Suspension:permanentlypreventcaking/sedimentation

Toothpaste:preventsdryingup/waterseparationwhile givingfinetexture

Emulsion:preventsemulsionbreakingwhilegivingfinetexture

Tablets:Improvesdissolution,binding&flowproperties

Suspension:permanentlypreventcaking/sedimentation

Toothpaste:preventsdryingup/waterseparationwhile givingfinetexture

Emulsion:preventsemulsionbreakingwhilegivingfinetexture

Tablets:Improvesdissolution,binding&flowproperties

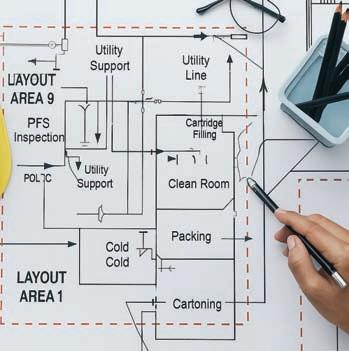

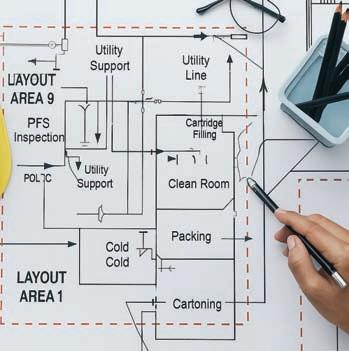

CustomToolRoom&MachiningSolutionsforEvolvingIndustries

AtKairishInnotech,ourfullyintegratedTool Room spans12,000sq.ft andishousedina temperature-controlledenvironment—ensuring idealconditionsforprecisionmachining,toollife, anddimensionalaccuracy.

Weserveawidespectrumofindustriesincluding pharmaceuticals,medicaldevices,packaging, foodprocessing,engineering,andautomation, offeringcustommachiningsolutionsforcomplex componentssuchas injectionmoulds,dies, tools,filling&washingneedles,changeparts, andmore.Whetherworkingwith plastics, metals,orhybridmaterials, wespecializeinfully bespokebuilds,tailoredtoyourfunctionaland operationalneeds.

01. 02.

08VMCs(VerticalMachining Centers)

3-axisand4-axisbyHAASandDMG

Moriforhigh-speed,high-precision manufacturing.

ElectricalDischargeMachining (EDM)

Fordetailedcavities,threading,and cylindricalpartmachining—ideal forintricateorhard-to-machine features.

03. 04. 05. 06.

Drilling&MillingMachines

Forreliable,repeatableshaping, cutting,andhole-makingacrossa rangeofsubstrates.

ChmerWire-CutEDM

Operatingwitha0.25mmwireand precisionupto±5microns,it deliversultra-finecutsinsteel, aluminum,copper,andalloys.

LaserWeldingSystem

Designedforultra-clean,highstrengthweldswithOD/ID concentricity<0.002mmand toleranceof0.005mm—essential forbothstructuralintegrityand aesthetics.

PrecisionLatheMachines

Enablingversatileturning,shaping, andsurfacefinishingwithtight tolerancesandhighrepeatability.

who helps you get to the finish line faster?

aquarius™ genesis

coating system

Who solves your customization needs? We do. Ashland Aquarius film coatings are carefully formulated and customized to achieve specific properties, depending on formulation requirements. And precise formulation is crucial for tablet appearance, performance, and processing. It’s also critical for achieving desired functionality like adhesion, strength, opacity, and more.

If you need technical support, customization, and a broad range of pharmaceutical film coating solutions, review our portfolio here Ashland.com/aquariusfilmcoatings and contact Ashland solvers –ashland.com/contact.

Chairman of the Board

ViveckGoenka

Sr.Vice President-BPD

Neil Viegas

Vice President-BPD

Harit Mohanty

Editor

Viveka Roychowdhury*

Editorial Team

Lakshmipriya Nair

Kalyani Sharma

Kavita Jani

Neha Aathavale

DESIGN

Art Director

Pravin Temble

Senior Designer

Rekha Bisht

Senior Artist

Rakesh Sharma

Marketing Team

Rajesh Bhatkal

Ashish Rampure

Production Co-ordinator

DhananjayNidre

Scheduling & Coordination

Pushkar Waralikar

CIRCULATION

Mohan Varadkar

26 STARTUPS: INDIA’S NEXTBIG BET ON PHARMA INNOVATION?

30 PRETTYRISKY: INDIA'S WELLNESS BOOM AND THE MISSING RULEBOOK

32

DIGITALTWINS: REVOLUTIONISING VACCINE TRIAL SITE PROCUREMENTIN DEVELOPING COUNTRIES

53 HOWPATIENT SUITES ARE RESHAPING THE FUTURE OF CLINICALTRIALS

P22: INTERVIEW DR SATISH WAGH CHAIRMAN,CHEMEXCIL, AND FOUNDER,SUPRIYA LIFESCIENCE

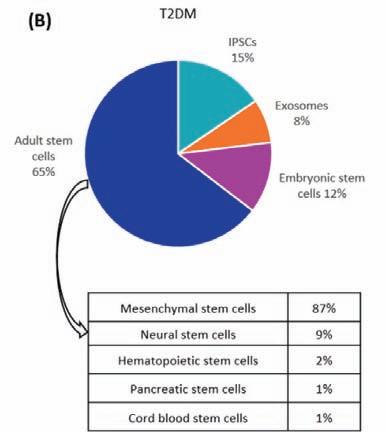

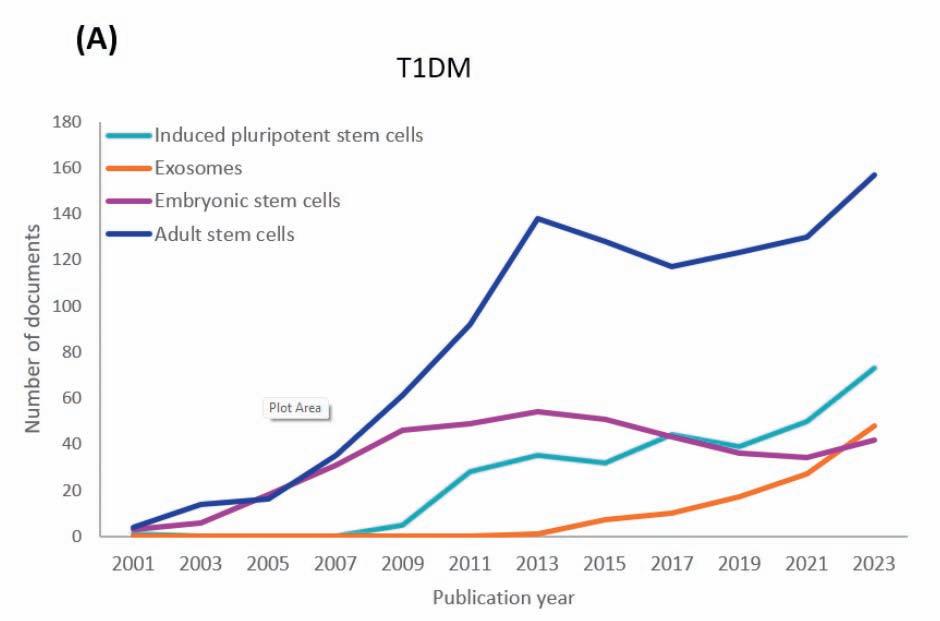

58 CAN STEM CELL THERAPYCURE DIABETES?

61 IIHMR UNIVERSITY'S ANNUALCONVOCATION 2025 FELICITATES 423 GRADUATES, HIGHLIGHTS GLOBALRECOGNITION AND ACADEMIC EXCELLENCE

Regd.With RNI No.MAHENG/2005/21398.Postal

Regd.No.MCS/164/2025 - 27.Printed and Published byVaidehi Thakar on behalf of The Indian Express (P) Limited and Printed at The Indian Express Press,Plot No.EL-208,TTC Industrial Area,Mahape,Navi Mumbai-400710 and Published at Mafatlal Centre,7th floor,Ramnath Goenka Marg,Nariman Point,Mumbai 400021.

Editor: Viveka Roychowdhury.* (Editorial & Administrative Offices: Mafatlal Centre,7th floor,Ramnath Goenka Marg,Nariman Point,Mumbai 400021) * Responsible for selection of news under the PRPAct.Copyright © 2017.The Indian Express (P) Ltd.All rights reserved throughout the world.Reproduction in anymanner,electronic or otherwise,in whole or in part,without prior written permission is prohibited.

“IDMA CARES should become what Indian pharma represents not just in molecules but in morals.”

This was Daara Patel, Secretary General, Indian Drug Manufacturers’ Association (IDMA), setting the tone on July 18, at the launch of IDMA CARES, an initiative which aims to strengthen workplace safety, Prevention of Sexual Harassment (POSH), and Environmental, Social, and Governance (ESG) principles. Express Pharma was a Media Partner for the launch and we’ll be featuring a detailed report soon but here are a few hard hitting comments that stayed with me.

Patel reiterated that “POSH, ESG are not just good ethics but smart business sense”, while Bharat Shah, National President, IDMA stressed that the industry cannot claim to save lives while polluting rivers, and must therefore deliver safe medicines while ensuring safe workplaces.

Neha Thakore, Chairperson, ESG Committee - IDMA, stressed that “doing good is no different from doing well” and urged pharma companies to consider laws like POSH as “reputational insurance”, and reframe their identity “as not just manufacturers but stewards of trust.”

For me, the highlight of the IDMA CARES launch was a panel discussion where Aditi Kare Panandikar, Managing Director, Indoco Remedies and P S R K Prasad, Director, Natco Pharma, shared how their companies have implemented sustainable practices. Meher Pudumjee, Chairperson,Thermax Group, highlighted that ESG is “not compliance but a competitive advantage” and is a “ticket to the world” with more regulators moving to cleaner, greener regulations around chemicals.

The panel was moderated by Sandeep Mohanty, PartnerSustainability Transformation, PwC India, who stressed that global clients are making it mandatory for suppliers and vendors to follow Scope 3 emission norms. Thus “sustainability does pay”, as it ensures ESG compliant companies have a competitive edge vis a vis those that do not follow global ESG norms.

While many pharma companies have started on the ESG path, we have a long long way to go. More importantly, the message has to filter down the line to suppliers and vendors. The recent explosion at Sigachi Industries where as many as 46 people died at its Pashamylaram plant in Sangareddy district, Telengana is the latest warning that workplace safety, a key part of ESG, needs to be top priority too.

The Sigachi Industries' Q1 FY26 results statement hints at the soul searching and introspection within senior ranks of the company, resulting in a ‘strategic realignment post Pashamylaram’. Amit Raj Sinha, MD & CEO, Sigachi Industries called the Q1 FY26 “an emotionally and operationally challenging quarter”, acknowledging that “the tragic incident led to the loss of lives and injuries among our workforce, and we extend our deepest condolences to all affected.”

The company has started the disbursal of interim compensation under the ex-gratia financial support package for the 46 families of the deceased and eight staff members who remain unaccounted for. Interim payments have also been made towards injury compensation and continues to support the families of three members still under medical care.

“This event has prompted a comprehensive review of our operational controls and risk governance," says Sinha. "Looking ahead, we are committed to a decisive reset, prioritising safety, accelerating cost improvements, focusing on margin-led portfolios, and rebuilding with global standards, resilience, and transparency. With the lessons behind us and our resolve strengthened, we are confident in our ability to deliver sustainable growth and improve

Proactively investing in employee and workplace safety is not just good for employees, but makes smart business sense

EBITDA margins.” This transparency is to be applauded and encouraged, and one hopes to see the company rebuild not just bigger but better than before.

Sigachi Industries is by no means the only company to have such incidents. On a recent post Q1 FY26 earnings call, Ashok Nair, Managing Director, RPG Life Sciences disclosed that the company’s API business had a temporary sales impact due to a fire incident at their Navi Mumbai-based API manufacturing plant in January. Thankfully there were no casualties, and as per Nair, “a dedicated team of 155 professionals is working on restoring the plant with a completion target in Q2.”

“RPG Life Sciences is built on a people-first, safety-first culture” and Nair credits the emergency response team, the RPG Group’s long standing manufacturing expertise across sectors from tyres to infrastructure and good insurance coverage that will allow the company to recover and get back on track. 85 per cent of APIs manufactured at the impacted plant were exported, 15 per cent were for the domestic market.

These statements underline the multiple ramifications of such incidents. At an individual level, such incidents leave a scar on the lives of the affected individuals and their families. At a company level, rebuilding physical infrastructure will have to go hand in hand with rebuilding trust with employees and clients. Thus proactively investing in employee and workplace safety is not just good for employees, but makes smart business sense.

However, one wonders how many such tragedies remain unreported in smaller unlisted companies, especially those in far flung industrial manufacturing zones? Do employees and their families receive adequate help with medical expenses and compensation for injuries and deaths? There are many MSMEs that serve the pharma industry, and not all of them are as visible as listed companies who are mandated to inform stock exchanges and answer to investors. Therefore, one has to assume that the incidence of such accidents and death tolls would be much higher.

While larger companies have the organisational bandwidth to disburse compensation (offset by partly insurance etc) and recover from the business setback, many other companies are not in the same position. They would prioritise a back-to-business policy, without rectifying faulty practices and employees would remain at risk.

Such incidents could tarnish the image of India’s pharma industry as a whole, just as promising bilateral agreements like the recent India-UK Free Trade Agreement (FTA) fructify after years of negotiation. UK PM Keir Starmer in fact reportedly termed it “the most significant deal since the UK left the EU.”

Namit Joshi, Chairman, Pharmexcil underlines that with India's pharma exports to the UK reaching $914 million in FY24, the India- UK FTA agreement strengthens supply chains, enhances access to affordable medicines, and drives Foreign Direct Investment (FDI).

According to his statement, this partnership paves the way for collaborations in bulk drug imports, CDMO, and joint research, empowering India’s competitive edge and promoting global partnerships.

India's pharma sector is already globally connected and has a reputation to uphold. Thus besides the moral case of putting employee safety first, workplace safety makes good business sense. If only to avoid disruptions to production schedules, revenue erosion and reputational damage.

VIVEKA ROYCHOWDHURY, Editor viveka.r@expressindia.com viveka.roy3@gmail.com

India’s chemical companies are undergoing a strategic transformation to be an integral part of global

Dr Satish Wagh, Chairman,CHEMEXCIL,and founder,Supriya Lifescience,discusses how the COVID-19 pandemic prompted Indian chemical exporters to rethink sourcing strategies, build domestic capacities,and embrace quality standards.He also shares insights on export trends,FTAutilisation,digital transformation,and policy recommendations for long-term sector resilience,in an interview with Viveka Roychowdury .Edited excerpts below…

Dr Wagh, as Chairman, CHEMEXCIL, and as the interface between government and industry, what are the learnings from the COVID era that have been incorporated by memberexporters connected to the pharma and life sciences sector?

The COVID-19 pandemic exposed vulnerabilities and offered important lessons for Indian chemical companies, shaping strategies to build resilience and competitiveness.

As a CHEMEXCIL chairman I have interacted with various sector companies. Heavy reliance on China for raw materials of key inputs led to shortages during lockdowns. Indian companies learned to diversify sourcing to countries like South Korea, Japan, and Europe, and prioritise local suppliers to overcome geopolitical and logistical risks.

Most Indian chemical and pharma companies rapidly expanded their inventory, stock, etc. Large scale manufacturing companies accelerated efforts to produce key inputs locally, reducing import dependency and ensuring supply stability.

IPA (isopropyl alcohol) shortages during the pandemic highlighted India’s overreliance on Chinese imports. It is sad to mention that some of the Indian companies manufacturing IPA are creating a monopolistic

India currently has 14 FTAs in effect,including those with EFTA, UAE,and Australia.In most of these FTAs chemicals are covered under preferential tariffs and are a good opportunity for Indian chemical exporters

situation by insisting that the department put anti-dumping duty on imports of IPA from China.

During COVID pandemic domestic companies inflated the cost of IPA and controlled the supply that ultimately burdened consumers. In fact, IPA prices in India had surged from ?65/kg to ?190/kg, (during March 2024).

As a CHEMEXCIL chairman I took the lead and strongly opposed the proposed imposition of anti-dumping duties on imports of IPA originating from China due to its potentially adverse consequences.

I appreciate the call for BIS standards which are important for domestic/pharma-grade material.

CHEMEXCIL as a part of capacity building initiative did the exporter engagement, organised various workshops, virtual sessions on BIS, QCO standards, ZED certification, etc. Liaised with competent authorities of BIS and Department of Chemicals and Petrochemicals, Govt of India on these issues.

What have been the cumulative export trends of your member companies in this category? Which are the segments showing an upward trajectory for the next few years?

Overall, the cumulative export trends for our CHEMEXCIL

member companies in the chemical sector have been quite robust over the past 20 years, demonstrating significant growth.

During 2004-2005, the exports of chemicals were USD 3.3 billion and now after 20 years it has reached USD 21 billion. (It includes the exports of Dyes, Dye intermediates, Basic Organic Inorganic Chemicals Including Agrochemicals, Cosmetics Soaps, toiletries, essential oils, Castor oil and Specialty Chemicals. It does not include petrochemicals).

While the chemical sector has faced some headwinds globally, our member companies have shown resilience in maintaining stable export levels.

The segments which will show an upward trend in the coming few years because of enough and added domestic capacities are Organic Chemicals, Organic Intermediates, Inorganic Chemicals especially Alkali Chemicals, Agrochemicals especially Herbicides, Insecticides and Fungicides, Cosmetics and Essential oil, Green Chemicals and Specialty Chemicals

What has been the impact of recent geopolitical moves like FTAs, tariffs etc on exports of your member companies?

Frankly the impact of recent

TranschemoffersBASF’sKollicoat® SR30Dand Kollidon® SRforpH-independentsustainedrelease formulations.

Kollicoat® SR30D isapolyvinylacetateaqueous dispersionstabilizedwithpovidoneandsodium laurylsulfate.

Thelowviscosityproducthasaweakcharacteristicodour andamilkywhiteorslightlyyellowishappearance.

•AmenableasaWetbinderforgranulationprocessesand/orcoatingapplicatio forsustainedrelease

•Providingconstantandreliabledrugreleaseinallintestinalfluids

•Drugreleaseprofilecanbeeasilyoptimizedwithcompatibleporeformers

•Providesmoderatetaste-maskinginmultipledosageforms

Kollidon® SR isaco-processedexcipientwitha compositionofpolyvinylacetateandpovidone.

Theproductisobtainedbyspray-drying.Itissuppliedas slightlyyellowish,free-flowingpowder.

•Thematrixformerprovidingsuperiorsustainedrelease

•Providingconstantandreliabledrugreleaseinallintestinalfluids

•Reliableprocessingduetoexcellentflowandcompressibilityfeatures

TranschemCorporationPharmaPvt.Ltd.

D421/422,NeelkanthBusinessPark,StationRoad,Vidyavihar(W), Mumbai-400086

Email:sales@transchemcorp.com

Phone:+91022-49711633

Web:www.transchemcorp.com

ons

geopolitical moves like FTA and tariffs is very positive on the Indian chemical sector.

From time-to-time the department is consulting CHEMEXCIL for negotiating the FTAs with partner countries. India currently has 14 FTAs in effect, including those with EFTA, UAE, and Australia. In most of these FTAs chemicals are covered under preferential tariffs and are a good opportunity for Indian chemical exporters.

But somehow most of the members (especially MSMEs) are not aware about these FTAs and rules of origin for preferential access. Hence FTAs are underutilised by Indian chemical companies. Hence, we organised a knowledge base session on FTA and its utilisation.

Hopefully in coming years this situation will be rectified and Indian chemical exporters can take the full advantage of these FTAs. As regards US reciprocal tariffs on Indian chemicals, Indian chemical industry has minimal impact on exports. There is no impact on imports of chemicals from the US to India. However, we have suggested that the department accelerate BTA with US covering preferential access to the US. This will boost Indian chemical exports.

How are your member companies ensuring that they are more integrated into global supply chains? How are digital tools helping to capitalise on identifying export opportunities?

Indian chemical companies are

undergoing a strategic transformation to be an integral part of global supply chains and explore new export opportunities across nontraditional markets by various initiatives.

Companies are investing in domestic feedstock production to reduce reliance on imports. They are also focusing and increasing investment in research and development.

Secondly, the Government is developing chemical hubs and upgrading port infrastructure to streamline logistics and reduce costs. And thirdly, the government is engaging with various countries and blocs for FTAs.

Digital transformation is playing an important role in helping Indian chemical companies. Analytics and

machine learning are being used to predict demand, optimise formulations, and identify high-potential export markets. Companies are using targeted digital marketing to reach global buyers and drive cross-border sales. Real-time tracking of shipments and inventory through advanced devices is enhancing the supply chain.

What are the policy suggestions from CHEMEXCIL to prevent future shortages of key input ingredients, etc?

To prevent future shortages of key chemical ingredients in India, the government and industry should come closer and address challenges like import dependency, infrastructure gaps, and

regulatory delays.

◆ Expand Domestic Feedstock Production by way of technology upgradation and R&D.

◆ Upgrade existing chemical clusters e.g., PCPIRs

◆ Streamline Environmental Clearance process

◆ Implement Production Linked Incentive Scheme for feedstock production

◆ Promote R&D in Chemical Sector by providing tax benefits

◆ Enhance skills of Industry people

◆ Improve port and logistic infrastructure.

◆ Negotiate Product Specific Rules in FTAs

Viveka Roychowdury, Editor viveka.r@expressindia.com viveka.roy3@gmail.com

While India’s pharma startups can resolve scientific and systemic blind spots,funding remains the missing link blocking scalable impact,finds Neha Aathavale

While established pharma companies focus on strategy and scale, pharma-focused startups in India are quietly laying their groundwork. Not yet driven by scale, but certainly by possibility. These early-stage ventures are doing the work that bigger players sometimes overlook: filling out the missing parts of India’s pharma jigsaw.

Rather than positioning themselves as challengers to big pharma companies, pharma startups are emerging as its R&D scouts; de-risking early innovation, translating academic research into viable therapies, and plugging capability gaps in areas like drug delivery, repurposing, and AI-led discovery. With risk-tolerant capital cautiously entering the fold, public schemes nudging R&D beyond academia, and large pharma firms showing interest in early-stage partnerships, the foundations are being laid. Can India now build the kind of patient, high-stakes startup ecosystem pharma innovation needs; before this quiet ambition loses steam?

Numbers sayit all The Indian pharma startup ecosystem is grappling with a pronounced funding downturn. "The Indian pharma space witnessed its peak funding in 2018, with a total of $399M raised. Since then, the industry has experienced a declining trend,” says Neha Singh, Co-founder of Tracxn. As of May 31, 2025, total funding stands at $25.3 million—down 75 per cent and 52 per cent compared to $101 million and $53.1 million raised during the same period in 2024 and 2023, respectively.

Singh attributes this decline to a mix of global and local challenges, “The slowdown is likely driven by a mix of global pricing pressures, regulatory shifts, and changing export dynamics, including stricter

scrutiny of pharmaceutical exports from India and adjustments in domestic drug pricing policies.” She adds that policy developments in key export markets, aimed at reducing

The Indian pharma space witnessed its peak funding in 2018,with a total of $399M raised.Since then,the industry has experienced a declining trend

Neha Singh Co-founder of Tracxn

In India,while there is vibrant startup energy across technology and health tech,pharma-only startups have yet to secure sustained investor traction

Sudarshan Jain

Secretary General,Indian

Pharmaceutical Alliance (IPA)

cines. Another deal came from Exsure, which raised $347K in seed funding for its nano drug delivery platform targeting cancer.

While aggregate numbers remain modest, Singh emphasised that such deals signal India’s continued relevance in global pharma innovation, “Despite recent headwinds, the sector’s ability to attract substantial investments in cuttingedge areas highlights its underlying strength and the continued global relevance of Indian pharma innovation,” Singh adds.

The Indian pharmaceutical sector has not seen any significant "big-ticket" VC deals in recent times,contrasting sharply with the more robust funding environment in the US,UK,and China

Aurojyoti

Bose Lead Analyst at GlobalData

drug costs, have “further intensified the challenges” for Indian pharma players; making investors more cautious.

Yet, May 2025 offered some respite. Funding that month hit

the year’s highest, marking an 11 per cent increase over May 2024. This was largely due to a $25M Series C round by Pharmazz, a clinical-stage company developing critical care medi-

Sagar Pawar, Partner & Lead, Lifesciences & Medical Devices, Deal Advisory - M&A Consulting at KPMG India, echoed the cautious optimism, “the Indian life sciences startup ecosystem attracted approximately $307 Mn in funding in 2024, marking a 36 per cent increase over 2023.” This growth, he says, reflects “sustained investor confidence in the sector’s innovation trajectory.” Pawar points to strong momentum in three areas: diagnostics and POC testing, biopharma ventures, and AI-powered imaging and screening in medtech. “This is driven by the growing demand for personalised medicine and tech-enabled healthcare solutions.”

However, the size and scale of venture capital deals in India still lag behind global counterparts. “The VC funding landscape for Indian pharmaceutical startups has been notably smaller in scale compared to their counterparts in western markets such as the US and the UK, as well as regional peers like China,” says Aurojyoti Bose, Lead Analyst at GlobalData. “India did not see many VC deals in 2025 so far,” he notes, and the ones that did happen lacked the high-value transactions common in the West.

Bose points out that “the Indian pharmaceutical market is

Confidently power your scientific IP research with CAS Solutions. The STN IP Protection Suite™ connects you to quality IP insights that spark innovation, uncover opportunities, and mitigate risk.

Learn more at cas.org

characterised by a focus on cost-effective production rather than high-value innovation,” but believes this may shift as Indian firms boost their R&D capabilities.

Encouragingly, some investors are doubling down. “Mumbai Angels has invested in Mestastop Solutions, a firm focusing on cancer metastasis drug discovery, twice,” Bose highlights; once in 2020 and again in 2024, indicating “ongoing investor confidence.”

Srikanth Mahadevan, Director, Deloitte India, notes that the investment climate is gradually improving. “Private venture capital was slow to embrace this space - historically, only a small fraction of India’s 10,000+ biotech startups secured funding,” he says. But momentum is building; in May 2025 alone, Indian pharma startups raised around $254M, including one early-stage company securing over $150M in a single round. “This uptick underscores that institutional investors and VCs are actively exploring pharma opportunities now.”

Offering the pharma industry’s view, Sudarshan Jain, Secretary General, Indian Pharmaceutical Alliance (IPA) states, “Globally, 2024 has been a relatively encouraging year for pharma and biotech investments, particularly in sectors such as AI-driven drug discovery.” But in India, “pharmaonly startups have yet to secure sustained investor traction.” The reason? The sector’s long gestation periods and capital-intensive nature. Still, Jain acknowledges “green shoots are emerging in areas such as novel drug delivery platforms and deep-tech R&D”, early indicators of longterm potential if the right enablers are in place.

Whyriskcapital still hesitates

Despite growing interest in pharma innovation, early-stage startups in India face a steep climb, especially when it comes to securing funding.

“Bringing a new drug or therapy to market involves navigating complex clinical trial and approval processes under

agencies like the CDSCO,” says Mahadevan. “Market entry can be delayed by 2–3 years just in obtaining approvals for a novel drug.” This prolonged regulatory timeline not only slows down growth but adds significantly to costs. “Developing a new drug in India can cost upwards of ?1,500 crore (around $200 million),” he explains, with R&D and trials consuming both time and capital. That, combined with a high failure rate (many drug candidates never make it to market), makes many investors cautious. “In contrast to quick-tomarket tech startups, pharma ventures require patience and specialised expertise, so raising capital is a constant hurdle.”

Market dynamics present further complications.

“Pharma startups must compete with well-established domestic and multinational companies,” says Mahadevan. Carving out space in India’s competitive generics market demands major resources and

Pharma startups are increasingly becoming critical players in the broader pharmaceutical ecosystem,with strong potential to bridge key strategic gaps

Sagar Pawar Partner & Lead,Lifesciences & Medical Devices,Deal Advisory - M&AConsulting,KPMG India

“Investors in India’s pharma startup space are increasingly drawn to innovation across the value chain, with a strong focus on AI integration, real-time diagnostics, precision medicine, and digital therapeutics.”

Investors are gravitating towards pharma startups that either push the frontier of science (new therapies, biologics,precision medicine) or innovate on process and business model (platform technologies, outsourced R&D/manufacturing,or digital efficiency tools)

Srikanth Mahadevan Director,Deloitte India

brand credibility, assets most young firms lack. Even after launching a product, startups must contend with price controls on essential drugs, which cap margins and impact profitability. “This means even a startup with an approved product might face profitability challenges due to government price controls on drugs,” he notes.

Intellectual property (IP) is another pain point. “Securing patents in India is a lengthy process—often taking five years or more,” Mahadevan adds. During that time, startups are vulnerable to having their innovations reverse-engineered or copied. “Such IP delays and the threat of reverseengineering or counterfeiting discourage innovation.”

Beyond regulation and IP, structural challenges persist: access to efficient manufacturing, cold-chain logistics, and quality distribution is limited for smaller players. “Cuttingedge pharma R&D requires

highly skilled scientists and regulatory experts, and startups must compete with big pharma companies to hire and retain this limited talent pool,” Mahadevan says.

In short, the sector’s hurdles include “long regulatory cycles, capital intensity, funding constraints, IP delays, intense competition, pricing pressure, and talent gaps.” None are insurmountable, but they demand strategic agility. “Entrepreneurs need to form strategic partnerships, tapping government grants, or focusing on niche markets to gain traction despite these barriers,” he advises.

Even with the challenges, the appetite for pharma startups is growing. Particularly those innovating across the value chain with deep-tech capabilities, digital platforms, and sciencefirst approaches.

Pawar notes a marked shift,

He also highlights the rise of AI-as-a-service for pharma: startups are using proprietary engines and generative AI for drug discovery, lead optimisation, and molecular screening. Meanwhile, commercial pharma platforms are redefining how pharma reps engage with healthcare professionals (HCPs) through CRM-powered, data-driven tools, and a new generation of patient-facing startups is integrating digital therapeutics to manage chronic conditions.

Startups developing personalised therapies, especially those aligning with global precision medicine trends are also commanding attention. “Clinical innovation is not just a buzzword; it’s where the frontier lies,” adds Pawar.

Mahadevan underscores that biopharma innovation remains the most dominant theme, accounting for 42 per cent of all life sciences startup funding in recent years. “With an estimated $100+ billion worth of biologic drugs set to go off-patent globally by 2030, Indian startups in the biosimilars space are especially attractive,” he explains. Indian companies that can produce affordable, high-quality biosimilars are well-positioned to claim a global share. “Biosimilars in India are expected to grow at nearly 30 per cent CAGR through 2027,” notes Mahadevan, calling it one of the hottest verticals for investors.

“In summary,” Mahadevan notes, “investors are gravitating towards pharma startups that either push the frontiers of science (new therapies, biologics, precision medicine); or innovate on process and business model. These areas align with both India’s comparative advantages and global pharma trends, offering the most promise for high returns.”

Backing the breakthroughs While investor interest in

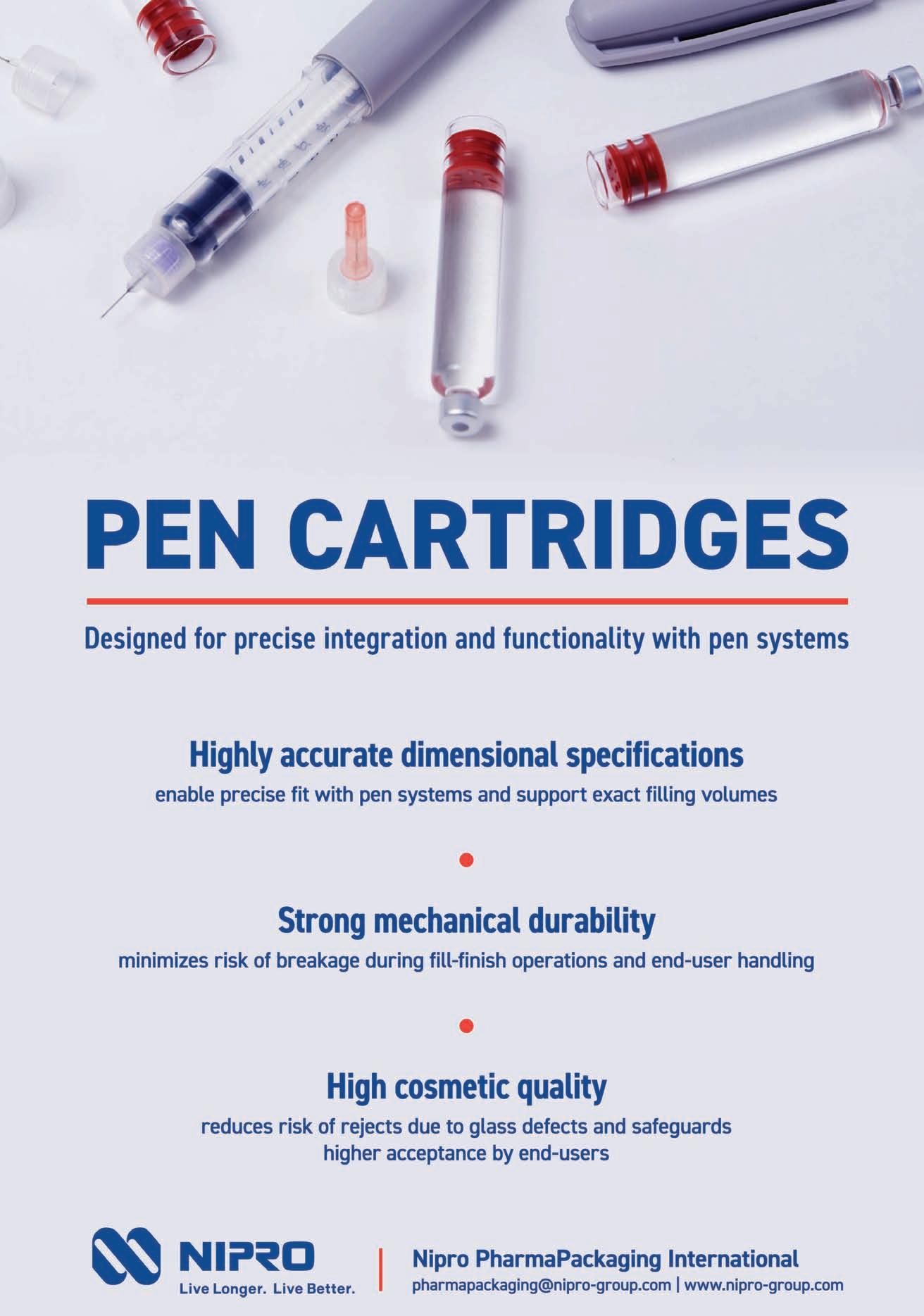

H6-10: High-speed fillingwithprecisionandcare

⚪ OptimizedforGLP-1:gentlehandlingandaccuratedosing

⚪ Provenreliabilityincommercialmanufacturing

⚪ Outputupto38,000/h

⚪ ProcessesRTUsyringes(glass&plastic),vials,andcartridges

⚪ Optionalvacuum filling&stoppering

⚪ StatisticalIPCforconsistentquality

⚪ Handleswaterytohighlyviscous,non-toxictotoxicproducts

OPTIMApharmaGmbH 74523SchwaebischHall|Germany|pharma@optima-packaging.com|www.optima-packaging.com/pharma

OPTIMAIndiaPackagingMachinesPvt.Ltd. unit110,1stfloor|BrigadeRubix,PlotNo.20|HMTmainroad|Bangalore560013|info-in@optima-packaging.com|Phone:+918046525900|www.optima-packaging.in

pharma innovation is clearly rising, the ecosystem still needs strong policy scaffolding to help startups translate their ideas into viable, scalable businesses.

According to Jain, one of the most immediate needs is more accessible capital; both domestic and international, including FDI, NRI funding, and cross-border venture capital.

Government efforts like the Promotion of Research & Innovation in Pharma MedTech (PRIP) scheme and the newly launched Research Development and Innovation (RDI) scheme are timely and welcome. However, he notes that the current funding cap of ?1 crore per startup under PRIP may not be sufficient. Suggests that grants in the ?5–8 crore range would be more effective in helping startups reach critical early milestones and build investor confidence. “These are

necessary to unlock subsequent rounds of funding and build investor confidence.”

Bridging the gap

With policy support firming up and investors gradually warming to science-driven ventures, the conversation naturally turns to the role of startups in India’s pharma ecosystem. Are they peripheral actors or could they become critical enablers of innovation?

According to Mahadevan, “pharma startups play a crucial, complementary role in India’s broader pharmaceutical ecosystem by filling innovation gaps and injecting agility into the industry.” While large pharma companies continue to dominate high-volume manufacturing and distribution, startups bring a sharper focus to untested ideas, emerging technologies, and high-risk research that big players may ini-

tially shy away from.

He adds that Indian startups often act as “innovation scouts for the industry,” working on new drug targets, AIpowered discovery tools, or advanced drug delivery systems. These ventures don’t just introduce new ideas, they often make them viable enough for scale, licensing, or acquisition. In doing so, they “significantly expand the pipeline of potential treatments that large pharma can eventually bring to market.”

However, despite this symbiotic potential, scalability remains a critical concern. Jain points out that India has “India has many essential pillars in place: world-class scientific talent, a growing base of academic–industry partnerships, and an evolving regulatory framework.” Yet startups often struggle to scale domestically. He highlights two barriers: lim-

ited domestic risk capital and a “cultural bias against failure.”

As a result, many startups register overseas to access what Jain calls “patient capital, mentorship, and global markets.”

To counter this trend, he recommends fostering a more supportive environment through policy and financial mechanisms. “Indian investors must adopt a higher-risk, highreward mindset, supported by policy guarantees like the RDI scheme, targeted grants, IP protections, and public–private translational hubs.”

Mahadevan reinforces this point, acknowledging that “pharma startup investment has lagged behind healthtech, primarily due to longer development timelines, higher costs, stricter regulation, and a historically lukewarm investor ecosystem for deep science ventures.”

However momentum is

building. Deloitte concludes on an optimistic note, “The good news is that this gap is starting to narrow as stakeholders recognise the immense longterm value pharma innovation can create. Investors are slowly gaining confidence as they see success stories and as government funds help de-risk early stages. Pharma entrepreneurship is inherently a long game, but with supportive trends now in motion, it may begin to catch up to the buzz of healthtech in the coming years.”

Together, these insights suggest that while Indian pharma startups are still finding their footing, they are well-positioned to plug innovation gaps, bring agility, and enable India’s shift up the value chain.

neha.aathavale@expressindia.com

nehaaathavale75@gmail.com

Swaroopa Bhatkar, Independent Researcher highlights that India’s aesthetic medicine and wellness industry,a fast-growing sector thrives in a legal grey zone,raising urgent questions about safety and accountability

Apandemic of oversight— but not for beauty

In 2020, as the world tackled emergency vaccine approvals and global headlines dissected clinical trials, in India, another kind of medical industry was flourishing in silence. Cosmetic clinics, offering facelifts, liposuctions, and hair transplants, continued to grow unchecked. Unlike pharmaceutical companies, which faced intense scrutiny during COVID, these beauty businesses operated in a legal grey zone, without dedicated regulations, licensing protocols, or standardized safety measures. Five years later, the story hasn’t changed.

The recent Express Pharma article, ‘Beauty Boosters and the Law: Who’s Watching India’s Wellness Market?’ (July 2025), reflects a regulatory landscape that seems to have remained largely unchanged over the past five years. The

concerns it raises, lack of oversight, the marketing of invasive treatments as wellness offerings, and blurred boundaries between medicine and consumer aspiration, strikingly mirror the patterns documented in a 2020 sociological study on India’s cosmetic surgery sector. That these parallels persist half a decade later suggests that the gaps noted then have not just endured, but perhaps deepened.

The question is no longer whether this industry is growing. It’s why we still aren’t watching.

During my master’s thesis (Engineered Beauty, 2020), I interviewed doctors and clients in Mumbai and Ahmedabad to study the cosmetic surgery boom. What I found was less about vanity and more about

social performance. Middleclass consumers were driven by workplace pressures, marriage markets, and digital self-presentation. Clinics operated like salons, offering EMI options and festival discounts. Regulation was almost invisible as patients signed consent forms, but risk disclosures were rarely explained in full.

Now, five years later, Express Pharma reports the same dynamics, only with new packaging. IV drips and injectable “wellness” boosters are marketed with the same aspirational language and unchecked claims. And just like in 2020, the rules are either too broad or too absent to matter. Additionally, influencers, not doctors, are shaping medical decisions.

Whythe regulation gap persists

A 2025 blog from SRMIST on aesthetic medicine confirms

that India has no specific regulatory framework for cosmetic or aesthetic procedures. They are loosely governed by the Indian Medical Council Act and general medical ethics, but no separate licensing body or regulatory mechanism exists to address this growing sector. This legal vacuum creates a two-tier reality; Firstly, Aesthetic procedures borrow the legitimacy of medicine, yet escape the strict oversight applied to pharmaceuticals or clinical healthcare. Secondly, Safety standards, advertising claims, and practitioner qualifications remain largely self-regulated.This raises an important question for the broader healthcare and pharmaceutical community: as a medically driven industry continues to expand rapidly, how can we ensure it is accompanied by frameworks that uphold quality, safety, and

Cosmetic medicine in India sits at the intersection of aspiration and clinical practice,but without a regulatory framework that reflects this duality.As the industry evolves,so must our approach to governing it,not to curb its growth,but to ensure that innovation is met with responsibility,and that choice is backed by care

ethical accountability?

The wellness boom: From surgeryto serums

The rise of injectable skin boosters and “glow” therapies represents the natural evolution of what I observed five years ago. The middle-class desire to “upgrade” the body has shifted from the scalpel to the syringe. While procedures are

marketed as “minimally invasive,” the risks - from infections to long-term side effects are real, especially in clinics where medical training is questionable.In 2020, the cosmetic surgery market was projected to grow exponentially. In 2025, the numbers are even larger, fueled by social media trends, influencer marketing, and post-pandemic wellness narratives. Yet,

the regulatory conversation lags far behind the business curve.

The unasked questions

Why does India hold pharma to rigorous compliance audits while allowing the aesthetic sector to operate in shadows?

Shouldn’t procedures that pierce skin, inject chemicals, or alter facial structure be moni-

tored as closely as any medical device?

These are not abstract questions. In both 2020 and 2025, the absence of oversight means the consumer bears the risks, often unknowingly. Cosmetic medicine in India sits at the intersection of aspiration and clinical practice, but without a regulatory framework that reflects this duality. As the industry evolves, so must our approach to governing it, not to curb its growth, but to ensure that innovation is met with responsibility, and that choice is backed by care. It’s not about slowing down the industry. It’s about giving it the structure it needs to grow safely, ethically, and with the confidence of those it serves.

The mirror may flatter, but it won’t protect. And a blind spot, left long enough becomes the norm.

Gourab Ray, Category Buyer,Sanofi Healthcare India,draws from his experience and real-world challenges,to explain how digital twins bring predictive power and resilience to vaccine trial procurement

Having spent significant years navigating the complex landscape of pharma procurement across developing countries, I've witnessed firsthand the challenges that can make or break vaccine clinical trials. From equipment failures in the Philippines that compromised an entire cold chain to customs delays in Malaysia and Vietnam that held up critical trial supplies for weeks, these experiences have taught me that traditional procurement approaches simply aren't equipped for the unique demands of vaccine trials in resource-constrained environments.

The emergence of digital twin technology represents what I believe to be the most significant advancement in procurement risk management since the introduction of enterprise resource planning systems. Unlike conventional monitoring tools, digital twins create comprehensive virtual replicas of entire procurement ecosystems, enabling us to predict problems before they occur and optimise resource allocation in ways that were previously impossible.

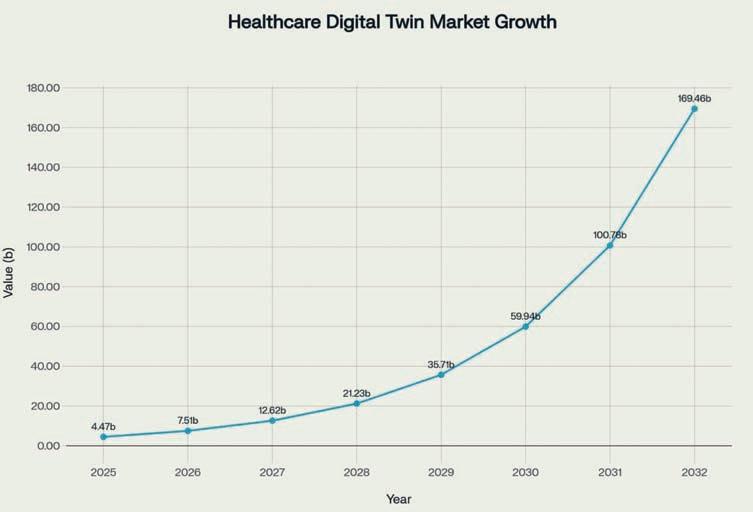

The global healthcare digital twin market's explosive growth—from $4.47 billion in 2025 to a projected $169.46 billion by 2032—reflects an industry-wide recognition that these technologies are no longer experimental but essential for competitive advantage¹. For vaccine trials in developing countries, where infrastructure limitations and regulatory complexities create cascading operational risks, digital twins offer a path toward truly resilient procurement operations.

My experience managing vaccine trial procurement across Bangladesh, Pakistan, Nepal, India, Vietnam, Philippines, Indonesia, and Malaysia has revealed consistent patterns of vulnerability that traditional approaches struggle to address.

The procurement of services, materials, goods, ancillary supplies, software, and medical devices for clinical trial sites involves coordinating hundreds of suppliers, managing complex regulatory requirements, and ensuring cold chain integrity across diverse geographical and infrastructure conditions.

The challenges extend far be-

but also the manufacturing schedules of local suppliers. In Nepal, the 18-month preparation time required to establish Phase

These aren't isolated incidents—they represent systemic challenges that require systemic solutions.

The COVID-19 pandemic amplified these vulnerabilities dramatically. Supply chain disruptions that might cause minor delays in developed markets can halt entire trials in developing countries, where alternative suppliers and logistics networks are limited. The interdependence of global supply chains means that a manufacturing disruption in China can affect API availability in India within days, while regulatory changes in one country can create bottlenecks that ripple across entire regional trial networks.

yond simple logistics. In Bangladesh, I've seen how unreliable electricity supply affects not just cold chain equipment

III vaccine trial capabilities demonstrates how human resource constraints compound procurement complexities².

Digital twin technology transforms procurement from a reac-

tive discipline into a predictive science. Rather than responding to disruptions after they occur, digital twins enable us to model potential scenarios, test mitigation strategies, and optimise resource allocation before problems manifest in the real world.

The technical foundation encompasses IoT sensors that monitor critical parameters such as temperature, humidity, location, and equipment status throughout vaccine supply chains. These sensors provide continuous data streams that feed into machine learning algorithms, enabling early detection of potential disruptions and proactive intervention strategies. Cloud infrastructure provides the computational power necessary for real-time simulation and scenario modeling, while integration with existing ERP systems ensures seamless data flow and comprehensive supply chain visibility.

What excites me most about this technology is its ability to address the specific challenges I've encountered in developing country procurement. When I consider the customs delays I've experienced in Vietnam, digital twins can model entire clearance processes, incorporating historical data on clearance times, current port congestion levels, and regulatory changes. This capability enables proactive identification of potential delays and implementation of alternative strategies before critical materials are affected.

Strategic framework: The enhanced Kraljic Matrix

The integration of digital twin technology with the Kraljic Matrix provides a robust framework for categorising and managing procurement items based

on supply risk and profit impact. This established tool, when enhanced with real-time digital twin capabilities, transforms static risk assessments into dynamic, predictive management systems.

Strategic items in vaccine trials include ultra-specialised cold chain equipment, rare vaccine components, and highly trained clinical personnel. These items are characterised by high supply risk and high profit impact, making their management critical for trial success. Digital twins enable predictive maintenance of refrigeration systems through continuous monitoring of compressor performance, temperature fluctuations, and power consumption patterns. Machine learning algorithms can identify subtle patterns indicating impending equipment failure, enabling proactive replacement before critical failures occur.

Bottleneck items such as specialized medical devices, regulatory documentation services, and logistics support services represent hidden vulnerabilities that can halt entire trials despite their relatively low cost. Digital twins excel at identifying and monitoring these vulnerabilities through comprehensive supply chain visibility and predictive analytics.

Leverage items including standard medical supplies, basic laboratory equipment, and commodity services represent opportunities where procurement teams can exercise significant buying power. Digital twins enhance leverage item management through real-time market intelligence and demand forecasting, enabling optimal timing of purchases and supplier negotiations.

Non-critical items often become critical in remote trial

•Monitoringoptimaltemperatureandhumiditylevelstoensure thehighestsafetyandqualityofsensitivegoods

•BluetoothconnectivityandUSB(optional),bothareavailable.

•16,000readingwitheasytraceabilityofallmeasurementvalues throughthefreetestoSmartApp

•Maximumflexibilitywithextremelysimpleoperation.

•Idealforpharmaceuticallab,storage,productionandhospital testoSmartApp forfreedownload

locations where replacement is difficult. Digital twins optimise inventory levels by balancing carrying costs with stockout risks in challenging logistics environments, incorporating consumption forecasting based on trial progress, seasonal variations, and local conditions.

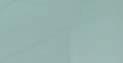

Through my analysis of industry implementations and discussions with colleagues who have piloted digital twin technologies, the measurable improvements across critical procurement areas are remarkable. The data demonstrates significant enhancements in operational efficiency and risk mitigation capabilities.

Site capability assessment shows the highest improvement potential, with organisations reporting up to 75 per cent enhancement in their ability to evaluate and optimise site capabilities before trial initiation³. This improvement directly addresses one of the most significant challenges I've encountered—understanding true site capabilities beyond what appears on paper.

Equipment procurement planning benefits significantly from digital twin technology, with 65 per cent improvement in forecasting accuracy and supplier management. This enhancement is particularly critical for complex equipment like ultra-low temperature freezers and specialized laboratory instruments, where procurement lead times can extend 6-18 months in developing countries.

Cold chain management represents another area of substantial improvement, with digital twin technology enabling 60 per cent enhancement in temperature monitoring, predictive maintenance, and route optimization. This capability is essential for maintaining vaccine integrity throughout the supply chain, particularly in regions with unreliable electricity and challenging transportation infrastructure.

One of the most frequent questions I receive from colleagues

concerns the investment requirements for digital twin implementation. Based on my research and industry benchmarking, the framework requires clear understanding of scale, scope, and financial responsibility across different implementation levels.

Per clinical trial site investment ranges from $25,000 to $50,000 per site in developing countries, covering IoT sensors, monitoring equipment, staff training, and basic connectivity infrastructure4. This represents only 0.1-0.2 per cent of typical Phase III trial costs while delivering 15-30 per cent efficiency improvements.

Per trial implementation for multi-site programmes requires $500,000 to $2,000,000 investment, covering single trials with 10-50 sites across multiple developing countries. This represents 1.5-6 per cent of Phase III trial budgets but delivers measurable procurement optimisation and risk reduction.

Company-wide digital twin platform requires $11.2 million total investment over 31 months, providing portfolio-wide capabilities across 5-10 concurrent trials. This represents 3.7-7.5 per cent of total portfolio value while delivering transformational capabilities and 85 per cent ROI upon full deployment.

The 2025 announcement requiring all new vaccines to undergo placebo-controlled clinical trials creates additional procurement challenges that digital twin technology can help address5. This "radical departure from past practices" increases trial complexity, duration, and resource requirements, particularly affecting developing country implementations where ethical considerations around placebo use are most complex.

Digital twin technology enables pharma companies to model the impact of extended trial durations on procurement requirements, optimise inventory management for longer study periods, and enhance supplier relationship management to ensure reliable supply throughout extended trials. The technology's simulation capabilities allow organisations to assess the procurement implications of placebo requirements before trial initiation.

Sanofi's substantial investment in digital twin technology provides compelling evidence of the technology's strategic value. The company's €900 million investment in EVolutive vaccine facili-

ties and advanced virtual patient population technologies demonstrates significant commitment to digital transformation6. The collaboration with Dassault Systèmes has enabled virtual testing of manufacturing processes before physical implementation, directly relevant to clinical trial supply chain challenges.

The company's digital twin implementations in manufacturing facilities—including predictive maintenance, process optimisation, and quality monitoring—provide direct parallels for site procurement applications. These capabilities enable remote adjustment of production parameters, virtual training for operators, and realtime supply chain optimisation, all of which translate effectively to managing procurement operations across distributed trial sites.

My experience across different developing country contexts has taught me that digital twin implementation must account for specific regional challenges and opportunities. South Asian countries including Bangladesh, India and Sri Lanka face particular challenges related to regulatory complexity, infrastructure reliability, and skilled personnel

availability.

India's substantial pharmal infrastructure provides opportunities for digital twin implementation at scale, but requires sophisticated approaches to manage complex supplier networks and regulatory requirements. The country's experience with clinical trials demonstrates both the potential for successful implementation and the need for comprehensive planning.

Southeast Asian countries including Vietnam, Philippines, Indonesia, and Malaysia present unique opportunities for digital twin implementation, particularly in cold chain management and equipment procurement. These countries' improving infrastructure provides a foundation for technology implementation while their growing pharma sectors create demand for advanced procurement capabilities.

African countries face the most significant infrastructure challenges but also represent the greatest opportunity for digital twin impact. The technology's ability to optimise procurement strategies in resource-constrained environments makes it particularly valuable for addressing the continent's vaccine trial procurement challenges.

Early digital twin adopters will gain valuable experience and develop capabilities that become increasingly difficult for competitors to replicate. The technology positions organisations for long-term competitive advantage in an increasingly digital healthcare landscape while contributing to improved global health outcomes.

Organisations should prioritise pilot implementations in high-risk, high-impact procurement categories where digital twin technology can demonstrate immediate value. This targeted approach enables rapid capability development while building organisational confidence for broader implementation.

Collaboration with established technology partners accelerates implementation timelines while reducing technical

risks. Strategic partnerships with proven digital twin providers offer access to validated platforms and implementation expertise, enabling faster time-to-value realisation for developing country vaccine trial operations.

Conclusion

The integration of digital twin technology with strategic procurement frameworks represents more than operational improvement—it's about fundamentally transforming how we approach the complex challenges of vaccine trial procurement in developing countries. My eight years in this field have convinced me that traditional approaches, while valuable, simply cannot address the dynamic, interconnected nature of modern global health challenges.

The convergence of market conditions, technology maturity, and proven business value creates an optimal adoption window for digital twin technology. Organisations that move decisively to embrace these capabilities will establish significant

Rather than responding to disruptions after they occur,digital twins enable us to model potential scenarios,test mitigation strategies,and optimise resource allocation before problems manifest in the real world

competitive advantages in vaccine trial procurement, ultimately contributing to improved global health outcomes and pharmaceutical innovation leadership. For those of us committed to advancing global health through innovative vaccine development, the question isn't whether to adopt digital twin technology, but how quickly we can implement it effectively. The technology offers a path toward truly resilient, predictive procurement operations that can navigate the complexities of developing country environments while ensuring the success of critical vaccine trials.

References

1. Markets and Markets. "Digi-

tal Twins in Healthcare Market by Application, Technology, End User - Global Forecast to 2030." Healthcare Market Research Reports, 2025.

2. HCP Live. "The Challenges of Vaccine Research in Developing Nations." Healthcare Communications, February 5, 2021.

3. Applied Clinical Trials. "How Digital Twins are Driving Sustainability in Clinical Supply Planning." Clinical Research Publications, June 18, 2025.

4. SSRN. "Real-Time Health Supply Chain Optimization Using Digital Twin Technology." Supply Chain Research Network, February 17, 2025.

5. The Vaccine Reaction. "'All New Vaccines' in the U.S. to Undergo Placebo-Controlled Safety Testing." Vaccine Policy Analy-

sis, May 28, 2025.

6. GSK. "Digital twin: using advanced technology to accelerate vaccine development." GSK Behind the Science Magazine, May 30, 2022.

7. PMC. "TWINVAX: conceptual model of a digital twin for immunisation services in primary health care centres."

PubMed Central, May 14, 2025.

8. Roots Analysis. "Digital Twins in Healthcare Market Size, Growth Analysis and Forecast 2024-2035." Healthcare Technology Reports, 2025.

9. IQVIA. "Clinical Data Analytics Solutions: Intelligent Document Review." Clinical Research Technology, 2025.

10. Deloitte. "End-to-End Digitalization of BioPharma Supply Chain." Healthcare Industry In-

Hall1,Booth:B01 18-20Sept,2025 HITEXExhibitionCentre Hyderabad

sights, 2025.

11. MIT Sloan Management Review. "Unlocking the Potential of Digital Twins in Supply Chains." Supply Chain Innovation, August 18, 2022.

12. Supply Chain Digital. "IoT: The Driving Force For Cold Chain Vaccine Distribution." Logistics Technology, July 11, 2021.

Disclaimer: The views, opinions, and insights expressed in this article are solely those of the author and are based on publicly available information and general industry practices. These views do not represent the official position, policies, or strategies of Sanofi Healthcare India Pvt. Ltd. or any of its affiliates. No proprietary, confidential, or trade secret information has been disclosed in this publication. The author has written this article in his personal capacity as an industry professional and any recommendations or conclusions are his own professional insights derived from experience in pharmaceutical procurement and supply chain management.

Website:www.srico-labworld.com|Telephone:+919900674407|Email:info@srico-labworld.com Bengaluru|Mumbai|Hyderabad|Bhubaneswar|Vadodara|Delhi

Chennai|Goa|Thiruvananthapuram|Pune|Visakhapatnam|Kolkata|Guwahati|Ahmedabad|Chandigarh|Lucknow

Industry leaders and innovators convene to decode the future of injectable therapies and showcase India’s growing strength in high-value injectables

The Injectable Innovations Conclave 2025 brought together leading minds to explore the next frontier in injectable drug delivery. The conclave featured breakthrough technologies, real-world case studies and thought-provoking discussions on manufacturing excellence, regulatory readiness, and the role of digital transformation in enhancing injectable therapies.

It began with a welcome address by Viveka Roychowdhury, Editor of Express Pharma, Express Healthcare, and Express Nutra, who outlined the vision behind the conclave. She highlighted the immense growth potential in the injectables market, driven by an aging global population, the increasing burden of chronic diseases, supportive policy shifts, and the wave of patent expirations opening up new opportunities for generics.

The welcome address was followed by the ceremonial lamp lighting, a moment that symbolised the official start of this knowledge-sharing initiative. Roychowdhury was joined by a distinguished group of industry leaders and partners.

L-R: Viveka Roychowdhury,Editor of Express Pharma,Express Healthcare,and Express Nutra; Klaus Braig,Global KeyAccount Manager, Uhlmann Pac-Systeme GmbH&Co.and MD,Uhlmann Switzerland;; Vidwans Rajendra Ramachandra,Senior Consultant – GMP,QA, and Sterile Dosage Forms,GAP& Consultant,Ami Polymer; ShaunakJ.Dave,MD & CEO,Antares Vision; Rajesh Bhatkal,GMExpress Pharma,Express Healthcare,and Express Nutra

Dr Pavan Bhat, CEO, Inventia Healthcare, set the tone for the day with a compelling presentation on the need to reimagine injectables through the lens of patient-centricity, technological precision, and environmental sustainability.

Dr Bhat emphasised that injectables are the lifeline of modern medicine, holding a dominant position in critical care, biologics, and vaccines. However, their growing importance is hindered by inherent challenges like working with fragile molecules, complex formulations, and the integration of increasingly sophisticated delivery devices.

As molecule diversity expands, so too does formulation complexity. This requires inn ovation that solves scien-

Dr Pavan Bhat,CEO,Inventia Healthcare

tific challenges while aligning with patient needs and considering environmental impact. Dr Bhat stressed the importance of aligning India’s pharma innovation agenda with a long-term vision that nurtures clusters to innovate, funding to de-risk, regulation to accelerate, and digital tools to scale.

By using the example of the evolution of semaglutide, from injectable to oral, from managing diabetes to tackling obesity, he explained how this stands as an example of what’s possible when scientific ingenuity, advanced delivery systems, and patient-focused design align. According to Dr Bhat, this kind of thinking is essential if India is to lead the next era of injectable innovation, not just for the patient, but for the planet.

L-R: Sandeep Amritkar,Assistant Director,Lupin Pharmaceuticals (MODERATOR); Dr Amarender ReddyDonthidi,VP& Head - R&D Injectables and Ophthalmics,Amneal Pharmaceuticals; Dr Khalid Akhter Ansari,Senior Director,Rising Pharmaceutical; Mayurbhai Sankalia,VP- Research & Development,Invengene; Loganathan S,AVP,Onesource Biopharma; Dr Ramesh Nagarwal,VPComplexInjectable,BDR Pharma and Dr Rakesh Kumar Sinha,VP& Head - Drug Product Manufacturing,Biological E

The first panel at the Injectable Innovations Conclave centred on how the future of injectables is increasingly defined not only by the molecule but also by how effectively, painlessly, and precisely it reaches the patient. The experts across pharmaceutical formulation, device design, and drug delivery systems explored the shifting paradigm in injectable therapies.

The panel was moderated by Sandeep Amritkar, Assistant Director, Lupin Pharmaceuticals. Panellists included Dr Amarender Reddy Donthidi, VP & Head - R&D Injectables and Ophthalmics, Amneal Pharmaceuticals; Mayurbhai Sankalia, VP - Research & Development, Invengene; Dr Ramesh Nagarwal, VP Complex Injectable, BDR Pharma; Rakesh Kumar Sinha, VP & Head - Drug Product Manufacturing, Biological E; Loganathan S, AVP, Onesource Biopharma; Dr Khalid Akhter Ansari, Senior Director, Rising Pharmaceuticals

The panellists began by defining how injectable therapies are moving toward more refined, painless delivery systems that prioritise patient-centricity. This transition is especially vital as therapies become more targeted and biologically complex. The shift from traditional vials and syringes to prefilled syringes, autoinjectors, and needle-free systems reflects a broader industry commitment to ease of use and reduction of injection-related anxiety.

Long-acting and extended-release formulations also emerged as a key innovation frontier. By reducing the frequency of administration, these formulations are improving patient convenience, enhancing adherence and clinical outcomes. Panellists discussed how these solutions are particularly beneficial in therapeutic areas where consistent dosing is critical but often challenging to maintain with conventional regimens.

The discussion further highlighted that the design of the injectable deliv-

ery system has become a key differentiator in today’s pharmaceutical landscape. How the drug is being delivered is becoming increasingly important. Devices must now be intuitive, ergonomic, and designed with the patient in mind, ensuring precise, targeted delivery while upholding the therapeutic intent of the drug. Whether it’s a caregiver administering treatment at home or a patient self-injecting, the delivery device must offer ease, comfort, and confidence.

Accessibility was another crucial matter of discussion for the panellists. As therapies become more complex and personalised, panelists stressed the importance of innovating for affordability and scalability. The challenge lies in delivering high-tech solutions without inflating costs, especially in emerging markets like India. The panel advocated for designing with manufacturing in mind from the outset, ensuring that delivery systems are effective, while easy to produce, assemble, and

distribute at scale.

The panel discussed the rise of smart injectables and connected autoinjectors, and how these technologies enable real-time monitoring, personalised dosing, and data sharing with healthcare providers. The integration of digital technology with injectables is also fostering a proactive approach to treatment, where adherence, adverse events, and therapy responses can be monitored and managed remotely.

To round up the conversation, the panellists agreed that while innovation is inevitable, sustainability must become necessary. With increasing awareness of environmental impact, innovations such as green needles, autoinjectors, or interconnected injectable systems are gaining attention. Panellists concluded that the future of injectables lies in systems that are not only clinically effective but also sustainable, affordable, and centred on the end user. Together, these drivers are reshaping injectable therapies.

Vidwans Rajendra Ramachandra, Senior ConsultantGMP,QA, in Sterile, Non-sterile dosage forms, GAP & Consultant, Ami Polymer, offered a critical lens into recurring audit observations specific to injectable dosage forms, drawing from his extensive consulting experience. He highlighted that many Standard Operating Procedures (SOPs) in injectable manufacturing are often overly brief and vague, failing to offer the detailed, actionable guidance necessary for the consistent execution of complex and critical processes. This lack of specificity not only introduces variability but also exposes operations to compliance risks during audits.

He pointed out that while SOPs define alarm systems, there is frequently a gap in real-time monitoring and response, undermining real-time quality control and risk management. Another area of concern, stressed by Rajendra, was the weak implementation of data integrity programmes. In many facilities, the SOPs for data integrity lacked clarity on roles, review frequen-

cies, and procedures for audit trail checks, raising red flags about data reliability and regulatory compliance. Rajendra also underscored that Out-of-Specification (OOS) investiga-

tions were often incomplete or superficial, lacking a structured root cause analysis. This weakens the quality system and fails to generate preventive insights, making repeat deviations more

Many Standard Operating Procedures in injectable manufacturing are often overly brief and vague,failing to offer the detailed, actionable guidance necessary for the consistent execution of complex and critical processes

likely. His session served as a strong reminder to re-examine compliance fundamentals with greater rigour.

At the IIC 2025, Nitin Khaladkar, Head R&D (Rubber stopper), Bharat Rubber Works, delivered an insightful session on the critical role of Moisture Vapour Transmission Rate (MVTR) in pharmaceutical packaging, highlighting its direct impact on product quality, stability, and shelf life. He explained that MVTR is a key parameter in pharma, as it determines the ability of a container or closure system to prevent moisture ingress over time. This is especially important for moisture-sensitive formulations, where even minimal exposure can compromise product efficacy and safety.

Khaladkar emphasised that temperature and humidity are the primary factors influencing MVTR. Elevated temperatures increase molecular movement, thereby accelerating vapour

Nitin Khaladkar,Head R&D (Rubber stopper),Bharat Rubber Works

transmission through packaging materials. Similarly, a higher humidity gradient across the packaging barrier creates a stronger driving force for moisture to penetrate, making it essential to account for these variables during package design and material selection.

He further stressed that MVTR performance cannot be evaluated in isolation; it must be validated across the entire supply chain, from manufacturing through storage and distribution. Variations in environmental conditions at each stage can undermine the effectiveness of even the best-engineered packaging systems. Beyond being a technical consideration, MVTR compliance is a regulatory mandate, essential for ensuring product safety, maintaining efficacy, and adhering to global pharma and food safety standards.

Akey session at Injectable Innovations Conclave 2025 focused on solutions that enable sustainable, traceable, and flexible packaging for parenteral products in pharma manufacturing.

The session, titled 'Sustainable, flexible, and traceable solutions for parenteral packaging', was led by Klaus Braig, Global Key Account Manager, Uhlmann PacSysteme GmbH & Co. and Managing Director, Uhlmann Switzerland. The session addressed what innovations are shaping parenteral packaging, who is providing integrated solutions, where these systems are being deployed globally, when they are being adopted in manufacturing processes, why adaptability and traceability are critical for sterile products, and how modular designs are enabling operational agility.

Uhlmann Group, with over 75 years of experience and presence in 21 global loca-

tions, shared its capabilities in supporting pharma manufacturers with packag-

ing solutions tailored for parenteral dosage forms. The company provides

flexible packaging systems designed to accommodate varied product types and evolving regulatory requirements.

The session introduced Uhlmann’s Parenteral Tray Center (PTC 200), a modular packaging system that delivers up to 200 units per minute. The PTC 200 enables quick format changes and easy system expansion, allowing manufacturers to adapt production lines based on demand and product types.

Braig also covered how Uhlmann supports partners through the integration of automation, sustainability measures, and digital tools in the packaging process. These offerings enable traceability, operational efficiency, and regulatory compliance in sterile injectable production.

By combining modular system design with holistic support across the packaging lifecycle, Uhlmann contributes to building responsive, compliant, and efficient pharma packaging ecosystems.

The session titled, ‘New Frontiers of Inspection Technologies (Visual Inspection and CCIT) with Artificial Intelligence’, at the Injectable Innovation Conclave 2025 focused on how artificial intelligence is being used to advance inspection systems in sterile injectable manufacturing.

Presented by Shaunak J. Dave, Managing Director and CEO, Antares Vision. The presentation addressed what new technologies are being applied in inspection systems, who is leading these developments, where they are being deployed, when they are being used across the product lifecycle, why they are needed to ensure sterility and compliance, and how these systems operate across functions.

Antares Vision highlighted its wide portfolio of inspection systems that support sterile injectable manufacturing from early development to commercial production. These systems range from

ShaunakJ.Dave,MD & CEO,Antares Vision

lab-scale tools to fully automated highthroughput platforms. The company has strengthened its capabilities in this space through acquisitions such

as Convel. Dave also outlined key technological features in Antares Vision’s systems. These include Short-Wave Infrared

(SWIR) technology, which enables reliable fill level detection under challenging conditions, and Automatic Visual Inspection (AVI) systems that detect particulate matter, vial cracks, and seal issues that could affect sterility.

In addition to inspection, Antares Vision Group provides integrated platforms in traceability, product and supply chain data management, and generative AI. These platforms include tools such as serialisation, aggregation, real-time IoT, authentication, warehouse management, business intelligence, cloud computing, and big data analysis.

The company’s multi-technology hub spans camera-based systems, laser and absorption spectroscopy, high voltage, sensor-based detection, and microwave solutions. The session demonstrated how these technologies work together to ensure quality, safety, and traceability in injectable manufacturing.

At the recently concluded Injectable Innovations Conclave, Chiranjeevi Kondapaka, CEO, Steriline Asia, gave a compelling presentation titled “Inn ovative Solutions by Steriline.” The session showcased the company’s approach in addressing the evolving needs of the injectable pharmaceuticals market.

He presented Steriline’s “Zero Loss Philosophy” as a cornerstone of future-ready manufacturing. The approach fouses on minimising wastage across production stages through automation and integrated process control.

The session highlighted the increasing complexity in injectable product portfolios. Kondapaka pointed out how pharma manufacturers are expected to accommodate productspecific requirements, shorter turnaround times, and in-line sterilisation

Kondapaka,CEO,Steriline Asia

protocols without compromising on throughput or compliance.

He also informed that through advanced robotics and closed-system designs, the company aims to eliminate costly product losses and human error while enhancing batch integrity. These innovations are particularly relevant for high-value biologics, where even minor losses can result in significant cost implications.

Kondapaka also presented Steriline’s latest solutions that are designed to handle a variety of container formats, for pharma companies to swiftly adapt to changing production needs.

The session concluded with the speaker asserting Steriline’s commitment to continuous innovation in aseptic manufacturing. The company aims to be a key enabler in the transition toward next-gen injectable drug production.

❒ Express Pharma accepts editorial material for regular columns and from pre-approved contributors / columnists.

❒ Express Pharma has a strict nontolerance policy of plagiarism and will blacklist all authors found to have used/refered to previously published material in any form,without giving due credit in the industry-accepted format. All authors have to declare that the article/column is an original piece of work and if not,they will bear the onus of taking permission for re-publishing in Express Pharma.

❒ Express Pharma's prime audience is senior management and pharma professionals in the industry.Editorial material addressing this audience would be given preference.

❒ The articles should cover technology and policy trends and business related discussions.

❒ Articles for columns should talk about concepts or trends without being too company or product specific.

❒ Article length for regular columns: Between 1200 - 1500 words.These should be accompanied by diagrams, illustrations,tables and photographs, wherever relevant.

❒ We welcome information on new products and services introduced by your organisation for our various sections: Pharma Ally (News,Products, Value Add),Pharma Packaging and Pharma Technology Review sections. Related photographs and brochures must accompany the information.

❒ Besides the regular columns,each issue will have a special focus on a specific topic of relevance to the Indian market.

❒ In e-mail communications,avoid large document attachments (above 1MB) as far as possible.

❒ Articles may be edited for brevity,style, and relevance.

❒ Do specify name,designation,company name,department and e-mail address for feedback,in the article.

❒ We encourage authors to send their photograph.Preferably in colour, postcard size and with a good contrast.

Email your contribution to: The Editor, Express Pharma, Business Publications Division, The Indian Express (P) Ltd, Mafatlal Centre,7th floor, Ramnath Goenka Marg, Nariman Point,Mumbai 400021 viveka.r@expressindia.com viveka.roy3@gmail.com