| contents | news | events | advertisers | website | e-newsletter |

Rapid alloy qualification for AM

Rapid qualification of new alloys for Additive Manufacturing through a holistic process chain The limited number of alloys currently commercially available for metal Additive Manufacturing is regarded as a key factor hindering the growth of the industry. In this article, Rosswag GmbH’s Daniel Beckers reports on a high-speed qualification process that the company has developed for new alloys, and that spans the complete AM process chain – from alloy atomisation to L-PBF process parameters, heat-treatment and mechanical testing.

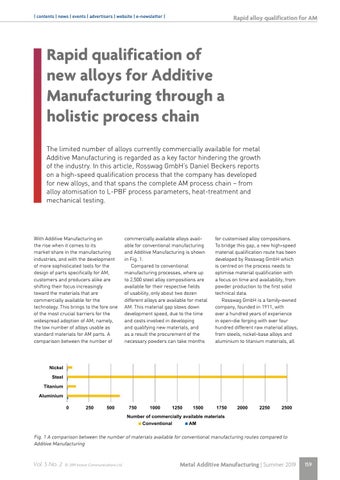

With Additive Manufacturing on the rise when it comes to its market share in the manufacturing industries, and with the development of more sophisticated tools for the design of parts specifically for AM, customers and producers alike are shifting their focus increasingly toward the materials that are commercially available for the technology. This brings to the fore one of the most crucial barriers for the widespread adoption of AM; namely, the low number of alloys usable as standard materials for AM parts. A comparison between the number of

commercially available alloys available for conventional manufacturing and Additive Manufacturing is shown in Fig. 1. Compared to conventional manufacturing processes, where up to 2,500 steel alloy compositions are available for their respective fields of usability, only about two dozen different alloys are available for metal AM. This material gap slows down development speed, due to the time and costs involved in developing and qualifying new materials, and as a result the procurement of the necessary powders can take months

for customised alloy compositions. To bridge this gap, a new high-speed material qualification route has been developed by Rosswag GmbH which is centred on the process needs to optimise material qualification with a focus on time and availability, from powder production to the first solid technical data. Rosswag GmbH is a family-owned company, founded in 1911, with over a hundred years of experience in open-die forging with over four hundred different raw material alloys, from steels, nickel-base alloys and aluminium to titanium materials, all

Nickel Steel Titanium Aluminium 0

250

500

750

1000

1250

1500

1750

2000

2250

2500

Number of commercially available materials Conventional AM

Fig. 1 A comparison between the number of materials available for conventional manufacturing routes compared to Additive Manufacturing

Vol. 5 No. 2 Š 2019 Inovar Communications Ltd

Metal Additive Manufacturing | Summer 2019

159