8 minute read

21, 27

Microgen offers IBM 3480 cartridge service

With a growing number of companies using the IBM 3480 cartridge system on their main frame computers, Microgen has become the first COM bureau in the United Kingdom to offer facilities on a national basis to transfer data held on cartridge to microfiche.

Contact: Barry Freedman, Microgen Ltd., Watling Street, Radlett, Herts. WD7 7HZ. Tel: (0923) 852233. Telex: 923040 micrgn g Fax: (0923) 855075.

On the move

Express Microfilm Services have recently moved, from East Kilbride, into new premises in Glasgow.

Contact: Express Microfilm Services Ltd, Express House, 319 Craigpark Drive, Dennistoun, Glasgow G31 2TB. Tel: 041-554 8851.

Change of address

Due to their experience with the recent postal strike and the necessity of a speedy turn round for the Archival Film Testing Service, Dass (Microfilm) Ltd. have changed their address to a city centre P.O. Box Number. This will cut out two sorting and delivery operations in the postal chain. The telephone number remains the same as does the address of their Sydenham Road factory.

Contact: Don Abbott, Dass (Microfilm) Ltd., P.O. Box 852, Birmingham B5 4DU. Tel: 021-643 4748.

Microfilm Shop to launch second Supplies Catalogue

Early in 1986 Genneg Associates launched its 24 page full colour catalogue for Microfilm Supplies under The Microfilm Shop brand name. A recent press release from The Microfilm Shop has let us know that an updated version is at the printers and will be launched straight after Christmas in the New Year. The new catalogue, whilst still incorporating many of the well known products, now puts greater emphasis on the various microfilm supplies items that are manufactured in The Microfilm Factory that has evolved in Nuneaton over the last few years. The new catalogue will include detailed information about three types of microfilm jacket, diazo film (both cut sheet and 105mm roll), cartridges, aperture cards and many other items. All people in the industry who receive The Micrographics Market Place don’t have to worry about where to get a copy. The Micrographics Market Place has just got the contract for supplying it with our first edition in the New Year which is due out at the end of February. Anyone who cannot wait that long will be sent a free copy in January, upon request from:- The Microfilm Shop, Hammond Close, A ttleborough Fields, Nuneaton, Works. CV11 6RY. Tel: (0203) 383998. Telex: 311603 Genneg. Fax: (0203) 382319.

New Brochure from DatagraphiX

Anacomp-DatagraphiX Ltd. has just produced a new, glossy, full colour brochure. This publication explains briefly the COM services and systems that they have on offer. It is available, free of charge, to anyone upon request from:-

Anacomp-DatagraphiX Ltd., New Lodge, Drift Road, Windsor, Berks. SL4 4RQ. Tel: (0344) 885611. Telex: 847320.

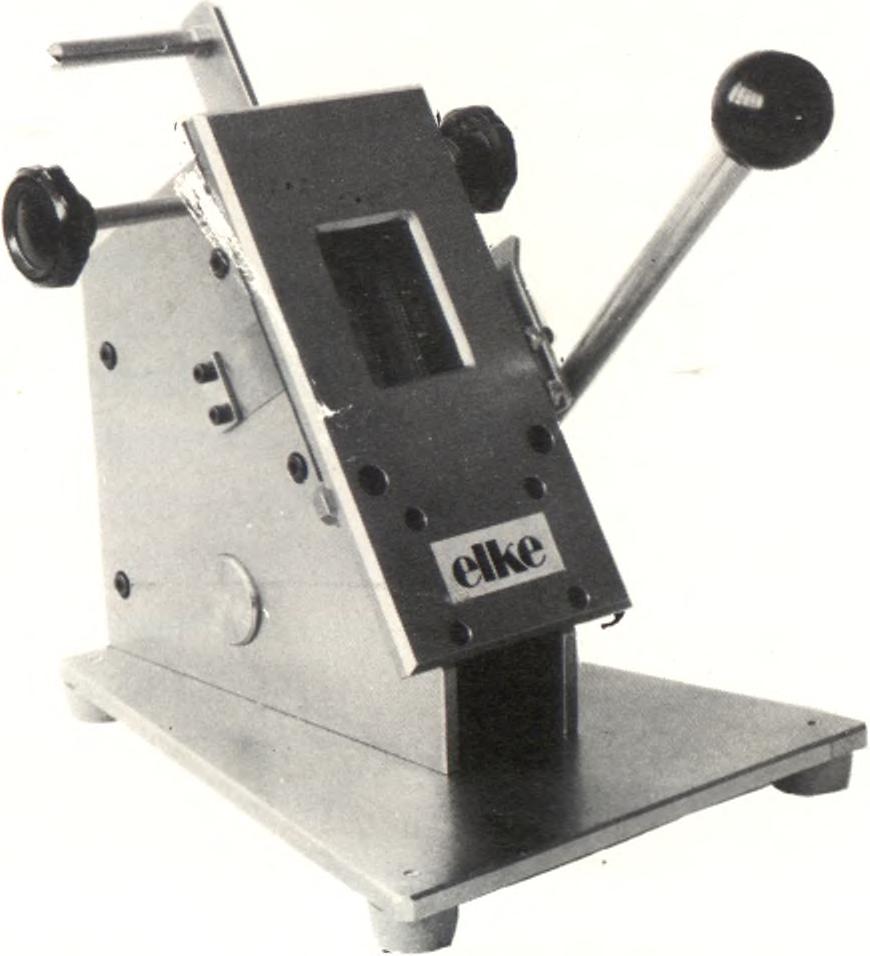

NEW semi autematic aperture card mounter

An experienced operator can m o u n t negatives a t an extrem ely fast speed. A fte r centring the first exposure, one p u ll o f the handle m ounts the negative into the card and the m ounter then autom atically positions the next fram e for loading, and so on for the com plete roll o f film. The standard hand m ounter is still available. M an u factu red to the sam e exacting high standards expected from all Elke products.

For full technical specifications please contact:-

elke microforms

• • " " A m ja ts p z

Sellafield solves data storage problem

At the Sellafield nuclear reprocessing complex British Nuclear Fuels Limited has chosen the in-house microfiching route for the majority of its research and development records, plus most other routine office records tasks. In addition to operating one of the world’s most advanced plants for the re-processing of spent nuclear fuel rods, B.N.F.L. is running a continuous research and development programme including the construction of a vitrification facility for long term storage of waste materials. This work, plus technical support programmes for the Thorpe nuclear power station which shares the Sellafield site and bioanalytical support for the entire workforce, are the responsibility of the Research and Development Department. Plant and research records which make up the majority of the data generated by the R & D Department must be kept for a period that exceeds the 25 year typical operating life of the actual plant, so that de-commissioning and long term storage activities can draw on detailed data if required. The actual scope of the records and the duration they are kept is dictated by the Nuclear Site Operating License granted and administered by the Health & Safety Executive’s Nuclear Inspectorate. The R & D Department which comprises some 500 technical staff plus a further 230 industrial personnel, operates as a number of ‘cells’ each of which is not only responsible for a group of specific projects but also the maintenance of all records etc. These records, fall broadly into 2 categories:- Technical reports, comprising up to 200 pages and containing large amounts of tabular information. Experimental records, comprising log books, run-time records and data generated on a day to day basis. The most important data had previously been transferred onto microfiche by a bureau. This microfiching work was created via B.N.F.L.’s headquarters at Risley which co-ordinates all information management operations for the Company, stores silver master fiche of technical reports and other primary information and produces diazo copies which are returned for storage and used by Sellafield and other BNFL sites. However, there still remained a considerable volume of data which was stored on paper and by the end of 1987 this had reached several million pages, presenting an ever increasing storage and retrieval problem. It was therefore decided to investigate alternative methods of ‘archiving’ the current files and a much larger proportion of future data. While the use of a bureau satisfied many of the requirements, it was naturally more costly and potentially less flexible than an in-house installation. Similarly, sending any important data outside of the direct control of the responsible department introduces other potential problems. These include:- the risk of information being recorded out of sequence when reports were de-collated and the obvious, if limited, security implications of ‘sendingout’ confidential information of any type. Having decided to take the ‘in-house’ route, the next decision was the choice of medium to be adopted. Microfiching was an obvious choice because it was the method previously used by the bureau but there were also other arguments in its favour. Naturally, the archival medium to be chosen needed not only to resist the ageing and degradation processes affecting paper, but must also be incorruptable i.e. the data must not be

12

capable of being altered. This meant that dry film microfiche systems were not acceptable as little long term track record existed. Similarly, laser disc and magnetic disc/tape storage were not accepted as having a proven long term viability. Traditional silver process, microfiching however offered concrete proof of archival quality as defined by BS 1153-1975. Roll film microfilming would also have met the archival qualities but was considered to be less accessible than cut fiche. An examination of the available microfiche camera systems soon identified the DatagraphiX 20/20 system as the most suitable choice. This decision followed extensive ‘field trials’ undertaken by DatagraphiX in conjunction with Sellafield, in which sample fiche were produced from a wide range of documents. During these trials, the two main advantages were identified. Firstly, the 20/20’s simplicity of operation which enabled a number of operators to use the camera, and secondly, the low cost per fiche, typically less than 20p. The complete installation comprises a 20/20 microprocessor controlled, step and repeat camera. DatagraphiX 240 film processor plus an OP 10 table top diazo fiche copier and a PC 70 fiche reader printer. The camera and processor is housed in a small room adjacent to the main library and operates entirely in normal room lighting. Standard and much used feature of the 20/20, is its automatic titling facility. This provides the key to fast and efficient data retrieval. Much of the archival information stored at Sellafield and other operating sites, is ‘live’ data which is regularly accessed by the technical staff. B.N.F.L. operates an internal reference system details of which are held on a Free Text System running on Risley’s mainframe computer. This lists all reports including those held on fiche. Using the 20/20’s keyboard and VDU, the operator can quickly create a fiche reference title. Up to 40 titles can be stored in memory, (more if PC option is fitted) retrieved and edited using simple word processing techniques. In this way, a range of similar titles can be rapidly created from a standard phrase. Company logos or graphics can also be produced on the title via the PC option. Since its installation at the beginning of this year, the 20/20 has demonstrated its effectiveness and is on schedule to convert the back-log of records. The change to microfiche will produce a massive saving in storage space, simplify long term fire protection of records, while improving access to the ever growing library of data. Instead of sending documents to the bureau, they are now microfiched on-site without leaving the control of the R & D Department. Silver masters of the technical reports are sent to Risley for copying onto diazo film which are then returned to Sellafield and stored in the department’s library. Staff can access the data and produce paper copies using either of the two PC 70 reader printers. When occasional diazo copies of locally held masters are required, these can be conveniently produced using the handy table-top OM10 duplicator.