15 minute read

Bacteriophages extract raw materials from fluorescent lamps

Rare earths are important materials in complex electronics. Seventeen different metals such as lanthanum, cerium, europium and terbium that are essential components of smartphones, flat screens, wind turbines and compact fluorescent lamps. China is the world market leader for the supply of rare earths, covering 86 percent of global demand and even 98 percent of Europe's demand. To reduce this dependence and protect the environment, innovative recycling technologies are needed. Researchers at the Helmholtz Institute Freiberg for Resource Technology (HIF) of the Helmholtz Center Dresden-Rossendorf (HZDR) have developed a process that allows them to extract rare earth metals from fluorescent lamps. The trick: bacteriophages: viruses that primarily infect bacteria. Waste electronic products contain a variety of valuable elements in very low concentrations. These include compact fluorescent lamps, which are currently

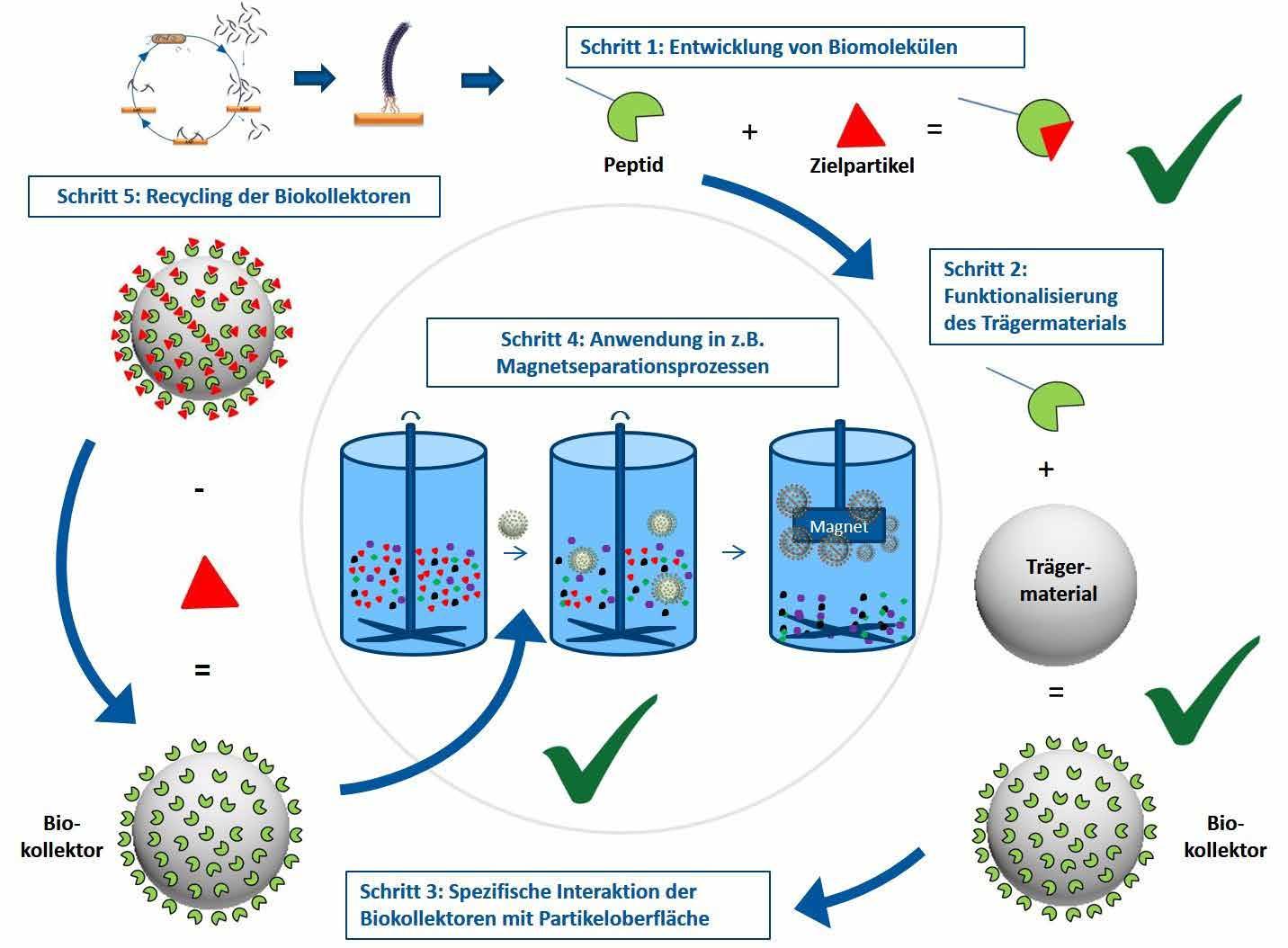

Using phage technology, the appropriate element-specific biomolecule is selected from bacteriophages containing one billion different biomolecules. This biomolecule is then produced biotechnologically and anchored on a spherical magnetic carrier material. This creates biocollectors that can recognize and bind their target element in a targeted manner (Image: Dr Franziska Lederer)

Advertisement

The vial contains magnetite particles functionalized with rare earth binding biomolecules. The magnet on the right attracts the particles (Image: HZDR/Detlev Müller)

collected separately from other electronic waste because the mercury-containing powder from the lamp has to be stored in special storage facilities. This powder contains barium magnesium aluminate, cerium magnesium aluminate, lanthanum phosphide, halophosphate and yttrium phosphide. By 2020, 25,000 tons of fluorescent powder had accumulated in the EU, of which 750 tons were rare earth metals. A share of 4,200 tons is assumed for other electronic end-oflife products. Therefore, HIF researchers have taken the lamp powder as a basis to demonstrate that it is possible and economically feasible to recover the elements contained in it. For recovery, they use a magnetic separation technique based on biocollectors: so-called 'Phage Surface Displays' (PSD).

The PSD method is based on bacteriophages. These are viruses that specialize in infecting bacteria. Using PSD technology, the correct element-specific biomolecule is selected from bacteriophages with a billion different biomolecules. This biomolecule is then anchored to a spherical, magnetic support material. This creates biocollectors that can recognize and bind their target element - a rare earth metal - in a specific manner. Depending on the target material, the biocollectors can be loaded with a different type of biomolecule and used to selectively recover a different metal. The researchers at HZDR subsequently saw the opportunity to use this technique for an applicable process, with which in the future rare earth metals can be effectively recovered with PSD bioreactors.

More at HZDR (German)>

For designers and architects, materials and constructive techniques play an essential role. Decisions have to be made and those decisions are often very complicated; especially when it comes to environmental impact. Wood, for instance, is a material with an excellent CO2 footprint and outstanding constructural properties, while on the other hand, the use of wood is often associated with deforestation, which not only destroys ecosystems and habitats, but also causes climate changes. A logical question then is: is the use of wood in architecture actually sustainable? Something different. The production of brick requires a relatively large amount of energy, which results in a serious CO2 footprint. On the other hand, bricks last for generations and are often made from a renewable raw material, namely river clay. Don’t the advantages outweigh the disadvantages?

Last September, the archdaily.com published an extremely complete overview online, titled ‘Best Practices for Materials and Constructive Techniques’. Not only the advantages and disadvantages of many construction materials and techniques are discussed, but also suggestions and tips are given to make best constructive and ecological choices as responsible as possible.

(Photo: Koninklijke Nederlandse Bouwkeramiek (KNB))

Read the entire article at archidaily. com>

Improving cement with shrimps

By adding nanoparticles from shrimp shells to cement paste, the material becomes considerably stronger. This could lead to less fishing waste and lower carbon emissions from concrete production. A typical win-win situation. The production of concrete causes a large amont of CO2 emissions worldwide. The stronger the concrete, the less of the material has to be used, the less CO2 it produces. On the other hand: seafood waste is a significant problem for the fishing industry. Most of this waste is dumped into the sea. A team of Washington State University and Pacific Northwest National Laboratory researchers created nanocrystals and nanofibers of chitin, the second most abundant biopolymer in nature, from waste shrimp shells. When these tiny bits of chitin, were added to cement paste, the resulting material was up to 40% stronger. In their work, the WSU team studied the chitin materials at the nanoscale. Crab, shrimp and lobster shells are made up of about 20 - 30 % chitin with much of the rest being calcium carbonate, another useful additive for cement. Compared to cellulose, chitin at the molecular scale happens to have an additional set of atoms - a functional carboxyl group - that allows the researchers to control the charge on the surface of the molecules and, consequently, how they behave in the cement slurry. The success in strengthening the cement paste came down to how the particles suspend themselves within the cement slurry and how they interact with the cement particles. As they added the processed nanocrystals of chitin to the cement, they were able to improve and target its properties, including its consistency, the setting time, strength and durability. They saw a 40 % increase in bend strength and a 12 % improvement in the ability to compress it. The researchers are now hoping to scale up the work to begin producing the additive at large scales.

Somayeh Nassiri and Li Hui measure properties of cement formulas that contain nanoparticles of chitin (Photo: Washington State University)

The article ‘Insights into setting time, rheological and mechanical properties of chitin nanocrystals- and chitin nanofibers-cement’ paste was published last September in Cement and Concrete Composites. It is online>

More at Washington State University>

The website of innovative materials has been renewed! Look at www.innovativematerials.nl or click this banner.

Electricity from your kitchen countertop

What if you could power the smart thermostats, speakers and lights in your home with a kitchen countertop? Stones, such as marble and granite, are natural, eco-friendly materials that many people building or renovating houses already use. Now, in a step toward integrating energy storage with these materials, researchers of the Korean Kookmin University have fabricated microsupercapacitors onto the surface of stone tiles. The devices, reported in ACS Nano, are durable and easily scaled up for customizable 3D power supplies.

Stones, even those that are polished and seem smooth, have microscopic bumps and divots, making it difficult to adhere electrical components to them. Researchers have recently figured out how to place microsupercapacitors, which have fast charging and discharging rates and excellent power supply storage, onto irregular surfaces with lasers.

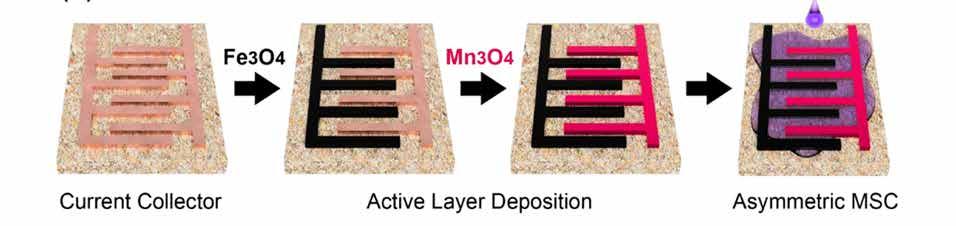

The researchers patterned a copper oxide nanoparticle solution on a marble tile into two comb-like sides whose prongs were interspersed. They pointed a near-infrared laser on the nanoparticles, producing pure copper electrodes that were porous, highly conductive and strongly attached to the stone’s surface. To form the microsupercapacitor, the

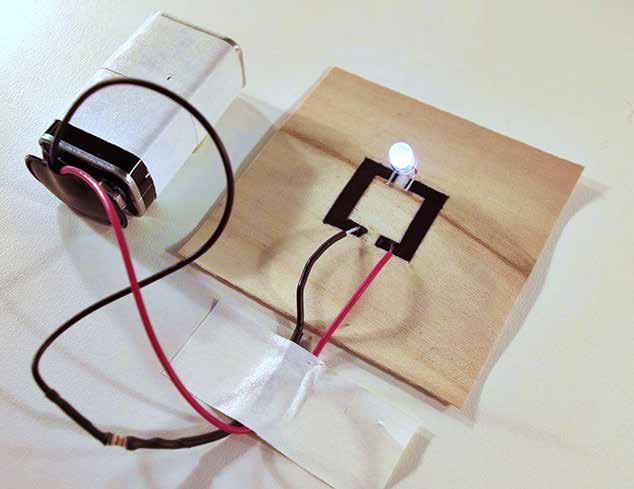

Interconnected microenergy devices built on marble tiles create customizable 3D power supply systems

researchers deposited iron oxide onto one of the electrodes to form a cathode, and manganese oxide on the other to form an anode. The electrolyte layer connecting the electrodes was made from a lithium perchlorate and polymer solution. In tests, the device maintained a high energy storage capacity even after 4,000 charge-discharge cycles. When multiple microenergy devices were strung together in a three-by-three array, enough energy was stored to light an LED. In addition, the stone energy storage devices were exceptionally durable against harsh impacts. The researchers say that stone microenergy devices could provide high-performance, customizable and conveniently accessible power from natural building materials.

This work was done by Seunghyun Back, Jung Hwan Park, and Bongchul Kang, School of Mechanical Engineering, Kookmin University, Seoul, Republic of Korea. The article ‘Microsupercapacitive Stone Module for Natural Energy Storage’ was published last summer in ACS Nano.

The researchers patterned a copper oxide nanoparticle solution on a marble tile into two comb-like sides whose prongs were interspersed More at ACS>

Invisible coating protects wood from fire

An invisible coating that can make wood ‘fireproof’ has been invented by scientists at NTU Singapore. With the popularity of engineered timber growing in the construction industry, one of the biggest challenges for wood is its flammability. When untreated, wood or timber can burn and combust easily. However, current practices to protect the interior of wooden buildings from fires require the use of fire-retardant panels or paint-like coatings that conceals the natural wood grains of timber. In comparison, the new invisible coating developed by NTU allows for natural beauty of timber to shine and yet can still provide a flame barrier when ‘activated’ by fire. It is low-cost, easy to apply, effective in kerbing the spread of fire and generates very little smoke when burnt.

Invented by a team led by Associate Professor Aravind Dasari from the NTU School of Materials Science and Engineering, this fireproof coating is just 0.075 millimetres thick and is highly transparent, making it invisible to the naked eye. When heated up by a hot flame, a series of complex chemical reactions happens, causing the coating to become a char that expands to more than 30 times its original thickness. This char prevents the

fire from combusting the wood underneath (see video). According to NTU, this new coating is expected to be in high demand by the construction industry, as timber buildings need to meet specific fire codes for buildings set by regulators. There are only a few products which can provide both transparency and fire retardance that are available in the market. According to NTU, products which claim to have both properties currently are either extremely prohibitive in cost or are unable to pass international standards required for industry use.

More at NTU Singapore>

Video

Recently, the Karlsruhe Institute of Technology (KIT) published a study on the importance of wood for urban construction. And remarkably, they concluded that more colour may be the key to greater acceptance of wood. The study, 'Farbige Holzfassaden im urbanen Kontext' (coloured wooden facades in urban contexts), was carried out by KIT's Institute for Building Design and Technology and commissioned and funded by Munich-based project developer Bauwerk. The research focused on Vinzent, a project by Allmann Sattler Wappner Architects. It is a new and innovative residential and office building with colourful wooden facades in the Neuhausen district of Munich. The research identifies trends that are currently determining the growing interest in urban timber construction: the favourable carbon and energy footprint, recyclability, low emissions and relatively good availability. Furthermore, much progress has been made in the field of drawing (CAD) and production (CNC) processes and wood is also excellent for prefab. In the meantime, persistent prejudices appear to have been refuted both in practice and by scientific research, especially in the field of fire protection, maintenance and lifespan. The Vinzent project would also show that the use of colour can be an important factor for further acceptance of wood in urban construction and the integration of wooden structures in urban areas.

The report can be downloaded HERE>

New funding for sustainable concrete substitute

More at the t Worcester Polytechnic Institute>

www.nsf.gov

Worcester Polytechnic Institute (WPI) researchers Nima Rahbar and Suzanne Scarlata have received $692,386 from the National Science Foundation (NSF) to further develop their Enzymatic Construction Material (ECM), a ‘living’, lowcost construction material with negative CO2 emissions. They developed the material as an alternative to concrete, which is responsible for serious greenhouse gas emissions worldwide. According to the scientists, the new material has properties that can compete with those of concrete.

ECM is made by an enzymatic process involving carbonic anhydrase, an enzyme that converts carbon dioxide and water into hydrogen carbonate. This reaction produces calcium carbonate crystals, which are the main component of ECM. A sand slurry is also added, along with a polymer, which initially holds the ECM together. In addition, this process ‘outstanding’ compression strength, rivaling traditional mortar, making it strong enough to be used in the construction of buildings as compressive elements. It also does not require baking at high temperatures like a traditional brick does, and it can be made quickly, unlike the 28 days needed to cure concrete. This new NSF funding will help the team improve the processes that will allow for EMC to move more swiftly from the lab to construction sites. Working with WPI’s Office of Technology Commercialization, Scarlata and Rahbar created Enzymatic, Inc., a start-up company launched to realize commercial opportunities for ECM and an earlier product - a self-healing concrete - they developed in their initial collaboration.

allows ECM to repair itself and repair cracks or other imperfections. Through extensive testing and experimentation, the research team found that ECM has

Graphene turns waste into gold

Throughout history, alchemists believed in the existence of the philosopher’s stone: a substance that could turn cheap substances into precious gold. Now scientists from The University of Manchester, Tsinghua University in China and the Chinese Academy of Sciences have shown that graphene can be a kind of philosopher’s stone, allowing gold extraction from waste containing only trace amounts of gold (down to billionth of a percent).

This new application of graphene works quite straightforwardly: add graphene into a solution containing traces of gold and, after a few minutes, pure gold appears on graphene sheets, with no other chemicals or energy input involved. After this you can extract your pure gold by simply burning the graphene off. The research shows that 1 gram of graphene can be sufficient for extracting nearly 2 grams of gold. As graphene costs less than $0.1 per gram, this can be very profitable, with gold priced at around $70 per gram.

Gold is used in many industries including consumer electronics (mobile phones, laptops etc.) and, when the products are eventually discarded, little of the electronic waste is recycled. The graphene-based process with its high extraction capacity and high selectivity can reclaim close to 100% of gold from electronic waste.

More at Universiteit van Manchester>

The article ‘Highly efficient and selective extraction of gold by reduced graphene oxide’ was published in Nature Communications. It's online>

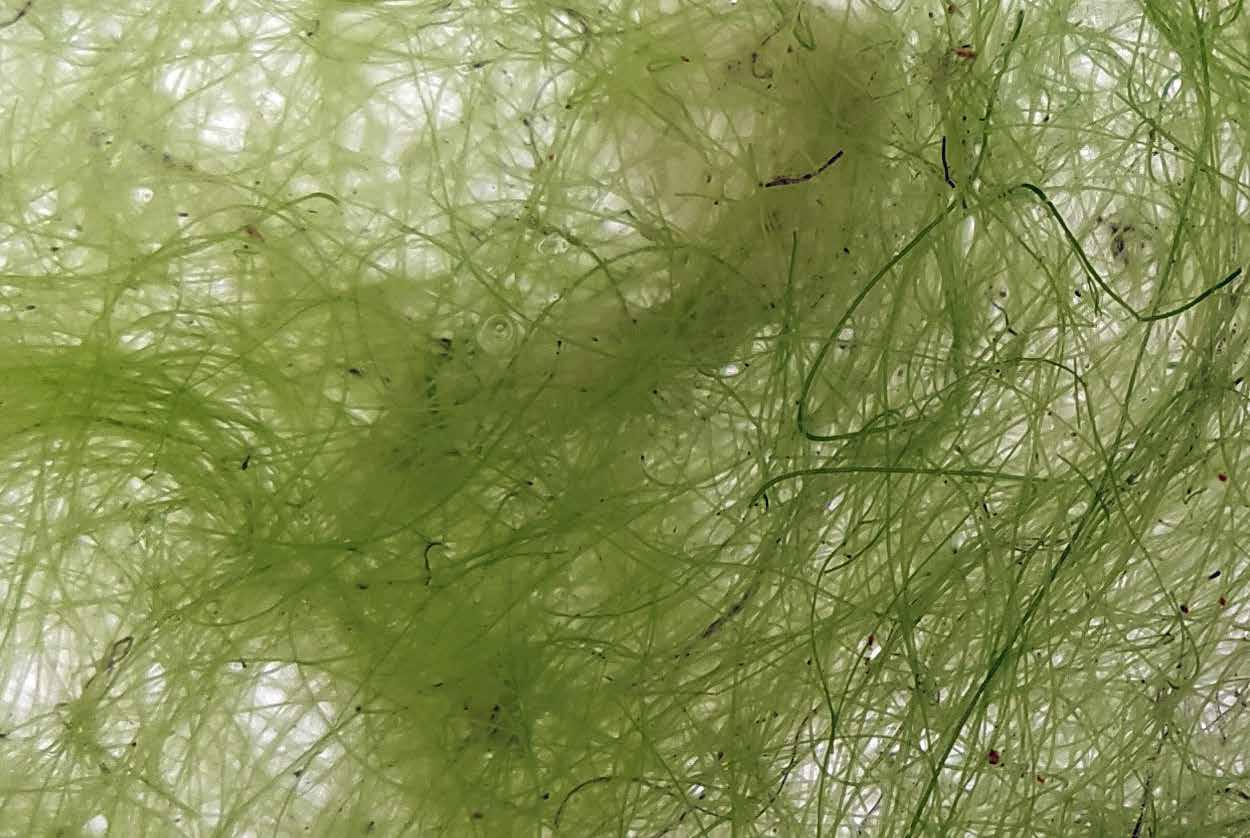

Algae bioplastics: the global state of the industry

Algae began attracting attention as a biofuel in the 1970s. While the sector grew rapidly in the 2000s, its gains were largely wiped out by the 2008 financial crash. Since then, investors have turned to other high-value chemical derivatives. Among them were bioplastics. For example, algae are nowadays seen as an environmentally friendly bio-raw material for many packaging and consumer applications. But to what extent has the industry actually picked up on those opportunities? Bio Market Insights inventoried the state of affairs on various continents.

Read the entire article at Bio Market Insights>

Green electronics made from wood

Non-biodegradable electronic waste continues to accumulate year after year. Wouldn't it therefore be useful to make electronic components from a natural, renewable raw material? Wood for instance. But it’s easier said than done. For one thing, wood is naturally an electrical insulator. It also has a complex structure, making it a challenge to achieve homogeneous electrical properties during large-scale fabrication. Now, a research team at Empa and at ETH’s Institute for Building Materials has developed a practical and versatile method for making wooden surfaces electrically conductive by graphitising them. In this way, devices such as touch panels and sensors can be produced on a large scale with great efficiency. The trick is to pretreat the wood with an ink containing iron. The project, led by Ingo Burgert and Guido Panzarasa, was supported by the Swiss National Science Foundation.

To make conductive structures on wood, the new method improves an existing process called laser-induced graphitization. A laser can engrave fine lines into wooden boards, or veneers. In this process, the energy of the laser beam heats the wood, causing a series of pyrolytic events leading to the formation of electrically conductive graphite. However, the obtained conductive patterns are irregular in depth and width, and there is also a fire hazard due to overheating. Often, multiple post-processing laser steps are needed as well. The density of wood varies depending on the tree species and growth, so the result can be very uneven graphitization.

The research team thus came up with the idea of using iron as a catalyst to enable a gentler process and a much more homogeneous surface. Searching for a biologically based catalyst material they chose an iron-gall ink, a mixture of iron salt and tannins used as early as the Middle Ages for writing. After optimizing the recipe, they coated a variety of wood veneers with a thin layer of the ink and then subjected them to the laser treatment. The ink layer showed the desired effect. The patterns engraved after just one pass showed a more uniform structure and conductivity, regardless of differences in the wood structure and type. The patterns are only a few micrometers deep and can thus be engraved into the thinnest veneer without actually damaging it.

The team then used their new method to produce trial electronic components from spruce, cherry and beech veneers less than half a millimeter thick. According to the researchers, bendable strain sensors could be integrated discreetly into load-bearing wood components in buildings, allowing for constant monitoring of their structural health. They were also able to make the wafer-thin wood glow by means of an electroluminescent layer; a phenomenon that could be used in applications such as backlighting for displays or for advertisements and control panels. For the electroluminescent wood, the researchers used still conventional wiring and electronic components, however. In the future, these could also be partially replaced by conductive wood. The next step is to refine and further develop the method for large-scale use.