What is IMMEX?

The IMMEX benefits aim to create an attractive regulatory framework for the export-oriented manufacturing industry; in other words, IMMEX companies can carry out manufacturing activities with temporarily imported goods in a low tax or tariff environment, but upon the condition that the imported goods are exported after in has been assembled, packaged, tested, manufactured, or transform, from is original importet form.

What is the IMMEX process?

The IMMEX program, formally known as the IMMEX maquiladora program, allows foreign manufacturers to import raw materials and components into Mexico, tax and duty free, under the condition that 80-100% of all finished/transformed goods will be exported out of Mexico within a government-mandated time frame.

What is the maquiladora program in Mexico?

Maquiladoras (also known as “twin plants”) are manufacturing plants in Mexico with the parent company’s administration facility in the United States. Maquiladoras allow companies to capitalize on the less expensive labor force in Mexico and also receive the benefits of doing business in the United States, or North America.

While any IMMEX approach will give manufacturers an edge over companies located elsewhere around the globe, operating under a shelter company allows you to take full advantage of everything Mexico has to offer manufacturers.

Perhaps the biggest, most well-known advantage of the IMMEX program is the cost savings. Nearshoring to Mexico alone can help manufacturers cut down on transport and labor costs, but with the added import tax and VAT exemptions, foreign companies in Mexico can significantly lower their spending.

Companies that choose the shelter route have the added advantage of being able to hand off any legal risk and liability. Rather than trying to operate as a standalone entity, which involves keeping up with complex foreign laws, companies can focus on their production while the shelter company worries about compliance.

Under most IMMEX approaches, receiving your permit can take anywhere from three to twev months, sometimes even longer, which is why more and more manufacturers are opting for the shelter model. Because the shelter company is already a legal Mexican entity, you can get your production up and running in a matter of weeks rather than months.

Moving your cornpany’s operations to Mexico means gaining access to low-cost labor, the world’s largest number of free trade agreements, and existing industry clusters-but you’re still operating in unfamiliar territory. When you work under a shelter cornpany, you get an experienced partner who has the linguistic, cultural, and legal knowledge you need to circumvent the obstacles of manufacturing in a foreign country and ensure a srnooth-running operation.

Nuevo Leon, Mexico

Queretaro, Mexico

Houston - Arlington, TX

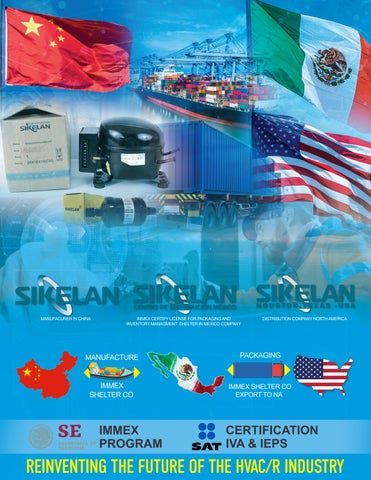

Manufacturer, China

Nuevo Leon, Mexico

Queretaro, Mexico

Houston - Arlington, TX

Manufacturer, China

The maquiladora program originally began in 1965 by the Mexican government as a means of alleviating unemployment problems along the borders, while providing foreign companies various tax- and duty-free benefits, special customs terms, and easy access to skilled, affordable labor. This is particularly applicable to the manufacturing industry. By 1985, maquiladoras became the largest source of foreign exchange in Mexico.

The maquiladora program truly boomed in 1994 with the approval of the North American Free Trade Agreement (NAFTA) Now (T-CEM), which opened foreign trade lines between Canada, the United States and Mexico by eliminating most tariffs and other barriers to free trade between the three countries. The agreement also removed quotas that prevented the U.S. and Mexico from fully sharing in their markets, while allowing maquiladoras to manufacture products without the previous limitations in place.

From then on

Since then, the manufacturing industry in Mexico has made up roughly 50% of all exports of the country, and opened up over a million jobs throughout over 3,000 export assembly, packaking, and manufacturing plants. One of the easiest ways to set up a maquiladora and save on operating expenses is by operating under a shelter company. This way, companies looking to move their manufacturing to Mexico can utilize all the benefits and resources available.

Why trust a shelter company?

Whether you are manufacturing in Mexico already and need IMMEX certification, or you are having trouble getting into Mexico due to the waiting process and red tape of getting IMMEX Certification, operating under a Mexico shelter company can help expedite the process. This is the fastest way to bypass the long waiting period. By operating under a shelter company, you operate under the IMMEX permits of the shelter company while also gaining access to resources that can help you get your manufacturing up and running faster.

What does a shelter company do?

The benefit of operating under a Lamcoint shelter company is that we are a IMMEX PACKAGING AND STOCK MANAGMENT CERTIFIED MEXICAN COMPANY 2024. You can spend less time worrying about the process of getting IMMEX-certified, and focus your time on the quality of your manufacturing. This is also the fastest way to get your business up and running because the shelter company would take care of logistics such as human resources, the hiring process, getting the proper licenses and permits, finding the manufacturing sites, and more.

• Aguascalientes

• Baja California

• Chihuahua

• Coahuila

• Guanajuato

• Nuevo Leon

• Puebla

• Queretaro

• San Luis Potosi

• Zacatecas

Lamcoint - Sikelan USA Distribution Center Houston,TX

Lamcoint - Sikelan Mexico Queretaro

Lamcoint - Sikelan USA Distribution Center Arlington,TX

Austin

Dallas Arlington

Lamcoint -Sikelan Mexico Monterrey

Lamcoint - Sikelan USA Distribution Center Houston,TX

Lamcoint - Sikelan Mexico Queretaro

Lamcoint - Sikelan USA Distribution Center Arlington,TX

Austin

Dallas Arlington

Lamcoint -Sikelan Mexico Monterrey

1. Increase brand market penetration,

2. Reduce your distribuitor freight, import, logistical cost and expenses,

3. Increase your distruitor competitiveness, profitability,

4. Increase brand and product value,

5. Delivered packaged well presented products,

6. Reduce damaged claims.

Under IMMEX packaging program your distributor will have readily available inventory at NO COST.

Under our IMMEX program your distribuitor logistical cost will be reduce to zero.

As resuld of our IMMEX program your distributor will increase its profitability.

Because the distributor will not allocate financial resources to invest in one brand name and maintain large imported inventory.

Under our IMMEX packaging shelter company your product will be delivery professionally boxed and packaged to the end consumer at no additional cost to your distributor.

Because of your product well packaged-boxed with installation guideline, and warranty program, your distributor will reduce any warranty and damage claims significantly.

Manufacturer concentrate in manufacturing,

Reducing its sales marketing cost,

Provides effeciently & competitive cost to the aftermarket,

Increase profit and revenues,

Increase product trust and value

35%

35% HVAC/R aftermarket distributor will benefit by 35% of cost savings allowing him to , Increment his revenues and profit margin, Minimizing his risk of managing inventory,

Dedicating and investing more time to increase costumer satisfation.

Because a “just in time” business model eliminates standing inventory, nearshoring companies save significant amounts of money on storage. Companies can also save money on transport costs, import tariffs, and labor costs. The money they save can be invested into other business opportunities. Most sectors can benefit from nearshoring. However, some are better situated to take advantage of nearshoring than others. Here are a few examples:

• Manufacturing

• Automotive and Transport

• Logistics and supply chain management

• Customer services

• IT

• Retail

• Healthcare

Because a “just in time” business model eliminates standing inventory, nearshoring companies save significant amounts of money on storage. Companies can also save money on transport costs, import tariffs, and labor costs. The money they save can be invested into other business opportunities.

Manufacturer concentrate in manufacturing,

Reducing its sales marketing cost,

Provides effeciently & competitive cost to the OEM,

Increase profit and revenues,

Increase product trust and value

Mexico IMMEX SHELTER COMPANY transform final product for HVAC/R OEM,

Allows for reduced costs in shipping, logistics, and supplier resources in Noth America,

Reducing in up to 35% or more in up front expenses (cash up front) expenses to the in contry goverment.

Reduce stock storage cost by getting IMMEX stock in mexico,

Reduce operational cost by getting just in time stock,

Reduced manufacturing cost,

Increase customer satisfaction,

Improved supply chain management.

Temporary import under IMMEX compliance license Contry Mexico Lamcoint Shelter Company IMMEX

IMMEX OEM LICENSE MAQUILADORA

STRATEGIC GLOBAL POSITIONING

OEM IMMEX MAQUILADORA BENEFITS

Manufacturer, China

Temporary import under IMMEX compliance license Contry Mexico Lamcoint Shelter Company IMMEX

IMMEX OEM LICENSE MAQUILADORA

STRATEGIC GLOBAL POSITIONING

OEM IMMEX MAQUILADORA BENEFITS

Manufacturer, China

IMMEX SHELTER COMPLIANCE PACKAGING - MANAGING STOCK - NEARSHORING

Distribution Capacity

Mexico 4,500 Mts - 48,000 SQF

• 2 disitribution center

• Nuevo Leon

• Queretaro

USA 4,000 Mts - 43,000 SQF

• 2 disitribution center

• Houston, Texas

• Arlington, Texas

Logistic Import -Export

• 36 years experience in import and export logistic procedure.

HVAC/R Warranty Program

• Developed propieratory mobile APP application for warranty management program.

Sales and Marketing Transportation

• Privately own truck fleet

• Experienced and professional sales team for HVAC/R aftermarket OEM industry.

• In house webmaster developer.

• In house multimedia and digital marketing developer team.

• Established disitribution network.

• Established OEM relationship.

ISO 9002-2015

ISO Certified and compliance company

IMMEX CERTIFIED PACKAGING AND STOCK MANAGMENT MEXICO SHELTER COMPANY

Mexico IMMEX certified and license company 2024.

• Manages Inventory for the plant.

• Acts as The Inventory Source (+200 SKUs)

• The Manufacture / Plant Can Supply Their

• Customers Directly

• From Factory Or

• From The Distribution Center Regionall, locally, nationally.

• Represent only one manufacture one brand

• Manages limited Inventory (< 100 SKUs)

• For local or regional demands to supply distribuitors and other business.

• In most cases, limited access to all models.

• Concentrates on fast movers only.

• Represent other brands

www.invotech-mx.com

LAMCOINT MEXICO GROUP SAPI

Corporate Office

Belisario Domínguez 2470, Piso 4, Col. Obispado, 64060 Monterrey, N.L.

• OEM can obtain their supply from factory or plant distribution center

• Special design and Specific Models.

• Manages limited Inventory (< 50 SKUs) to supply local or regional demands. In most cases, supplies retailers, dealers, small stores and even final consumer & Technician

• Represent other brands

• Manages Inventory (< 20 SKUs) for local demands to supply final consumers & Technician.

• Represent other brands

• End of the supply chain.

• Needs after sale services (technical and producto info), warranty, training programs, and troubleshooting.