2 minute read

A swarm of 3D printing drones for construction and repair

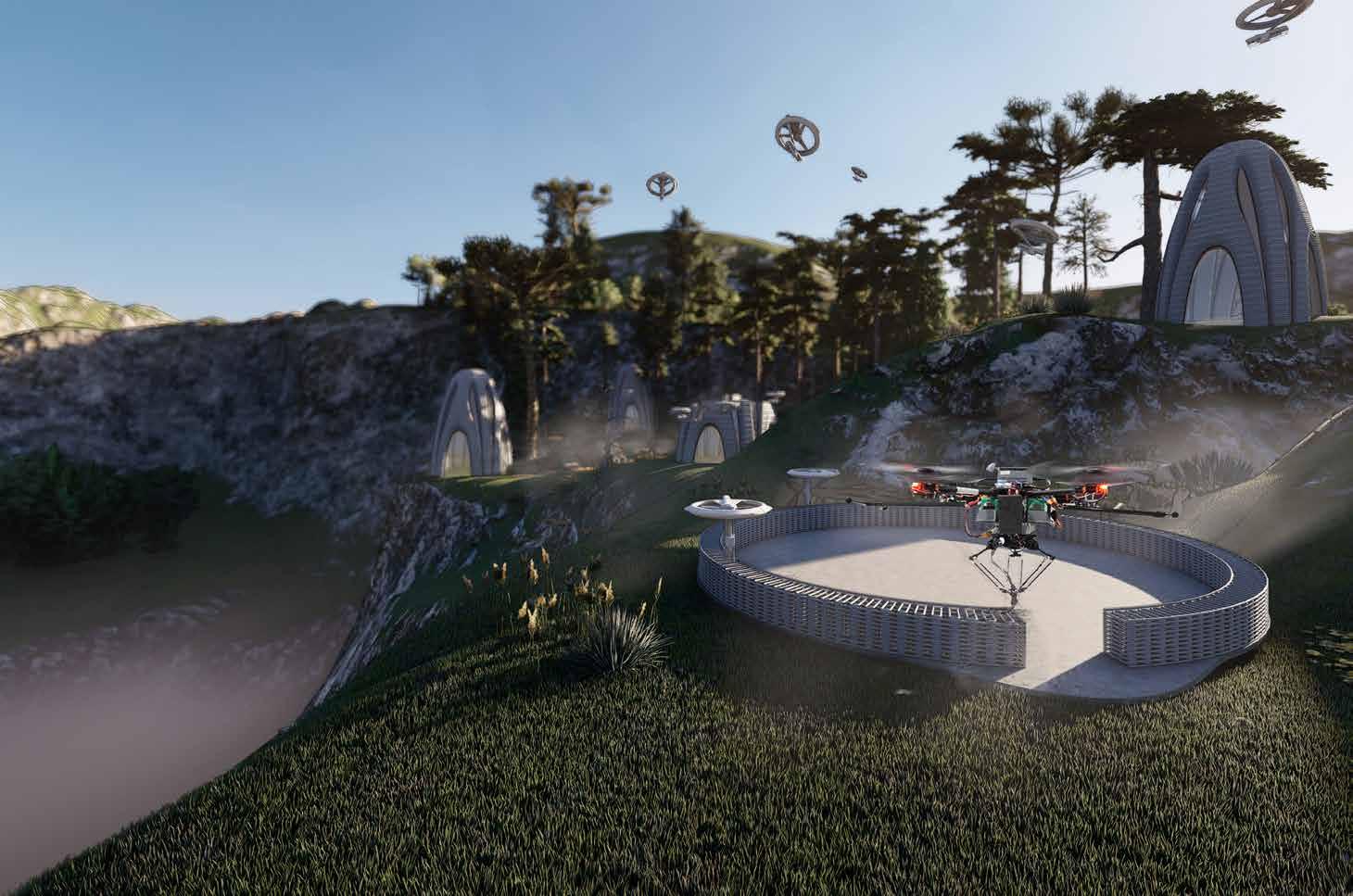

Swarms of drones could also be used in space, for example on a future Mars mission. Image: Yusuf Furkan KAYA, Aerial Robotics Laboratory, Imperial College London/Empa

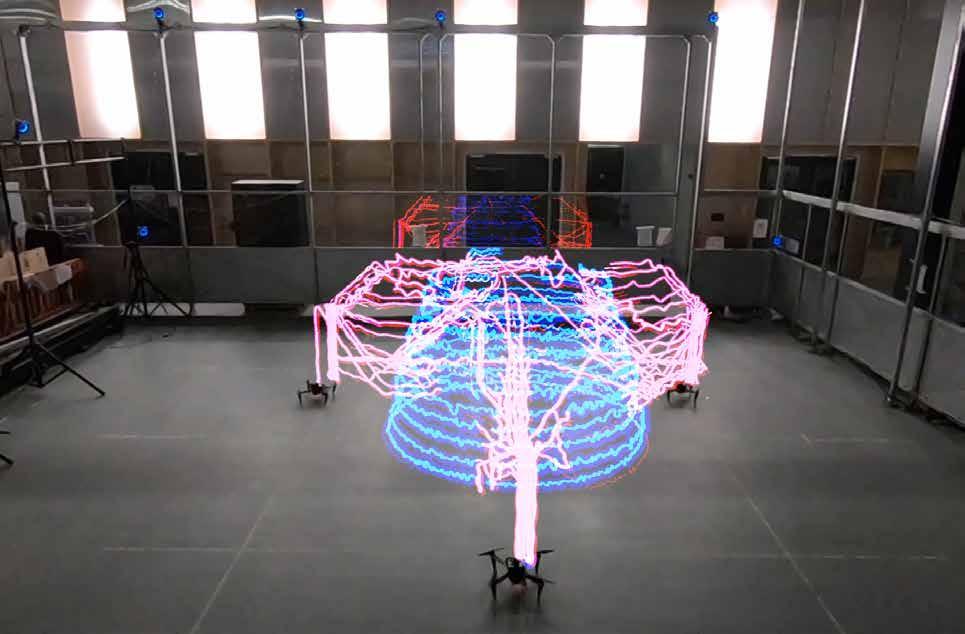

During tests with a scaled up building session, the team virtually tracked the drone's patht to show how a large group could efficiency print large structures

Advertisement

An international research team led the Swiss Federal Laboratories of Materials Science and Technology Empa and Imperial College London has taken bees as a model to develop a swarm of cooperative, 3D-printing drones. Under human control, these flying robots work as a team to print 3D materials for building or repairing structures while flying.

The system, called Aerial Additive Manufacturing (Aerial-AM), involves a fleet of drones working together from a single blueprint. It consists of so-called BuilDrones, which deposit materials during flight, and quality-controlling ScanDrones, which continually measure the BuilDrones’ output and inform their next manufacturing steps. The researchers say that in-flight 3D printing unlocks doors that will lead to on-site manufacturing and building in difficult-to-access or dangerous locations such as post-disaster relief construction and tall buildings or difficult to reach infrastructure. Aerial-AM uses both a 3D printing and path-planning framework so the drones can adapt to variations in geometry of the structure as a build progresses.

A BuilDrone and a ScanDrone built this approximately two-meter-high ‘tower’ of fast-curing foam - layer by layer (image: University College London)

The drones are fully autonomous in flight, but there is a human controller in the loop can monitor progress and intervene if necessary, based on the information provided by the drones. To test the concept, the researchers developed four cement-like mixtures for the drones to build with.

Throughout the build, the drones assess the printed geometry in real time and adapt their behaviour to ensure they meet the build specifications, with manufacturing accuracy of five millimetres. The proof-of-concept prints included a 2.05-metre cylinder (72 layers) with a polyurethane-based foam material, and an 18-centimetre cylinder (28 layers) with a custom designed structural cement–like material.

According to Empa, this technology mainly opens up possibilities for building and repairing structures in hard-to-reach locations. The researchers now want to work with construction companies to validate the principle and expand repair and manufacturing capabilities. They expect the technology to deliver significant cost savings and reduce risks compared to conventional methods.

More at EMPA>

Video