Government trims industry, promises

The Federal Budget of 25 October has reduced overall funding to the industry portfolio by $293 million over four years, including by $101 million in 2023-24. The government says more funding will be provided under its new National Reconstruction Fund.

In July this year, Industry Update called for the new gov ernment to guarantee no net cuts to the industry portfolio and we urge the government to re-establish and increase industry funding in the next budget update.

Budget savings include cancelling uncommitted funding under the former government’s Modern Manufacturing Strategy and Entrepreneurs’ Program, cuts worth around $500 million. However, existing commitments to busi nesses have been honoured.

By Margie Smithurst

By Margie Smithurst

Treotham’s new 3000-square-me tre Macquarie Park warehouse is a far cry from the humble begin nings where Mikael Paltoft started his business 30 years ago.

Back then, Swedish-born Paltoft saw an opportunity in the relatively new industrial automation market in Australia, and began by selling energy chains and accessories from his home garage in Sydney.

“There were no cuts to any project already funded or announced as part of the Modern Manufacturing Initiative,” said a spokesperson for Industry Minister Ed Husic. Continues on page 20 Continues on page 26

Designed to support operational requirements and tra ic management needs.

From Health & Safety notices to directing tra ic, the sign cap supports your factory flow and processes. Using universally-recognised signage, it is positioned at the optimum height to be visible to both moving tra ic and pedestrians.

The fully-customisable product seamlessly integrates into the A-SAFE product range, providing you with a comprehensive Health & Safety solution.

Bollard

Bollard

Designed to support operational requirements and tra ic management needs.

the highest levels of protection to pedestrians, assets and infrastructure The range includes a full suite of high-performance safety products for applications within very low-temperature environments.

have been purpose-designed for use in frozen food storage facilities and other challenging sub zero environments.

Designed to support operational

From Health & Safety notices to directing tra ic, the sign cap supports your factory flow and processes. Using universally-recognised signage, it is positioned at the optimum height to be visible to both moving tra ic and pedestrians.

The fully-customisable product seamlessly integrates into the A-SAFE product range, providing you with a comprehensive Health & Safety solution.

Using universally-recognised signage, it is positioned at the optimum height to be visible to The fully-customisable product seamlessly integrates with a comprehensive Health & Safety solution. providing you

www.greasemax.au

Industry Update Media Pty Ltd ABN 25 083 502 783 Suite 403, Level 4, 116-118 Christie Street, St. Leonards NSW 2065 +61 2 9439 1288 / sales@industryupdate.com.au

Circulation 17,754 Readership 71,016 as at September 2022

All material in this publication is copyright to the publisher and/or its contributors. No material may be reproduced in part or in whole without the written consent from the Publisher. It is a condition of purchase or acceptance of this magazine that the Publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission on this publication or from the use of the information in this publication or from the use of the information and illustrations contained herein and the Publisher makes no warranties, express or implied, with respect to any of the material contained herein. © Copyright Industry Update Media Pty Ltd 2022

Publisher SCOTT FILBY scott@industryupdate.com.au

Editor CHRISTINE POWIS editor@industryupdate.com.au

Writer MARGIE SMITHURST writer@industryupdate.com.au

Universities & Collaboration Editor DAVID SLIGAR unieditor@industryupdate.com.au

Sub Editor WILLIAM POOLE subeditor@industryupdate.com.au

Advertising Sales Director SCOTT FILBY scott@industryupdate.com.au

Marketing Manager DUMI UDESHIKA marketing@industryupdate.com.au

Creative Director EDWIN KWONG production@industryupdate.com.au

Production Manager DUMI UDESHIKA copy@industryupdate.com.au

Video Editor & Producer CHARLIE LOUGHLIN video@industryupdate.com.au

Office Manager NICOLE CHARLES nicole@industryupdate.com.au

Finance & Accounts MICHELLE ALCOCK michelle@industryupdate.com.au

Consultant TRACY FILBY tracy@industryupdate.com.au

Accounts Receivable LYN SLIGAR lyn@industryupdate.com.au

Subscription Assistant SAM HICKS info@industryupdate.com.au

Sales Assistant RUBEN PANDEY salesassist@industryupdate.com.au

Circulation Assistant TAYLOR PARSONS circ@industryupdate.com.au

Printer

Editor Christine Powis

Editor Christine Powis

Remember our blessings this Christmas. In the Western tra dition, Christmas has long been a time of joy and celebration. But this year should be particularly special. After two long years we’ve finally seen the back of the pandemic.

Australian businesses and Australians across all walks of life worked together to defeat the spread of the disease while keeping the econ omy running. Average Australians showed their basic decency, taking sensible precautions and looking out for each other.

Governments across all states and territories also worked together – not always perfectly, but better than in many other countries.

Aussie manufacturing not only sur vived; it thrived. The fiscal years 202021 and 2021-2022 marked the first back-to-back years of annual growth in manufacturing by value in 14 years.

Manufacturing has turned a corner – not just in output but in the national consciousness. The pan demic made clear to everyone just how much is riding on the shoulders of manufacturers.

The onus is now on the Albanese Government to deliver manufacturing

policy settings that are as capable and resourceful as our manufacturers themselves.

At Industry Update, we believe the best of Australian industry is yet to come. The industry of the future will look very different to the industry of the past. It is increasingly high tech, and increasingly research-driven. This year saw Industry Update launch a ‘Universities, research and collabo ration’ section to reflect and promote that transformation.

The year also saw a change in federal government. We thank the Morrison government and wish the new one the best. More needs to be done for manu facturing, whoever is in power.

While the budget’s $293 million cuts to industry are disappointing, we sincerely hope the government delivers on its big promises, including the $15 billion National Reconstruction Fund.

At Christmas, let’s also think of the less fortunate.

Most of the world isn’t as lucky as we are in Australia. This Christmas let’s be grateful for all that we have and pray for those in need. Today in the town of David a Saviour has been born to you; he is the Messiah, the Lord.

Luke 2:11

The importance of tech for manu facturing is becoming more and more apparent with every issue of Industry Update

BOC gas and engineering has opened its second smart welding and gas tech hub, this time in south-west Sydney. And, backed by a Defence Department grant, SoftIron has opened a manufacturing hub to pro duce Information, Communications and Telecommunications compo nents for its cloud-building technol ogy. Making the ICT componentry in Australia will protect UK-based SoftIron’s customers from disrup tion to their supply chains and boost our manufacturing sovereignty (see story p 12).

While we’re on the cloud, RMIT in Melbourne is using Amazon Web Services’ Cloud Supercomputing and AARNet to host a supercomput ing capability engineered for up to 400 Gbps. Called RACE, it’s already being used by industry and RMIT researchers to create new battery technologies, photonic microchips and medical devices among other things (see story page 14).

Robotics are at the fore, too. Queensland’s Advanced Robotics for

Manufacturing Hub has partnered with a venture capital firm to find backers for emerging technologies and advanced manufacturers to help them enter the US marketplace.

Uni of NSW has been busy perfect ing its R&D spin-offs: the latest from this leader in solar cells is success fully using copper rather than silver on cells and it’s now being commer cialised by SunDrive (see story page 27).

East-coast steelmaker, recycler and services firm InfraBuild says it’s slow to come to the robotics party but, with much R&D from the Australian Cobotics Centre (ACC), their teams have created a cobot to remove ‘off-spec’ steel items from the production line and get its staff onto less monotonous, less risky work (see story page 24).

The moral of several stories is that employees should not fear tech. As ACC Director, Jonathan Roberts says, that old conversation about tech taking jobs has been “flipped around because many businesses can’t find enough people for jobs so we need to use new technologies to keep compa nies competitive and running.”

For the first time the Workplace Health & Safety (WHS) Show will be held in Brisbane from 31 May to 1 June 2023 at the Brisbane Convention and Exhibition Centre. There has never been a better time to take the show to Queensland.

Applications to exhibit at the Brisbane show are now open for every one wanting to reach a new audience of industry professionals eager to learn about the latest in health and safety.

Prospective exhibitors at the twoday event will capitalise on regional opportunities that have opened up following news of the location for the Brisbane 2032 Summer Olympics (23 July-8 Aug). Research by KPMG esti mates the 2032 Olympics will deliver $8.1 billion in economic benefits to Queensland’s economy and create 91,600 jobs in the next 20 years.

As Queensland Premier Annastacia Palaszczuk says: “Hosting the 2032 Olympic and Paralympic Games was never about a few weeks of competition, it’s about the next decade of investment and development for the games.”

Show organiser, IEC Group, antic ipates a huge boost in construction and development in the region, with

many significant infrastructure proj ects already underway. These projects cast a spotlight on the increased need for workplace health and safety standards in these labour-intensive sectors and ensuring that the mea sures taken in preparation will reflect well on the global stage.

With a significant spike in new employment opportunities comes the need to boost skills and business readi ness to ensure that the local workforce is able to meet this demand.

These skills include a crucial understanding of new safety tech niques and technologies in the work place which are the foundation of the WHS Show, and the huge appetite of companies in Queensland, which ain to ensure their readiness in these fields, is significant.

As Australia’s only dedicated trade WH&S show, the Brisbane WHS Show is the perfect platform to reach this market.

We are also hugely excited to bring the show to Queensland because of the region’s large mining industry, where adherence to health and safety proce dures is paramount. Bringing the WHS Show to this location makes it easier for mining managers operating in rural

and outlying areas to attend, whereas previous shows in Melbourne and Sydney may have been inaccessible.

This means many of the attendees will be face to face with cutting-edge and targeted work and safety solu tions in this type of exhibition for the first time. This gives exhibitors a rare and exciting marketing opportunity to introduce safety professionals to a range of offerings under one roof, where they can discover, buy and stay updated on the latest products, resources and policies.

Thousands of occupational health and safety managers are expected to attend. Exhibitors who wish to posi tion themselves as thought leaders are invited to take advantage of the lim ited speaking opportunities available at well-attended seminars.

After successful 2022 events, this WH&S Show expects hundreds of exhibitors in 2023. It’s an opportu nity to shape the future of workplace health and safety in Queensland –apply early or risk missing out!

Workplace, Health and Safety Show 2023, 31 May to 1 June 2023 Brisbane Convention & Exhibition Centre

caasafety.com.au/products/super-air-knife

The Albanese government has hit the ground running in its sup port for regional industry and started the longer-term work invest ing in advanced manufacturing.

We were elected with a mandate to rebuild Australian industry and we are focused on delivering on our election commitments.

I was pleased that the October bud get included $111.4 million in support for regional manufacturing from Hobart and Adelaide to Ipswich and the NSW Central Coast.

The budget also provides $50

million over two years to establish the framework for our billion National Reconstruction Fund. This fund will include $1 billion in dedicated support for advanced manufacturing.

This is the first in a series of investments to roll out the National Reconstruction Fund, a co-invest ment vehicle that will revitalise industry, provide well-paid secure jobs and deliver for regional Australia.

The budget was delivered at a time of increased economic turbulence after a decade of missed opportunity. It is right for the times and prepares

us for the future.

As well as measures for regional manufacturing, the budget is deliv ering 180,000 fee-free TAFE and vocational education places for 2023 – an essential step for our ambitious manufacturing plans.

The budget also allocated $17.2 million to establish a pilot Food Manufacturing Innovation Hub on the Central Coast of New South Wales and $12.6 million to support Cytiva’s Springfield BioPark project in Ipswich, Queensland.

The support for manufacturing network Central Coast Industry Connect will create jobs in construc tion and food product manufacturing, and spur local economic growth.

The budget provided $10.1 million for the Factory of the Future project at Flinders University. This inspiring facility brings together innovation, industry 4.0 tech, research and training.

Regional manufacturing measures for Tasmania in the budget included $50 million for the Nyrstar Hobart zinc smelter; $11.1 million to support upgrades to Ingham’s poultry facility in Sorell; $6.1 million to upgrade Launceston’s Waverley Wool Mill.

The grant to Nyrstar will support a $400 million modernisation of the plant and is a good example of how the

This food processing and man ufacturing project at Lisarow is of strategic importance to further devel oping our onshore manufacturing capabilities.

The support for Cytiva will help it

Government is backing the value-add ing of Australian resources.

About 90% of Nyrstar’s raw mate rial zinc for processing comes from Australian sources.

Zinc is an essential input for critical supply chains, including renewable energy infrastructure, construction materials and anti-corrosion coatings on steel.

The company says the upgrade will help secure the long-term sustainabil ity of 650 jobs in Hobart and a further 1000 jobs at the linked Nyrstar opera tions in Port Pirie, South Australia.

buy new equipment so it can expand its biomanufacturing capabilities for high-value medicines.

These projects align well with the Albanese Labor government’s indus trial priorities.

The budget also included $14.2 million to deliver on our election commitment to implement a National Rail Manufacturing Plan.

The plan will have oversight from the Assistant Minister for Trade and Manufacturing, Senator Tim Ayres. It will support the rail industry and skilled manufacturing jobs by ensur ing more trains are built in Australia.

This includes establishing the Office of National Rail Industry Coordination to deliver a National Rail Procurement and Manufacturing Strategy, in consultation with state and territory governments and rail industry stakeholders.

Brick by brick we are laying the foun dations for an industrial revival that will allow Australia to take its place among advanced manufacturing nations.

Australia is one step closer towards developing its first sovereign capability in the area of critical technology, with the official November opening of the nation’s first component-level IT infrastructure manufacturing facility.

SoftIron’s Advanced Manufacturing Facility at Botany in Sydney positions Australia to take advantage of the AUKUS agreement, which will see an unprecedented level of information sharing between the US, the UK and Australia, and their industry partners.

SoftIron says manufacturing locally all but eliminates the risk of malicious state actors introducing firmware implants or so-called “back doors’’ into critical information systems.

Backed by a Defence Department innovation grant, the IT infrastruc ture provider’s facility is Australia’s first advanced manufacturing hub that produces ICT componentry for SoftIron’s ground-breaking HyperCloud Intelligent Cloud Fabric, the world’s first complete technology for building clouds.

Capral now offers lower-carbon aluminium with a certified CO2e content of 8kgCO2e/kg AL or below. Make a responsible choice; choose locally extruded, lower carbon aluminium from Capral.

For more information visit: capral.com.au

SoftIron is a venture-backed com pany founded in 2012 and specialises in managing IT security risks by manufacturing and assembling all of its own equipment; it offers its cus tomers a unique security verification process. Headquartered in the UK, with offices in the U.S., Europe and Asia Pacific, SoftIron established a wholly owned subsidiary in Australia in 2020.

business risk, our reliance on for eign-manufactured componentry has increased the risk of malicious state actors introducing covert hardware or firmware during the manufactur ing process.

“We are seeing other Western nations like the United States move toward supply chain security in the area of critical technology with initia tives like the Chips Act,” Mr Van der Schyff said. “SoftIron is ahead of the curve here in Australia by identifying the looming challenge and putting in place capabilities to meet it.’’

“Unlike manufacturers who rely on opaque supply chains for their componentry, SoftIron offers total transparency of the design and man ufacturing of hardware and software supply chains in its HyperCloud IT infrastructure,” added Mr Van der Schyff.

SoftIron Chief Operating Officer, Jason Van der Schyff said recent events had made it clear that onshor ing or “friend-shoring’’ ICT supply chains was the only sure way for Australian IT providers to manage their commercial and strategic risk.

“Recent geopolitical events and the deteriorating strategic environment have exposed major weaknesses in global supply chains, particularly in the area of critical technology,” Mr Van der Schyff said.

“Aside from exposing Australian companies to an unacceptable

Through a verification process called Secure Provenance, select SoftIron customers can audit prod ucts from end-to-end to ensure they are delivered precisely as designed and specified.

The approach makes HyperCloud an ideal fit for enterprises, govern ment and defence organisations that are especially concerned about protecting sensitive data.

“Manufacturing locally all but eliminates the risk of malicious state actors introducing …so-called ‘back doors’.”

SoftIron softiron.com

our data and produce high-resolution animations that help us to interpret data and communicate our research findings,” Spencer said.

Associate Professor Thach Nguyen and team at the Integrated Photonics and Applications Centre rely heavily on high performance computing to design fingernail-sized photonic chips that can plug into optic fibre networks to make our internet faster, or plug into medical diagnostic tools to analyse how cancer cells spread in real time. The team is now using RACE to conduct research that was almost impossible with stan dard computing power.

RACE is now open to industry partners following its pub lic launch last month. It is Australia’s first university supercom puting facility on the cloud and will enable industry to move from initial concepts, and testing to proven con cept and commercialisation up to 80 times faster.

The AWS Cloud Supercomputing facility, or RACE, is already being used by RMIT researchers to power advances into battery technologies, photonics and medical devices.

RACE provides fast, secure and pri vate connections powered by Amazon Web Services (AWS) and AARNet which RMIT has found ideal for proj ects demanding more speed and less delays than the internet.

Director of RACE Dr Robert Shen said the service means discoveries will be made faster.

“RACE enables researchers to test ideas and solutions up to 80 times faster compared to the existing on-premises servers,” Shen said.

“Research typically involves many

failures before success: this facility lets researchers fail quickly so they can fine-tune their solutions and improve them.”

AARNet CEO Chris Hancock said high speed internet and communication services for RACE were designed to ser vice both current and future demand.

“The network AARNet deployed for RACE is engineered to scale to 400Gbps to provide RMIT research ers with plenty of headroom for transferring massive amounts of data to AWS on demand, now and into the future,” Hancock said

The new service is already making a difference for RMIT research groups who’ve already used RACE.

Professor Michelle Spencer has used it to analyse data and communicate a new, ultra-fast way to screen hundreds of potential molecules that could make suitable electrolytes for lithium-metal batteries, which could potentially increase storage capacity 10-fold.

“We are using RACE to analyse

“Direct access to RACE means that when designing and simulating brain-like chips or creating a chip which could break the record for the world’s fastest internet, the team can run multiple processes at once with computing capability that expands and scales as needed,” said Nguyen.

“RACE has provided our team with on-demand computing power anywhere, any time to simulate our photonic chips 10 times faster than previously possible.”

This work opens the door to new opportunities including the design of chips that could make our internet faster, help drones more accurately inspect railway infrastructure, and build handheld devices to detect ovar ian cancer more accurately.

Professor Matt Duckham’s team is using the computing power to design new ways to automatically pinpoint a person’s exact location using just a verbal description of the features around them. This approach could be especially important in emergencies if satellite positioning fails.

Duckham said his team now has the ability to process massive informa tion streams including drone imagery,

satellite data, data from sensor networks and crowd-sourced data that could overwhelm conventional computing facilities.

“Enabling us to analyse these huge volumes of data from new sources can help better inform evidence-based pol icy decisions to improve public trans port, traffic, infrastructure and many other aspects of quality of life,” he said.

AWS Chief Technologist for Australia and New Zealand, Simon Elisha, said high performance com puting is key to solving the most com plex problems across many industries.

“AWS’s portfolio of cloud services allows researchers at RMIT to focus on ground-breaking research across a broad range of sectors, and innovate faster,” he said.

“Using AWS, RMIT can securely deliver advanced computer performance, memory capacity, and scalability.”

RACE is supported by the Victorian Government under the Victorian Higher Education State Investment Fund and represents a step change in how universities and industries access high performance computing capabili ties for advanced data processing.

RACE is now officially open for industry partners with an interest in driving digital innovation in research and education.

Helping Australian businesses improve their access to the US market is the driver of a new partnership between the Advanced Robotics for Manufacturing (ARM) Hub and Azcende Venture Capital. Both Brisbane-based companies, the two will work together to acceler ate new businesses and emerging and innovative technologies for national security and critical infrastructure.

“ARM Hub and Azcende will collaborate in the development of programs and networks and lever age funding for Defence, Defence Industry, advanced manufacturing, and related supply chains to help secure a pathway into US markets for local manufacturers,” ARM Hub CEO

Dr Cori Stewart said.

Azcende, a new Venture Capital (VC) fund established by former Deloitte Smart Cities and Cyber Risk Partner, Lani Refiti; entrepreneur and technology leader Alok Patel; soft ware developer and start-up advisor Peter Laurie; and US-based engineer Matt Yeoh, is tapping high net worth investors for its $30 million fund.

Azcende CEO and Managing Partner Alok Patel said the fund will focus on investing in Australian critical and emerging technology businesses that can take advantage of the United States marketplace.

“Azcende has partnered with ARM Hub due its success in positioning itself with strong technological

expertise, arising from its deep aca demic networks,” Mr Patel said.

we are excited to bring global com mercialisation experience combined with venture investments to activate critical and emerging technologies together with ARM Hub’s technologi cal expertise.”

He said Australian industry faces major problems, from supply chain security, staffing availability and skill levels.

“Emerging technology presents the most pragmatic manner to solving these issues – whether it be AI, reduc ing the complexity of skills required, or robotics and autonomous systems increasing the production capacity of smaller teams,” Mr Patel said.

“With Azcende’s focus on national security and critical Infrastructure,

“Manufacturing is core to industry.

www.ams-ic.com.au

AMS have been suppliers of instrumentation and calibration equipment to all industries since 1973 representing some of the world’s leading manufacturers of the equipment in their field.

Flow Measurement Specialists www.ams-ic.com.au sales@ams-ic.com.au

“Azcende has partnered with ARM Hub due its success in positioning itself with strong technological expertise”

While for many, COVID-19 feels like a distant mem ory, its impact has created disruptions in the manufacturing industry that will likely be felt for sev eral years. Labour shortages, a drop in demand for product, and supply chain dislocations remain key challenges for the industry. Yet, a few opportunities have also emerged, including acceler ated adoption of cloud technologies and automation, and nimbler product design that solves for specific needs.

As we approach our first calendar year without restrictions since the pandemic began, industry leaders are asking themselves, “What’s the future of the manufacturing industry? And what position does my business occupy”

In this four-part series, William Buck Accountants and Advisors share strategies manufacturing leaders can employ to adopt new ways of thinking and accelerate growth.

These strategies fall into 4 key areas

• Revive: Immediate actions for restarting

• Review: What’s working and what’s not

• Refocus: Strategy and planning

• Thrive: Growth and opportunities

Look out for our second part in this four-part series “Review: What’s working and what’s not” in the next edition of Industry Update.

For a complimentary consultation on your business strategy contact the experts at William Buck at 02 8263 4000 or www.williambuck.com

Get on top of your business’s financial situation.

Ensure that your accounting records are kept up to date. Make managing your working capital easier by preparing forecasts and implementing real time cashflow tracking. Consider adopting an Enterprise Resource Planning (ERP) solution with integrated accounting software. Having all your financial information in one place will allow you to understand which product lines are profit able and make critical decisions faster.

Stay on top of loans and deferred expenses.

In the last few years, several relief measures (such as deferral of taxes and loan holidays) were put in place to assist businesses through the worst of the pandemic. Ensure you stay on top of repayment dates and loan plans; they can easily sneak up on you. Now’s also the time to ensure these are accurately accounted for in your profit and loss statement to avoid any hidden tax liabilities.

Retain your best people. Your people are critical to your ongoing success. Make sure your key players are aware of their importance to the business’s future. With unem ployment at an all-time low, competing for talent can be challenging. If you don’t have the cashflow to compete on salaries, you may be able to adopt other longer-term remuneration or incentive strategies such as employee share schemes.

Now’s also the time to revisit training and develop ment and wellbeing programmes for the future. Are there any programmes that were put on hold over the last couple of years that should be revisited? Does your team need to reskill to meet changes in your business or industry?

Speed up your digital adoption. We’ve seen accelerated spending in manufacturing on digital innovation in recent years. Businesses are embracing cloud technologies and automation in response to labour shortages.

Ongoing investment in technology will likely form part of your ongoing strategy. Now may be the time to take advantage of the Federal Government’s Temporary Full Expensing (TFE) Incentive (avail able until June 2023) to purchase new or second hand technologies.

This is the first of a four-part series by John Spender, Director of William Buck

Unsurprisingly, the first budget of this Labor government was austere and fiscally conservative, designed to rein in inflation and the bloated deficit created by years of pandemic economics.

The budget confirmed that tempo rary full expensing will end on June 30, 2023, along with temporary loss carryback. Both were intended to stimulate activity and profit through incentives to purchase new equip ment by giving full write-off (instead of gradual depreciation), and writing off current year profits against previ ous year losses. After 30 June 2023, instant write-off will again be con fined to purchases only up to $1,000.

There are seven months remain ing to have new business equipment installed and ready for use and it is important to plan in advance, given supply and labour restraints. The incentive applies to new and used goods for any business-related activ ity, including motor vehicles, pro duction equipment, machinery, office equipment, etc.

Energy-efficient vehicles

Electric vehicles (EV) were singled out for removal of customs duty and the 5% import tariff. Novated leases for energy-efficient vehicles up to the ‘luxury’ limit ($84,916) have been exempted from fringe benefits tax. An additional 20% deduction for small business expenditure and purchases of depreciable assets that support adoption of digital technologies, up to $100,000.

While on the topic of passenger vehicles, the luxury car limit for

energy-efficient vehicles (those achieving 7.0 litres per 100k) is now at $84,916 and other cars $71,849. The luxury limit represents the maximum available for depreciation, GST input and the stage at which luxury car tax begins — at 33% for each dollar in excess of the limit.

The above represents most incen tives for purchasing EVs offered by the federal government, but each state has its own program ranging across purchase rebates of $3,000, reduced registration and stamp duty.

Business finance comes in many forms and there is a vast range of products to accommodate specif ics such as purchase of equipment, machinery and motor vehicles, non-specific funding for expan sion, short-term lending to assist with stock purchase or import of

equipment, and larger loans for purchase of other businesses or real estate. Outstanding debtor ledgers may be leveraged to provide capital, owned assets can be used as security for a particular project or need for additional funds. Large annual insur ance premiums (and even vehicle registrations for fleets) may be spread over 10-12 months at minimal cost to ease cashflow.

Today there is an ever-increasing array of fintech lenders offering unse cured lending, and equipment and motor vehicle finance, across a broad range of rates and lending criteria. Finance is becoming increasingly

dependent on artificial intelligence and emphasis is on business longevity, experience, and evidence of income and outgoings, less upon historical financial reports analysed by credit officers. When seeking out finance for business needs, it is appropriate to have a clear plan of those needs then to consult an industry professional with experience and an overview of all available products and services.

It ensures that we can locally develop product and services to bolster key supply chains for critical industries, in particular Defence, whose supply chain is broad and strategic.

“However, industry struggles with adopting new technologies due to their disruptive nature which forces significant change to how a business operates.

“Helping to establish these emerging technol ogies as future businesses is essential to enabling adoption and achieving Australian sovereign capability.”

Mr Patel said Australia’s track record of inge nuity, such as the invention of WiFi, there is a real opportunity to establishing Australia as a net exporter of intellectual capital.

Dr Stewart said ARM Hub welcomed the partnership.

“ARM Hub and Azcende share a commitment to accelerating the manufacturing readiness level of technology and overcome brakes and barriers to commercialisation, working predominantly in technologies that are relevant to Defence and Defence industries, including medical, transport, energy, and space to achieve their vision,” Dr Stewart said.

“Azcende will further support the work we do with manufacturers by providing commercialisa tion advice and business networks with a view to supporting export to a North American market.”

ARM Hub is an agile centre working in robotics, AI, and design-led manufacturing. The hub de-risks technology adoption, development, and commer cialisation for Australian manufacturers by drawing together the best scientists, technical specialists, designers, and engineers to work side by side with industry to develop commercial solutions. ARM Hub has in-house expertise and is a trusted partner for universities and research organisations, providing industry with access to a world-leading network of research and development expertise.

The William Buck Hour is designed to help middle-market businesses assess their current position, realign thinking and maximise their business’s potential. In just one hour, we’ll guide you through a detailed discussion structured around a range of key fundamentals. Following the session, our advisors will conduct an analysis of your business using commercial insights, professional experience and best practice standards to develop a prioritised action plan for your business.

The end result is a fresh perspective and a focused strategy to help you move forward.

“...there is a real opportunity to establish Australia as a net exporter of intellectual capital”

By Margie Smithurst

By Margie Smithurst

After contacting leading suppliers in Germany (Igus) and Switzerland (PMA), he was made the Australian distributor for their energy chains, chainflex cables, polymer bearings and flexible conduit systems.

still has a strong relationship with both companies.

In the first couple of years, Paltoft focused on Australia’s automo tive manufacturing sector, with Mitsubishi, Toyota, Holden and Ford

elsewhere.

A new warehouse in Perth began supplying the booming mining indus try, and Treotham shifted towards mining too — it’s still one of its biggest customer bases.

Along with the food and bever age industry, mining and transport sectors, Treotham now also supplies railway construction, not only to mines but to the resurgent local train manufacturing sector.

This includes Queensland’s New Generation Rolling Stock (NGR) trains, and the new train manufactur ing facility in Perth.

again … we even have a Chinese com pany assembling the trains in Victoria.”

“We can see an upswing … Even the New South Wales government says the next trains hopefully will be built in New South Wales.”

Covid also infamously brought supply chain issues, which led Paltoft to invest in $10 million worth of products that are currently stocked in its warehouses around the country — Sydney, Melbourne, Brisbane and Perth, and also in New Zealand.

Both Igus and PMA, recalls Paltoft, gave him a year’s credit, and he expanded the business to a mate’s garage, stocking one product group from each supplier. Treotham

as clients, and then added two white goods manufacturers, Electrolux and Fisher & Paykel.

As those companies left the man ufacturing landscape, he had to look

Covid has changed things, says Paltoft.

“It was a worry … four years ago, there was nothing manufactured in this country, everything went abroad. Now manufacturing is rebounding

“It’s a lot of stock. But it reduces the lag time in supply, because it can all be sourced domestically, which is a bonus for our customers.”

At present, the wait time for international orders can be up to 20 weeks and even up to a year for some

Continued from front page“...four years ago, there was nothing manufactured in this country, everything went abroad. Now manufacturing is rebounding again...”

products.

As a result of its stock build-up, Treotham has become a ‘supermar ket’ for industrial automation needs.

The new centralised Sydney ware house is basically a one-stop shop, providing full automation system products: energy chains, cables, sen sors, polymer bearings, gear boxes, safety products and more, all under one roof.

The size of the new warehouse means Treotham can offer a dedicated assembly area for customers’ custom ised energy chain and cable needs — known as ‘Ready Chain’.

The sturdy plastic chains and cop per wire-filled cables, both of which are manufactured in Germany, can be cut to length and configured on site. The cables are fed into the chain, and then delivered to or picked up by customers.

“We now have the capital capa bilities and capacity to build bigger and longer chains,” says Paltoft, “which we can customise to clients specifications.

“Chains from as little as one metre up to 40 metres with multiple cable config urations can be assembled on site.”

“Previously we didn’t have the space or facilities. We were purely importing components and selling them on. Now we can provide more

in-house builds.”

Treotham’s customers include the major ports, most of which use the Igus energy chain system in their cranes. Depending on demand, these cranes may need to operate up to 24 hours a day so a reliable system is a necessity.

In the last few years, Treotham has grown significantly. In 2020/21, Paltoft says the company enjoyed double-digit growth, which has con tinued so far this year.

Having significant stock on site has been a vital factor, says Paltoft, but so has winning bigger projects amid the growth of local automated manu facturing, helped by the fact that a number of its key suppliers are world leaders.

The next step for the company is to provide the ‘harnessing’ process on site at its Sydney warehouse, where customers can order a complete project, the chain, cables and the connectors and have them delivered as a complete system.

Igus is a world leader in the pro duction and supply of energy chains, says Paltoft, and the new technology is gradually replacing the festoon sys tems typically used on cranes which leave the cables subject to tangling as they hang free and open to damage. This results in costly down-time and loss of productivity, whereas efficient setup of the energy chain systems removes the chance of damage, as they contain the cables and require minimal maintenance.

Treotham is also building up its service offerings. Specialists in the field already go out to customers in Australia to provide assistance with chain installations and maintenance where necessary.

While retaining staff and hiring new people is a challenge for many Australian companies at the moment, Treotham has managed to keep a number of its employees for 10 years, and even 20 years.

Now with 40 employees in Australia and New Zealand, the company remains 100% Australianowned and managed.

A success story so far but perhaps, says Paltoft in his unassuming style, still just the beginning.

“We now have the capital capabilities and capacity to build bigger and longer chains”

Treotham treotham.com.au

Supply chain issues and labour shortages continue to impact Australian manufacturing. According to Ai Group’s Australian Performance Manufacturing Index (PMI), production levels fell in July 2022, but have rallied to be relatively stable in September, despite four out of six sectors contracting.However, most businesses reported labour shortages as a key issue constraining output.

In August 2022, Australia’s recruitment difficulty rate was 22% higher than the same time last year. Meanwhile, the percentage of Australian employers expecting to increase their staff levels went up by 13% over the same period.

Fuse Recruitment, a specialist in manufacturing recruitment across Australia, has partnered with many manufacturers over the past 12 months who have struggled to secure talent.

Jaquline Farag, Senior Recruitment Consultant at Fuse Recruitment, says “Clients will often contact me when their requirement is already overdue, which means they’re left to squeeze as much as they can out of their current workforce until they hire new talent”.

In September, the Australian PMI capacity utilisation index rose above the long-run average of 74.6% to reach 80.4% of available capacity. To increase production and prevent burnout in future, manufacturers will need to increase employment levels. Demand is not slowing down.

According to Ai Group, sales and orders continued to grow in September. Additionally, the increas ing number of Australian consumers post-pandemic now trying to source locally made products has highlighted the need for local manufacturing.

“Australian consumers have always had a preference for buying Australian products, this has been heightened in recent years,” says Ben Lazzaro, Australian Made’s Chief Executive.“During the pandemic, Australian Made experienced a fourfold increase in applications to use the logo, with consumers increasingly seeking authentic Aussie products produced in our clean, green environ ment and manufactured to our high standards.”

Throughout 2022, the number of jobs

advertised on SEEK grew consistently as businesses in Australia expanded and fought for candidates amidst labour shortages.

There were 15.5% more job ads posted in September than the same time last year in 2021.According to Ai Group’s research, average wages in Australia’s manufacturing industry have also reached a new high and have continued to increase for most of 2022.

Farag warns that while offering high wages is an easy way to bring on new talent, it is not a sustainable approach. She encourages businesses to pay attention to what their employ ees really want out of their employ ment, incentivising them to stay.

Your employer value proposition (EVP) is the best tool for locking in talent when high salaries are not an option.

Your EVP is the benefits and work conditions you offer your employees, and influences how people feel and think about working for your com pany.Apart from a high salary, our consultants have found the biggest demands from job seekers are a better work culture, opportunity for career

growth and the need to feel valued.

“Some of our clients get creative with what they offer, to align with their business’s needs,” says Aya Inazato, Recruitment Consultant at Fuse Recruitment and former manu facturing scientist.

“Some will offer RDOs where employees work nine-days per fort night and one of my clients who is try ing to attract more women into their workforce is offering paid maternity leave to their employees.”

“Offering benefits to attract and retain employees doesn’t have to be expensive and, if thought about care fully, it is possible to make employees happy at the same time as achieving organisational goals.”

Fuse Recruitment is a specialist in manufacturing recruitment. Many of our consultants have a background working in the industry and hands on experience, meaning they understand the intricacies and technicalities of the roles for which they recruit.

In order to thrive in an increasingly competitive global market, the Australian manufacturing sector is embracing new technology.

Companies are investing in auto mation technologies, including robot ics and artificial intelligence (AI), to achieve greater efficiencies and meet the demand for higher productionwhile keeping costs down.

The integration of new technol ogies does, at times, raise concerns from employees, who may fear they’ll be replaced by robots or automation.

They predict increased demand for jobs such as Data and Machine Learning Specialists, but also very ‘human-driven’ professions, includ ing Digital Marketing Specialists and Business Development Professionals.

While these findings are encouraging, they will do little to assuage the concerns of manufacturing employees who may not yet be equipped with these skills.

The question for manufacturers is, how to embrace advanced manu facturing without leaving employees feeling vulnerable or alienated?

important that employees feel that their contributions are a valued part of the overall initiative,” says Stewart

“This is a common misconcep tion,” says Hazel Stewart, Director of Innovate Learn, a Melbourne-based distributor of solutions from Wilson Learning Worldwide.

“The Harvard Business Review puts it best: ‘technology does not purge the need for human labour but rather changes the type of labour required. Autonomous does not mean humanless.’”

“The change to new technology actually brings a wide range of new employment opportunities” , says Stewart

She points to the findings of the World Economic Forum’s 2020 Future of Jobs Report, which esti mate that by 2025, advanced tech nologies will lead to the creation of at least 12 million new jobs.

For the transition to advanced manufacturing to be successful, it is essential that employees are educated about the new technology, as well as its benefits and goals.

“It’s not that employees are resis tant to change – but rather that they need clarity on how the change stands to benefit them on both an organi sational and an individual level. It’s

A great point of departure in a change management initiative is to highlight the benefits afforded by automation and new technology.“Robots enhance the workplace for employees by taking on dull, dangerous and repetitive jobs,” says James McKew, Regional Director APAC for Universal Robots, the special ist developer of collaborative robots for industry (i.e. robots that can work safely alongside humans).

According to McKew, the argu ment that robots will take jobs from humans is an argument they regu larly encounter.

Yet robotic automation, he explains, has many advantages for the workforce.

Collaborative robots are freeing up people to do more meaningful and fulfilling tasks, and Universal Robots has seen this repeatedly with their customers across the globe.

An unexpected but major benefit of automation is that it is reinvigorating the manufacturing sector by making

it more attractive to young candi dates, presenting an exciting pathway into a sector that may otherwise have limited appeal.

As well, more ‘abstract’ skills will be required by future-thinking man ufacturing businesses that wish to thrive. Skills such as learning agility, collaboration, critical thinking, and problem solving.

“Change is inevitable, but once teams see new technologies for the oppor tunities and advantages they present, they can focus on strengthening their uniquely human capabilities.

“These capabilities will always be in demand in the fourth industrial revolution and beyond – no matter how many robots are working along side us,” Stewart concludes.

McKew,Regional

DirectorAPAC for Universal Robots

“The change to new technology actually brings a wide range of new employment opportunities”

“Robots enhance the workplace for employees by taking on dull, dangerous and repetitive jobs”

began the Centre’s first collabora tive project, known as ‘The Shorts Project’.

The ACC works to solve manufac turing problems with collaborative robots — or cobots — in a way that creates a safer, more efficient and competitive industry, and by taking ethical contexts into account.

Partnering with the Australian Cobotics Centre, steel maker InfraBuild was able to design and test a cobot for production line work, rather than going straight to a robotics integrator.

When steel manufacturer InfraBuild approached the Australian Cobotics Centre (ACC) a year ago, they were looking for a collaborative robotic solution to a repetitive and potentially risky manual task.

InfraBuild’s production line churns out hot steel bars in a range of shapes and sizes. To remove short,‘off-spec’ bars, the company employs several

people sharing a 12-hour rotating shift to pick out any short items, or ‘shorts’, and throw them off the conveyor. It is intense work, requiring constant focus to reduce risk.

InfraBuild was clear about what it wanted: better working conditions for its employees, lower fixed costs, and better product quality and therefore customer satisfaction.

“We charge a premium for qual ity. Customers get upset if they’ve got a slightly short product in their bundle,” says Andrew Thomas, InfraBuild’s Industry 4.0 Program Lead.

“Lights and ribbed debar moving on a conveyor can be disorienting, too. There’s not been any major incidents but we are always looking at improv ing our safety to reduce the potential for an accident.”

“Using the cobot, we will save on labour and be even more cost-efficient against imports, and can maintain the premium price because we have the best quality.”

Impressed with the develop ment work being done at the ACC’s industrial robot and testing space in Brisbane at ARM Hub (another ACC partner), InfraBuild and the ACC

The Centre fills a gap for indus try by acting as a testing ground for companies’ ideas, allowing firms like InfraBuild to explore outcomes, rather than wasting potential time and money by going directly to a robotic integrator without a well-defined project.

“Our job at the Cobotics Centre is often to work out how a cobot can per form a task,” says Jonathan Roberts, the ACC’s Director. “If we’re successful or unsuccessful then a company such as Infrabuild can go to a robot integra tion company, armed with our results, to better inform that company on how a solution might be possible.

“Either way, [success or failure] would be a win-win because it low ers the risk of failure for everyone involved.”

InfraBuild’s problem was that off-theshelf solutions to automate the detec tion and removal of ‘shorts’ couldn’t deal with the variety of bars produced by the steel manufacturer.

ACC’s team of engineers and researchers from Queensland University of Technology and

together legal, accounting and banking expertise, THE MANUFACTURING LAB provides wrap around advice across the three critical areas that help manufacturing businesses to grow and thrive.

“The Centre fills a gap for industry by acting as a testing ground for companies’ ideas, allowing firms .... to explore outcomes”

University of Technology, Sydney, worked with InfraBuild’s team at the steel mill to design and test a handful of possible solutions over six months.

This involved building a life-sized, working version of InfraBuild’s con veyor system and using an industrial robot to pick up and move steel bars.

“We tested about five different iter ations — there’s a blooper reel of all the versions tested!” said Thomas.

and flick the bars off the conveyor, using the same movement and con veyor momentum as InfraBuild’s staff do manually.

Tests showed the cobot can handle as much variety as people do now — about half a dozen products of different lengths and weights. And there was another benefit: the cobot never missed.

“We expect the cobot to pick up all the shorts on the roller table. In tests, it didn’t matter how many bars were on the table, the cobot picked up all the shorts,” says Thomas.

The ACC engineers eventually developed a flexible system using a large, industrial-sized cobot that had adjustable inbuilt and external sensors to manipulate more of the different steel bars that InfraBuild makes – even those it might make in the future –while working safely around workers.

Roberts says the cobot’s simple hook which picked up the shorts was the “genius” part of the concept.

“The hook was the tricky thing, and it took a lot of innovation. A typical engineering approach would have been to design a fancy gripping sys tem or magnetic system that’d need maintenance, power, and be expen sive — but we wanted something passive and low-maintenance that could be replaced within 10 minutes if something went wrong with it.”

Before the steel bars reach the cobot, cameras identify the short bar. Identification is based on algorithms in the vision system which then sends that position’s coordinates down the line to the cobot.

The cobot then uses the hook to lift

When solving industrial problems, the ACC uses a biomimicry lens: looking at how people are currently doing a job and designing a cobot to mimic it. It’s not the way a typical engineer would initially approach it — measuring and weighing steel rods up to 30kg each and concluding that what’s needed is a gripper or series of grippers which can lift 30kg.

“But if you use biomimics-coloured glasses you say ‘hang on, these people doing the job now could not easily lift 30kg with one arm’,” says Roberts.

“You can see they pick up one end of the bar and, with some of the weight still on the conveyor, they then flick it, using the momentum of the moving bar, too.”

Importantly, Infrabuild did not want to be locked into a cobot-only solution.

The company wanted the solution to fit into existing operations rather than requiring extensive changes to plant, equipment or processes. A cobot meant a straight-forward implementation and the option to switch back to manual if, for some reason, the cobot failed.

“Another good reason for a biomim icry perspective is that if something happens and the robot needs to be fixed, we want a person to step in and do the job while it’s being fixed. We needed flexibility to switch back to

manual if possible.”

Roberts says it’s likely that InfraBuild could wheel the cobot in to where a person now stands and when it’s not needed, it could be wheeled out.

“Cobots were also chosen,” says Thomas, “because they are designed to work around people so you don’t have to have interlocking guarding and exclusion areas.”

Thomas says they also wanted to avoid “exotic” parts, in order to sim plify maintenance and repairs.

“We used locally available, bog-standard components so it’s easy to replace anything. The simplicity of the hook was important because steel will wear it out.”

For the ACC, ethics are always in mind.

“If you’re doing backbreaking work of any kind and we know that using a

collaborative robot is a better way … then it should be used. It’s like the old coal-mining practice of putting chil dren down mines into tight spaces — the world knew that was bad option,” says Roberts.

“I think with some of these new technologies we’ll be ethically com pelled to use them.”

As for jobs, InfraBuild has plenty of less monotonous and safer work for current employees. Generally, Roberts says cobots could save other wise dwindling businesses, which will in turn save jobs.

“The whole conversation has been flipped around because, at the moment, many businesses can’t find enough people for jobs so we need to use these new technologies to keep companies competitive and running.”

With investors, governments and even risk-averse super funds funnelling mil lions into commercialising early stage Australian technology projects, it’s a lucrative time to be an innovative start-up.

University research collaborations are critical to the R&D ecosystem, and UNSW ranks as SCOPR’s* top institution in Australia for startups and com mercial spin-offs, particularly in engineering and physical sciences.

“We can only do so much on our own. To get our products to market, we need to collaborate with industry and investors. It’s always been part of our remit but it’s accelerated in the last few years, one of the silver linings from Covid perhaps,” says Warwick Dawson, Director of Knowledge Exchange at UNSW.

One hundred of the latest innovations and capabil ities powered by UNSW were on show at the univer sity’s Research Translation Expo in October, where the uni’s entrepreneurs and researchers mixed with businesses, investors and industry partners.

One area the university has always led the way is in solar cell technology.

UNSW’s Sydney Scientia Professor Martin Green invented the Passivated Emitter and Rear Cell (PERC) technology that’s now used in more than 90% of the world’s solar cells, and he and his team have been recognised for this with the prestigious and lucrative 2022 Millennial Technology Prize (see story page 48).

But when Prof. Green developed the PERC technology in the early 80s, his team was unable to manufacture it here at a competitive cost. So the technology was pushed offshore while Green and his team continued R&D on next-generation solutions. One of Green’s PhD students, Zhengrong Shi, set up Suntech Power in China and became the world’s first solar billionaire.

Now, finally, the situation seems to be changing for Australia’s solar industry. The massive Sun Cable proj ect in the NT aims to be the world’s biggest solar and battery storage project, sending most of its renewable energy via undersea cable to Singapore. And there’s local movement in solar cell manufacturing.

One to watch is SunDrive Solar, started in 2015 by a UNSW PhD student who dropped out of his study to set up the company.

In 2021, it fabricated a world record-breaking solar cell that uses copper rather than silver in its electrodes.

In an expanding solar sector, “the industry’s use of silver is growing to a point where it’s unsus tainable,” says Jack Colwell, Senior Photovoltaic Engineer for Sundrive Solar and former UNSW PhD student, speaking at the Expo.

The industry’s been looking at copper for a while, Colwell told Industry Update, but no one’s really been able to perfect the technology, in particular to get the copper to adhere to the cell.

“So the solution SunDrive developed actually gets copper to stick to the cell,” says Colwell.

Given the abundance of copper compared with silver, and the purity of the copper that they elec troplate, Colwell says this makes the concept viable for large-scale, low-cost and high-performance solar PV cell manufacturing.

SunDrive has just received $21 million in private investment to help it scale up its manufacturing, which it plans to start in Australia in 18 months. Seeing the potential for Australian solar cell

innovation to be manufactured here is not lost on Daniel Chen, also a former UNSW PhD student and Senior Photovoltaic Engineer with SunDrive.

“For us, this opportunity of taking research and applying it to a company in Australia, that’s huge.”

Continuing in the environmental vein and with the possibility of a market coup in the US, is UNSWaffiliated Vecor Technologies.

Fly-ash is an under-used by-product of burning coal to produce energy. Considered waste, some is used in cement and concrete while much is dumped in ponds or just stored underground.

Vecor is processing fly-ash to make advanced materials for a variety of sectors which will benefit from lower costs and greater sustainability.

One of those sectors is the paint industry, Vecor’s Alec Rowan told Industry Update at the Expo.

“The paint industry uses large quantities of tita nium dioxide. It’s one of the whitest substances on the planet and requires heavy refinement.”

Recent supply chain disruption has made sourc ing titanium dioxide harder, says Rowan, which is where Vecor’s fly-ash comes in.

“Currently we are developing a ceramic pigment using fly-ash as a partial replacement for titanium diox ide, and we expect to provide the replacement material at a significantly lower cost than titanium dioxide.

“We also expect to improve the customer’s envi ronmental profile by replacing a mined material with a recycled waste product.”

Vecor is now working with potential customers in the US to establish demand for its product.

“At the moment we’re working on establishing industrial scale manufacturing processes and con tinuing product trials,” says Rowan.

“Vecor has been working with UNSW academics Professor Charles Sorrell and Associate Professor Pramod Koshy for more than a decade, and has established dedicated research laboratories at UNSW to support further technical innovation and

product development for fly-ash use and also other product areas.”

UNSW has had a vital role in the company’s devel opment, giving Vecor access to UNSW specialists in materials science and engineering, as well as facilities.

*The Survey of Commercialisation on Outcomes from Public Research, 2021

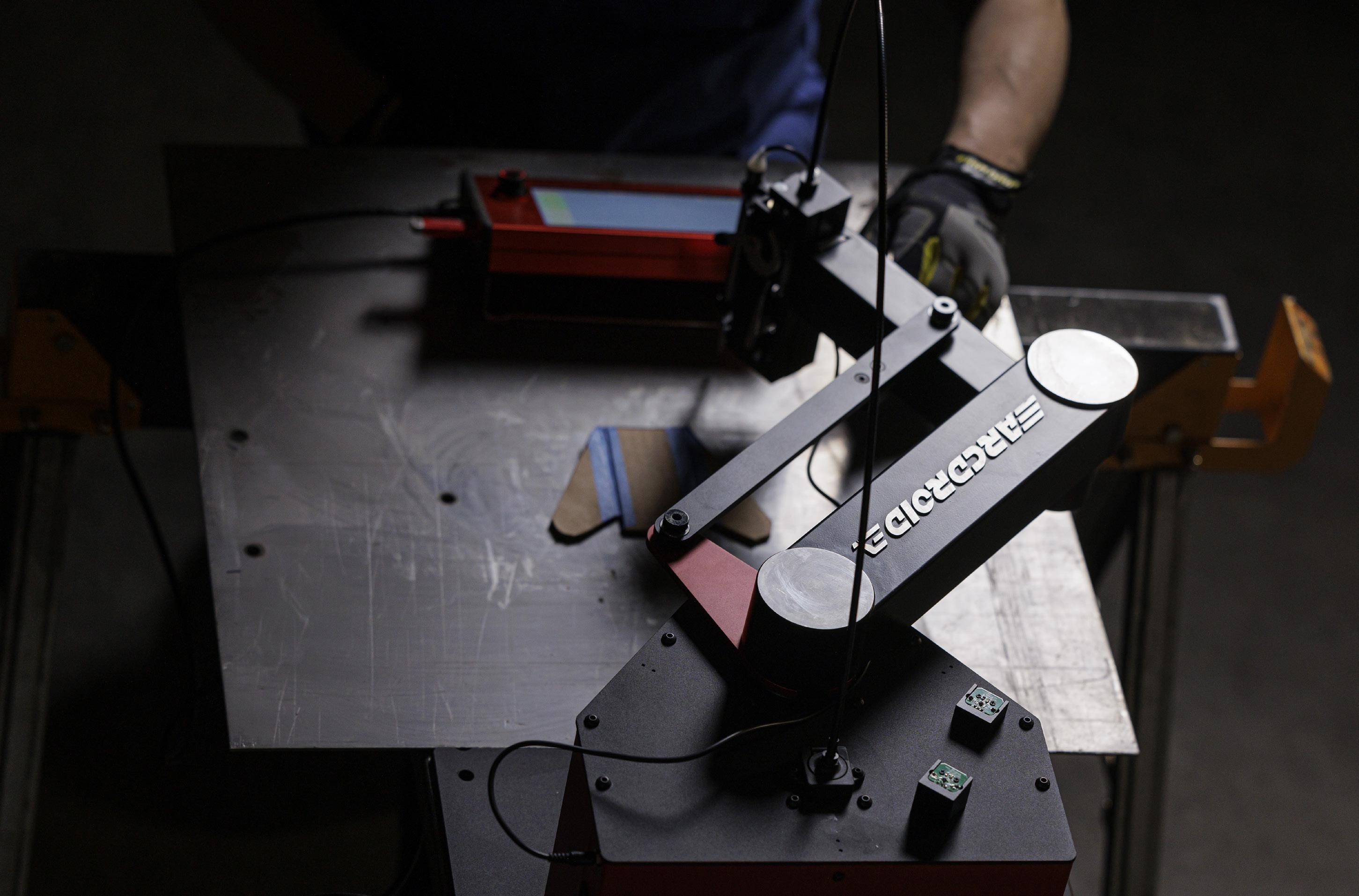

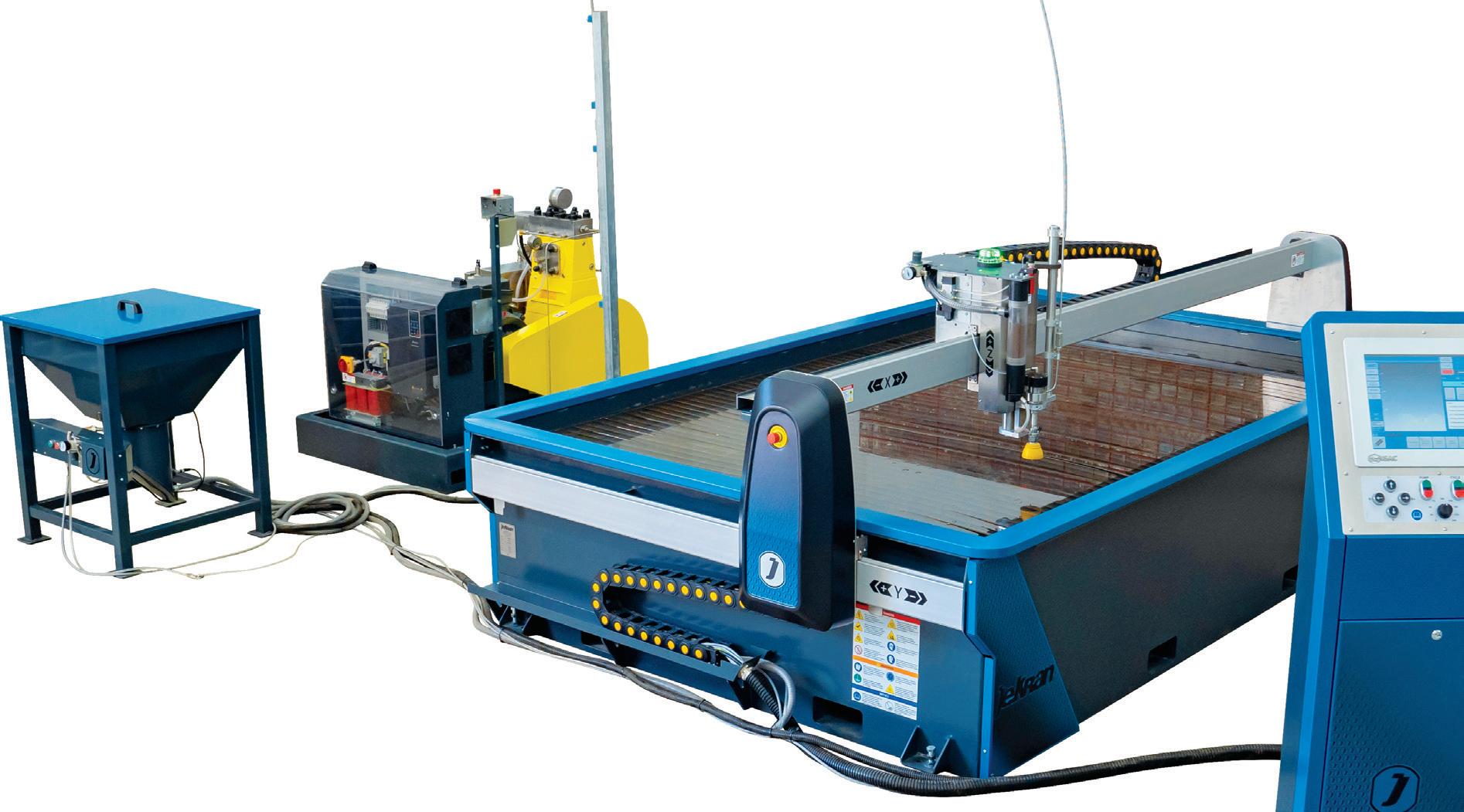

Weighing just 16 kilograms and having a convenient cut envelope of 660 mm x 380 mm, the portable ArcDroid plasma robot is fully functional, easy to use and set up.

It is ideal for anyone who needs to cut custom shapes and plates or is doing onsite structural work, agricul tural repairs or automotive resto ration. Small fabricators with limited space or even home hobby workshops will benefit from this compact, versa tile portable plasma robot.

It operates from a 10 amp 240v supply that’s also easy to transport

and store.

The ArcDroid’s touch screen interface is glove-friendly and s standard with quick-change holders allow changes from trace to cut mode quickly making it extremely user friendly.

Thanks to its Simple Trace technol ogy, no programming experience is needed to use the ArcDroid. This makes it a simple matter to produce fast, accurate, repeatable parts.

Simple Trace lets users trace a template point-to-point or freehand,

by moving the ArcDroid arm to follow the contours of a template. The high accuracy encoders and high-reso lution drives will map every move.

When finished tracing, users can define the cutting order of the com ponent features and instantly create a cut file which can then be saved to a USB stick for future use.

DXF drawing files can be downloaded directly to the ArcDroid for part processing. The ArcDroid is also compatible with CAD/CAM packages such as Fusion 360 and Sheetcam and detailed g-code files can be down loaded directly to the ArcDroid via the USB port.

Most air plasma cutters can be used with ArcDroid as long as a two-wire switch can be provided for turning on and off the torch. (High frequency start plasma is not suitable). Plasma cutters are available as an optional extra.

Further details

full specifications of the ArcDroid™ CNC Portable Plasma Robot are available at Hare & Forbes Machinery House. More stock arriving mid December.

The process of laser peening is to creates compres sive stresses, deformations or plasticisation on the surface of fabricated components causing the mate rial to compress inwards leading to denser sections.

Laser peening creates high-pressure plasma, and on expansion, strong shockwaves penetrate through the treated metal, creating a residual compressive stress field that fights crack propaga tion and fatigue issues. The process works by using a high-energy pulsed laser to generate high-ampli tude stress waves on the surface of the target part.

Residual compressive stresses to improve reli ability and lifetime of metal parts were with a ball-peen hammer! THEIA, a diode-pumped Nd:YAG laser from Thales offers a method of lifting metal fatigue prevention to a higher plane. Now laser shock peening offers a more accurate process that’s useful in critical industries such as nuclear, biomedical and aerospace.

A new way to improve the reliability and lifetime of metal parts, laser shock peening (LSP) offers significantly deeper, residual compressive stresses (RCS) than traditional shot peening methods.

Peening has been widely perceived as a simple, effective, and industrially reliable way to modify surfaces, applied to improve mechanical proper ties, such as hardness, corrosion resistance, fatigue life, tensile strength, residual stress, and wear resistance for metals and alloys.

The laser is not used for heat effects but for the dynamic mechanical effects of the shockwave gen erated by the laser beam. A plasma is created where the laser beam strikes the metal surface.

Laser shock peening (LSP) is now used across dif ferent industries to strengthen turbine fan blades. Tests have demonstrated fatigue strength three times as effective as traditional processes.

It’s now being applied to 3D printed parts for the same purpose. LSP has been shown to enhance cracking resistance up to 10 times deeper than shot peening for fatigue prevention and part performance.

Recent research has shown it can be successfully applied to thin wall welds of Ti6A14V, to strengthen components of aircraft engines. While residual stress profiles vary based on part thickness and material properties, laser shock peening consis tently produces deep residual compressive stresses that reduce fatigue.

LSP is widely used in post-processing welds, for example in the nuclear sector where stress corrosion

cracking is a serious threat to nuclear reactors and canisters, laser shock peening is an effective solution.

Used in passenger and military aircraft to enhance the fatigue performance of compressor blades, landing gear, shafts, valves, discs, and the complex forming of wing surfaces.

More common industrial use includes connect ing rods in heavy equipment (bulldozers, etc) metal forming dyes, aluminium ship decks, power plant components even racing car parts.

THEIA meets demand with its high-power and high-frequency laser system that delivers nano second pulses at different wavelengths in the near infrared (1064 nm), in the visible (532 nm), and in the near ultraviolet (355 nm).

The new configuration can be used for LSP without any thermal protective coating on the part to receive the peening treatment. THEIA boasts a very high laser frequency at 200Hz with a small laser spot size of 0.8-1.5mm and high overlap ratios (>1,000 per cent). This capability opens up new opportunities for enhanced peening.

To confine the energy from the laser beam along with confining the plasma to the metal surface, and gain maximum mechanical force, a thin layer of water overlays the part. The water is transparent to the laser beam. It is only recently that water has been applied, previously parts had to be coated in aluminium, copper, zinc and black paint.

These were considered effective coatings to help prevent the thermal effects like laser ablation, melt ing, and generation of tensile stress, and enhance the peak pressure of the shock wave induced during direct laser interaction.

Providing a protective coating is generally a costly and time-consuming requirement, but recent developments in Thales’s new THEIA, a high-power, high-frequency laser system, the only ‘tamping material’ now required is a thin film of water.

On-the-spot fines for WHS breaches in NSW

“The change in the regulation gives SafeWork inspectors the power to issue immediate penalty notices for work near overhead wires, with fines of $3,600 for corporations and $720 for individuals,” said Head of SafeWork NSW, Natasha Mann.

“In the past two and half years, SafeWork NSW has responded to more than 1,000 workplace inci dents involving workers coming into contact with electricity, two of which resulted in fatalities,” Ms Mann said.

“The most common risks associated with electrical work include contact with overhead power lines, under ground services and unsafe wiring that includes temporary wiring, installa tions and electrical equipment.”

Electrical incidents can also result in power outages, fires, damage to infrastructure, businesses and even road closures.

“We’re urging businesses and workers undertaking electrical work to shut off mains power supply when working near electricity and under no circumstance should electrical work

n amendment to Work Health and Safety Regulations means SafeWork NSW can now issue on-the-spot fines for existing electri cal work and asbestos offences.be done without holding a licence to do so,” Ms Mann said.

Asbestos removal penalties

“The new on-the-spot penalties will provide SafeWork NSW inspectors an additional compliance tool to take immediate action when they observe workers and businesses engaging in highly unsafe activities onsite.

“We will continue to take a zero-tol erance approach to workers’ lives being placed at risk,” Ms Mann said.

The proposed penalty notice offences are existing offences under the WHS Regulation, meaning busi nesses in NSW should already be com plying, and can already be prosecuted if they do not comply.

The Surftest SJ-210

is a user-friendly surface roughness measurement instrument designed as a handheld tool that can be carried with you and used on-site

• 2.4-inch colour graphic LCD with backlight

• Simple key layout

The Surftest SJ-210 can be operated easily using the keys on the front of the unit and under the sliding cover. Highly functional • Advanced data storage capabilities • Optional memory card

Password protection

Multilingual support • Stylus alarm An alarm warns you when the cumulative measurement distance exceeds a preset limit.

• Complies with many industry standards

The Surftest SJ-210 complies with the following standards: JIS (JISB0601- 2001, JIS-B0601-1994, JIS B0601-1982), VDA, ISO-1997, and ANSI.

• Displays assessed profiles and graphical data

Industry Update Issue 129 November 2022 | 31 industryupdate.com.au

AMTIL’s long-standing advanced manufac turing expo, AMW2023, will take place at the Melbourne Convention and Exhibition Centre (MCEC) from 9 to 12 May, 2023.

Kim Banks, Head of Events said the expo will be a one-stop manufacturing solutions event.

“Attendees can see the latest technologies on display, connect with like-minded individuals, and participate in learning opportunities designed to help them grow their business.”

There will be several featured zones at the expo:

This Zone will highlight the latest advances in 3D printing, additive manufacturing users, suppliers, and supporters. The process of 3D printing was first patented by Charles Hull in 1986, as stereolithog raphy, and the additive manufacturing industry began as a ‘rapid prototyping process’.

The innovations brought about by this tech nology have been ground-breaking. Today the precision, repeatability, and material range of 3D printing has extended its use into boat and building construction, through to nanotech.

This pavilion, sponsored by Sutton Tools, will showcase the capabilities of Australia’s precision engineering and the advanced manufacturing industry.

The Australian Manufacturers Pavilion is where AMW celebrates the best in Australian manufacturing, provid ing a showcase for some of this country’s most accomplished component manufacturers, preci sion engineering firms, toolmakers, advanced manufacturers, and gen eral engineering companies.

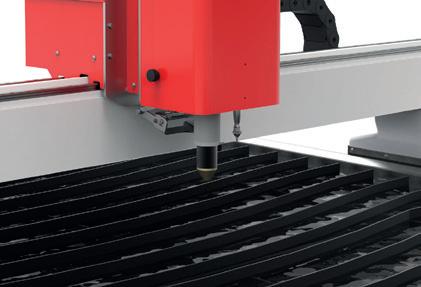

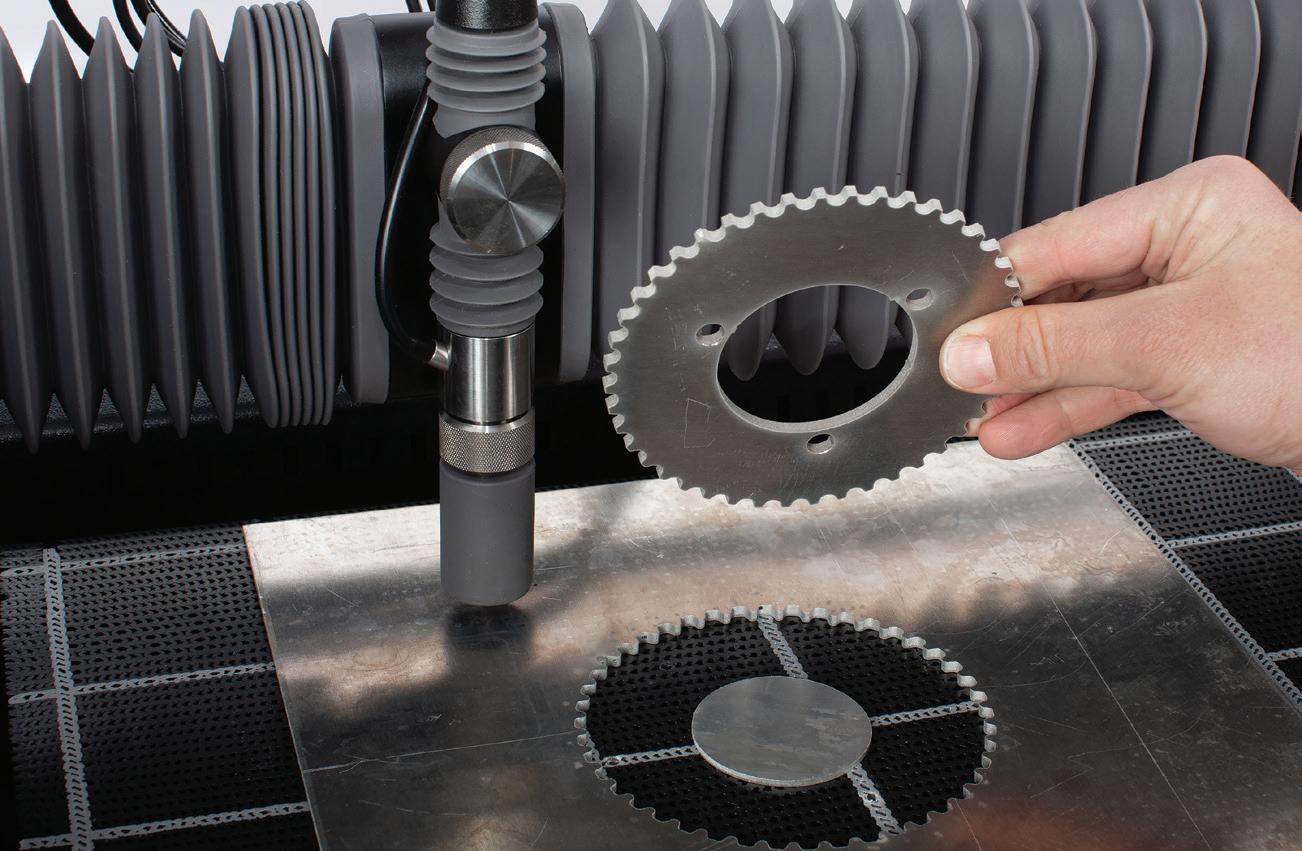

This zone is targeted at the metalworking, machine tool and ancillary market in Australia. Sponsored by Iscar Australia, this Product Zone covers advanced manufacturing products and processes including:

CNC machinery, lathes, mills, contract manufac turing/precision machining, cutting tools, tooling and tool holding, forming and fabricating machines, plasma, laser, waterjet and ultrasonic Machines,

and Ancillary equipment suppliers.

Manufacturing Solutions Zone will showcase the ancillary technologies and support services for warehousing logistics and materials handling.

The Robotics & Automation Zone will be buzzing with the latest state-of-the-art artificially intelli gent software brains. Not to be missed!

The Weld and Air Solutions Zone will highlight advanced welding processes and provide high-qual ity interactive experiences that demonstrate devel opments and applications in the welding sector.

The Plastics Technology Zone will bring the lat est in plastics, related injection and blow moulding technology, recycling and toolmaking in one place.

AMW 2023 will also feature a comprehensive four day speaker program. Further details on this program will be released in the coming months

The Australian Manufacturing Technology Institute Limited (AMTIL) is a member-based organisation which represents the interests of man ufacturing technology suppliers and users working in precision engineering and advanced manufac turing. Since its establishment in 1999, AMTIL has engaged in a range of initiatives aimed at support

ing and promoting the industry in Australia. These include: Austech, Australia’s premier advanced manufacturing and machine tool exhibition; the industry-leading publication AMT Magazine; and an array of other services for its members.

Afourth-generation family business celebrating 90 years of engineering and adaptation is the only manufacturer of electric steam boilers in Australia today.

Simons Boilers started in 1932 and is now run by Derek Simons and his father, Robert, who have been work ing together for 30 years.

The milestone was celebrated at Sydney’s Powerhouse Museum in October with guests including one of the founders, Sol Simons, the brother of Derek’s grandfather.

Artisan carpenter Woolf Simons started the business making ice chests in the days before refrigera tion. Then with sons Asher, Percy and Sol, founded Simons Boiler Company.

In the late 1930s, Asher, a mechan ical engineer, invented a new way of pressing clothes using an electric iron with a small steam boiler.

“While he was delivering ice chests, he saw ladies ironing uniforms for the war effort and realised the way they were ironing was not productive,” said Derek, who joined the business in the 1990s.

“He went on to invent the first steam boiler and steam iron and pat ented it straight away.”

The invention of the Simons iron

was an instant success and later became part of Australia’s war effort.

A member of The Australian Industry Group (formally MTIA)

Our new 3 in 1 package allows food manufacturers to easily automate their production line and enjoy multiple benefits including significantly improved production efficiencies and reduced labour costs.

The package consists of a Storage Screener, Mi-CON Elevating Conveyor and Hopper Feeder. Like all our products, the

for over 70 years, Simons Boilers has grown into a leading supplier of steam and hot water boilers, steam humidi fiers and garment pressing machinery

throughout Australia.

Mr Simons describes the steam boiler as an unsung hero of industry.

“Most people don’t know how

components are constructed to meet the toughest WH&S standards whilst maintaining the highest quality and reliability that we are known for.

One of the key benefits of this modular package is that it eliminates equipment redundancy. It can be added to, extended and modified in the years ahead as your production needs evolve.

important this piece of equipment is,” he said.

“Steam boilers create steam, which is used in most industries, but they are rarely seen.

“Boilers are tucked away in the corner of plant rooms, quietly powering the more glamorous machines that make many of the products used in our daily lives.

“Everything you eat, drink and wear and even the medicines you take have all been processed using steam or hot water.

“Without steam boilers, we cannot operate on hos pital patients or make beer and whiskey.

“We can’t manufacture food items such as cornflakes, soups or ice cream. We can’t make concrete, press our clothes or heat buildings and pools. We can’t even make Covid vaccines.

“Each day, we field dozens of dis tress calls from our customers when these often-forgotten machines are out of action.”

The family’s willingness to pivot is one of the secrets to its success.

“When Asher was at the helm, clothing was predominantly made in Australia, so our steam boilers were in huge demand from clothing manu facturers,” Mr Simons said.

“However, that changed in the 1980s when clothing manufacturing started happening offshore. It meant we had to adapt our business model and begin selling overseas.”

Other challenges followed.

In later years, the export market for steam boilers into south-east Asia became under threat from cheaper boilers out of India and China, and the local market for electric steam boilers was challenged by cheaper fuel — natural gas. A defensive position