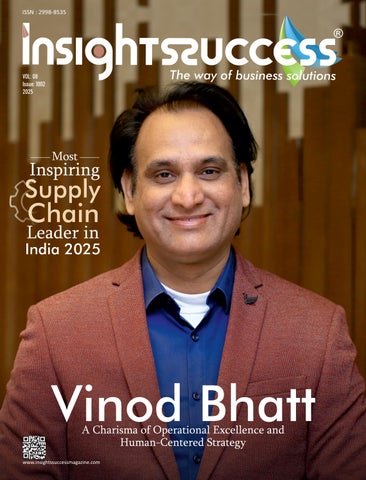

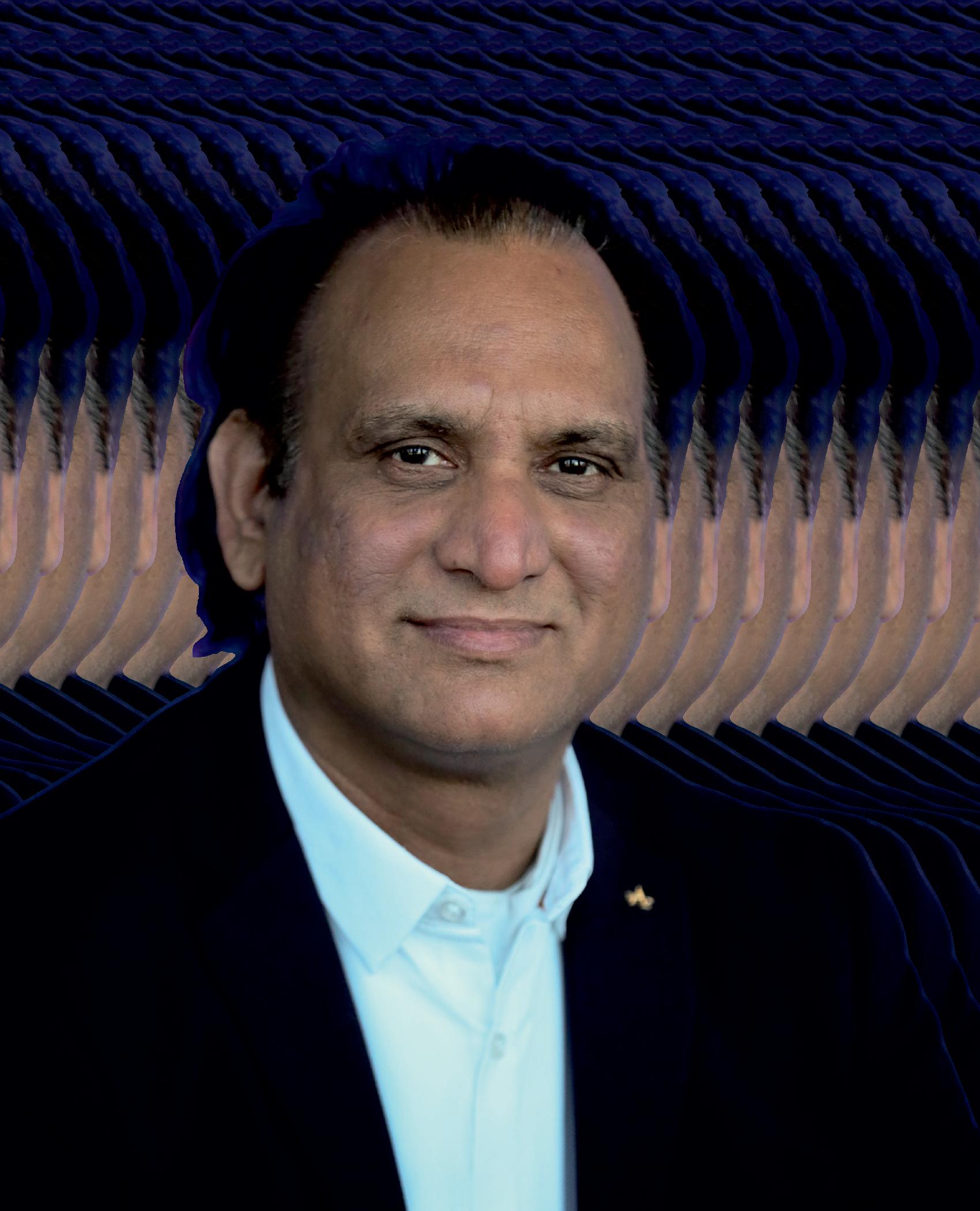

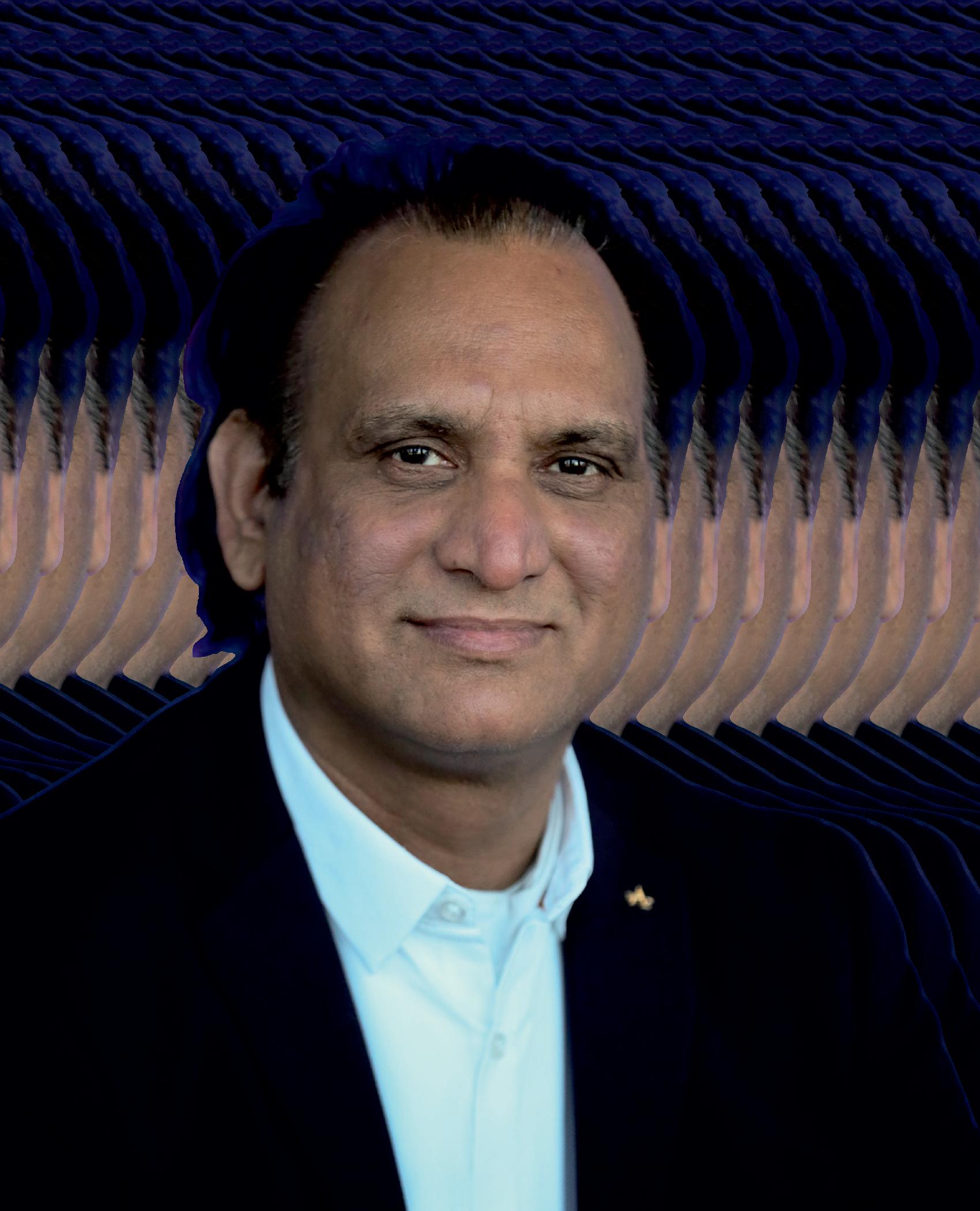

Most Inspiring Supply Chain Leader in India 2025

Most Inspiring Supply Chain Leader in India 2025

A Charisma of Operational Excellence and Human-Centered Strategy

Inanerawherethesupplychainhastransformedfromabehind-the-scenesfunctionintothebeating

heartofbusinessresilience,leadershipinthisfielddemandsmorethanoperationalexpertiseit requiresvision,adaptability,andanunwaveringcommitmenttoinnovation.Thedisruptionsofrecent yearshavemadeonetruthabundantlyclear:theleaderswhocananticipatechange,navigateuncertainty, andinspireteamswillshapethefutureofcommerce.

Itisinthiscontextthatweproudlypresentour Most Inspiring Supply Chain Leader in India 2025 editionbyInsightsSuccess,headlinedbyVinodBhatt.Anamesynonymouswithstrategicforesightand operationalexcellence,Vinodhasredefinedhowsupplychainscanbecomeenginesofgrowthratherthan costcenters.Hisjourneyisoneofdetermination,deeptechnicalinsight,andarareabilitytounitepeople, processes,andtechnologyintoaseamless,future-readyecosystem.

WhatmakesVinod’sstorytrulyinspiringisnotjustthemilestoneshehasachieved,buttheprincipleshe standsbyintegrityinleadership,empathyinmanagement,andrelentlesspursuitofefficiencywithout compromisingsustainability.Hisinitiativeshaveconsistentlydrivenmeasurableimpact,fromreducing leadtimesandoptimizinginventorytoembeddingdigitalintelligenceineverylinkofthechain.

Thiseditiongoesbeyondcelebratingprofessionalsuccess;itaimstosparkdialogueontheevolvingrole ofsupplychainleadersinshapingIndia’seconomicgrowthstory Throughexclusiveinterviews,expert analyses,andcasestudies,weexplorehowinnovation,collaboration,andethicalleadershiparesetting newbenchmarksfortheindustry

Toeveryreaderwhetheryou’reaseasonedleader,anaspiringprofessional,oranindustryobserverwe hopethisissueoffersnotonlyinsight,butalsoinspiration.Afterall,thesupplychainsoftomorrowwillbe builtbythevisionariesoftoday.

Happy Reading!

Most Inspiring Supply Chain Leader in India 2025

A Charisma of Operational Excellence and Human-Centered Strategy

Navigating this duality of opportunity and risk will dene the next-generation supply chain leaders, setting apart those who can adapt with resilience, innovation, and foresight.”

Theuniversalhumofambitionresonateswithinusall.

From the first spark of an idea to the grandest aspirations,weashumansarepropelledbythedesire to climb, to achieve, to reach that shimmering horizon of success.Yet,forallthestriving,onlyaselectfewtrulymakeit to the pinnacle. What sets them apart? It's more than just effort;it'saprofoundcommitmentandthevisiontodevelop powerful frameworks that transform dreams into tangible realities. This thought has been a catalyst for Vinod Bhatt, HeadofSupplyChain,HP(India).

Vinod’s career began in 1994 with a clear intent—to build operational frameworks that drive sustainable business advantage. He was drawn to operational disciplines because theyhaveauniqueabilitytotransformbusinessstrategyinto real, measurable outcomes. Early experiences at Unilever, LG,HughesTelecom,andNortelNetworkshelpedshapehis understanding of end-to-end supply chain management in fast-paced,dynamicindustries.

ThedefiningphaseofhiscareerbeganwhenhejoinedHPin 2007.Beyondtheglobalscaleandbrandstature,whatstood out immediately was HP’s deep-rooted culture of transformation.Heshares,“Ihadtheprivilegeofcontributing to several pivotal milestones in HP’s history—from largescale acquisitions and strategic integrations—reshaping our global supply chain from a regional construct to a marketcentric model ” He drives HP India’s commitment to customer-centricityandoperationalexcellence.

The Ideology that Defines the True Meaning of Leadership

More recently, Vinod has led teams through the transformation journey towards a digitally enabled, customer-first operating model anchored in resilience and sustainability key pillars of HP’s growth strategy and

competitiveedge.HeremainstrulyinspiredbyHP’spurposedrivenethosandvalues-basedleadership,committednotonly to driving profitable growth but also to creating long-term valuefortheplanetandpeople.Inessence,theseexperiences reaffirmedVinod’sbeliefthatsupplychainisfarmorethanan operational backbone—it is a strategic engine powering resilience, growth, and customer experience. That belief continuestofuelhiscommitmenttothisprofession.

Vinod’sleadershipphilosophyemphasizesthefundamentals of

Ÿ

Ÿ BestinClass

Ÿ CompetitiveSpirit

Theseprinciplesserveasacompassthatguidesnotonlydayto-day operations but also drives tactical and strategic decisions to bring value to the business. Vinod reflects HP’s core leadership values: Start with the customer, develop the team, own the outcome He expresses, “My leadership philosophy is rooted in transformation: not just setting the standardthroughpersonalexamplebutcultivatingleadership withintheteam.Tome,trueleadershiptranscendshierarchy; it’saboutclarityofpurpose,empoweringindividualstotake ownership of their journey, and fostering an environment wherepeoplecanthrive.”Vinodisafirmbelieverintheethos of“DoingitRightratherthanRightNow.”

Heunderstandsthatthoughtfulandintegrity-drivendecisions mattermorethanshort-termwins.AtHP,whiletheleadership structure has evolved, the behaviors and values remain enduring and ingrained in the company culture, which has profoundlyshapedhiscareerpath.

That spirit continues to resonate within HP and serves as a personal reminder that enduring value is built through integrity, courage, and purpose. What motivates me daily is the opportunity to make a positive impact on business outcomes, customer experiences, and people’s careers.”

He has led pivotal initiatives such as driving HP India's Customer-Centricity principle across the supply chain, embedding agility, responsiveness, and end-user alignment into core operations. Under his leadership, the supply chain has been positioned as a strategic growth enabler—through closecollaborationwithSalestoinfluencecustomerdecisionmakinganddrivebusinesswins.

Hehasalsoplayedakeyroleinenhancingcustomervisibility into HP’s global scale, operational resilience, and sustainabilityimpact.“Forus,itisnotjustaboutproducts,but how those products go into the hands of customers in a completely sustainable manner – via an entire sustainable supply chain of green warehouses and low carbon emission options,”sharesVinod.

Throughout this journey, he has drawn inspiration from leaderswho emphasizedcontinuouslearning,bold thinking, and the ability to convert operational capabilities into strategic advantage—principles that continue to inform his leadershipapproachtoday

From Vinod’s perspective, supply chain management has decisively transformed from being a traditional support function to a strategic differentiator in today’s business landscape, focusing on agility, resilience, and sustainable value creation across the enterprise In an environment markedbyextremevolatility,geopolitical¯oeconomic challenges, and constantly evolving consumer expectations, an agile and resilient supply chain is essential to deliver on brand reliability, profitable growth, and best-in-class customerexperience.

He elaborates on the fact that, “At HP, the supply chain has played a pivotal role in sustaining operational continuity during global disruptions and overcoming those challenges to deliver on operational excellence and customer promise. Today, a high-performing supply chain isn’t one that merely responds to challenges; it’s one that anticipates risks, capitalizesonopportunities,andpositionstheorganizationto deliver consistently on its business priorities and customer commitments.”

“Resilience isn’t built overnight it’s an intentional, structuralcommitment,anditcannotbeimprovisedduringa crisis,”sharesVinod.Resilienceframeworkspivotonseveral keystrategies:

Ÿ De-risking geographical and supplier concentration to reduceover-relianceonspecificnodes

Ÿ Balancing working capital efficiency with resilience — optimizinginventorybuffers,strategicstocking,andagile inventorypractices

Ÿ Building real-time e2e visibility through integrated data ecosystems connecting suppliers, logistics partners, and customers

Ÿ Forging strategic supplier partnerships for mutual resilienceandcollaborativecrisisresponse

Ÿ Adopting agile fulfilment models, including regional hubs,cross-docking,andmulti-modaloptions

Ÿ Embedding organizational resilience through structured crisis management frameworks, resilience KPIs, and businesscontinuityplaybooks.

Such strategies enable companies to proactively navigate volatility while ensuring operational continuity through a multi-layered strategy, driving agility and resilience as core leversofbusinessimpact.

Emerging technological trends are fundamentally rearchitectinghowvariousoperationsfunctionandcreatevalue across industries This transformation transcends mere incremental improvements, instead enabling profound structural shifts in areas such as resilience, agility, sustainability,andcustomer-centricity.

Keyareasundergoingthissignificanttransformationinclude optimizing resource management, where digital platforms help organizations use resources more efficiently and keep better track of products throughout the supply chain

Furthermore, the application of predictive analytics, heavily reliant on AI and machine learning, enables proactive risk management and more precise capacity planning across diversesystems.

These advancements also extend to operational flows, facilitating digitally enabled movements that contribute to carbon efficiency through optimized routing and automated logistics.Real-timevisibilityintooperationalstatus,whether it's order fulfillment or service delivery, significantly enhances overall stakeholder confidence. Collectively, these capabilities,drivenbythestrategicdeploymentof

automation, robotics, and artificial intelligence, are building smarter,faster,andmoreresponsivesystemsthateffectively catertobothbusinessandenvironmentalimperatives.

The strength of any supply chain lies in the strength of its relationships—bothwithintheorganizationandwithexternal partners. HP’s team cultivates a relationship-driven, resilience-firstculturethrough:

Ÿ SharedKPIsandoutcome-basedmetricswithsuppliersto alignobjectivesandjointlyownoutcomes

Ÿ Promotinga‘OneTeam’mindsetacrossglobal,regional, andfunctionalteamstobreakdownoperationalsilos

Ÿ Establishing structured governance forums for collaborative decision-making on strategy, performance, andriskresponse

Ÿ Embedding business continuity planning and crisis responsemechanismscollaborativelywithpartners

WithinHP,cross-functionalcollaborationisinstitutionalized through integrated business operations reviews, risk management councils, and improvement roadmaps that enablecollectiveproblem-solvingandinnovation.

Asanexperiencedleaderinthesupplychaindomain, Vinod reflectsuponaverypracticalscenario:thenuanceddecisionmaking involved in balancing operational efficiency and resilience.Heexpresses,"For us, it comes down to pursuing Value Creation & Experience to Stakeholders."Thisguiding principle underscores a strategic approach that extends far beyondmerecostreduction.

Hesuggeststhatorganizationsshouldbuildtheirsupplychain strategiesaroundabsoluteend-to-endcustomerdeliverables, emphasizing resilience, lifecycle costs, and operational scalability This includes a strong focus on network optimization, ensuring that the entire supply chain infrastructure – from sourcing to distribution – is strategicallyconfiguredforoptimalflowandresponsiveness. This comprehensive approach enables organizations to effectively deal with global uncertainties, shifting market demands,andunforeseendisruptions,transformingpotential weaknessesintosourcesofstrength.

Facilitatingcross-functionalengagementandcollaborationis alsocriticaltoaligningbusinessgoalswithanoptimizedcostto-serve. This collaborative model recognizes that every aspect of the supply chain, from initial planning to final delivery,impactsthecustomerexperience.

Ultimately,everythingstartsandendswithcustomers–that’s where the supply chain plays its pivotal role.Thisbalanced, collaborative model has consistently enabled Vinod and his team to ensure operational reliability, enhance overall operational efficiency, and maintain robust financial disciplineamidstdynamicglobalconditions.

Behindeverysuccessfulcompany,astrongintentionalculture fosters trust, inclusiveness, and a shared sense of purpose. When culture aligns with strategy, it becomes a powerful driver of performance, innovation, and long-term impact. Vinod acknowledges the fact that ‘Culture isn’t just an enabler—it’s the invisible operating system behind every strategicsupplychainoutcome.’

Vinodproudlyrevels,“AtHP,ourcultureprioritizes:

Ÿ Customer Centricity: keeping the end customer at the heartofeveryoperationaldecision

Ÿ Operational Resilience: embedding a bias for proactive, agiledecision-making

Ÿ Continuous Improvement and Innovation: fostering a growth mindset to challenge the status quo and experimentwithnewideas

Ÿ Transparency, fairness, and Diversity: fostering an inclusive environment where diverse perspectives drive betteroutcomes.”

HP’s firm commitment to meaningful innovation and sustainabilityhasbecomeacentraltenetofitsglobalsupply chain strategy. This ethos—anchored in the foundational principles of the HP Way ensures that supply chain operationsarenotonlyefficientbutalsoresponsible,futureready, and value-driven In India, this vision has been translated into aligning the local supply chain with HP’s global sustainability agenda, seamlessly integrating environmentalgoalsintocoreoperations,whileconsistently meetingcustomerexpectations.

At HP, the supply chain has played a pivotal role in sustaining operational continuity during global disruptions and overcoming those challenges to deliver on operational excellence and customer promise. Today, a high-performing supply chain isn’t one that merely responds to challenges; it’s one that anticipates risks, capitalizes on opportunities, and positions the organization to deliver consistently on its business priorities and customer commitments.”

Vinod’s observation is that the supply chains are entering a newera.AI-leddigitaltransformationisunlockingpredictive, adaptive,andautonomoussupplychaincapabilities,enabling businesses to respond to disruptions with agility and foresight.

At the same time, regionalization and supply network rebalancingaredrivingthecreationofnewoperatingmodels that are closer to consumption centers, enhancing responsiveness and reducing lead times. Sustainability is emergingasacompetitiveadvantage,wherecarbon-efficient, ethical,andtransparentsupplychainsarenolongerjustgood practice—theyarebecomingkeybranddifferentiators.

In this environment, partner and ecosystem collaboration is proving to be the new strategic advantage, enabling organizations to build more resilient, innovative, and connected supply networks However, despite the momentum, several challenges continue to test the path forward.

Geopolitical volatility and regulatory unpredictability continue to disrupt global supply networks, forcing organizationstoremainagileandvigilant.Atthesametime, the rise in cybersecurity threats poses serious risks to increasingdigitalandconnectedoperations.Talentshortages and the urgent need for workforce reskilling are further straining capabilities, especially as supply chains become moretechnology-driven.

Cost inflation and rising margin pressures demand smarter, leaner operations, while escalating complexity in risk management fueled by deeply interconnected global systems requires more sophisticated and proactive approaches.

Heexpresses,“Navigatingthisdualityofopportunityandrisk will define the next-generation supply chain leaders, setting apart those who can adapt with resilience, innovation, and foresight.”

For the budding aspirants of the supply chain niche, Vinod offersadvicethatisbothpracticalandprofound.Staycurious, agile, and resilient—thesearenotjusttraitsbutsurvivaltools inaconstantlyshiftinglandscape. Challenge the status quo; don’t just execute — innovate, because true impact lies in creatingbetterwaysofdoingthings.

He urges young professionals to cultivate a cross-functional perspective,remindingthemthatthesupplychainisuniquely positioned at the intersection of planning, procurement, manufacturing, sales, and customer experience. Stay true to your integrity and values, especially when tough decisions arise.

And perhaps most importantly, in every crisis, see opportunity—becauseinthesupplychain,themostdefining momentsarecreatedindisruption.Thisisaprofessionwhere your ability to stay ahead of change doesn’t just support the business—itcanredefineitsfuture.

The HP Garage and the story behind it as the “home for innovation”istheinspirationnotonlyforVinodbutformany withinandoutsidethisgreatcompany.

Hebestows,“That spirit continues to resonate within HPand serves as a personal reminder that enduring value is built through integrity, courage, and purpose. What motivates me daily is the opportunity to make a positive impact on business outcomes, customer experiences, and people’s careers.”The commitment to the HP Way—a culture grounded in trust, respect,andresponsibility—iswhatdrivesVinodtoleadwith intentionandhumility

For Vinod, a resilient, digitally empowered, sustainably conscioussupplychainorganization,onerecognizednotjust foroperationalexcellenceandstrategicforesight,butequally foritsdeepcommitmenttopeople,partnerships,andpurpose.

HeadmitsthatTheHPWayhasinstilledinhimthebeliefthat leadershipisaboutleavingthingsbetterthanyoufoundthem.

“That remains my personal leadership promise—to lead with integrity, build with resilience, and empower others to thrive,”concludesVinod.

Thewidening,globalizedenterpriseeconomyhasmade

supplychainleadershipanevermoreessentialfunction than ever previously Supply chains are no longer discrete operating processes but strategic assets that influence the performance, profitability, and resilience of the firm directly. As companies struggle to keep up with changing consumer trends, geopolitics, and accelerated technology revolutions, the demand for effectivesupply chain leaders has grownexponentially Suchmanagersneedtonotonlyoversee logistics and procurement but also lead innovation, sustainability, and digitalization in the value chain. Supply chain leaders are made by subjecting professionals to end-toend thinking. It is a matter of comprehending end-to-end processes comprehensively, relocating interdepartmental and partnershipcooperation,andconstantlybeinginresponsemode for surfacing trends. Supply chain masters must balance strategicthinkingandtacticalexcellence.Theymustbeableto respondtosurpriseshocks,whilesettinguptheirorganizations tobecompetitiveinthelongterm.

Perhaps the most critical of all the individual components of supply chain leadership is creating and communicating strategicvision.Itinvolvesknowledgeoftheoverallcompany objectives and contribution of supply chain to their achievement.Effectiveleadersstrikeabalancebetweensupply chainstrategyandfirmobjectives,makingthesupplychainand firm goals converge through activities such as marketing, finance, and product development. Unshakeable vision is to inform decision-making, maximize resources utilization, and refocus marketing effort towards ultimate success. It also enables leaders to invest in capabilitiesthatwill be capableof maintaining competitive edge for upcoming challenges Operationexcellence,however,isthefrontlinebuildingblock onadailybasistosuccessinsupplychains.

Itcomprisesongoingdeliveryofprocesses,costmanagement,

qualitymonitoring,andon-timedelivery.Leadersmustgive their employees tools, training, and performance measures requiredforoperatingimprovements.Leadersmustensurea cultureofcontinuousimprovementandinnovationculturefor everyoneintheorganization.Operatingimplementationand strategic vision must be harmonized. The organizations can therefore satisfy the customers' needs, counter threats, and leverageopportunitiesinthemarket.

Today, supply chain leaders must become data-driven decision-makers. Supply chains today are being reshaped with the help of digital technologies such as artificial intelligence, machine learning, blockchain, and predictive analytics. They provide increased transparency, enable realtime tracking, and generate actionable insights that drive improved forecasting, inventory, and supplier performance. High-performing data leaders have visibility beyond the bends, end inefficiencies, and create more responsive and adaptable supply chains With all different systems and partners' data in one place, they can make faster, better decisions that yield short-term payback and long-term innovation.Adoptionoftechnologyalonewillnotbringabout transformation,though.

Leadership intervenes to propel the organisational change through digitalization. This entails creating digital culture, cross-functional alignment creation, and talent building investments.Digitalprojectworthinessisjustifiedbyleaders, andchangeresistanceisovercomebythem.Leadersengage inbuildingcompetencywithteamswithaviewtoexploiting new technology. With technical and good change management capability, supply chain leaders are able to revolutionise legacy models into smart, customer-centric networksdrivingbusinessgrowthandsustainability

High-performance teams and partner relationships are also becomingasupplychainleaderbecausetheseleadersshould establish partner relationships and teams with internal and external partners Supply chains cut across numerous functionsandstakeholders,andgreatleadersunderstandthe importance of collaboration and communication. They help buildtrustwithindepartments,breaksilos,andgeteveryone aligned to similar objectives This model brings in transparency,accountability,andcollaborativeresponsibility

for outcomes. It also enables the organization to come back from disruptions quicker, innovate quicker, and provide customer value more consistently. On the outside, leaders must extend to suppliers, logistics partners, and other businesspartnerstobuildastrongandresilientsystem.

This involves creating supplier relationship management programs, involvement in collaborative planning processes, and the meeting of some performance expectations. Joint systemsalsoplayahugeroleinavoidingrisk,continuity,and innovation. Non-transactional sellers but strategic partners suppliers will be more proactive on issues of quality, flexibility, and sustainability Good leaders in creating such partnershipsmaketheirsupplychainsstrongerandeffective.

Leadershipexcellenceinthesupplychainisacombinationof strategic thinkers, operations acumen, technical expertise, andmanmanagement.Havingtherightfittorunprocessesis not sufficient; the leaders must be change visionaries and coordination drivers along the value chain As there is increasingvolatilityandcomplexityinglobalsupplychains, leadership will be one of the differentiators.Those who will succeedtoeffectivelylinksupplychaininitiativestobusiness objectives, leverage innovation, and construct strong ecosystems will steer their organizations toward sustainable competitivenessandgrowth.Supplychainexcellenceisona path,butwiththerightmindsetandability,leaderscandesign strong,flexible,andfuture-proofsupplychains.

www.insightssuccessmagazine.com

Intoday’shyper-connectedandfast-movingworld,businessesare

under constant pressure to deliver products faster, cheaper, and morereliablythaneverbefore.Thegrowingcomplexityofsupply chains, rising customer expectations, and global competition have pushed companies to rethink the way they manage logistics. One solution that has emerged as a game-changer is smart logistics a technology-drivenapproachthatblendsautomation,dataintelligence, and real-time communication to create highly efficient and adaptable supplychainsystems.

From e-commerce giants to mid-sized manufacturers, businesses across industries are adopting smart logistics not simply as a costsaving measure but as a strategic investment that drives growth, innovation,andsustainability

Fordecades,logisticswaslargelyaboutmovinggoodsfrompointAto point B in the most economical way possible. While effective in the past, this traditional model left room for delays, miscommunication, andinefficiencies.Changesindemand,trafficdisruptions,orinventory mismatches could quickly ripple through the entire chain, causing costlysetbacks.

Smart logistics marks a fundamental shift from reactive to proactive logisticsmanagement.Itintegratesadvancedtechnologiessuchasthe InternetofThings(IoT),artificialintelligence(AI),cloudcomputing, andblockchainintoeverystageofthesupplychain.Insteadofwaiting for problems to arise, businesses can now anticipate them, respond instantly,andcontinuouslyoptimizetheirprocesses.

Thisevolutionisnotjustaboutspeedit’saboutprecision,transparency, andadaptability.

At the heart of smart logistics is real-time visibility GPS-enabled devices, RFID tags, and IoT sensors allow companies to monitor shipments every step of the way, tracking not only location but also environmental conditions like temperature and humidity This is

especially critical for sensitive products such as pharmaceuticals and fresh produce, where even slight deviationscanleadtospoilage.

Automation also plays a key role. In modern warehouses, robotic picking systems and automated guided vehicles (AGVs) are handling repetitive tasks with remarkable accuracy This reduces human error, speeds up order processing,andmaximizesspaceutilization.

Equallyimportantistheuseofdataanalytics.Smartlogistics systems gather vast amounts of information—from traffic patterns to seasonal demand trends—and use it to make informeddecisions.Predictiveanalyticscanhelpcompanies forecast inventory needs, while AI-powered route optimizationensuresdeliveriesarecompletedintheshortest possibletimewithminimalfuelconsumption.

Blockchain adds another layer of trust and transparency, creatingasecureandtamper-proofrecordofeverytransaction andmovementwithinthesupplychain.

The benefits of smart logistics are tangible. Businesses see shorterdeliverytimes,fewererrors,andreducedoperational costs. By optimizing routes and avoiding unnecessary trips, fuelconsumptiondrops,whichnotonlysavesmoneybutalso supportsenvironmentalsustainability

Customers, too, feel the impact. Real-time tracking gives them clear, reliable delivery estimates, and timely updates build trust. For many brands, this level of transparency has becomeacompetitivedifferentiatorincrowdedmarkets.

Perhaps most importantly, smart logistics makes companies more agile. In a world where disruptions—whether from weather events, geopolitical tensions, or sudden demand shifts—are increasingly common, having a system that can adaptquicklyisessentialforresilience.

While technology is the driving force, human expertise remainstheguidinghand.AlgorithmsandAIcanprocessdata at incredible speeds, but it’s people who interpret that data withinthecontextofbusinessgoalsandcustomerneeds.

Adriver’slocalknowledgemightstillhelpavoidatrafficjam that the system hasn’t yet detected. A warehouse manager might identify a subtle operational improvement that

automation alone wouldn’t spot. Smart logistics works best when the strengths of technology and human judgment are combined,creatingapartnershipthatelevatesperformance.

The applications of smart logistics are already reshaping industries.Ine-commerce,fulfillmentcentersequippedwith AI-driven systems are processing thousands of orders with near-perfect accuracy. In the cold chain sector, IoT-enabled sensorsensurevaccinesandperishablegoodsaretransported under strict temperature controls. Even in congested urban areas, logistics providers are using AI to map out the most efficientdeliveryroutes,savingtimeandreducingemissions.

Theseexampleshighlighthowsmartlogisticsisnotadistant conceptbutanactive,measurableforcetransformingday-todayoperations.

Adoptingsmartlogisticsisnotwithoutitshurdles.Theinitial investment in advanced technology can be significant, and integrating new systems with existing infrastructure often requirescarefulplanning.Datasecurityisanotherconcern,as connected devices and cloud platforms must be safeguarded againstcyberthreats.

There is also the human factor businesses need skilled personnel to operate, maintain, and optimize these systems. Withouttherighttrainingandchangemanagementstrategies, thefullpotentialofsmartlogisticscanbedifficulttorealize.

Manycompaniesaddressthesechallengesbytakingaphased approach:startingwithapilotproject,provingitsvalue,and thenscalingupgradually Thisallowsthemtomanagecosts, buildinternalexpertise,andgainbuy-infromstakeholders.

Smart logistics is not just a technological upgrade—it’s a strategic transformation that blends innovation with human expertise to unlock unprecedented efficiency. By adopting real-time tracking, automation, data analytics, and transparent processes, businesses can reduce costs, enhance customersatisfaction,andbuildresilienceagainstdisruption.

In an increasingly unpredictable world, those who embrace smartlogisticsarenotjustoptimizingtheiroperations—they areshapingthefutureofglobaltrade.