we drive say a lot about us

Theauto-techisbeingreshapedbyinfluentialleaders

whoaredrivingsignificantchangeintheindustry. Theseleadersareattheforefrontofinnovation, pushingboundarieswiththeirvisionaryapproachesand transformativestrategies.Throughtheirguidance,auto-tech isexperiencingadvancementsinautonomousdriving, electricvehicletechnologies,andsustainablepractices.

Leadersinauto-techarenotonlyfocusedontechnological advancementsbutalsoonreshapingbusinessmodelsto meettheevolvingdemandsofconsumersandregulatory requirements.Theyarefosteringcollaborationbetween traditionalautomotivecompaniesandtechgiants, acceleratingtheintegrationofAI,machinelearning,and augmentedrealityintovehicledesign,manufacturing,and maintenance.

Theseinfluentialfiguresarechampioningsustainability initiativespromotingthedevelopmentofeco-friendly

vehiclesandinfrastructure.Theyareadvocatingforcleaner energysourcesandsupportinginitiativesthataimtoreduce thecarbonfootprintoftheautomotiveindustry

Inautonomousvehicles,influentialleadersarenavigating regulatorylandscapesandsocietalacceptance,pavingthe wayforsaferandmoreefficienttransportationsolutions. Theirstrategicdecisionsareshapingthefutureofmobility, influencingeverythingfromurbanplanningtologisticsand beyond.

Asauto-techcontinuestoevolve,theinfluenceofthese leaderswillbepivotalindrivingindustry-wide transformationsandshapingafuturewherevehiclesarenot justmeansoftransportationbutalsoplatformsfor innovationandsustainabledevelopment.

-PrestonBannister

O N T E N T S

AkinlawonFayokun InformationTechnology Instructor; CyberSecurityandCloud Computing

AlejandroMorate Director-Autonomous Drive

ArthurWagner Director

AugustinFriedel SeniorManager MobilityTransformation

BerndNiedermeier HeadofAutomotive BusinessDevelopment

JoachimSchaper

HeadofAIand BigData

JuergenDickmann

HeadofRadarand Radar-Perception Mercedes-BenzAG

MartinStock

SeniorExpert FunctionalSafety, SOTIF&Safetyfor Automated

OferDavid Founder,CTO& ExecutiveChairman

TamirMizrahi Automotive& AerospaceDesigner

AkinlawonisanexperiencedenterpriseanddedicatedITand CybersecurityProfessionalwithastrongpassionforsecuring criticalITinfrastructures. HouseofHeroz www.houseofheroz.com

AlejandroisDirectorofAutonomousDriveatZEEKR TechnologyEurope,oneoftheleadingmobilityinnovation centersworldwide. ZEEKRTechnologyEurope www.zeekrtech.eu

ArthurisaDirectoratREGOM,anorganizationthatdevelops solutionsforsortingusedtyres,inparticulartheMTP-TRI,its firstsemi-automaticindustrialsortingmachine. REGOM www.regommachinery.com

MHP–APorsche Company www.mhp.com

AtthehelmofMobilityTransformationwithMHP–APorsche Company,Augustin'sstrategicacumenhasbeencrucialin steeringtheautomotiveindustrytowardsafutureshapedby sharedmobilityservices.

Berndisaseniorsalesprofessionalwithover30yearsof experiencesellingandmanagingcomplexsoftwareand hardwaresolutions,creatingcreativebusinessmodels,etc. Tuxera www.tuxera.com

PorscheEngineering ServicesGmbH www.porscheengineering.com

Mercedes-BenzAG www.mercedes-benz.com

AsaHeadofAIandBigDataofPorscheEngineeringServices GmbH,JoachimisworkingonAIandBigData,todeliver innovativesolutionsintothecurrentengineeringeffortsin Porsche.

InhisroleasHeadofRadarandRadar-Perception,Juergenis responsibleforthe6thgenerationatMercedes-BenzAGand futureradarsolutionstowardsautonomousdriving.

SGS-TÜV www.sgs-tuev-saar.com

BrightWayVision www.brightwayvision.com

MartinisSeniorExpertFunctionalSafety,SOTIF,&Safetyfor AutomatedatSGS-TÜV,anorganizationthatoffers comprehensiveservicesfortheindustrialsectorsincluding automotive,automation,software,andforestry

OferisaFounder,CTO,andExecutiveChairmanofBrightWay Vision,whichintroducestheworld'sfirstautomotivegated cameraforultimatevehiclevisioninanydarkcondition, includingnight,rain,fog,snow,andglare.

TamirisanAutomotiveandAerospacedesigneratAIR,an organizationcombiningasleek,moderndesignwith cutting-edgeflightcontrolsoftwarethatupholdingthe highestFAA-approvedsafetystandards. AIR www.airev.aero

Through our machine, we are revolutionizing and optimizing processes.

ArthurWagner Director REGOM

Driving Industry Change Through Innovation!

Thetirerecyclingindustrystandsonthebrinkof transformation,evolvingfromtraditionalmethodsto embraceinnovativesolutionsforasustainablefuture.In thisdynamiclandscape,thereisagrowingneedfor advancedtechnologiesandstrategicapproachestooptimize recyclingprocessesandminimizeenvironmentalimpact.

LeadingthischargeisArthurWagner,theDirectorwitha deep-rootedcommitmenttodrivingchangeand revolutionizingtirerecyclingpractices.Withakeeneyefor innovationandawealthofexperience,thisexecutivehas positionedthemselvesasacatalystforprogressinthe industry.

AttheforefrontofthistransformationisREGOM,a pioneeringcompanydedicatedtoadvancingtirerecycling solutionsglobally Througharelentlesspursuitof excellenceandafocusoncustomer-centricapproaches, REGOMisredefiningindustrystandardsandsettingnew benchmarksforefficiencyandsustainability.

Let’s delve deeper to learn more:

ArthurservesastheCEOofthecompany,whichhecofoundedfouryearsagoalongsidehispartner,Jean-François Cassier,thePresidentofTCGroup,atransportcompany andcollectorandsorterofusedtiresfortheFrench ecoorganismAliapur.WithabackgroundinFinanceand BusinessAdministration,Arthurgraduatednearlytenyears ago,andaftergainingentrepreneurialexperienceinthe foodindustry,heembarkedontheREGOMprojectin2020. InitiallyconceivedasaprojectwithinTCGroup,whichhad beeninvolvedincollectingandsorting40,000tonsofused tiresayearfortwodecades,REGOMaimedtostreamline theworkingconditionsforsortingoperatorsandimprove sortingquality.Fouryearslater,thecompanysuccessfully marketssortingmachinesworldwide.

InadditiontohisroleasREGOM’sCEO,Arthuralso overseesthetirerecyclingactivitieswithinTCGroup(TC Environnement),encompassingthecollectionandsorting ofEnd-of-LifeTires(ELTs)aswellasthesaleofreusable tires.

AtREGOM,Arthurspearheadsthecompany’sdevelopment initiativesandthestructuringofinnovativesolutions tailoredtomeetmarketdemands.TheteamatREGOMis dedicatedtoeitherdevelopingnewsolutionsoradapting existingonestoaddresscustomerrequirementsprecisely EmphasizingextensiveResearchandDevelopment(R&D), thecompanymaintainsacompetitiveedgebyoffering solutionsfinelytunedtothepracticalitiesoftirerecycling. Currently,particularattentionisgiventoadvancingthe recognitionofseverelydamagedtires.Additionally, REGOMisactivelyexpandingintonewgeographical markets.Thisexpansionincludestheestablishmentofan officeinBostoninSeptember,aimedatsupportingthe company’sinauguralmachinesintheUSandventuringinto Asianmarkets,particularlyJapan.Asaburgeoningentity, REGOMplacessignificantemphasisonfosteringclose relationshipswithcustomerstocultivateenduring partnerships.

MTP-TRIstandsasthepioneeringmachinecapableof identifyingandsortingusedtires(PassengerCarandTruck Tires)basedonuser-definedidentificationcriteria.Sorting parametersencompassthetire’sbrand,model,dimensions, loadandspeedindexes,productiondate,andtreadwear Operatingatarateofonetireeverythreeseconds,equating toapproximately+/-1,000tiresperhour,themachineis engineeredtothriveindemandingrecyclingenvironments characterizedbyhumidity,dirt,andspeedchallenges.What distinguishesthemachineisitsadaptabilitytovarious recyclingprocessessuchasgranulation,pyrolysis, devulcanization,reuse,andretreading.Usersbenefitfrom streamlinedtiresorting,datacreation,andmanagement capabilities,aswellasalleviatedworkload,sortinglist integration,andsimplifiedoperatortraining.Throughthe machine,theyarerevolutionizingandoptimizingprocesses toelevatetheefficiencyoftheirclients’operations.

REGOMhasbeendedicatedtodevelopingAIsolutions tailoredtoaddressgenuineindustrialdemands,particularly withinthenichemarketofusedtirerecycling.Despitethe industry’slimitedvolume,itboastsasignificantnumberof stakeholders.REGOM’sapproachhasbeentochannelits effortsintomeetingtheuniquerequirementsofthese diversestakeholdersthroughacomprehensiverangeof

sorting,mechanical,software,AI,andPLCsolutions. Internally,REGOMhasdevelopedarobustinfrastructureto swiftlyadapttoeachclient’sspecificneedsandmarket dynamics.Fromcollectiontovalorization,thecompanyhas engineeredacompleteprocessencompassingsortingaimed atenhancingoverallqualityforoperatorsandtiresorting outcomes.BeyondAI-basedindustrialmachineproduction, REGOMofferscomprehensiveengineeringservicesfor sortinglinesandcollaborateswithclientsonprocess enhancements,humanresourcesconsiderations,andreturn oninvestmentanalyses.

Inordertopromoteanddisseminatetheirinnovations, REGOMcollaboratesextensivelywithregulatorybodies. OnenotableexampleistheirpartnershipwiththeFrench

Fostering positive outcomes requires trust and commitment to the common good.

normativeassociationAFNOR,wheretheyhave contributedtothedevelopmentofacontrolnormfocused ondeterminingqualitycriteriafortheclassificationof reusedtiresforlightvehicles.Buildinguponthisnorm, REGOMhascollaboratedwiththeRCubeFederationto introducetheRECQlabel,whichisaimedatassuringfinal customersregardingthequalityandsafetyofreusabletires. Additionally,REGOMactivelyparticipatesinvarious projectssuchas“BlackCyle”and“Cirpass,”whichaimto showcasetheadvantagesofidentifyingandsortingtiresfor materialrecoverybasedontheirchemicalcontents. Moreover,REGOM’smachineassistssortersandgraders byindicatingpotentialvalorizationdestinationswhile prioritizingergonomicconsiderationstominimizephysical strainonoperators.

AtREGOM,fosteringinnovationisafundamental principle,drivingthecontinualdevelopmentofnovel solutions.EachmemberoftheREGOMteamisactively engagedattheTCEnvironmentproductionsitewhennot travelingabroad,immersingthemselvesinthegroup’s productionactivitiestodevisepracticalsolutions.Rigorous testingofeverynewapplicationoccursontheirproduction sitestovalidatetheirindustrialviability Weeklymeetings convenealldepartments,includingR&D,AI,software, marketing,andcommerce,forthoroughtwo-hour discussionsonvarioustopics.Thiscollaborativeapproach ensuresthateveryoneremainsinformedaboutongoing

initiativesandunderstandsthecollectiveneedsand expectations.Encouraginganenvironmentofopenideation, allteammembersareinvitedtocontributeideaswithout constraints,andprojectideasundergomonthlyreviewsto determinetheirfeasibility.

Toremainabreastofindustrydevelopments,REGOM activelyengagesinpertinenttradeshowsandconferences likeETRA,EURRIC,TireTechnology,TireCologne,IFAT, GTRC,andCES,amongothers.However,theprimary sourceofinformationremainstheircustomers,who

Arthur is actively focused on nurturing and developing the teams.

articulatedemandsbasedonmarketrequirementsanddaily hurdles.Uponidentifyinganewavenuefordevelopment, REGOMmeticulouslyevaluatesthebenefitsandpotential returnoninvestment(ROI)ofautomationcomparedto existingprocesses.Thisensuresthatinnovationseffectively addressmarketneedswhileofferingarealisticROI.

Arthurfindsmotivationinthetirerecyclingindustry’s transitionfromanagingsectortooneembracingIndustry 4.0principles.HeseesREGOM’spotentialtocontributeto thistransformativeshift,particularlyinadvancingfrom energy-basedtochemistry-basedrecyclingmethods.The prospectofdevelopingmoreefficientvalorizationprocesses andreducingrelianceonrawmaterialsforamore sustainablefuturefuelshisexcitementandmotivation.

Inmakingcriticaldecisions,Arthurvaluesdiverse perspectivesfrombothinternalteamsandexternal individuals.Hetypicallyoptsforswiftdecision-making, prioritizingadaptabilityovermissedopportunities.Arthur oftenturnstohiswifeashismosttrustedadvisor,drawing onhersupportandenduringpartnershipspanningovera decade.Whentacklingchallenges,Arthurandhisteam employasystematicapproach,breakingdownproblems intomanageablecomponentstostreamlineandpropose effectivesolutions.

Arthurbelievesthatfosteringpositiveoutcomesrequires trustinone’sactionsandacommitmenttothecommon good.Heemphasizesthatindividualeffortsalonemaynot achieveasignificantglobalimpact;instead,cooperation shouldbeembracedastheprevailingbusinessmodelofthe century

Arthuraimstomaintainhiscurrenttrajectoryofpersonal growthanddevelopment.Hisfrequenttravelsaffordhim theopportunitytoforgeconnectionswithindividualsfrom diverseculturalbackgrounds,prioritizingthecultivationof humanrelationshipsalongsidebusinessendeavors.Through theseinteractions,Arthurgainsinsightsintovarious processes,enablinghimtoofferassistanceintheir enhancementwhilealsoembracingthechancetoimmerse himselfindifferentcountries,customs,andcultures.

ForREGOMasacollective,theoverarchingobjectiveisto consistentlyprovidetailoredsolutionstousers,facilitating theirattainmentofoperationalobjectives,particularlyinthe realmoftirerecycling.Torealizethisambition,Arthuris activelyfocusedonnurturinganddevelopingtheteams withinREGOMtoeffectivelymeettheescalatingdemands oftheindustry.

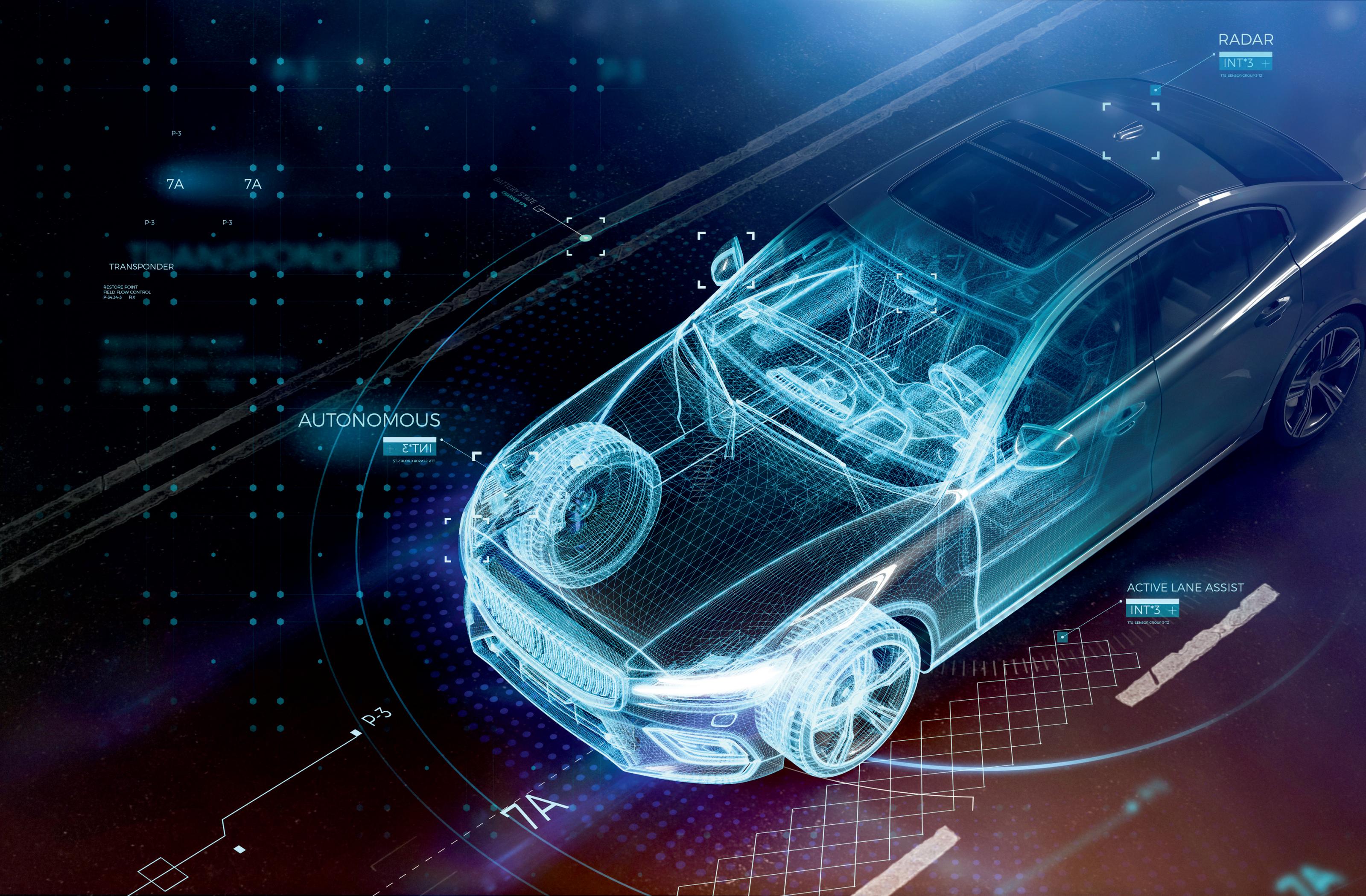

Inrecentyears,theintegrationofmachinelearning

(ML)technologiesinautomobilemanufacturinghas usheredinaneweraofefficiency,innovation,and safetyacrosstheindustry Asautomotivemanufacturers strivetostaycompetitiveinaprogressingmarket,theyare increasinglyturningtoAIandMLtostreamlineprocesses, enhanceproductquality,andmeetthegrowingdemandsof consumersworldwide.

Oneoftheprimaryareaswheremachinelearninghasmade asignificantimpactisinoptimizingmanufacturing processes.Traditionally,automotiveassemblylineshave beencomplex,requiringmeticulousplanningand coordinationtoensureseamlessproduction.However,with theintroductionofMLalgorithms,manufacturerscannow analyzevastamountsofdatainreal-timetoidentify inefficiencies,predictmaintenanceneeds,andoptimize workflows.

Forexample,MLalgorithmscananalyzedatafromsensors installedthroughouttheproductionlinetodetectanomalies orpotentialfailuresbeforetheyoccur Thisproactive approachnotonlyreducesdowntimebutalsominimizesthe likelihoodofcostlyequipmentfailures,ultimately improvingoverallproductivityandreducingmanufacturing costs.

Qualitycontrolisanothercriticalareawheremachine learninghasrevolutionizedautomobilemanufacturing. Ensuringthehigheststandardsofqualityisessentialto maintainingcustomersatisfactionandbrandreputation. ML-poweredsystemscaninspectpartsandcomponents withunprecedentedaccuracy,detectingeventhesmallest defectsthatmightgounnoticedbyhumaninspectors.

Machinelearningmodelscanbetrainedonvastdatasetsof imagesandsensordatatorecognizepatternsassociated withdefectsorirregularities.Thiscapabilityallows manufacturerstoimplementmorerigorousqualitycontrol measures,leadingtofewerdefects,fewerrecalls,and, ultimately,highercustomersatisfaction.

Predictivemaintenanceisanareawheremachinelearning hashadaprofoundimpactontheautomotiveindustry.By analyzingdatafromsensorsembeddedinvehiclesand manufacturingequipment,MLalgorithmscanpredictwhen maintenanceislikelytobeneededbeforecomponentsfail. Thispredictivecapabilitynotonlyreducesdowntimebut alsoextendsthelifespanofmachineryandequipment, optimizingresourceallocationandreducingoperational costs.

Furthermore,ML-drivenassetmanagementsystemshelp manufacturerstracktheusageandperformanceoftheir equipmentinrealtime.Thisdata-drivenapproachenables proactivedecision-makingregardingmaintenance schedules,replacementcycles,andupgrades,ensuringthat assetsareutilizedefficientlyandcost-effectively

Beyondthefactoryfloor,machinelearningisalsodriving innovationinvehicledesignandfunctionality.Advanced driverassistancesystems(ADAS)relyheavilyonML algorithmstointerpretdatafromcameras,radar,andother sensorstoenhancedriversafety Thesesystemscandetect

potentialhazards,assistwithparking,andevenenable semi-autonomousdrivingcapabilities,makingroadssafer foreveryone.

Moreover,thedevelopmentofautonomousvehicles representsthepinnacleofmachinelearningintegrationin theautomotiveindustry.Self-drivingcarsrelyonML modelstonavigatecomplexenvironments,makereal-time decisions,andadapttochangingroadconditions.While fullyautonomousvehiclesarestillindevelopment,ongoing advancementsinmachinelearningcontinuetobringthis futuristicvisionclosertoreality

Despiteitstransformativepotential,integratingmachine learningintoautomobilemanufacturingcomeswithitsown setofchallenges.Onemajorhurdleistheneedformassive amountsofhigh-qualitydatatotrainaccurateMLmodels. Ensuringdataprivacyandsecurityisalsocrucial, especiallyasvehiclesbecomeincreasinglyconnectedand autonomous.

By Akinlawon Fayokun

Intheeraofrapidtechnologicaladvancementand

digitaltransformation,leadershipplaysapivotalrole inshapingthesuccessoforganizations.Theshift towardadigitalizedworldhasbroughtforthnewchallenges andopportunities,necessitatingleaderstoadaptandevolve.

Here are key aspects of leadership in this digital landscape:

Leadersinadigitalizedworldmustpossessasolid understandingofemergingtechnologies.Whetherit's artificialintelligence,dataanalytics,orblockchain,a technologicallyliterateleadercanharnessthepowerof thesetoolstodriveinnovation,streamlineprocesses,and gainacompetitiveedge.

Thedigitallandscapeisdynamicandmarkedbyconstant change.Effectiveleadersembraceadaptabilityandinstilla cultureofchangeresiliencewithintheirteams.Navigating digitaldisruptionsrequiresleaderswhocanswiftlyadjust strategies,seizeopportunities,andguidetheirteams throughtransformationalshifts.

Inadigitalizedworld,dataisavaluableasset.Leaderswho leveragedataanalyticsforinformeddecision-makinggaina strategicadvantage.Byunderstandingandinterpretingdata, leaderscanmakeproactivedecisions,identifytrends,and optimizeorganizationalperformance.

Theriseofremoteworkhasbecomeahallmarkofthe digitalera.Leadersneedtomastertheartofremote leadership,fosteringeffectivecommunication,collaboration,andteamcohesioninvirtualenvironments.Utilizing digitaltoolsforremotecollaborationbecomesessentialfor success.

Withincreasedrelianceondigitalplatformscomestheneed forheightenedcybersecuritymeasures.Leadersmust prioritizecybersecurityawarenesstosafeguardsensitive informationandmaintainthetrustofclients,customers,and employees.

Inclusiveleadershipextendstothedigitalrealm.Leaders shouldensurethatdigitalinitiativesandtechnologiesare accessibletoallmembersoftheirorganization,promoting diversityandavoidingthecreationofdigitaldivideswithin theworkforce.

Leadershipinadigitalizedworlddemandsacommitmentto continuouslearning.Leadersneedtostayabreastof technologicaladvancements,industrytrends,andleadership bestpractices.Byfosteringacultureofcontinuousskill development,leadersempowertheirteamstothriveinthe digitallandscape.

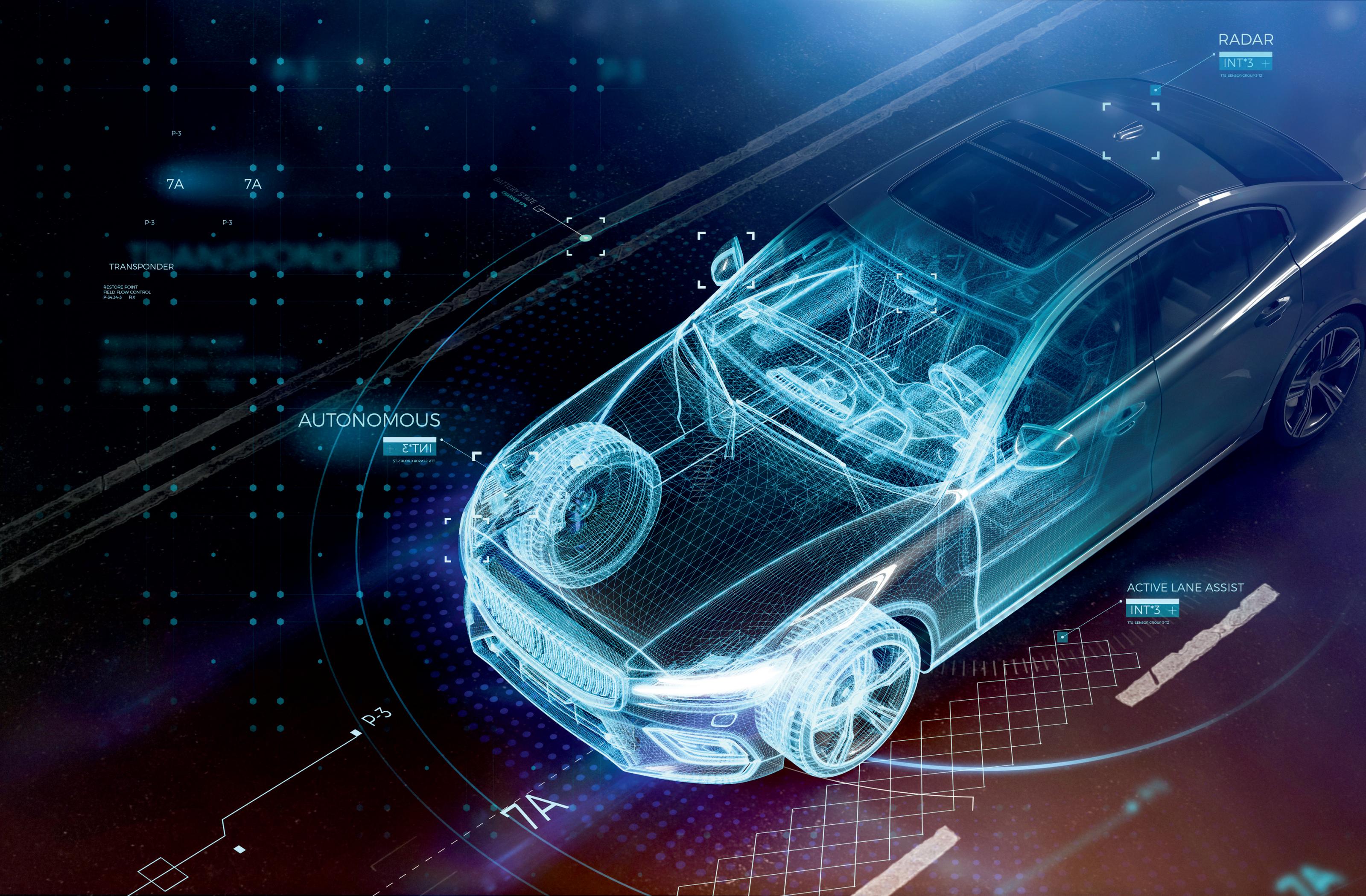

Inautomotivetechnology,augmentedreality(AR)hasemergedasa

transformativetoolinboththedesignandmaintenancephases.From conceptualizingnewvehiclemodelstoenhancingrepairandmaintenance tasks,ARisrevolutionizingtheautomotiveindustrybybridgingthegap betweenvirtualsimulationsandreal-worldapplications.

Intherealmofautomotivedesign,ARhasredefinedtraditionalworkflowsby offeringdesignersandengineersamoreimmersiveandcollaborativeplatform. Unlikevirtualreality(VR),whichcreatesentirelysimulatedenvironments,AR overlaysdigitalinformationontothephysicalworld,providingaseamless integrationofvirtualelementswithreal-worldcontexts.

ARallowsdesignerstovisualizeandinteractwith3Dmodelsofvehiclesin real-worldsettings.Thiscapabilityenablesstakeholderstogainamore accuratesenseofscale,proportion,andaestheticdetailsearlyinthedesign process.Byoverlayingdigitalprototypesontophysicalspaces,designerscan assesshowdifferentdesignelementsfitwithintheenvironment,facilitating better-informeddecisionsandreducingtheneedforcostlyphysicalprototypes.

Moreover,ARenhancescollaborationamongmultidisciplinaryteamsby enablingreal-timeannotations,virtualmeetings,andsharedexperiencesacross differentlocations.Designers,engineers,andstakeholderscancollectively reviewandrefinedesigns,speedinguptheiterationprocessandfostering innovation.

ARalsoplaysapivotalroleinvehiclecustomizationandpersonalization. CustomerscanuseAR-enabledapplicationstovisualizevariouscoloroptions, interiorconfigurations,andoptionalfeaturesoverlaidontoarealvehicleorin theirpreferredenvironment.Thisinteractiveexperienceempowerscustomers tomakeinformeddecisionsandenhancestheirengagementwiththe purchasingprocess,leadingtohighersatisfactionandreducedreturns.

Furthermore,automotivemanufacturerscanleverageARto showcasenewmodelsandfeaturesinvirtualshowroomsor duringpromotionalevents.Byofferingimmersive experiences,ARhelpsattractpotentialbuyersand differentiatebrandsinacompetitivemarket.

Beyonddesign,ARisrevolutionizingautomotive maintenanceandrepairprocessesbyprovidingtechnicians withadvancedtoolsandcapabilitiestostreamline operationsandimproveefficiency

AR-equippedsmartglassesortabletsallowtechniciansto overlaydiagnosticinformation,repairinstructions,and schematicsdirectlyontothevehicleorcomponenttheyare servicing.Thishands-freeapproachenablestechniciansto accesscriticaldatawithoutdisruptingworkflow,leadingto fasterdiagnosticsandmoreaccuraterepairs.

Forexample,ARcanhighlightspecificcomponentsthat requireattention,providestep-by-steprepairinstructions, andevenconnecttechnicianswithremoteexpertsforrealtimeguidance.Thisaugmentedsupportreducesthe likelihoodoferrors,minimizesdowntime,andenhances overallservicequality

ARalsoservesasavaluabletrainingtoolfornew techniciansandongoingskilldevelopmentforexperienced professionals.Bysimulatingcomplexrepairscenariosina controlledvirtualenvironment,ARhelpstechnicians familiarizethemselveswithequipment,procedures,and safetyprotocolsbeforeperformingtasksonactualvehicles.

Moreover,AR-basedtrainingmodulescanbeupdatedin realtimetoreflectthelatesttechnologiesandbestpractices, ensuringthattechniciansremainproficientandadaptablein anindustrycharacterizedbyrapidtechnological advancements.

Despiteitstransformativepotential,thewidespread adoptionofARinautomotivedesignandmaintenancefaces severalchallenges:

CostandInfrastructure:ImplementingARtechnologies requiressignificantupfrontinvestmentinhardware, software,andinfrastructureupgrades.Automotive manufacturersandserviceprovidersmustweighthesecosts againstpotentialbenefitsandROI.

IntegrationwithExistingSystems:IntegratingARsolutions withexistingITinfrastructureandsoftwareplatformscan becomplexandtime-consuming.Seamlessinteroperability isessentialtomaximizetheefficiencyandeffectivenessof ARapplications.

DataSecurityandPrivacy:AR-enableddevicescollectand transmitsensitivedataduringdesignandmaintenance operations.Ensuringrobustcybersecuritymeasuresand compliancewithdataprivacyregulationsareparamountto safeguardingcustomerinformationandintellectual property.

Lookingahead,thefutureofaugmentedrealityin automotivedesignandmaintenanceappearspromising:

AdvancementsinARHardware:Continuedadvancements inARglasses,headsets,andwearabledeviceswillenhance comfort,functionality,anddurabilityforautomotive professionals.

AIIntegration:CombiningARwithartificialintelligence (AI)algorithmswillenablepredictivemaintenance capabilities,real-timeperformancemonitoring,and autonomousdiagnostics.

ExpandedApplications:ARispoisedtoexpandbeyond designandmaintenanceintoareassuchasmanufacturing, customerservice,anddriverassistancesystems,further enhancingoperationalefficienciesanduserexperiences.

In conclusion, augmentedrealityrepresentsaparadigm shiftinhowautomotivemanufacturersandservice providersapproachdesign,maintenance,andcustomer engagement.ByleveragingARtechnologies,stakeholders canstreamlineworkflows,improvedecision-making processes,anddeliverinnovativesolutionsthatmeetthe evolvingdemandsoftheautomotiveindustry AsAR continuestoevolve,itstransformativeimpactwill undoubtedlyshapethefutureofautomotivedesignand maintenance,turningvirtualblueprintsintotangible realitiesontheroad.

Every car was once just a dream in somebody's head