HIGHLIGHT OF THE MONTH

Euromask® Increases Its Hook Packaging Automation Level Simeone Maitan Finishing Group Srl, Lainate – Italy

info@euromask.com

© ipcm ®

E

uromask®, belonging

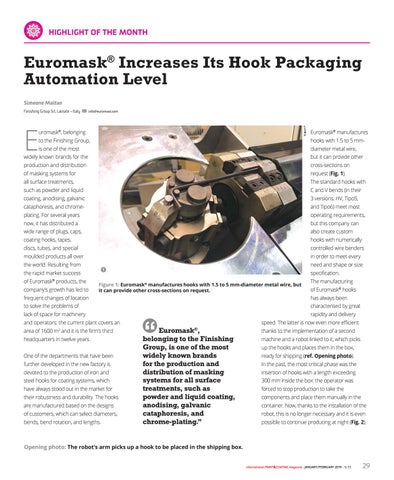

Euromask® manufactures

to the Finishing Group,

hooks with 1.5 to 5 mm-

is one of the most

diameter metal wire,

widely known brands for the

but it can provide other

production and distribution

cross-sections on

of masking systems for

request (Fig. 1).

all surface treatments,

The standard hooks with

such as powder and liquid

C and V bends (in their

coating, anodising, galvanic

3 versions: HV, Tipo5,

cataphoresis, and chrome-

and Tipo6) meet most

plating. For several years

operating requirements,

now, it has distributed a

but this company can

wide range of plugs, caps,

also create custom

coating hooks, tapes,

hooks with numerically

discs, tubes, and special

controlled wire benders

moulded products all over

in order to meet every

the world. Resulting from of Euromask products, the ®

company’s growth has led to

need and shape or size

1

the rapid market success

specification.

Figure 1: Euromask® manufactures hooks with 1.5 to 5 mm-diameter metal wire, but it can provide other cross-sections on request.

The manufacturing of Euromask® hooks

frequent changes of location

has always been

to solve the problems of

characterised by great

lack of space for machinery

rapidity and delivery

and operators: the current plant covers an area of 1600 m2 and it is the firm’s third headquarters in twelve years. One of the departments that have been further developed in the new factory is devoted to the production of iron and steel hooks for coating systems, which have always stood out in the market for their robustness and durability. The hooks are manufactured based on the designs of customers, which can select diameters, bends, bend rotation, and lengths.

speed. The latter is now even more efficient

Euromask®, belonging to the Finishing Group, is one of the most widely known brands for the production and distribution of masking systems for all surface treatments, such as powder and liquid coating, anodising, galvanic cataphoresis, and chrome-plating.”

thanks to the implementation of a second machine and a robot linked to it, which picks up the hooks and places them in the box, ready for shipping (ref. Opening photo). In the past, the most critical phase was the insertion of hooks with a length exceeding 300 mm inside the box: the operator was forced to stop production to take the components and place them manually in the container. Now, thanks to the installation of the robot, this is no longer necessary and it is even possible to continue producing at night (Fig. 2).

Opening photo: The robot’s arm picks up a hook to be placed in the shipping box.

international PAINT&COATING magazine - JANUARY/FEBRUARY 2019 - N. 55

29