SUCCESS STORIES

World Market Leader Kässbohrer Automates Production of its PistenBully with Painting Robot from Dürr

K

the process means greater efficiency in

the harsh environmental influences, two

groomers are now being painted

production and less exposure to paints

primer coats as well as the base coat are

by a Dürr robot. This halves

and solvents for workers.

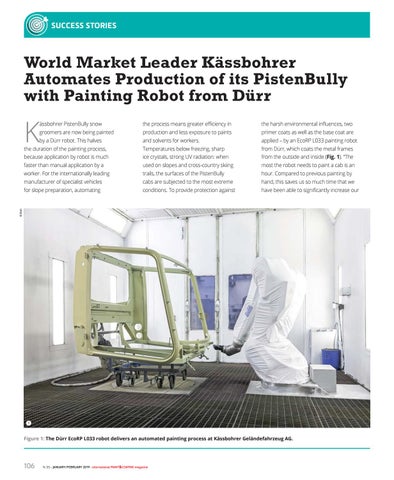

applied – by an EcoRP L033 painting robot

the duration of the painting process,

Temperatures below freezing, sharp

from Dürr, which coats the metal frames

because application by robot is much

ice crystals, strong UV radiation: when

from the outside and inside (Fig. 1). “The

faster than manual application by a

used on slopes and cross-country skiing

most the robot needs to paint a cab is an

worker. For the internationally leading

trails, the surfaces of the PistenBully

hour. Compared to previous painting by

manufacturer of specialist vehicles

cabs are subjected to the most extreme

hand, this saves us so much time that we

for slope preparation, automating

conditions. To provide protection against

have been able to significantly increase our

© Dürr

ässbohrer PistenBully snow

1

Figure 1: The Dürr EcoRP L033 robot delivers an automated painting process at Kässbohrer Geländefahrzeug AG.

106

N. 55 - JANUARY/FEBRUARY 2019 - international PAINT&COATING magazine