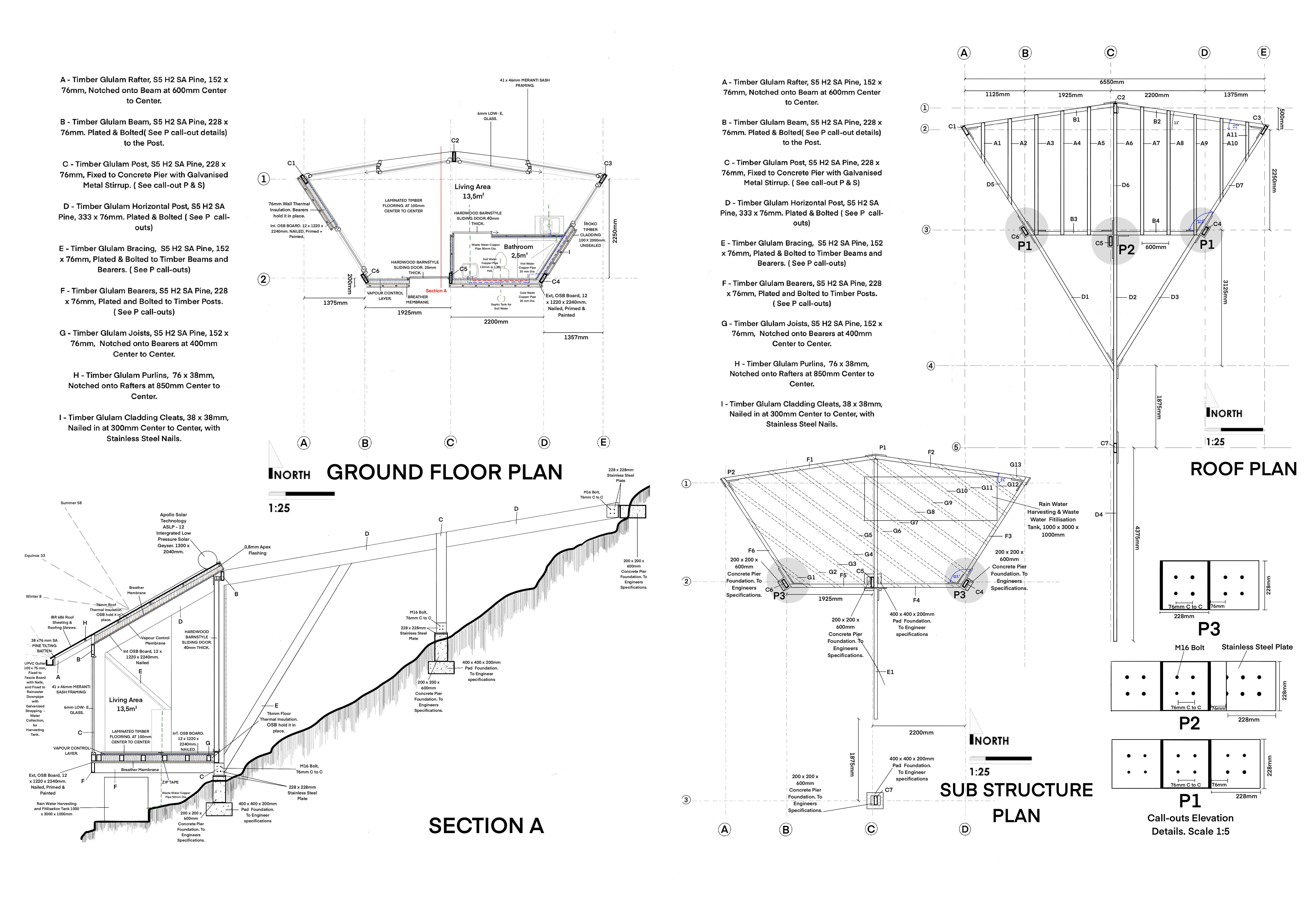

340mm RC slab to engineers specifications. 20mm soft

Backing Cord.

Tremco PU515 Polyurethane sealant with min 20mm throat.

230mm clay brick wall with brickforce every fourth course unless specified otherwise by engineer. Stack bond, interior and exterior plasted, primed and painted.

Cemflex and Cemflex Membrane

280mm Cavity brick Wall, Stack bond, exterior left facebrick, interior plasted and painted

80mm Expanded Polytherene Insulation.

280mm Cavity brick Wall, Stack bond, exterior left facebrick, interior plasted and painted. 50mm Expanded Polytherene Insulation. 10mm repurposed steel plate, bolted to the 20mm repurposed steel plate and customised blecha 100mm x 200mm Ibeam and embedded in mortar.

Concrete Foundation - to engineers specification.

Galvanised Steel Strapping as per engineers specifications. Hoop irons to engineers specification.

PU515 Polyurethane sealant with min 20mm throat. Polyethylene backing cord, applied to clean dry and sound substrate.

32mm Dia Repurposed Metal handrail. Plated to the wall with a 40mm Gap.

50mm

50mm laminated Iroko wood landing S5 H3. Screwed on 20mm Repurposed metal plate.

76mm laminated Iroko wood stair S5 H3. Screwed on 20mm Repurposed metal plate.

50mm Expanded Polytherene Insulation.

280mm Cavity brick Wall, Stack bond, exterior left facebrick, interior plasted and painted

10mm repurposed steel plate, bolted to the 20mm repurposed steel plate and customised blecha 100mm x 200mm I-beam and embedded in mortar.

@ layers of150mm.

280mm Cavity brick Wall, Stack bond, exterior left facebrick, interior plasted and painted

80mm Expanded Polytherene Insulation.

10mm repurposed steel plate, bolted to the 20mm repurposed steel plate and customised blecha 100mm x 200mm I-beam and embedded in mortar.

35mm Screed to 1:80 fall. 50mm Expanded Polytherene Insulation. 340mm RC slab to engineers specifications.

38mm Gap.

50mm laminated Iroko wood stair S5 H3. Screwed on 20mm Repurposed metal plate.

340mm RC slab to engineers specifications.

50mm concrete coping stone embedded in mortar. 0,4mm x 3m Charcoal suparoof counter flashing.

280mm Cavity brick Wall, Stack bond, exterior left facebrick, interior plasted and painted Tremco PU515 Polyurethane sealant with min 20mm throat. Polyethylene backing cord, applied to clean dry and sound substrate. 20mm soft board or jointex joint former.

Horizontal 375um DPC embedded in mortar. Drip min 20mm away from wall face.

Vertical 375um DPM embedded in mortar.

Shelf angle 120 x120 x10mm type 1 in flush with slab edge, galvanised finish, to struct eng detail

50mm Expanded Polytherene Insulation.

Derbigum SP4 soaker flange

340mm RC slab to engineers specifications.

Customised Blecha 100mm repurposed metal tread, welded to the Blecha 200x 100mm repurposed IBeam.

Horizontal 375um DPC embedded in mortar. Drip min 20mm away from wall face.

280mm Cavity brick Wall, Stack bond, exterior left facebrick, interior plasted and painted

Customised Blecha 100mm repurposed metal tread, welded to the Blecha 200x 100mm repurposed IBeam.

200mm x 100mm Customised Blecha I- Beam

35mm Screed. 75mm Concrete Surface Bed @ 28 days. 80mm Expanded Polytherene Insulation.

50mm Sand Binding Layer. Compact Fill - Graded and Piosened @ layers of150mm.

Concrete Foundation and repurposed metal post - to engineers specification.

35mm Screed. 75mm Concrete Surface Bed @ 28 days. 80mm Expanded Polytherene Insulation.

50mm Sand Binding Layer. Compact Fill - Graded and Piosened @ layers of150mm.

50mm laminated Iroko wood stair S5 H3. Screwed on 20mm Repurposed metal plate.

200mm x 100mm Customised Blecha I- Beam mounted to 200 x 100 customised eye beam, and welded to the 20mm repurposed metal plate.