For over 75 YEARS the Instron brand has been widely recognized for producing some of the most advanced mechanical testing systems in the world. Our systems are designed by industry experts, vetted by active members of major standards organizations, and supported by a global network of skilled and experienced service technicians. This comprehensive approach allows us to back each Instron system with an unmatched level of industry and application expertise designed to support it throughout its lifetime.

30,000+

We service and calibrate more than 30,000 Instron systems in active use worldwide every year.

96%

96% of the Fortune 100 list of the world’s largest manufacturing companies use Instron test systems.

50,000+

Systems have been installed worldwide with a diverse product range for nearly all global markets and industries.

18,000+

Instron systems have been cited in more than 18,000 patents since 1975.

We stake our reputation on the integrity of data. From the measurement of primary test data to result generation, we design and manufacture the full data integrity chain (e.g. load cells, sensor conditioning, and software). Additionally, we calibrate more than 90,000 of these sensors annually with the lowest accumulated uncertainty.

From protecting your brand to ensuring the safety of operators in your laboratory, Instron systems are designed to minimize the risks inherent in mechanical testing. Our commitment to user safety is a top priority: innovations such as our Operator Protect system architecture and software that emphasizes data security help to mitigate risk to the test operator, manufacturer, and users of end products.

With the largest team of service engineers in the industry, representing 160 countries and speaking 40+ languages, we’re here to ensure the long-term health of your system - no matter where in the world it’s located. We offer accessories and system upgrades to enhance your instrument as needs change over time, and you can be sure your investment will last. The average age of Instron systems we maintain and calibrate is 18 years.

With active membership on national and international standards boards, our product development team is continually striving to anticipate your future testing needs. Emerging materials technology requires innovative testing solutions, and Instron works continually to develop safe, accurate, and efficient tools to help you meet new challenges.

Materials testing is a critical part of the product development process and helps ensure the quality of your products. To do this successfully, you need to be able to produce accurate and repeatable data that you can trust. This means finding a testing partner you can rely on.

As the leading global manufacturer of testing equipment for the material and structural testing markets, our product line includes universal, dynamic & fatigue, impact, rheology, HDT & Vicat, automated testing systems, torsion testers, structural durability testing, & crash simulation systems. Our large product portfolio allows technicians to evaluate materials ranging from biological tissue to advanced high-strength alloys by performing a variety of tests such as compression, cyclic, fatigue, impact, multi-axis, rheology, tensile, and torsion.

Universal testing machines include electromechanical and hydraulic systems to perform static testing, including tensile, compression, bend, peel, tear, shear, friction, puncture, and other mechanical tests.

Instron 3400 and 6800 Series electromechanical universal testing are designed to test materials, components, and products in accordance with ASTM, ISO, and other industry standards. Compatible with hundreds of accessories for a wide range of applications, these universal testing systems are available in multiple sizes and configurations for R&D, QC, and other mechanical testing up to 300 kN force.

Compatible with hundreds of accessories, including grips, fixtures, extensometers, load cells, and more

The Industrial Series is comprised of high-capacity, hydraulic testing ranging from 600 kN (135,000 lbf) to 2,000 kN (450,000 lbf). Standard models feature large diameter columns and rugged components for superior frame stiffness and durability. Custom designs are also available in higher capacities or unique configurations such as compression-only frames.

Capable of measuring forces ranging from 0.02 N to 2000 kN

Dynamic testing systems are used to perform fatigue, fracture mechanics, bi-axial, multi-axial, high strain rate, and thermo-mechanical fatigue tests.

Since 2007, running tests over billions of cycles, ElectroPuls systems are the established materials testing instruments using patented linear motor technology. Offering slow-speed static and high-frequency fatigue testing, this versatile testing capability means ElectroPuls systems are ideal for any lab or office space.The ElectroPuls machines are available in 4 sizes, and as axial only or combined axial-torsion systems that can deliver up to 20 kN and 130 Nm.

Fully integrated dynamic and fatigue testing systems capable of measuring forces ranging from 1000 N up to 5000 kN

General purpose servohydraulic systems are ideal for high-cycle and low-cycle fatigue, fracture mechanics, and quasi-static testing. They can perform a wide variety of low and high cycle fatigue, crack propagation, fracture toughness and other dynamic tests. Each system can be readily configured with appropriate sized servo valve, manifold and hydraulic power unit to suit the particular application.

Slow speed static and high frequency fatigue testing

Instron offers a wide variety of options when it comes to torsion testing including stand-alone torsion testing machines available in a range of force capacities, a torsion add-on for universal testing systems which allows you to convert an axial only system into a biaxial system, and dynamic and fatigue testing machines that offer both axial and torsional testing capabilities.

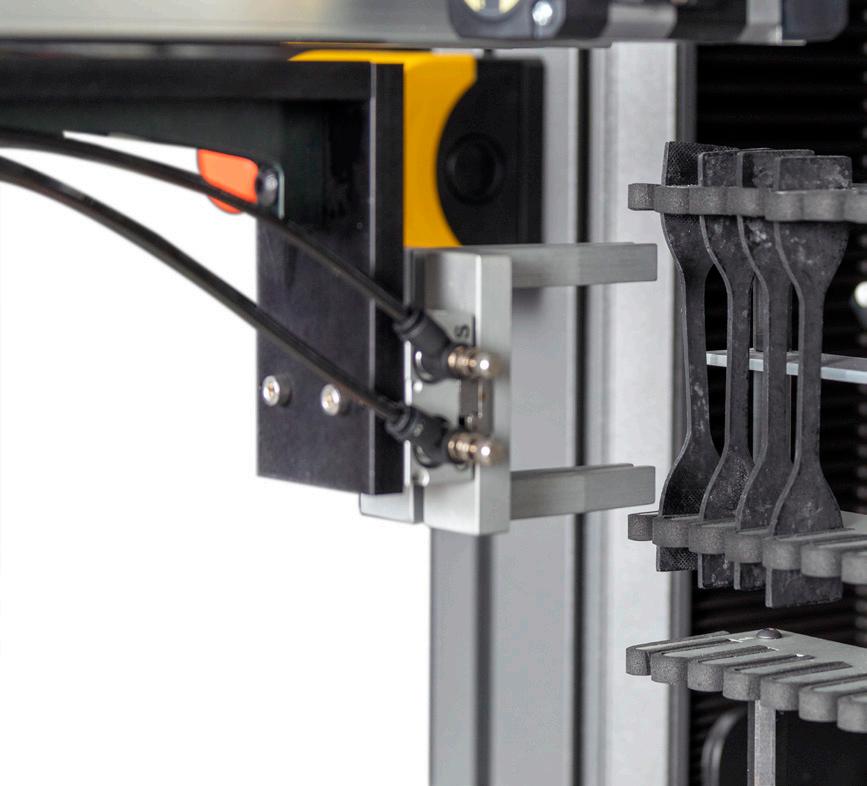

Instron’s range of automated testing systems empowers labs to improve throughput, repeatability, and safety while freeing up skilled operators to focus on other valuable tasks. Available as either a complete turnkey solution or as modules fitted to existing Instron testing instruments, both options are tailored to your program’s specific requirements and provide the broad control and handling capability needed to test to a wide range of applications. Standardized systems are available for tensile, flexural, and compression testing of plastics, thin films, metals, and components.

HDT and Vicat test systems are used to characterize the behavior of plastic materials at high temperatures, measuring the heat deflection temperature (HDT) and the Vicat softening temperature (Vicat). The design of the HV systems and Bluehill HV software is based on the full understanding of customers’ needs for both an enhanced user experience and outstanding productivity, making materials testing simpler, smarter, and safer.

Bluehill HV software is based on the full understanding of customers’ needs

Instron’s bench top capillary rheometers are suitable for both quality control and research & development laboratories. With a velocity ratio of 1:500,000 corresponding to a piston speed of 0.0024 to 1200 mm/min, they perform tests with unlimited steps constant speed, meeting ISO, ASTM, and equivalent standards.

Instron’s modular line of melt flow testers measures, with great accuracy, the MFR and MVR - basic data required for thermoplastic quality control in the rheology field.

Measure the rheological properties of thermoplastics to characterize the polymer melt flow behavior

Instron drop towers are used to develop, fine tune, and validate material models. The 9400 Series produces reliable, repeatable results whether you are testing materials and components before production to improve product acceptance or testing during production to ensure continuous improvement.

Instron pendulums are designed to meet the growing demand for accurate and repeatable impact testing on a wide range of materials. Used to determine the mechanical and physical properties of metals, polymers, composites, and finished products for both research and development (R&D) and quality control (QC), the pendulum family is capable of performing Charpy, Izod, and tensile tests according to international standards.

Instron’s acceleration sled systems are used for development and approval of passive safety components such as air bags, safety belts, seat fixing elements and headrests. Therefore the sled system precisely reproduces both, measured and normed crash signals for frontal-, side- and rear-crashes as well as for tests with yawing and pitching motion.

Growing demands on the comfort and reliability of vehicles require functional and lifetime tests of components and complete systems to improve safety and reduce environmental impact.

With over 300 field service engineers spread across every major market, Instron has all the tools, services, and staff needed to offer you exceptional personalized support. Our global team is on hand to help you achieve your objectives, from regular preventative maintenance and calibration of testing instruments to application support and training. Partnering with Instron will extend the life of your investment, minimize downtime, and reduce the cost of equipment ownership while streamlining your testing processes and helping to future-proof your testing.

We are regionally close to our customers with 1,500+ worldwide employees

We speak 40+ languages with documentation in 20+ languages

Sales in 120 countries with 250+ field service engineers globally

ITALY

BARCELONA, SPAIN

KOREA

JAPAN