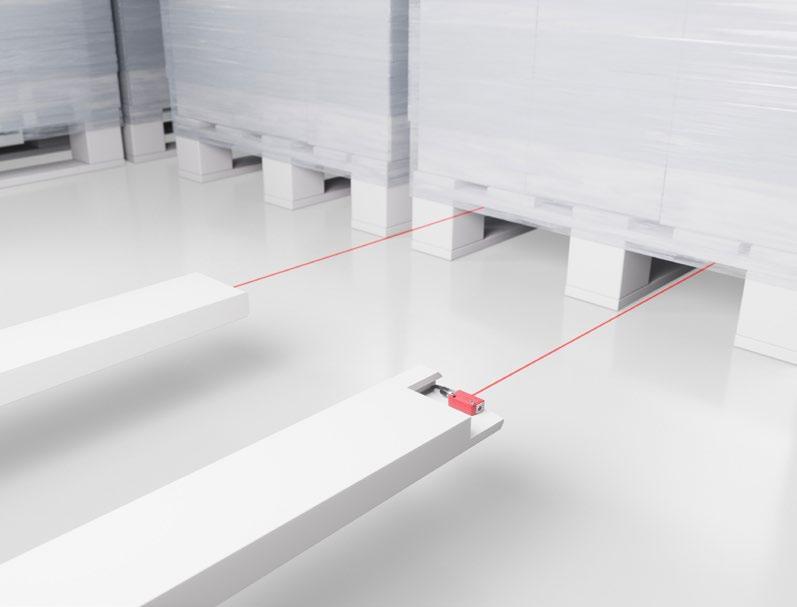

Small housing, big operating range: the new ODT3CL1-2M compact diffuse sensor from Leuze achieves an operating range of up to two meters.

With the new ODT3Cl1-2M laser diffuse sensor, the Sensor people from leuze are extending the operating range of their 3C series distance sensors. Thanks to innovative time-of-flight (TOF) technology, the switching and measuring sensor with background suppression works with an operating range of up to two meters. This makes the ODT3Cl1-2M suitable for all applications in intralogistics where long distances need to be bridged: e.g., in automated guided vehicles for monitoring the position of goods, for controlling robot grippers or in quality control. reliable use is guaranteed even under harsh conditions. This is because the sensor satisfies the high requirements of degree of protection ip69K.

Practical 2-in-1 solution

As a 2-in-1 solution, the ODT3Cl1-2M reduces the cost and effort for users in terms of procurement, installation, commissioning and in operation. With its two independent switching points, it is able to perform detection and measurement tasks at the same time. System operators can therefore solve both requirements using just one sensor. This is an advantage if, for example, shuttles are used: They can optimally set and vary their speed via the independent switching points. This enables goods to be transported quickly to their target position.

Everything in view via IO-Link iO-link can be used to transmit measurement values and process data of the sensor to the machine control. This allows users to effortlessly evaluate the comprehensive diagnostic data from the diffuse sensor – e.g., temperature information, information on signal quality and warnings. it also makes device swap-out easy: The presettings are transferred to the new device loss-free via iO-link without the sensor having to be taught in again.

03 • INDUSTRY | April 2024 4 MORE INFORMATION MEASU r EMENT

On automated guided vehicles, the ODT3CL1-2M optical sensors monitor that pallets are correctly received and transferred

The diffuse sensors are ideal for compartment occupation checking with shuttles. They detect whether a space to be occupied is free

Fits in any space

Thanks to its compact design (11.4 x 34.2 x 18.3 millimeters; W x H x l), the ODT3Cl1-2M laser diffuse sensor can also be used where space is limited. For example, it can be used in the gripper of a robot arm, on shuttles or stacker cranes. The small, clearly visible light spot allows fast alignment during commissioning. The operating range can be set numerically via iO link. Another advantage of the diffuse sensor is its integrated object test. This allows the function reserve to be quickly checked.

3C series: for any operating range

With the 3C series, leuze provides a sensor solution that is also suitable for distances of less than two meters. The ODT3C diffuse sensor is therefore ideal for operating ranges up to 150 millimeters – perfect for packaging processes, for example.

in addition to detecting the presence of a component, the ODT3Cl1-2M laser diffuse sensor can also detect defined reference points on the component and thus check the quality. Here the sensors work reliably even with different surface structures

www.leuze.com

03 • INDUSTRY | April 2024 6 MORE INFORMATION

In addition to detecting the presence of a component, the ODT3CL1-2M laser diffuse sensor can also detect defined reference points on the component and thus check the quality. Here the sensors work reliably even with different surface structures.

OPTIMIZE YOUR INTERNATIONAL PR AND ADVERTISING FOR THE INDUSTRIAL MARKET!

International capability

More than 80 employees in 35 different countries, ensuring a strong relationship with main local media.

Mepax distinguishes itself through its extensive media knowledge and ability to select the best international online/print advertising options. PR can be translated into 35 languages.

Outstanding results

50,000 published articles in 2023: EMEA: 48% - Asia: 31% - Americas: 21%. Most of the articles are published in the top 1000 media worldwide.

Optimized process

With a proven process set for more than 200 active customers, we can adapt to all specific client needs with the highest reliability. We have developed in house the most advanced PR dedicated ERP, enabling transparency and real-time full online reporting. International media management is then made easy, fast, and efficient for optimal results.

www.mepax.com

THE MOST INNOVATIVE PR AGENCY

info@mepax.com

IDS JOINS THE INNOVATION PARK ARTIFICIAL INTELLIGENCE (IPAI)

Unique ecosystem promotes collaboration in the field of artificial intelligence in Heilbronn, Germany.

iDS imaging Development Systems GmbH joined ipAi, the innovation park Artificial intelligence, at the outset of 2024 ipAi/MVrDV. This initiative stands as one of the most ambitious endeavors for applied artificial intelligence across Europe. Nestled in Heilbronn, adjacent to iDS’s headquarters, the circular campus of ipAi will serve as its hub. Here, corporations, startups, and academic institutions will converge, pooling their efforts towards pioneering Ai solutions.

iDS, renowned for its expertise in artificial intelligence within image processing, has been an active contributor to this network since the inception of 2024. Heilbronn, traditionally recognized as an industrial stronghold, is undergoing a remarkable metamorphosis fueled by the Dieter Schwarz Foundation’s fervent dedication to emerging technologies. “Artificial intelligence dominates conversations, with rapid advancements anticipated in the years ahead. Heilbronn is keen on shaping these transformations locally rather than merely observing,” elucidates iDS Managing Director Jan Hartmann. “Our involvement in the ipAi underscores our pride in contributing to Heilbronn’s evolution.”

i DS’s contribution to the ipA i extends its wealth of A i knowledge garnered from image processing. The concept of an Ai innovation park in Baden-Württemberg took root as early as 2018. Following a feasibility study and broad consultation, Heilbronn emerged as the chosen site, with government backing solidifying its establishment. iDS lent support during the project’s nascent stages, culminating in its official membership in 2024. “Membership in the ipAi signifies iDS’s deepened commitment to Ai. We eagerly anticipate sharing our expertise in image processing and beyond, fostering collaboration on promising ventures,”

03 • INDUSTRY | April 2024 8 MORE INFORMATION CO rp O r ATE

remarks Sigrid

remarks Sigrid

Through the platform’s open innovation ethos, iDS stands to gain from the collective wisdom of fellow Ai specialists, facilitating advancements such as A i camera series optimization and internal data processing. Carolin rehder, Head of Membership & Community at ipA i , enthuses, “Welcoming iDS, a leader in image processing, to the ipAi community is a cause for celebration. Their profound expertise and proactive engagement promise to enrich our innovation ecosystem immeasurably.”

www.ids-imaging.com

03 • INDUSTRY | April 2024 9 MORE INFORMATION

rögner, Head of Business innovation and Ecosystem at iDS.

Carolin Rehder, Head of Membership & Community at IPAI.

Jan Hartmann, Managing Director at IDS Imaging Development Systems GmbH

Sigrid Rögner, Head of Business Innovation and Ecosystem at IDS Imaging Development Systems GmbH

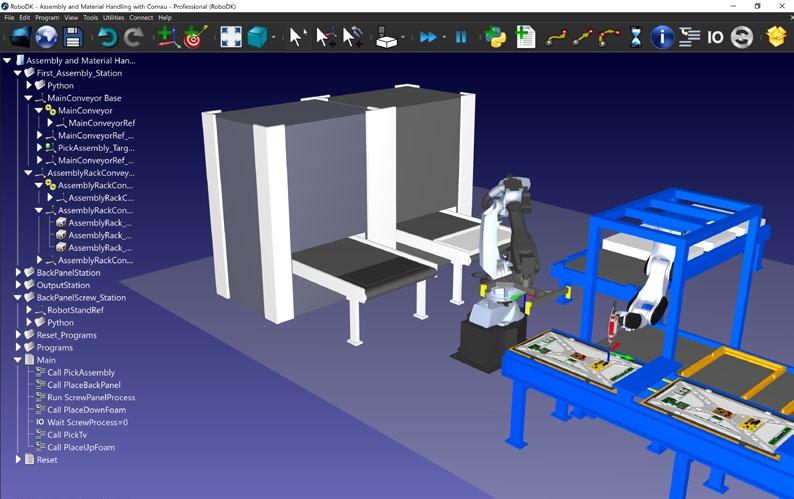

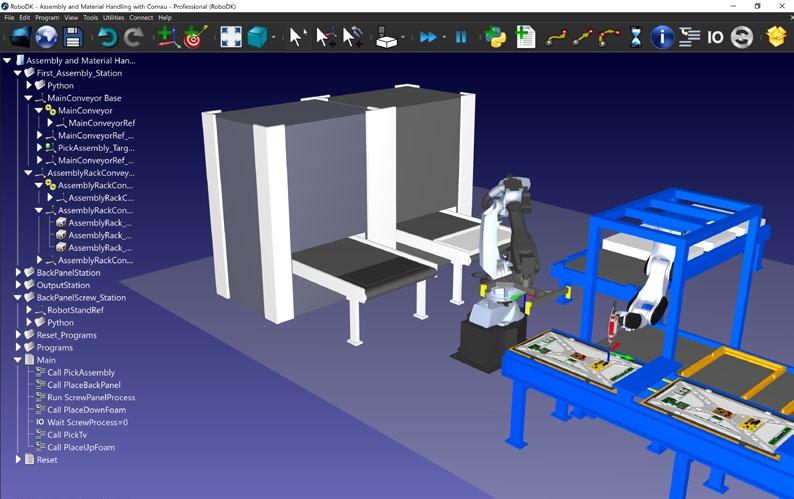

ROBODK AND COMAU PARTNER TO OFFER IMPROVED ROBOTIC SIMULATION AND OFFLINE PROGRAMMING

The latest version of Comau Roboshop Next Gen software now fully integrates with RoboDK, bringing unparalleled benefits to the world of automation.

roboDK, a pioneer in the world of robotics simulation and offline programming, announces its strategic partnership with Comau, a global leader in advanced automation solutions and robot manufacturer. The latest version of Comau roboshop Next Gen software seamlessly integrates with roboDK, making simulation more advanced.

This collaboration solidifies roboDK’s presence in the OEM market, marking a significant step as an embedded solution. Comau users can now enjoy the benefits of roboDK directly due to roboDK’s integration into Comau’s roboshop Next Gen software suite. This integration allows users to easily simulate and program robots using advanced CAD to path features, import 3D Models, detect collisions, integrate with external axes such as turntables and linear rails, support multiple robot cells in the same project, improved integration with CAD/CAM software and use advanced simulation features such as conveyors and grippers. This allows Comau robot programmers to easily use Comau robots for advanced manufacturing applications such as robot machining or 3D printing.

in addition to these technical benefits, the collaboration also introduces support for r ealistic r obot Simulation (rrS), providing accurate path and cycle time estimates. This advancement aims to provide businesses with a clear understanding of robot behavior and precise cycle time details, ensuring more efficient and optimized robot operations.

Using r oboDK it will therefore be possible to create a program in a very intuitive way. Then through roboshop Next Gen, it can be executed in a simulation with a Virtual Control and then deployed on a real robot!

While this partnership marks a significant step for embedded solutions, r oboDK remains committed to its ongoing collaboration efforts with various partners, reinforcing its dedication to make automation more affordable across industries.

phillip from the roboDK team shares his insights on the collaboration: “By working closely with Comau we were able to improve our integration with Comau robot controllers while keeping everything backwards compatible. The level

03 • INDUSTRY | April 2024 10 MORE INFORMATION r OBOT i CS

of integration resulting from this partnership is immensely beneficial for all Comau users.”

Albert Nubiola, CEO and Founder of roboDK, comments: “We’re excited to partner with Comau and bring roboDK’s advanced simulation features to roboshop software at an unbeatable price. By working together, we were able to make advanced simulation more affordable.”

He continues: “Our mission is to build a software platform where users can program any robot arm using the same software, democratizing robot simulation and programming. partnering with Comau, one of the world’s premier robot manufacturers, marks a pivotal moment for us.”

r oboDK distinguishes itself by embracing modern technologies, thus setting itself apart from peers reliant on older and more expensive software frameworks. With modern tools, integrations, competitive pricing, and an array of complementary features—including advanced CAD to path features, integrations with CAD/CAM software, collision checking, singularity avoidance, robot calibration and brand-agnostic offline programming— r oboDK stands out as a frontrunner. Users have access to extensive documentation and libraries at no cost. Moreover, roboDK’s website, documentation and YouTube channel offers a rich collection of tutorials.

Alessandro piscioneri, Head of product and Solutions Management, remarks: “Comau has recently launched the latest version of roboShop Next Gen, that allows our customers and partners to program our robots and simulate their functionalities in an easy and fast way. Thanks to the collaboration with roboDK, a truly innovative company in robot programming and 3D simulation, it is possible for companies to create their virtual environments and simulate their applications in a matter of minutes, while using Comau’s software. i t’s important to emphasize that this solution is aimed at both experienced and new programmers, in an effort to make robotics easier to design and use. This is a priority for us and we are investing heavily in this direction”.

About RoboDK

Founded by Albert Nubiola in January 2015, roboDK is a spin-off company from the prestigious Coro laboratory at ETS University in Montreal, Canada. Designed to bring robust robotics simulation and programming capabilities to the automation sector, roboDK supports over 1000 robots from more than 70 manufacturers.

www.comau.com

03 • INDUSTRY | April 2024 11 MORE INFORMATION

FLIR ANNOUNCES SI2-SERIES OF ACOUSTIC IMAGERS TO DETECT COMPRESSED AIR LEAKS, PARTIAL DISCHARGES, MECHANICAL FAULTS, AND QUANTIFY GAS LEAKS

New Si2-Pro, Si2-LD, and Si2-PD models provide best-in-class performance, decision support, fleet management and enterprise data integration with new on-screen gas leak quantification, partial discharge assessment, and mechanical fault measurement.

Flir, a Teledyne Technologies company, announced the expansion of its versatile Si-Series of acoustic imaging cameras with three models in the new Si2 family, designed for detecting compressed air leaks, specialty gas leaks, mechanical faults, and partial discharges: the Si2-pro, Si2-lD, and Si2-pD. The Si2-Series offers industrialgrade solutions for the detection of air and gas leaks as well as mechanical faults such as bearing issues, addressing the top inspection requirements for industries such as manufacturing, electrical, and utilities.

Flir’s new Si2-Series cameras provide superior performance, with the ability to identify issues over longer distances, detect and measure with increased sensitivity, and produce more accurate classification of issues.

The new Si2-pro, the Si2-lD and the Si2-pD models offer the best image quality on the market. improvements in acoustic camera picture quality include 12 Mp color camera, 8x digital zoom, and lED illumination for addressing dark areas. The Si2 also has increased battery life to keep professionals in the field longer without the need for swapping power sources. The specialty gas leak quantification and cost estimates have been expanded beyond compressed air to include other common industrial gases such as hydrogen, CO₂, methane, helium, argon, ammonia, and more.

The Si2 cameras apply an array of acoustic imaging advancements that work to detect and quantify air and gas leaks, mechanical faults, and partial discharge, making them the top-performing acoustic imaging cameras on the market for these types of detections.

03 • INDUSTRY | April 2024 12 MORE INFORMATION V i S i ON SYSTEM

• FLIR Si2-Pro: i ndustrial acoustic imaging camera for pressurized leak detection, mechanical fault detection, and partial discharge detection with on-camera severity assessments

• FLIR Si2-LD : i ndustrial acoustic imaging camera for pressurized leak detection and mechanical fault detection in manufacturing and other industrial environments

• FLIR Si2-PD: industrial acoustic imaging camera for partial discharge detection with on-camera severity assessments for power infrastructure inspection

Flir ’s advanced automatic filtering identifies leaks by their sound signatures even in the noisiest of industrial environments. The new ’mech mode’ feature of the Si2Series enhances site safety by enabling quick detection of mechanical issues, such as bearing faults, empowering professionals to rapidly evaluate conditions, identify problems, and implement solutions.

plant professionals can swiftly identify mechanical, leak and partial discharge issues, then generate reports for urgent attention. On-camera decision support tools include mechanical defect measurement, classification and severity assessment of partial discharges, leak size estimation, and cost analysis.

The Si2-pro, the most comprehensive solution that combines the features of the Si2-pD and Si2-lD, actively lowers costs by addressing mechanical bearing issues and partial discharge on electrical equipment, and it also significantly cuts leaks in facilities to reduce expenses from compressed air and gas leaks.

“increasing safety while avoiding costly failures is the aim of the new Si-Series. With the addition of three leading-edge models that scale up for professional use in a wide variety of situations, the new Si2-Series of cameras cement their position as the industry’s most complete, enterprise-ready solution,” said rob Milner, Business Development Director, Flir. “The highly capable Flir Thermal Studio will also be upgraded to include gas-leak quantification, making data simple to record and easier to share via reports between users, cutting down the time to perform and record multiple site inspections.”

To complement the Si2-Series of acoustic imaging cameras, Flir provides its acoustic training platform and 24/7 support through its global service organization.

https://www.flir.com/browse/industrial/acoustic-imagingcameras/

03 • INDUSTRY | April 2024 13 MORE INFORMATION

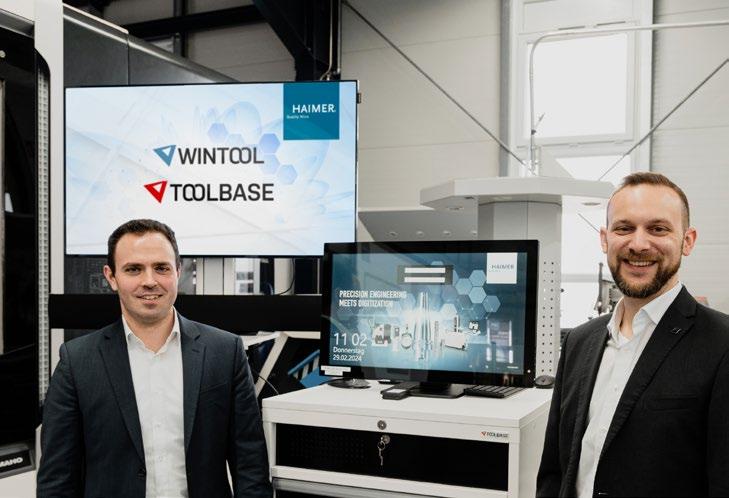

HAIMER TOOL ROOM NOW WITH WINTOOL AND TOOLBASE SYSTEM

The Haimer Group becomes a 25% shareholder in WinTool AG and agrees on a strategic partnership with the TCM Group, which grants HAIMER global distribution rights to WinTool and Toolbase.

prior to the decision to acquire this stake in the company, WinTool and Toolbase were introduced in the company’s own production facilities and tested in continuous use, proving their worth in a very short period of time. in the future, TCM will rely on HAiMEr as a strategic supplier in the field of tool holders, shrinking, balancing and presetting machines in the core business of tool management.

Tool management is becoming increasingly important in manufacturing companies. HAiMEr, a global player and market leader for tool holding and presetting, has therefore been offering innovative tool room solutions for years, in which HAiMEr shrinking, balancing and presetting machines ensure high efficiency.

At EMO 2023, HAiMEr took an important step forward and has since been offering its successful hardware products for machine tools alongside a powerful digital range consisting of the WinTool software, an independent tool management system, and Toolbase, a smart tool dispensing system with software and hardware components. in order to realize this, HAiMEr entered into a competence partnership with the TCM Group, which includes WinTool AG and Achterberg GmbH, who have built up an excellent reputation as developers and producers of the WinTool and Toolbase solutions over many years. The partnership has now been anchored strategically and long-term by the 25% shareholding in WinTool AG and consolidated by further global distribution agreements. This enables HAiMEr to offer and distribute both product lines to its worldwide distribution partners and customers.

Markus Temmel, CEO of TCM, is delighted about the new partner and anchor investor at WinTool AG and the global cooperation with HAiMEr: “in 2023, we worked together very intensively and were able to achieve significant success in a very short period of time. The product portfolios of HA i ME r and the TCM Group complement each other seamlessly and our shared understanding of our customers’

03 • INDUSTRY | April 2024 14 MORE INFORMATION CO rp O r ATE

and TCM

Group,

entered into a strategic and long-term competence

Andreas Haimer

President Haimer Group, are looking forward to further intensifying their cooperation. HAIMER has acquired a 25% stake in WinTool AG, which belongs to the TCM Group. In the future HAIMER will distribute WinTool tool management and Toolbase tool dispensing systems worldwide. In return, TCM strengthens its market position in the business field of tool management by adding the HAIMER product range.

With the new WinTool tool management and the Toolbase tool dispensing system, HAIMER creates digital and analog consistency of the tool room process. Customers can now obtain all the key components for greater efficiency and productivity in the tool room from a single source.

requirements will lead to even more powerful overall solutions. Both partners stand for practical, high-quality solutions that are geared towards the long-term benefit of the customer. Furthermore, we are convinced that the HAiMEr product range will enrich our range of services in the tool management business field and strengthen our market position and our claim to be the market leader for tool management services. All TCM tool management customers worldwide will benefit from this in the future. We look forward to consolidating this strategic partnership and welcome HAiMEr as a shareholder at WinTool."

Offer for digital tool management

Andreas Haimer, president of the HAiMEr Group, explains: “The strategic partnership with TCM and the investment in WinTool fit perfectly with our strategy: We want to offer our customers worldwide a coherent system concept with regard to digitization and automation of tool room management. This requires easy-to-implement products and intuitive software solutions that enable users to increase productivity on the shopfloor. With our new WinTool and Toolbase products, we are able to offer our customers the most complete solution on the market. in a record time of

just four months, we introduced the systems in our own large production facility with over 200 CNC machines. Our own positive experiences and the great customer feedback at EMO 2023, along with the trustful cooperation with the TCM team, has encouraged us to take the next step with WinTool and TCM."

Software implemented in own production

As is always the case, HAiMEr first tests new products that they are bringing to market in its own production facilities. “We are a manufacturing company ourselves, producing up to 4,000 tool holders a day at our headquarters in igenhausen and the neighboring Motzenhofen plant. We also produce our 3D sensors, shrinking, balancing and presetting machines ourselves. We are therefore also very interested in constantly optimizing our tool management,” explains Andreas Haimer.

HAiMEr succeeded in introducing the WinTool software, including the Toolbase dispensing system with fully integrated connectivity to the HAiMEr devices, in a very short period of time. “The simple implementation of these products is already an important initial factor,” explains

03 • INDUSTRY | April 2024 15 MORE INFORMATION

HAIMER

have

partnership. Markus Temmel (right), CEO of the TCM

and

(left),

Stefan Echle, Head of product Management at HAiMEr, who acted as project manager and interface between suppliers, iT, tool room and production during the introduction. “in the short time available, we entered all of our existing tools, spare parts and C-items - no less than 10,000 items - as a digital twin in a central WinTool database and also digitized the HAiMEr application know-how for each job. This means that the information is always available to us, regardless of the user. We have also connected our existing large vertical lift cabinet systems with Toolbase and put additional lockable Toolbase cabinets into operation, giving us a decentralized supply network for the consumables in our production."

The user training confirmed that the software has a very practical structure. “There are no fancy extra bells and whistles on the user interface, it concentrates on the essentials,” confirms Stefan Echle. “The production employees and the people in the tool room working with the products have no problems understanding and using it.”

What are the capabilities of WinTool?

As a software solution for tool and data management, WinTool enables the collection and use of tool, master and operating equipment data as well as CNC machine programs and processes. Thanks to its modular structure, users can “start small” with WinTool, says Stefan Echle, “by initially only entering their cutting tools and tool holders. This is the first step: collecting and fine-tuning their tool data.” To ensure that this can be done easily and efficiently, WinTool provides an open database that can be used to import existing data from other data software systems. 2D and 3D data provided online by manufacturers can also be easily imported.

This first action alone provides the user with an overview of which tools and sister tools are available in production and where they are located. in a second step, the user can clean up the initial stock and further optimize their tool stock based on the consumption determined over time.

“The respective tool life can also be stored in WinTool, which is essential for maximizing cutting tool usage in machining,” mentions Stefan Echle, adding another strength of the system: “Assembling complete tools in 3D is much easier in WinTool than in a CAM system.” For the subsequent transfer to CAD/CAM, WinTool offers 25 direct interfaces to all common systems - ideal for companies like HAiMEr that use more than just one CAD/CAM system. Thimo rotter, Area Sales Manager at WinTool, summarizes: “WinTool is the optimal data hub for all tool information and, thanks to the connection to CAM, Erp, Toolbase, the presetter, and other software systems, the customer has access to uniform and relevant data anytime and anywhere."

Of course, WinTool can do much more, and HAiMEr will expand its use step by step. The software can be used as a library for working materials as well as for CNC data, process and inventory management. The benefit: Shorter programming and set-up times, reduced tool inventory, integrated documentation and ultimately higher productivity.

Find the right tool quickly and safely - thanks to

HAIMER Toolbase

The perfect complement to the tool management system is the smart Toolbase dispensing system, an easy-to-use software-supported tool dispensing system. “We have also equipped our existing dispensing cabinets with Toolbase

03 • INDUSTRY | April 2024 16 MORE INFORMATION

Thimo Rotter (left), Area Sales Manager at WinTool AG, and Stefan Echle (right), Head of Product Management at HAIMER, are pleased with the successful implementation of the WinTool tool management system at HAIMER’s large machining plant in Motzenhofen.

"We have already been able to reduce our inventories in the first few months and expect the investment in the WinTool and Toolbase systems to pay off within a period of six to 12 months,” says Manfred Mayr, Plant Manager at the Motzenhofen production site and a HAIMER employee for over 45 years.

software,” explains Stefan Echle, “and are extremely satisfied. The dispensing system saves us cost-intensive processes, such as searching for the right tool, ongoing stock control and determining consumption requirements."

ideally, Toolbase as a logistics module is combined with WinTool, as the interface is available and has been tried and tested many times. However, Toolbase can also be combined with other tool management systems or operated manually as an entry-level solution. Stefan Echle points out that for small and medium sized companies the combination of a HAiMEr Microset tool presetter with a Toolbase dispensing cabinet is a beneficial solution: “Many processes can be made leaner and more efficient with slimmed-down management and automated warehousing."

The Toolbase software allows user access as well as searching via barcode, rFiD chip or manual input and enables tools and consumables to always be withdrawn correctly without time-consuming searching. The gains in terms of time and process reliability are noticeable from day one. Accurate consumption data also creates transparency and is the key to more efficient warehouse management and a reduction in storage costs. “We have already been able to reduce our stock in the first few months and expect the investment in the WinTool and Toolbase systems to pay for itself within a period of six to 12 months,” says Manfred Mayr, plant Manager and a HAiMEr employee for over 45 years. “From the very first minute, i was impressed by the simplicity of the WinTool and Toolbase user interface as well as the intuitive operation of the software. The machine operators for our more than 120 CNC machines at the Motzenhofen plant procure their consumables themselves via the output systems. The automatic ordering of tools from the Toolbase

software ensures that there are always enough tools in stock and that we can concentrate fully on the production of around 4,000 tool holders per day."

Efficient and digital tool management with HAIMER

For Managing Director Andreas Haimer, WinTool and Toolbase are important elements in the digitization of CNC machining: “We benefit in our own production and gain experience that we are happy to pass on to our customers. We are convinced that tool management with our analog and digital HAiMEr products will continue to gain in importance as automation increases. All systems are modular, so every company can choose the right entry point for the digitization of its own production."

This is why all HAiMEr Microset tool presetters can be supplemented with WinTool as a standard in the future. Because if the master data is available in WinTool, a digital twin of a complete tool can be created and used for simulations in just a few minutes without any complications. As far as the master data for HAiMEr cutting tools and tool holders is concerned, the company has already created all parameters, STEp and DXF files in accordance with DiN 4000 and iSO 13399. The data is available for download on the HAiMEr website and the Tooltracer platform.

https://www.haimer.com/en

03 • INDUSTRY | April 2024 17 MORE INFORMATION

REVOLUTIONISING CABLE LABELLING: A CALL TO ACCELERATE YOUR PRODUCTION WITH BRADY’S AUTOMATED SOLUTIONS

For process engineers grappling with the challenges of cable traceability, the need for automated identification becomes a key requirement. Are you ready to explore the transformative benefits of automated cable label print and apply systems?

Many companies face a common obstacle – the timeconsuming process of manual cable labelling. These complexities, urge them to recognise the impact of slowed production due to cumbersome traceability requirements. The call is clear: it’s time to reevaluate cable labelling methods for enhanced efficiency.

Brady’s has 100-year experience and continues to lead the development of innovative identification solutions, bringing the answer to the challenge to revolutionise the speed and accuracy of seamless cable labelling, freeing up valuable time and resources for other critical aspects of production.

The need to automate is the focus to increase production speed and compliance. This is enabled by using Brady’s Systems which has the ability to print and apply labels three times faster than a manual application. it’s speed and mechanical precision ensures labels are applied flawlessly, eliminating the need for costly rework.

Watch the comparison between manual and automated labelling:

https://youtu.be/-Zv3B9iUrKU

The systems not only expedite the labelling process but also bring versatility to the forefront. Capable of handling a diverse range of cable diameters and printing various types of information, from serial numbers to barcodes, Brady’s offerings align with the dynamic needs of modern manufacturing.

There are 4 reasons why quite some companies decided to partner with Brady on solving the cable labelling challenge:

Speed: Brady’s automated systems print and apply labels three times faster, significantly boosting production output.

Precision: Mechanical precision ensures labels are applied with accuracy, reducing the likelihood of rework.

Versatility: The systems accommodate a wide range of cable diameters and offer flexibility in printing different types of information.

Reliability: Brady’s cable labels undergo rigorous testing, adhering to internationally accepted standards, ensuring durability in challenging industrial environments.

Brady’s automated cable label print and apply systems present a transformative solution, which helps companies to adhere, maintain and control the best of industry quality standards. The invitation is extended to process engineers, production managers, quality managers, and plant managers alike – embrace innovation, accelerate your production, and usher in a new era of efficiency with Brady’s cutting-edge solutions.

www.bradyeurope.com

03 • INDUSTRY | April 2024 18 MORE INFORMATION l ABE lli NG

ELECTRO RENT ANNOUNCES DISTRIBUTION AGREEMENT WITH VIAVI SOLUTIONS

Electro Rent, the global leader in test and measurement equipment rental solutions and services today announced a distribution agreement with VIAVI Solutions, a global leader in communications test and measurement and optical technologies.

This agreement enables Electro rent to sell new ViAVi test instruments in North America, including fiber optics, optical transport, antenna, and wireless field equipment. Therefore, Electro rent customers are now able to purchase new ViAVi equipment for their testing needs, in addition to the rental, and used purchase options for ViAVi equipment already available through Electro rent.

As a leading supplier of test equipment to the telecom industry, ViAVi equipment has been instrumental in testing, monitoring, and ensuring the integrity of communication networks, including cable, fiber optic, and wireless communications.

“ViAVi test instruments are integral to customer work in growing markets that push communications performance. This agreement gives our customers the convenience of purchasing new ViAVi equipment in addition to renting and buying used instruments,” said Stijn Sallaerts, Vice president of product Group, Electro rent.

“We welcome Electro rent as a ViAVi Distribution partner. This distribution agreement builds on a long and successful relationship with Electro rent as one of our valued rental partners,” said Jason Wensel, Sr Director, NA NEMs Sales.

www.electrorent.com

03 • INDUSTRY | April 2024 19 MORE INFORMATION E l ECT r ON i CS

WEARIN PROVIDES ADVANCING POLICE SAFETY WITH IOT AND AI-ENABLED TACTICAL VESTS

The innovative connected tactical vest project uses artificial intelligence (AI) for its abnormal-situation detection system and can transmit this warning to a command center via the Internet of Things (IoT).

This innovation, applied to the operational needs of various law-enforcement professions, is the first result of a partnership between France’s General Directorate of the National Gendarmerie (DGGN) and Wearin’, the Swiss technology group Conextivity’s startup.

The new tactical ioT solution, which attaches to pre-installed body armor, ensures redundant safety and connectivity through a state-of-the-art Ai-enhanced warning device that is independent of current radio systems. Called the Wearin’ Brain, this ruggedized device is triggered either manually by an SOS button, or automatically when it detects an abnormal situation such as loss of verticality, piercing of the body armor cover after a stab wound, or a bullet impact. in the event of a warning, the device also transmits the geolocation of personnel.

The connectivity kit features smart power management via a central high-performance battery guaranteeing 8 hours of autonomy, which considerably increases the running time of gendarmes’ electronic equipment. The kit’s optimized cabling allows equipment to be recharged via a single cable, which the agent can easily connect at the end of a mission, or to his/her vehicle if required during an extended mission.

The Wearin’ Brain, the Wearin’ Battery and its quick-release system are integrated ergonomically into the vest via MOllE fasteners and/or heavy-duty multifunctional pouches with no snagging areas. The kit also features luminous fibers integrated into the front and back of the vest offering personnel on night operations the option of enhanced visibility.

"The vest that we are co-developing with Wearin’ embeds the latest technologies in connectivity, detection, communication and visibility,” explains lieutenant-Colonel Fabrice Blanc, director of the “connected vest” program at the DGGN. The ioT solution called Wearin’ X DGGN Smart Tactical Vest has been designed with an open, modular architecture that keeps the interoperability of current and future systems in focus. Over the course of the partnership,

03 • INDUSTRY | April 2024 20 MORE INFORMATION DEFENSE

it will be able to evolve and adapt to meet the operational needs of law-enforcement agencies, which vary according to the different types of intervention by gendarmes, national or municipal police officers, or customs agents.

" i t’s the field that commands in this type of applied innovation,” confirms Jonathan Brossard, Director of Wearin’ and CEO of Conextivity Group.” Versatility, modularity and interoperability are at the heart of our r&D approach. The smart vest’s functionalities and performances will be tested by various units of the gendarmerie throughout 2024, with the aim of meeting their diverse needs in terms of safety, resilience and efficiency in the field. Our collaboration with the DGGN involves pooling our experience, skills and technologies to deliver a cutting-edge, open system that will evolve in line with the current and future requirements of agents’ multiple professions and missions.”

The ioT platform developed by Wearin’ can be delivered with a dashboard integrated into the command-center system to provide real-time information about the situation on the ground, via data from sensors, warning devices and communication systems worn by personnel on operations. Based on this precise intelligence of operations underway, transmitted in bidirectional streams, commanders can speed up tactical decision-making and improve the coordination of intervention units, as well as their response times.

Signed in November 2023, the innovation partnership between Wearin’ and the DGGN is supported by the French Ministry of the Armed Forces’ Defense innovation Agency and the National Gendarmerie’s Transformation Department.

Officially unveiled at the Milipol show in paris in November 2023, the connected tactical vest from Wearin’ and the DGGN will be showcased on the international stage at the World police Summit in Dubai, March 5-7, 2024, on Wearin´stand no. SS2 A32. The vest has also been shortlisted by the show’s jury to compete for the prestigious World police Summit Awards in the innovative police Force category.

www.wearin.com

03 • INDUSTRY | April 2024 21 MORE INFORMATION

The prototype connected tactical vest co-developed by Wearin’ and the DGGN offers optimal ergonomics and physical-anddigital integration of the warning-and-communication devices worn by gendarmes (police officers belonging to the French armed forces).

EMERSON’S NEW COMPACT, RUGGED PC BUILT TO CONNECT INDUSTRIAL FLOOR TO CLOUD

PACSystems IPC 2010, pre-loaded with Movicon software and PACEdge IIoT platform, delivers high-performance computing for industrial edge data visualization applications.

Emerson has announced the new pACSystems™ ipC 2010 Compact industrial pC (ipC), a rugged industrial computer designed to handle a wide range of machine and discrete part manufacturing automation applications. The new solution is designed to serve manufacturing sites and OEM machine builders who need a ruggedized, compact, durable ipC to cost-effectively support their i ndustrial i nternet of Things ( ii oT) and other digital transformation initiatives.

The ipC 2010 addresses this by pre-loading the pACEdge™ industrial edge platform and elements of Movicon.NExT™ SCADA software, helping users run applications quickly using browser-based configuration. provisions are included for keeping the software platform current and passively maintained, minimizing user effort, while maximizing reliability.

running an industrial version of linux, and including serial and Ethernet connectivity, the ipC 2010 can be used as a communications gateway in a variety of topologies, and simultaneously or separately as an edge computing device. Users can implement the ipC 2010 as a flexible protocol converter—and for many other computing functions— in many iioT, edge, OT/iT convergence, HMi visualization, SCADA connectivity, and digital transformation roles.

Both the hardware and software are designed to be adaptable, universal, and scalable, providing a standardized and unified user experience that is easy-to-use, powerful, and supported by Emerson’s lifecycle services. The compact form factor ip C 2010 features the widest operating temperature range of any passively cooled ipC, with a low power consumption of just four watts, and tough packaging so it can be installed virtually anywhere.

The ipC 2010 offers an advantageous price/performance ratio, with no ongoing annual licensing costs, or charges for general and cybersecurity updates. Additional features, such as Movicon Connext© or WebHMi, can be activated or added at any time.

“Many customers undergoing a digital transformation want to start small and earn trust as they seek out value from edge-enabled applications,” said William paczkowski, product manager for the ipC 2010 for Emerson’s discrete automation business. “The ipC 2010 is specifically designed as a pre-packaged and economical solution so they can get running quickly and cost effectively.”

Emerson is already building the ipC 2010 into a range of larger offerings for leak detection, compressed air monitoring, batching systems, cloud enablement services, and other packaged solutions. This flexible industrial technology will enable customers of all types to benefit from their advanced capabilities.

www.emerson.com

03 • INDUSTRY | April 2024 22 MORE INFORMATION i NDUST ri A l COMMUN i CAT i ONS

NEW MINI LEVER ACTUATED PLUNGER SAVES TIME AND SPACE

Limited space should not mean limited quality. Experience quick and reliable actuation in a more compact package with Southco’s new 56 Mini Lever Actuated Plunger. This solution features the same leveractuated operation as the full-size version for faster and easier latching and unlatching of electronic components.

The 56 Mini lever Actuated p lunger keeps the convenient hold-open feature from the full-size version, so technicians can easily see whether or not a device is secure by looking at the lever’s position. it is also available in a variety of distinct colors, so designers can easily differentiate application zones, or fit the aesthetic of any device. These features combine to ensure that devices using the plunger keep their distinct identity, and are easily identifiable as secure or not.

Additionally, while other compact solutions may have a greater chance of being lost during maintenance, the 56 Mini lever Actuated plunger’s captive installation ensures that it stays attached to the side of any device it is used in. That means one less thing for technicians to keep track of, faster maintenance, and more uptime for your server. i n a digital world where every second of uptime counts, the small things matter on the physical side too.

www.southco.com

03 • INDUSTRY | April 2024 23 MORE INFORMATION E l ECT r ON i C COM p ONENTS

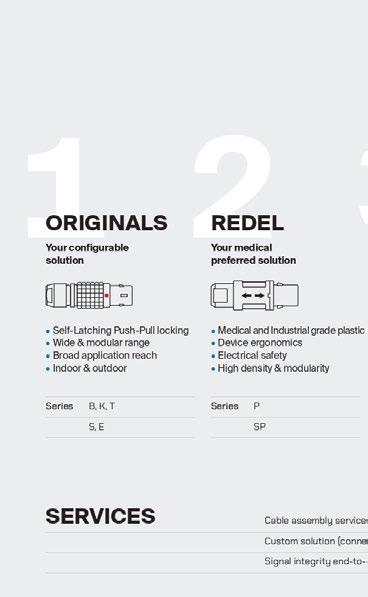

NEW LEMO PRODUCT FAMILY PORTFOLIO SIMPLIFIES SELECTION PROCESS

LEMO, a leading manufacturer of high-performance interconnect solutions, is thrilled to announce the launch of its enhanced product family portfolio aimed at simplifying the selection process for customers.

With a commitment to offering over 90,000 custom solutions tailored to meet specific requirements, lEMO continuously expands its product offerings to meet evolving market demands.

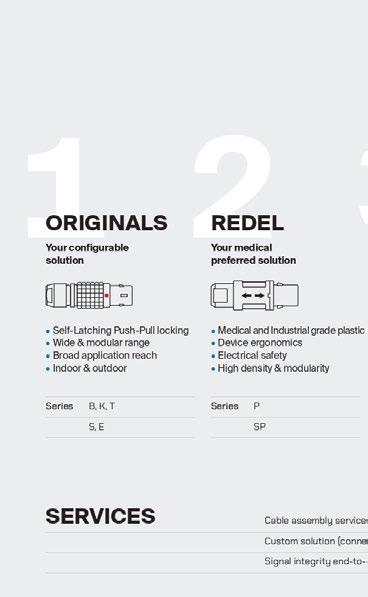

Designed to streamline the presentation of l EMO’s extensive range of solutions, the new product family portfolio highlights core series organized into six distinct families based on shared functionality and specific market applications.

“We used basically two concepts: the first one was really to focus on the series that sell most; the second was to regroup those series that share similar features and that share similar needs in the market” explained Wim Vanheertum, Head of product Marketing.

The six product families include:

• OriGiNAlS: Configurable solutions tailored to individual needs.

• rEDEl: Medical preferred solutions designed for reliability and performance.

• OpTiMA: Optimized solutions engineered for efficiency.

• SUprEME: Extreme solutions built to withstand harsh environments.

• SpECiAlTiES: Specialized solutions catering to unique requirements.

• CAB l E SO lUT i ONS: Unique cable solutions offering comprehensive connectivity.

This classification system enables customers to swiftly identify the most suitable series for their applications, ensuring a seamless selection process.

03 • INDUSTRY | April 2024 24 MORE INFORMATION CONNECTO r S

in addition to the product families, lEMO emphasizes its commitment to providing customized and comprehensive connectivity solutions through a range of complementary services.

Embrace the future of connectivity with lEMO, where innovation converges with precision, and customer success remains the top priority.

For more information, please visit our website: Solutions | lEMO Connectors and cables

03 • INDUSTRY | April 2024 25 MORE INFORMATION

SECO NANOJET REAMERS OPTIMIZE CHIP CONTROL TO ELIMINATE SCRAPPED PARTS

Seco Nanojet Solid Carbide Reamers enhance chip control with an innovative through-coolant outlet for optimal chip evacuation. This design eliminates costly scrapped parts, jamming and edge damage to increase safety, part quality and tool life.

Better coolant flow for better parts

Critical reaming operations require stable, secure, predictable tools. On blind and through bores, Seco Nanojet Solid Carbide reamers extend the proven performance of Seco Nanofix products with innovative through-coolant outlets that stop chip jamming and enhance application stability. The unique design of these new tools delivers a powerful, precise stream of lubrication directly to the cut zone for optimal chip evacuation and tool life. Along with production stability, shops can rely on Seco Nanojet Solid Carbide reamers to maintain cutting speeds as well as part quality.

This versatile range of multi-flute reamers comes in eight grades and more than 10 geometries, along with custom sizes and tolerances. The tools work with any precision toolholder. They hold tolerances from 10 µm - 15 µm (0.0004"- 0.0006") and produce surface finishes from ra 0.2 µm-ra 1.2 µm (ra 8 µ"-ra 50 µ"). Seco inspects each Nanojet Solid Carbide reamer and documents its measured diameter for consistent performance.

Predictable precision with every tool

Many industries, including general engineering, automotive and aerospace rely on secure, reliable reaming to avoid costly scrap. According to Jean-Bernard Hantin, product Manager at Seco, manufacturers realize that poorly manufactured or incorrectly specified reamers can jeopardize high-value parts. “Nanojet Solid Carbide reamers provide cost-efficient performance with much needed quality and stability,” he said.

Order customized tools online

Seco Nanojet Solid Carbide reamers are available in stock and custom diameters down to 1.461 mm (0.057’’). Through the online Seco MyDesign tool configurator, shops can obtain customized tools with the stability, reliability and availability of commodity products.

www.secotools.com

03 • INDUSTRY | April 2024 26 MORE INFORMATION META l WO r K i NG

NEW PRODUCTION SITE: FEINTOOL CONTINUES SUCCESS STORY IN ASIA WITH PLANT IN INDIA

With the founding of “Feintool System Parts India Pvt Ltd” and a new production site in the metropolitan region of Pune, Feintool is consolidating its strategic position as an important supplier of high-precision parts in Asian automotive production.

With an initial investment of CHF 15 million, Feintool is moving closer to long-standing customers who already produce in the region. “Feintool System parts india pvt ltd” is establishing its presence in a promising market and reducing its CO2 footprint through significantly lower delivery-related emissions. Feintool production in pune is expected to start in summer 2025.

«With our expansion into india, we are meeting the needs of our long-standing customers, entering a promising geographic market and contributing to shorter and, therefore, ecologically sustainable supply chains.»

Torsten Greiner, CEO Feintool

The new facility in pune complements Feintool’s presence in Asia, with two production sites each in Japan (Atsugi and Tokoname) and China (Taicang and Tianjin). i n the initial phase, starting from 2025, seat adjusters for various major automotive manufacturers will be produced in india. Feintool is the global market leader in the production of this fineblanked component. The site will also facilitate the implementation of new applications in the areas of battery and hydrogen-powered mobility, industry, and renewable energies in the future.

«We are pleased that we can now meet customer demand for production in india with the new Feintool plant in pune and offer our technological expertise in the production of high-precision automotive parts locally.»

Marcel pernici, president Feintool System parts Asia

https://www.feintool.com

03 • INDUSTRY | April 2024 27 MORE INFORMATION MACH i NE AND TOO l S

HUTCHINSON LAUNCHES FIRE-RESISTANT, HALOGEN-FREE EPDM MATERIAL FOR SEALING BATTERY PACKS IN ELECTRIC VEHICLES

The automotive industry is undergoing a major shift towards electric vehicles, and battery safety is a top priority. Protecting the battery pack against fire is one of the main concerns of OEMs.

Hutchinson p recision Sealing Systems, sealing specialist and expert in elastomer formulation, has developed a fire-resistant E p DM compound for automotive applications in electric vehicles.

This new EpDM meets the requirements of Ul94, V-0, the most stringent level of fire resistance. it has the significant advantage of containing no halogens, substances that are controversial for their toxicity, making it not only safer, but also more sustainable than other materials on the market.

Excellent fire resistance and sealing performance

• Fire resistance to Ul94 V-0 standard

• Halogen-free

• Optimized Compression Set

• Excellent low-temperature performance

• Better chemical compatibility with sealing fluids

• Blue compound for easy identification of the seal in its environment

The main applications for this new material are battery pack gaskets and seals for the battery pack cooling circuit (quick connectors, sensors) to prevent coolant from coming in contact with the battery cells. Battery protection is then guaranteed in the event of flame propagation. its use can be extended to electric motor cooling applications and battery peripheral equipment.

its chemical characteristics and excellent fire resistance also make it a promising choice for demanding industrial and aerospace applications.

Contact us for more information on our fire-resistant EpDM and precision sealing solutions.

www.hutchinson.com

03 • INDUSTRY | April 2024 28 MORE INFORMATION E l ECT ri C VEH i C l E

03 • INDUSTRY | April 2024 29 MORE INFORMATION

TWO OFFERS FOR WAREHOUSE LOGISTICS

With the LogiDrive solution space, NORD offers its warehouse logistics customers two industryoptimised drive concepts. LogiDrive Advanced and LogiDrive Basic both impress with their low weight and compact installation space. In addition, they are optimised for different factors.

Chain and roller conveyors, belt and pallet conveyors, container and overhead conveyors: i n warehouse logistics, they all require reliable drives with sufficient power for the corresponding application. This is guaranteed by both solutions from the drive specialist NO r D. Furthermore, both feature maximum user-friendliness, easy wiring, low weight and compact installation space. What sets them apart: logiDrive Advanced was optimised for energy efficiency and logiDrive Basic with regards to costs.

The drive solutions in detail:

LogiDrive Advanced

- Highly efficient iE5+ synchronous motor

- Decentralised NOrDAC ON+ frequency inverter, which was specially designed for combination with the iE5+

- A gear unit from the NOrD portfolio

LogiDrive Basic

- iE3 asynchronous motor

- Decentralised NOrDAC ON frequency inverter

- A gear unit from the NOrD portfolio

According to the customer’s requirements: Focus on costs or energy efficiency

The logiDrive Advanced drive solution ensures maximum energy efficiency and thus achieves high savings in CO2 emissions. it achieves its very high efficiency via large speed and load ranges, and allows for a variant reduction. This is particularly attractive for large systems with numerous drives: Fewer drive variants in a system result in streamlined logistics, warehouse and service processes and thus in reduced administrative costs.

03 • INDUSTRY | April 2024 30 MORE INFORMATION MECHAN i CS D ri VES

The components of the logiDrive Basic are perfectly matched. They meet all essential warehouse application standards and impress with a large adjustment range. This drive solution does not offer maximum efficiency but features low investment costs.

Whether logiDrive Advanced or logiDrive Basic: The decision is determined by the specific application requirements. Either way, the user receives a perfectly industry-optimised solution, including a frequency inverter with integrated multi-protocol Ethernet interface. Furthermore, both solutions are equipped with all international certifications and can thus be used worldwide, which is important for globally active companies.

https://www.nord.com/en/solutions/systems-services/ systems/logidrive/logidrive.jsp

https://www.nord.com/en/solutions/industries/ intralogistics-airport/warehouse-logistics/warehouse.jsp

03 • INDUSTRY | April 2024 31 MORE INFORMATION

Pallet and container conveyors are driven by the LogiDrive drive system in the warehouse area.

OLYMPIC SHOWS AND ARTIFICIAL MOONS

Today, every large event includes an elaborate laser show. Laser projections are used at trade fairs, in advertising, art, and at architectural events. The magically glowing light patterns are made possible by highly complex technology, and at many of the most spectacular installations this technology is provided by Berlin-based LaserAnimation Sollinger. When it comes to the alignment of beams and the creation of effects, motors from FAULHABER play an important role in the company’s laser projectors.

Caution: You may get hooked! Once you click on the project examples on the website of laserAnimation Sollinger, you may find it difficult to leave again. But the photos and videos on the computer screen are hardly capable of reproducing the actual effect that the laser projections have on site during a performance.

One example is the “Global rainbow” by the artist Yvette

Mattern: seven brightly colored very powerful laser beams shine towards the sky from Berlin’s Ernst-reuter-platz in the direction of the Victory Column and change the vibe of an entire city center. Or ’Another Moon’ by the artist duo Kimchi and Chips, where a second moon appears in the sky over the Zeche Zollverein in Essen. Or the fast-paced show at the closing ceremony of the Winter Olympics in pyeongchang... these are just a handful of many examples.

Light pen with a diameter of four millimeters

The often surprising and sometimes breathtaking light effects are based on the unique qualities of the laser beam. in terms of intensity, beam focus, and range, it outperforms light beams from other artificial sources many times over. On the other hand, the laser is subject to optical and technical limitations, as sales manager richard Schäfer explains: “The

03 • INDUSTRY | April 2024 32 MORE INFORMATION SHOW TECHNO l OG i ES

beam is usually very small. With our devices, its diameter is usually around 4.0 millimeters. So only a small dot appears on a projection surface.”

i n order create a pattern – such as a logo, lettering, or cartoon-like moving images – laser projection relies on the inertia of the human eye. To be precise, it is the image processing in the brain, which also creates a continuous progression in a film made up of 24 individual frames per second. if the laser beam moves fast enough, the person “sees” the projected animation instead of a point of light darting around. To achieve this, the beam in the projector is deflected by means of two mirrors – one each for the x and y axes. its movement is induced electro-magnetically and reaches a very high speed.

Another limitation is the color. The color of a laser depends on the laser-active material in which the beam is generated. in the case of laser projection, it is the semiconductor, since diode lasers or Coherent OpSl sources are used here. But laser diodes can only produce a few basic colors, mainly red, green, and blue. The high-end devices from laserAnimation Sollinger also have Coherent OpSl sources for yellow, orange, and cyan. To produce a white beam, beams of multiple colors must be “collinearly superimposed.” The same is the case for other colors: in order to create the different tones of the entire palette, the intensity of the individual rays is modulated.

Not even a hundredth of a degree of deviation is allowed

The trick is to superimpose the different laser sources, each with different wavelengths, as collinearly as possible. The more precisely this is carried out, the sharper and more precise the final beam will appear to the human eye. This is where special optical filters, so-called “dichroic filters,” are used, which deflect certain wavelengths while other wavelengths (colors) beam through the glass filtrate. This is how different laser beams can be “superimposed” to form a single beam. So what looks like a “white” ray to the human eye is ultimately the combination of red, green, and blue sources.

But that only works if the beams stay together very precisely and, above all, for a long time and at a great distance, because laser installations often have to be visible from hundreds of meters or even several kilometers away. The dichroic filters have to be adjusted with the appropriate precision, as richard Schäfer explains: “A deviation of one hundredth of a degree results in an offset of 1.7 centimeters per one hundred meters. This means that the individual colors are no longer on top of each other and can be distinguished by the human eye – the color mixing effect is lost.”

Now, it’s not unheard of that a device from laserAnimation Sollinger leaves the premises in Berlin to be set up a day later, for example, for a laser show on the Burj Khalifa in Dubai. After minus twenty degrees on the cargo flight, the

03 • INDUSTRY | April 2024 33 MORE INFORMATION

housing heats up to sixty degrees or more in the desert sun. Despite high-quality materials and sophisticated fastening technology, a certain level of distortion in the optics is inevitable. This means that the position of the dichroic filters may need to be slightly readjusted. This is the reason why the dichroic mirror holders are equipped with a drive: brushless DC motors from FAUlHABEr with integrated gears are used for software-controlled fine adjustment to at least a thousandth of a degree.

Optical gratings for breathtaking effects

Another motor is used for protection. To prevent the intense laser light from penetrating the human eye in an uncontrolled manner, the projectors are equipped with a two-stage switch-off mechanism. in addition to an electronic protective circuit, there is also a mechanical shutter for emergencies. its flap is held open during regular operation by a motorized rotary magnet. in the event of a fault, the safety circuit stops the motor and allows the flap to fall into the beam exit.

Other drives from FAUlHABEr are used in the grating module. Diffraction grating is an optical element that uses the deflection of light rays when passing through very narrow gaps. in addition to beams and graphics, a laser projector can also generate a variety of patterns and effects, such as a kind of artificial polar light or the wafting, abstract forms of robert Henke’s “Destructive Observation Field”: A light object that changes continuously and looks like a mix

between cosmic fog and biological cell structure, reflecting the micro- and macrocosm, as it were. The effects can not only be produced on a projection wall, but also freely suspended in space.

The wheels in the grating module are positioned by stepper motors to select a specific grating for the projection. The circular gratings themselves are set in motion by brushless DC motors, which in turn creates its own optical effect that can range from wild fidgeting to meditatively slow changes in the image at a snail’s pace.

Highest demands on drives

“For these types of effects, we often use several projectors,” explains richard Schäfer. “They can only unfold their effect if the gratings move completely synchronously, at the highest and lowest speed as well as in start/stop operation with constant changes of direction.” The projectors and the grating modules are full of technology, which means that the installation space is extremely tight. Only very small motors can be accommodated here.

Maximum precision and repeatability are additional minimum requirements. The integrated backlash-free gears play an important role here. When asked about the beginning of the collaboration with FAUlHABEr, richard Schäfer replies that it must have been before his time. looking for the very first order, he finds the year 2003. This means that FAUlHABEr motors have stood the test of time

03 • INDUSTRY | April 2024 34 MORE INFORMATION

for this demanding application over the course of twenty years: “We build top of the line devices for laser projections. To do this, we need drives that are on the same level.”

https://laseranimation.com/en/projects/ https://www.faulhaber.com/

03 • INDUSTRY | April 2024 35 MORE INFORMATION

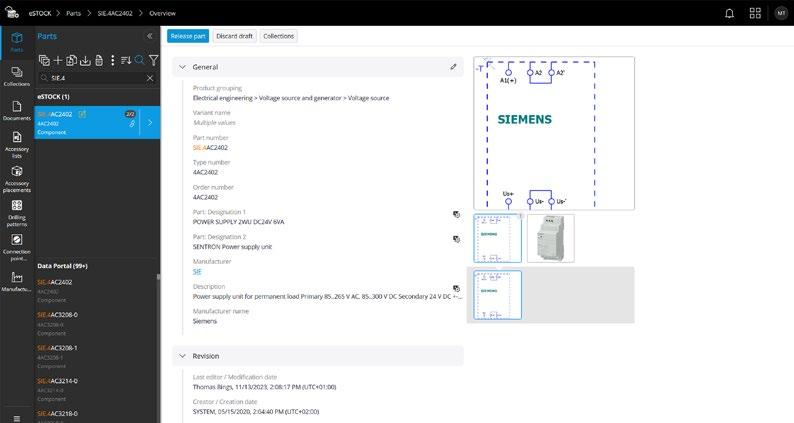

FASTER ACCESS TO DEVICE DATA

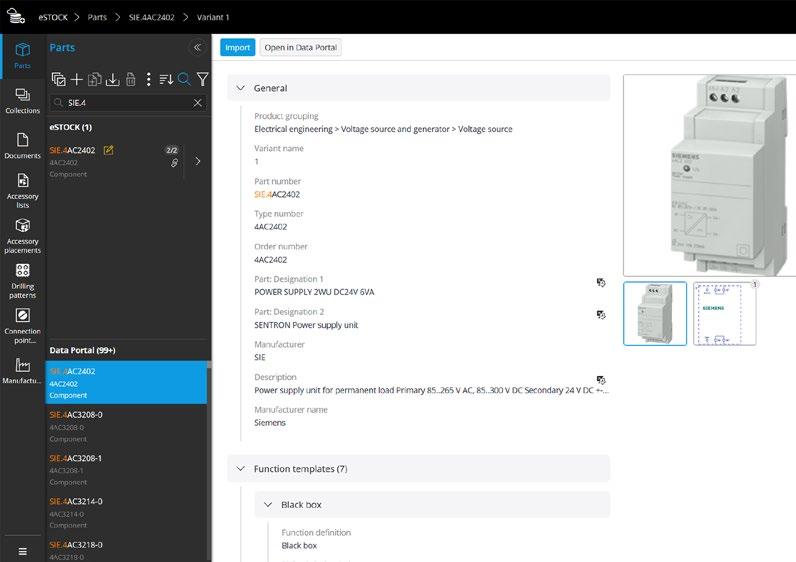

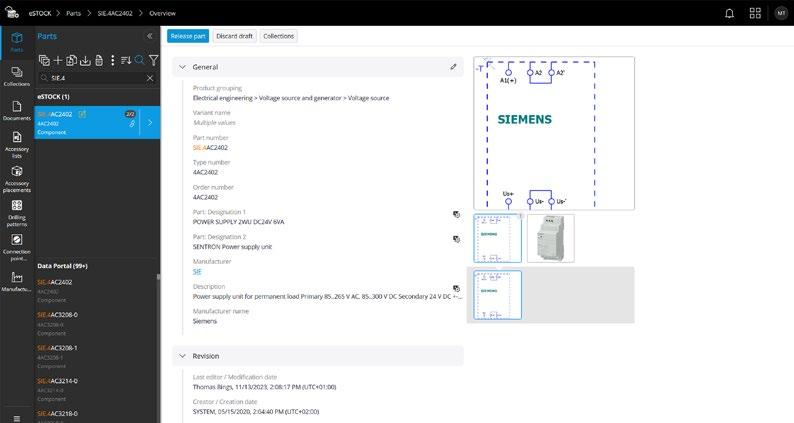

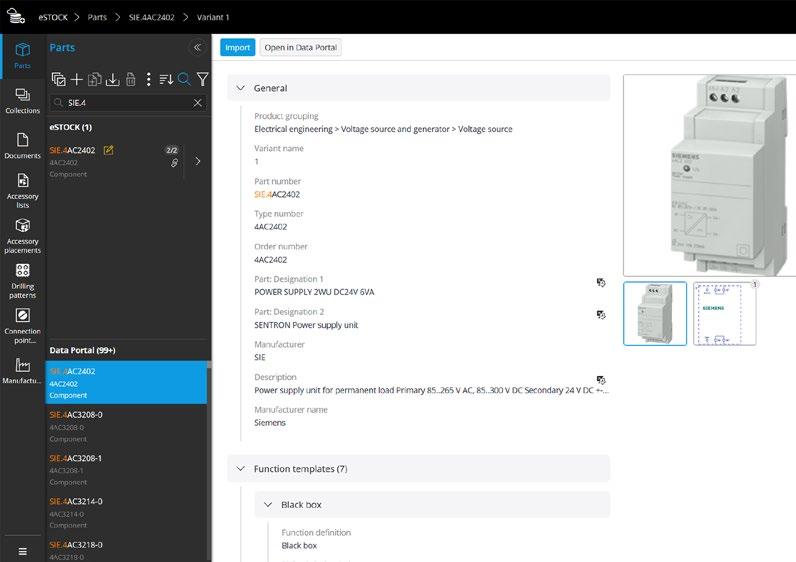

Eplan eStock gives companies access to centralised device management in the Eplan Cloud, simplifying collaboration and reducing coordination times and media discontinuities.

Working with eStock has become even easier in the Eplan platform 2024, meaning that users can automatically and quickly access the full range of more than 1.5 million device datasets in the Eplan Data portal. Another benefit is that all the data – from a company’s inhouse device management system or from the Data portal – can be edited together and saved via user rights management.

Eplan eStock – the cloud-based device management system on the Eplan platform – lets users manage and maintain device data right in a browser, including voltages, currents, data sheets and component designations. They have already had access to the data stored there since Version 2023. This all makes collaboration easier and reduces coordination times and media discontinuities. The data is thus more consistent and of higher quality – after all, there is no need for multiple data entry. This is also reflected in the project quality while taking into account all the required standards.

New: Eplan Data Portal integration

Now a few crucial innovations have been added: devices can be imported from the Eplan Data portal into eStock. When making the first keystrokes for the entry, users see all devices in their own database in addition to all the relevant devices for the search in the Eplan Data portal. Users can then open the desired device in the same window and, in case it hasn’t been already, import it with one or two clicks. When items are transferred from the Data portal into Eplan eStock, the software initially created a draft version – meaning that previously approved device data isn’t automatically “overwritten” but the saving must instead be actively

03 • INDUSTRY | April 2024 36 MORE INFORMATION SOFTWA r E

When searching for a component in Eplan eStock, the system display potential hits in the Eplan Data Portal.

confirmed – i.e., accepted – by the user. Users can thus add data and/or make changes to the draft version before approving it and actually using the device in a project.

Eplan Platform 2024 – faster data access

Another practical benefit is that users have access to more than 1.5 million device datasets in eStock with the new direct integration to the Eplan Data portal. Component manufacturers involved in the Data portal upload new and/or updated data on an ongoing basis and the pool of device data is continually growing. Eplan’s developers have also paid attention to efficiency when using data from the cloud and the system only downloads data changes to a local computer based on the last time it accessed eStock, considerably speeding up data access. Another performance gain also benefits users – in the Eplan platform 2024, it is quick and easy to switch between the source of a local database and an eStock collection based in the Eplan Cloud. This also offers users considered time savings and even greater ease of use.

Better cross-departmental collaboration

Eplan eStock, the centralised device data management system in the cloud, simplifies collaboration. Data sovereignty always lies with the company or the user, who determine the quality and level of access themselves. Standards can be easily and comprehensively implemented via rights management. Access to the centralised device management in the cloud is available to Eplan users with

a subscription licence for the Eplan platform 2023 at no additional cost.

http://www.eplan-software.com/solutions/eplan-estock/ www.eplan.com

03 • INDUSTRY | April 2024 37 MORE INFORMATION

If a device is opened in the Eplan Data Portal, it can be imported into eStock with just one or two clicks.

EMERSON INTRODUCES ULTRASONIC METAL WELDERS WITH ADVANCED CONTROLS FOR FAST-CYCLING, HIGH-PRECISION WELDS

New Branson GMX-Micro ultrasonic welders offer advanced controls and better connectivity for faster welding of EV batteries, conductors and terminations.

Emerson has launched the BransonTM Series GMXMicro, a line of high-precision ultrasonic metal welders that feature a new computerized operating system, multiple power levels and configurations, advanced controls, and improved connectivity. The new welders are able to meet changing material and production requirements for electric vehicle batteries, battery chargers, conductors, and electronics applications, with faster cycle times that can increase productivity and reduce costs.

redesigned and upgraded from the existing Branson GMX20MA and GMX-20Dp welders, the GMX-Micro series is available in two power levels: With 4,000 watts of welding power, the GMX-Micro 4400W is equipped with a standard weld stack, while the more powerful 5,500-watt GMX-Micro 5500W is available with either a standard metal welding stack or a direct press weld stack. The direct press stack is specially designed to exert higher downforce with greater stability, making it possible to complete complex, manylayered battery film welds or large-conductor welds with greater stability and consistency.

“Emerson has engineered the new Branson GMX-Micro series welders to help electric vehicle, battery, and charging system manufacturers increase the output and quality of more energy-dense, thin-film and solid-state batteries, and to reliably bond the larger conductors now required for rapid charging at higher voltages,” said Alex Yeung, global business development manager, metal welding, Emerson.

The GMX-Micro welders feature all-new power supplies and controls, including an upgraded pneumatic actuation system that resets more quickly (within 100 milliseconds of weld completion), to enable faster weld cycles and greater production rates. Weld stacks are held in rigid polar mounts, while actuators feature dual linear bearings, integral height calibration, and a linear encoder with 5-micron resolution that eliminates the need for external measurement devices. These features, together with a nodal support design that precisely balances the GMX-Micro weld stack and horn with the anvil during welding, ensure effective ultrasonic energy transfer and repeatable, high-precision bonding.

Users of the all-new GMX-Micro power supplies (5,500 or 4,000 watt) manage welder functions through a standard 7-inch lCD touchscreen, or optional extended display, that can develop, store or retrieve weld recipes quickly. The display also graphs critical weld parameters — power, height or frequency — in real time. The new power supplies also provide extensive weld-quality data capture and storage, multilingual operation, and easy software-based upgrades.

The new GMX-Micro series are built on a compact, modular chassis, with two styles based on the choice of normal or direct-press actuator. Designed to simplify configuration, automation, and mounting of single- or multi-welder systems, both chassis offer expanded working space below the actuator, allowing for easier insertion and removal of larger parts. Weld stacks are also equipped with quickchange tooling to enable rapid production changeovers. Additional connectivity, including 1000/100/10 megabits per second Ethernet, supports real-time data transmission to manufacturing execution systems (MES) or retrieval of stored production recipes via secure internet.

To learn more, please visit https://www.emerson.com/enus/catalog/automation-solutions/branson-gmx-micro.

03 • INDUSTRY | April 2024 38 MORE INFORMATION WE l D i NG

03 • INDUSTRY | April 2024 39

The Branson™ GMX-Micro ultrasonic spot welder is designed and built to assure the highest degree of reliability and weld quality. The unique mechanical design of the GMX-Micro allows for a wide range of complex applications while delivering high levels of speed, precision and process control.

THE FUTURE OF AUTONOMOUS TRUCK SAFETY AND USABILITY

New Hardware Concepts for Autonomous Trucks of the Future

by

Steve Antcliff,

Business Development Manager, Automotive & Truck, Southco, Inc.

The era of the long-haul autonomous truck is fast approaching. With it will come both challenges and opportunities to redesign the interior of autonomous vehicles to serve new functions and activities of those who operate them.

The advent of autonomous long-haul trucking sets the stage for significant changes in the role and responsibilities of the drivers. instead of constantly controlling the vehicle, they will transition from “drivers” to multirole operators. This will also lead to some major changes to the design of the truck’s cabin and sleeping areas, providing opportunities for engineers and component suppliers to consider new ways that position control and access hardware products can help facilitate and serve this new architecture.

Much of the technology to support autonomous trucks is being implemented. Advanced GpS and 5G network communications technology, sophisticated onboard vehicle control systems and onboard radar and lidar sensors make it possible for these large vehicles to safely track and respond to highway traffic conditions, so they can operate autonomously for much of their time on the road.

Autonomous truck models that are either prototyped or ready for use already feature substantial capabilities: They can pull into loading docks or park themselves, maintain safe speeds and distances, change lanes, navigate automatically to and through interchanges and respond to changing traffic conditions and sudden actions by other vehicles to prevent accidents.

With large strides being made in the technological innovations that have lead us to developments in autonomous driving, there are a plethora of obstacles Truck manufacturers are having to overcome. With this in mind, the industry are innovating and producing brand new solutions to aid the ever-changing responsibilities and expectations of the cab driver.

New role for operators changes the cabin presently, truck drivers have to continually manage their vehicles, even with the latest collision avoidance and brake control systems. That is expected to change with autonomous trucks, with the operator turning over control of the vehicle while maintaining a more “supervisory” role, similar to airline pilots.

This provides truck designers with the opportunity to make changes in multiple areas of the truck cab to reflect how operators on long-haul vehicles will use their cab and sleeping area spaces. For example, one truck designer is seeking to improve the driver side of the cab by exploring a way to place the brake and accelerator pedals in a box that could be moved out of the way, providing greater leg room; similar approaches are being explored for moving the steering wheel and column as well — or even replacing

wheel and column with another kind of control device that’s purely digital.

These kinds of driver control modifications will require careful engineering to ensure that, if control does need to be returned to the driver, it can be done quickly and safely. To be successful, these modifications may require the use of hinges that can quickly open or reposition controls, as well as access latches that make devices fully secure when in their “out of the way” position, keeping them from suddenly shifting in response to movement by the vehicle.

With these modifications, operators will perform tasks they would normally have to postpone to times when the vehicle is not in motion. This can include handling documentation such as trip journals and paperwork related to the current loads they are delivering or the next load they are scheduled to pick up.

Fixtures to support changes in cab design and functionality

New designs for cabin and crew quarters can help fleet managers staff their vehicles with two operators, allowing the vehicle to operate over much longer distances and improve return on investment. Truck designers are modifying the passenger side of the cab to provide larger flat screens to support web, streaming video and gaming applications so it is easier to attract and staff the vehicles with two operators.

These screens can either be built into the cab console or mounted on hinges to enable users to adjust the screen’s angle. Hinges and display mounts that are designed with pre-engineered constant torque technology provide a “touch point” experience that is both ergonomic and intuitive.

Using controlled torque hinges for these display mounts offers several benefits

• They are engineered to withstand vibration and inertial loading that may result while the vehicle is in operation

• Depending on the type of mount chosen, the displays can be easily pulled toward or pushed away from the passenger as needed

• One-handed operation allows simple one-touch positioning of displays

in order to save space and be as compact as possible, some designers are exploring having flat screens serve double duty: on one side is the display screen and the other side could serve as a flat surface, as a table to hold food, books or laptop computers.

Fixed position detent hinges can easily support that kind of configuration. They can hold doors or flat panels open

03 • INDUSTRY | April 2024 40 MORE INFORMATION AUTOMOT i VE MANUFACTU ri NG