Waste management with a circular vision

Message from our CEO

Dear reader,

Indaver was founded 40 years ago out of necessity: a sustainable solution was needed for the chemical waste from Antwerp industry and later for the non-hazardous waste from residential households. This is a role that we have fulfilled completely. Now, we are active in 9 countries and have grown into one of the largest players in Europe for the treatment of multiple and complex waste streams.

From the very beginning, we have always focused on value creation from waste. We do this by recovering materials and energy from the waste, and also by keeping material cycles clean. That dual role is more relevant today than ever.

Driving the circular economy together

Europe is facing several crises, with significant environmental and social impacts, from climate change to the raw materials and energy crisis.

There is only one possible way forward: we urgently need to adapt our consumption and production patterns and accelerate the transition to a circular economy. To help achieve this, Indaver further specialises in optimal value creation from waste.

First, we are becoming more and more technically adept at recovering valuable raw materials from waste, whether it is solvent waste, complex plastics, organic waste, bottom ashes, chemical liquids or other streams. Our goal is to recover raw materials with an everincreasing value (e.g. ruthenium and palladium) that our economy explicitly needs. In this way, Indaver is broadening its role from waste management to the management of materials. At the same time, we remain fully committed to efficient energy recovery, while we keep on looking ahead for the next opportunity, such as useful applications for CO2.

In many areas, Indaver safely closes cycles. This also means that we keep those cycles clean, including with sustainable and effective solutions for Substances of Very High Concern.

Unique culture, unique momentum

We will continue on the same path. For instance, we have many leading projects in the pipeline for the coming years, which you will encounter throughout this report. But Indaver’s real strength lies in the numerous incremental improvement projects that are continuously going on behind the scenes. In 2024, for example, we registered almost 300 of these projects, each time raising the bar a little higher for ourselves.

“Our motto: leading in sustainable waste management is more relevant than ever. What we achieve together has enormous social added value today and tomorrow. And we do that with a good dose of pragmatism.”

This determination to take on our social role and to excel in it has characterised Indaver’s approach since our early years. Our people

work and breathe this determination, it infuses everything they do. For many, in fact, it is the reason why they work for Indaver. Such a culture is priceless. As the new CEO, I can only be grateful for this and I will do everything I can to further expand Indaver’s positive contribution to society and to the environment.

As long as society generates waste, someone has to roll up their sleeves and tackle it with vision and decisiveness. We gladly answer this call together with our partners. Enjoy reading.

Karl Huts, CEO

6 takeaways from 2024

If we want to summarise our work in 2024, we can do so in just four words: responding smartly to changes. This applies, in the first place, to our external environment. For example, a lot of (re)new(ed) legislation came into effect that had a direct impact on our organisation. But it is also about a tight labour market in some regions, a growing ecological awareness in society, and a turbulent economic climate. In addition, there were changes in our internal environment. For example, 2024 was the year in which we fully embraced our subsidiaries, Dranco and Inopsys, in which we made great strides in the field of digitisation, and in which we welcomed a raft of new talent.

You can discover how Indaver is also making progress from responding to change in this sustainability report. These 6 key takeaways will help you quickly find your way to relevant chapters.

#1 Collaboration

#2 Responsibility

We firmly believe that we can move forward together

The collaborations we entered into and continued in 2024 took various forms. Within Indaver, our business lines and units work together optimally to unburden customers as much as possible. Beyond Indaver, there are numerous external collaborations underway. A few examples: we joined forces with players from other sectors in the strategically important FOSTER project; we explored the future of solvent recycling together with research institutions; we organised customer events to keep the lines of communication open; we supported competitors to guarantee continuity at all times for our customers.

We embrace our social role

We do this by minimising the impact on people and the environment in all of our activities, but also by devising innovative solutions for new or complex waste streams. An excellent example is our approach to Substances of Very High Concern, for which we offer a suitable solution to what is a growing social problem. For example, we effectively destroy c. 668,000 kg of PFAS annually at our site in Antwerp (Belgium).

#3 Innovation

We push beyond our comfort zone every day

Innovation is the key to progress and we live up to that across all areas of our operations. We practice strategic innovation, such as Indanova for MSW Belgium and Cornerstones for IWS, which makes us an innovative project partner. We practice process innovation, such as tailormade AI solutions for quality checks in the sorting of plastics. We practice product innovation, such as transforming waste streams into products that the market demands. We practice technological innovation, such as our research into carbon capture, storage and reuse. Whatever type of innovation it is, our golden rule is that it must always contribute to one of the three Ds: decarbonisation, digitalisation, diversification.

#4 Customer Focus We always think and plan alongside our customers

Indaver closely monitors all relevant legislation and responds proactively, but we do much more than that. Indaver takes on its customers’ burdens by offering the necessary expertise, experience and scale, to responsibly manage their waste processing. In doing so, we always start from our ambition to close cycles with a systemic approach. It is an ambition that we fulfil with an open mind. For example, we explicitly seek out and invest in technologies that can better serve our customers and we look beyond our core activities and our own sector in this willingness to invest. A good example is our multifaceted total waste treatments: we can both transform packaging materials into ready-to-use r-styrene and we can upgrade leftover bottom ashes for new and useful applications.

#5 Agility We adjust our sails but stay the course

Change inevitably brings uncertainty. And uncertainty forces us to respond quickly, so that we can capitalise on the right opportunities and tackle the necessary challenges. This has always been Indaver’s approach to change. Thanks to our highly motivated team, into which we welcomed 400 new employees in 2024, we have proven ourselves to be particularly agile. In 2024, we encountered volatile energy prices, new waste streams, legal uncertainty ... and we didn’t let ourselves get knocked off course. On the contrary, we ended the year with healthy financial results and we are continuing to invest in projects that accelerate the circular transition.

#6 Entrepreneurship We make a positive impact

Our core activities limit the impact of waste on people, climate and the environment, but we are also fully committed to positive impact. Indaver supplies carbon-free heat to the world’s largest malting plant (Belgium) via the Antwerp North Heat Network (WAN). We are looking at how we can supply the Essex region (UK) with green electricity from the Rivenhall site. We are producing more and more useful organic product flows from organic waste (the Netherlands). We are creating greater support for the circular economy in the Hamburg region (Germany). We are focusing on hydrogen production in Meath (Ireland) to make the energy system more sustainable. Positive action delivers positive impact.

Indaver inside out

Indaver has been a leader in sustainable waste management since 1985. We are convinced that value creation from waste is essential to guarantee prosperity and well-being in the Europe of tomorrow.

Indaver in figures

Our employees

2,306 colleagues signing up for a circular economy

Our activities

9 countries with facilities for value creation from waste

5 core values that shape our culture

5.6 million tonnes of waste managed and treated in 2024

Our business Governments and major industry as key partners in Europe

EBITDA €161 million as a sign of our strong financials

Volumes under management

In 2024, Indaver had 5.6 million tonnes of waste under management. Of this, 4.6 million tonnes were processed in our own installations and 1 million tonnes at third parties’ installations.

Our

sustainable

mission: value creation from waste

As a leading organisation in sustainable waste management, Indaver aims to make an active contribution to the realisation of a carbonneutral, environmentally sustainable and circular European economy, without pollutants, by 2050, in line with the EU’s sustainability and climate ambitions.

More specifically, our societal role focuses on the efficient recovery of high-quality materials and energy, and on protecting our ecosystems and material cycles from harmful substances.

Tackling the triple planetary crisis through waste management

Our ecosystems are currently under pressure from three closely related crises: climate change, biodiversity loss, pollution. With our linear production and consumption systems,

we simply do not succeed in meeting the current needs for food, housing and mobility without threatening the opportunities of future generations.

We urgently need to rethink technologies, production processes, consumption patterns and our way of living. Indaver is ideally placed to actively contribute to a fundamentally reimagined and revised system. This is, after all, what we do every day with our circular mission.

A circular economy can relieve pressure on our ecosystems and set up sustainable materials and energy management.

By recovering high-quality materials and energy from waste and protecting our ecosystems, Indaver offers a much-needed answer to some of the biggest challenges facing Europe, such as material scarcity, energy dependence, climate change and environmental pollution.

How Indaver creates value from waste streams

Indaver is both an enabler and a gatekeeper within the circular economy. Enabler because we extend chains, gatekeeper because we keep chains safe. In practice, it looks like this:

Our focus is on keeping the cycle safe. Using innovative techniques we can recover energy and valuable molecules from waste streams with a low circular potential.

Enabler: recovering and supplying raw materials

Every year, humans use up twice as many natural resources as the Earth can regenerate. That means we are depleting nature. In addition, Europe is too dependent on the rest of the world for the supply of materials needed to meet our climate and sustainability goals. Through sustainable waste management, Indaver is helping to turn the tide.

As an enabler, we guarantee that waste streams with a high circular potential (i.e. high value, low pollution) receive the appropriate treatment. In doing so, we are not only focusing on recycling and recovery of materials but also exploring other R strategies, such as reuse.

Strengthening customer relationships

The broadening of our role with material management fits perfectly with the wishes and needs of our customers: by working closely together, we can support them in using fewer resources and/or reusing materials when possible.

In Willebroek, Indaver sorts PMD waste into 16 different pure material streams.

Enabler: generating and supplying energy

Few subjects are as important to the future of our planet as energy. We all need to use less energy, while the energy we do consume must come from sustainable sources. This is the only way we can reduce the use of polluting fossil fuels. This revolution is also necessary to combat Europe’s energy dependence.

Indaver plays a significant role in this. Our installations produce energy from the waste treatment process. We use that energy ourselves at our sites in the form of steam and electricity, and we also supply heat, steam, electricity and green gas to companies and residential areas via designated networks.

Gatekeeper: protecting people and the environment

To keep the circular economy running, we need to remove pollutants from the chain. These are dangerous or other undesirable fractions such as heavy metals, Substances of Very High Concern, asbestos and high-risk medical waste.

Indaver guarantees safe solutions. Depending on the type of waste, we either destroy the unwanted fractions at a high temperature or neutralise the hazardous components. The unavoidable residual fractions – which are becoming smaller and smaller thanks to our continuous improvements – are stored in our specially equipped landfills, always in line with the strict standards in force.

The ECLUSE steam network supplies sustainable steam to other companies from our site in Doel.

Landfills play a crucial role in safely and sustainably storing unwanted fractions.

Driven by 5 core values

In achieving our mission, we consistently adhere to five core values that reflect what Indaver truly cares about. These values have been the same for 40 years, but our growth proves that they are still very relevant. All our employees, customers, partners and other stakeholders can expect this from us:

With constant vigilance for people, safety and the environment

In mutual trust With a consistent focus on results

With openness in word and deed With a focus on continuous improvement

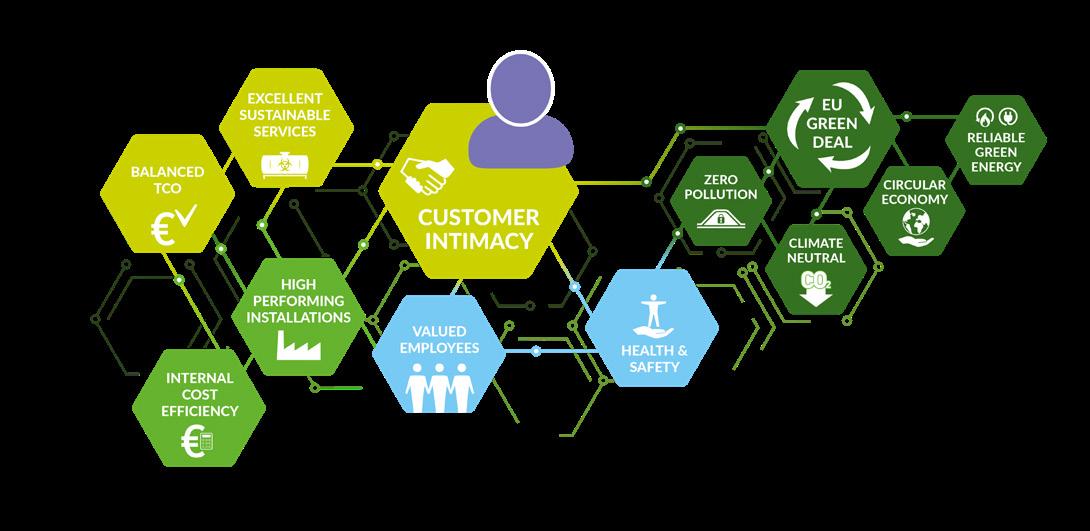

Our ambitions and how we achieve them

Indaver wants to remain a leader in sustainable waste management and close material cycles in the safest, most effective and most CO2- and energy-efficient way. This is how we will make a maximum contribution to Europe’s climate and sustainability ambitions.

To achieve these ambitions, we use a strategy that comprises three pillars:

Pillar 1: Making progress in ESG

Our first pillar focuses on Environmental, Social, and Governance (ESG). This well-known concept provides a framework for concrete implementation of sustainability in our own operations and value chain. ESG is also the cornerstone of CSRD (Corporate Sustainability Reporting Directive) reporting and is now well-established among the general public.

By formulating objectives, implementing best practices, accurately measuring and reporting on our progress, we can contribute effectively to a cleaner, circular and just society.

How do we strategically progress in ESG?

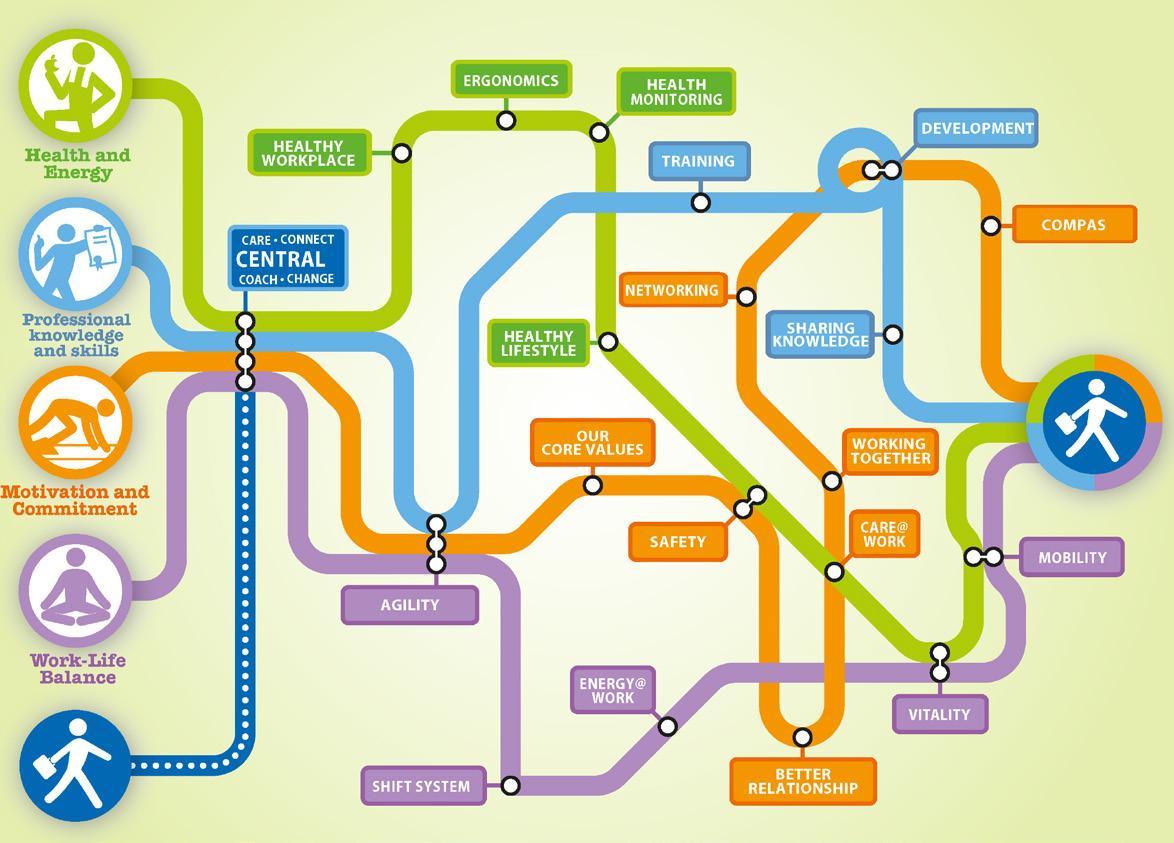

Our ambition is to continuously improve for E, S and G and to raise the bar for ourselves. For example, we are currently drawing up a company-wide decarbonisation plan (Environmental), we actively support our employees to remain sustainably employable (Social), and we are increasing our focus on the screening of our suppliers (Governance).

All of our goals and associated initiatives can be found in this report: Environmental chapter, Social chapter, and Governance chapter.

Pillar 2: Sustainable growth and investment

Our second pillar concerns the ambition to strengthen our essential role in society. We do this by continuously improving our processes, technologies and installations. This allows us to take an important dual approach to waste processing: we are committed to recovering more and more highquality materials and energy from waste, and we keep ecological and material chains clean through decontamination.

How do we grow and invest strategically?

Our power for change comes from a clear vision: waste is a valuable source of materials and energy that must be managed sustainably. Through strategies like innovative technologies for molecular recycling and new business models we want to extract even more value from waste than we already do today.

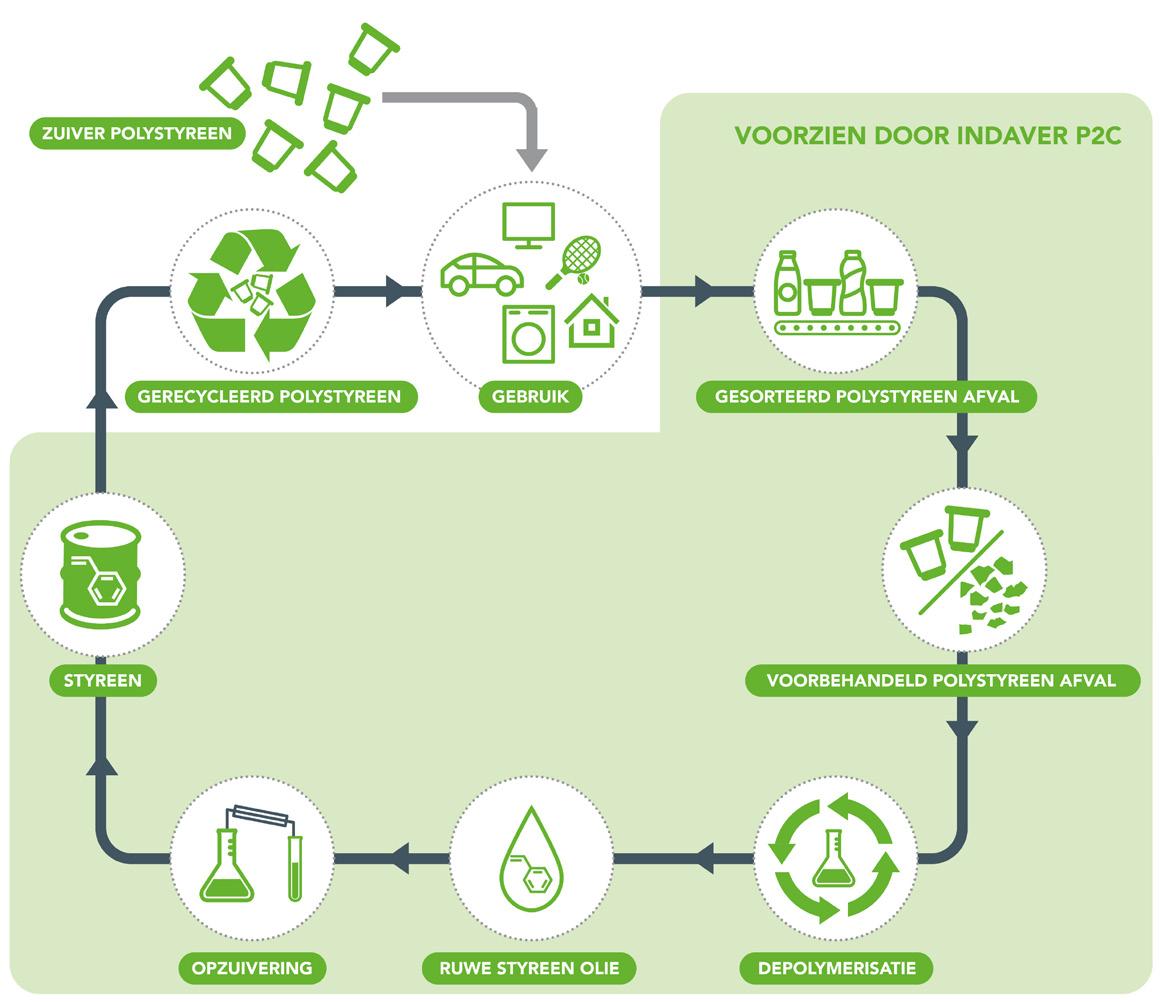

In our Plastics2Chemicals (P2C) demo plant, we turn end-of-life plastics into new primary materials.

Investing in our existing installations

We are continuously improving our existing installations to recover even more valuable materials from waste. We proved this in 2024 by, for example, recovering raw materials through ash treatment and by extracting even more useful organic material from our composting plants. These are materials that the industry specifically requests.

In addition, we continue to invest in our Wasteto-Energy facilities and high-temperature incineration. These will remain crucial technologies in the future circular economy because these are the means by which we extract energy from non-recyclable waste and destroy hazardous components to keep the materials cycle clean.

Our landfills also remain useful for better material and energy recovery. Non-recyclable harmful materials need a ‘safe sink’ after processing, to protect our ecosystems. For some materials, the landfill will be their final destination. For others, it will be a temporary repository until new recycling technologies become available, affordable and reliable. And at the end of their life, landfills can become renewable energy hubs, as we are doing in Antwerp (Belgium) by putting solar panels in place.

Investing in new installations and partnerships for material recovery

Through molecular recycling, advanced technological innovation and industrial collaboration, waste streams that have a low circular potential today can have a high circular potential tomorrow. These are our focus areas.

For example, we are investing in an installation that can convert plastic packaging waste into high-quality products with the same functionality as virgin material – something that is not possible with current commercially available recycling techniques. We are always looking at how we can bring companies into contact with one other, so that we can achieve economies of scale, strategically site an installation (e.g. near partners) and optimally supply the materials to partners (e.g. via a pipeline).

Investing in new business models

In addition to technological innovation, a circular economy also implies changes in the way we do business. In short: we want to evolve from a waste manager to a material manager. That will require a change of perspective. By offering new services to our customers or taking on different roles, we can better leverage our knowledge and contacts and create more value from the same volume of waste, while at the same time improving our customers’ carbon footprint.

Investing in synergies between installations

If we are aiming for a higher quality of recycled products, we will need to remove more contamination from the original waste streams and often we will also need to treat the recovered products further before they can serve as new feedstock. Indaver offers a solution for the residual fractions that are created during these processes. By effectively neutralising (or storing) the harmful and sensitive components in specialised installations, we keep material chains clean.

In other words, these purifying plants play a crucial role in the success of our installations that focus primarily on material extraction. They also recover a lot of clean energy that we can use for our own operations and distribute externally.

The treatment of end-of-life plastics results in feedstock for Plastics2Chemicals.

Thanks to our advanced ash treatment, we recover materials from thermically treated waste.

Landfills offer a safe solution for the storage of residual fractions from recycling processes.

Pillar 3: Innovate

Our third pillar focuses on innovation. We see innovation as the engine for evolving from waste manager and recycler to a material manager offering tailormade total solutions that respect and support people and the environment.

How do we innovate strategically?

At the beginning of 2025, Indaver launched its renewed innovation strategy that revolves around three guiding principles: decarbonisation, digitalisation and diversification.

Digitalisation

In order to close material cycles in a safe, sustainable and efficient way, society must be able to track and trace material flows. Digitalisation will play a key role in this. Product passports, digital twins and other traceability tools will not only improve the sustainability of material processing but also increase the transparency of the chain for all stakeholders.

Digitalisation is a means by which to improve the efficiency and performance of our operations. For example, AI-based process control can improve our waste sorting, while AI-based search systems can streamline the procurement of raw materials.

Digitalisation in action: quality checks with AI

In Willebroek (Belgium), Indaver mechanically sorts PMD waste from local authorities and companies. Every hour, around 1 million objects are divided into 16 pure fractions, ready for recycling into new applications. Since 2024, we have been using AI to optimise the quality control of the sorting process. This gives us these advantages:

No more labour-intensive random checks. Higher statistical relevance (because each object is characterised). Fast process adjustment is possible.

Decarbonisation

Within our Carbon Management Plan (see p. 46), both recovered energy and carbon capture and utilisation are important.

The energy we extract from the residual heat from our incineration plants ensures that the industrial companies and municipalities to which we supply energy no longer need coal- or gas-fired power stations for their heat, process steam or electricity. This helps to avoid emissions and thus contribute to the decarbonisation of society.

Carbon capture and utilisation are likely to grow in importance in the coming decades. Whether Indaver invests in this for the greenhouse gases that are inevitable in responsible material management depends not only on our own willingness to invest, but also on external factors such as the availability of infrastructure and storage capacity.

Decarbonisation in action: converting landfills into solar farms

At the end of 2024, Indaver received a permit for the construction of a Solar Park on the flanks of the landfills in Antwerp and Hooge Maey (Belgium). This Solar Park is the final piece of a broader energy cluster to make the energy consumption of Indaver and Antwerp’s major industry more sustainable. More info on p. 69.

Diversification

Access to critical raw materials, the production of bio-based materials, the phasing out of Substances of Very High Concern and the sustainable management of materials are central to the European government agenda. These are strategic innovation areas to make both the European Green Deal and the Clean Industrial Deal a success. Indaver wants to contribute to their implementation, e.g. through our PFAS approach (see p. 76) and the processing of organic waste into feedstock for bio-based materials.

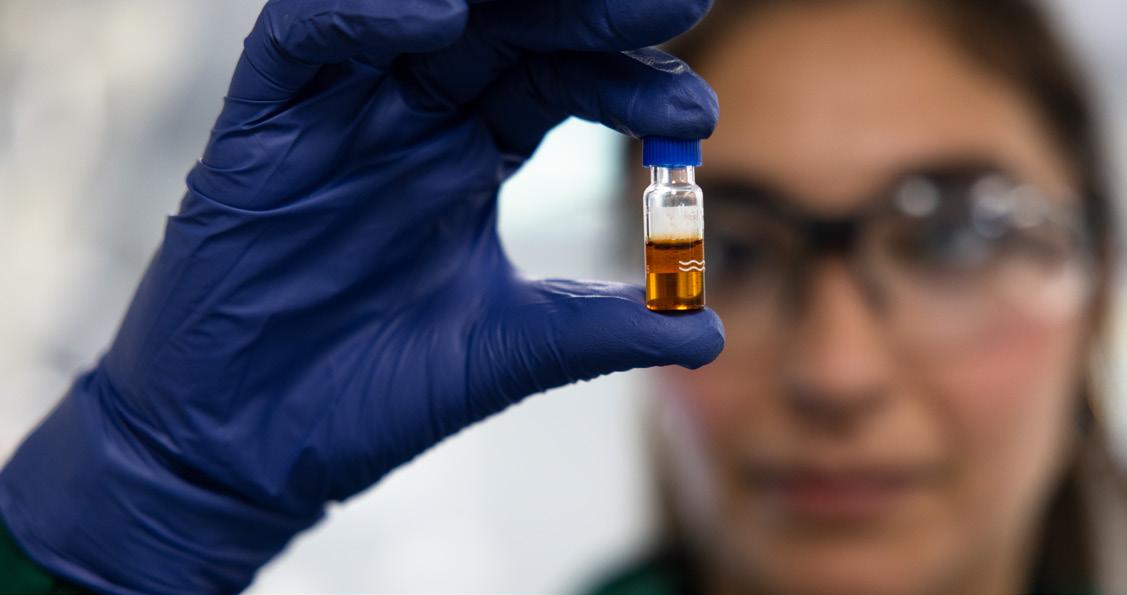

Diversification in action: better recovery of precious metals

From more than 6,000 tonnes of liquid waste that would otherwise end up in the incinerator, Indaver has already recovered +2,500 kg of palladium and platinum, as well as +250 kg of ruthenium. In addition, the team has now developed extraction solutions for streams containing rhodium and iridium, two high-performance metals. More info on p. 62.

Our specialised business lines and units

To put our 5 core values into practice, we rely on our specialised business lines and units. They all work to the same circular vision, but do so in a very targeted way for certain groups and/or areas of work. Good to know: the business lines and units are supported by central and regional shared services.

Industrial Waste Services (IWS)

What does IWS do?

Business lines and units Target audience Region

Industrial Waste Services (IWS) Industry International

Municipal Solid Waste (MSW) Public and private sector

Belgium, Netherlands, Ireland, United Kingdom

Plastics2Chemicals (P2C) Industry International

Indaver Separation Technologies (IST) Industry

Belgium, the Netherlands and France

IWS is the European total partner for value creation from industrial waste. The business line focuses on the safe processing and disposal of complex, hazardous or sensitive waste streams with its Total Waste Management services. At the same time, IWS is fully committed to the recovery of materials and energy from the same industrial streams.

IWS actively ensures the recovered materials find their way back to the industry, which means we contribute to a more circular economy.

To which industries does IWS offer its services?

How does IWS make a difference?

Broad expertise Waste is becoming more and more complex, as is the composition of the various contaminants that waste contains. This means that we must continuously optimise and supplement our solutions. A recent addition to our IWS portfolio was, for example, the acquisition of the scale-up Inopsys. This allows us to offer customers not only large-scale but also on-site solutions to purify complex and toxic wastewater and to recover valuable components from it.

Indaver receives liquid waste streams from the industry for thermal treatment in its rotary kilns.

Strong reliability

Our customers know that we always offer the best solutions in terms of technology, safety, cost and environmental compliance. And they know that we guarantee continuity through our own installations and collaborations with third parties. The trust we enjoy so much resulted in the renewal of large contracts in 2024. For example, in Ireland, we started the second and most challenging phase of a large remediation project for a pharmaceutical company.

Circular vision

In the spotlight: more attention for (international) logistics

We continue to invest in increasing our ability to recover a greater amount of valuable components from complex waste. Think of how Inda-MP recovered more palladium, platinum, rhodium and ruthenium for reuse in 2024. We also continue to invest heavily in the sustainable and safe processing of industrial, complex and/or hazardous waste, e.g. in Hamburg and Biebesheim (Germany) and in Antwerp (Belgium). This is how we keep the circular economy clean and safe. “ De IWS Cornerstonneses weerspiegelen het kader waarop IWS inzet om maximaal in te spelen op de noden van haar klanten. In dezelfde lijn herbekeken we ook het businessmodel en werkten we algemene strategische doelstellingen uit. Onze klantenfocus, diensten en

Demand for our logistics services is increasing strongly, partly due to the growing IWS activities in Ireland. Ireland has a limited number of treatment facilities, so we transport waste to facilities in the rest of Western Europe. Our German installations are also being used more to serve international customers. To manage these logistical tasks, we implemented a number of efficiency measures in 2024 that allow us to make maximum use of Katoen Natie’s fleet.

See how ExxonMobil and Schirm GmbH rate the partnership with IWS

What did the business line focus on in 2024?

Customer centricity. That is at the heart of our brand new IWS cornerstones. These cornerstones reflect the ethos and aims of IWS. They show that we continue to respond to the unique but also increasing needs of our customers, Europe’s major industries.

“The IWS Cornerstones reflect the framework within which IWS is committed to responding to the needs of its customers as far as possible. In the same vein, we also reviewed the business model and worked out general strategic objectives. Our customer focus, services and organisation ensure that we can switch quickly in a dynamic market.”

Bart Goethals, General Manager IWS

Customer centricity in practice

A striking example of how IWS responds to the individual needs and preferences of our customers is the turnaround project at SABIC in Geleen (the Netherlands). We designed a tailormade total solution for this petrochemical company.

Strategy: SABIC carries out thorough maintenance work – also known as ‘turnarounds’ – at the Chemelot Industrial Park every 6 years. During the works in 2024, the company wanted to permanently decommission the naphtha cracker Olefins 3 to make way for new activities. This decision is in line with the company’s sustainable future strategy.

Approach: For this ambitious project, a real turnaround village was built for the more than 1,500 SABIC employees and contractors. Indaver was appointed for waste management, was involved in the construction of a temporary water treatment plant and also set up a temporary waste park.

This is how we took on the responsibilities of SABIC with Total Waste Management:

waste collection and ADR labelling management of the container park transport

processing largely in our own facilities

Result: within a few weeks we had collected a volume of 2,500 tonnes of waste, 90% of which was hazardous waste. More than 200 transports, 50 solid waste containers and 100 tank containers were used to take the waste to our and other sites for processing.

Municipal Solid Waste (MSW)

A look at new key projects in 2024

What does MSW do?

MSW converts recyclable household and commercial waste into new high-quality raw materials. The non-recyclable waste is used to generate sustainable energy for industrial partners and residential areas.

Who does MSW work for?

For collectors and local authorities in Belgium, the Netherlands, the United Kingdom and Ireland.

What did the business line focus on in 2024?

Decisiveness was our key focus in 2024. In a challenging market, in which many governments are considering the future of their waste management and permits are difficult to secure, Indaver is continuing on its chosen path. Our targeted investments are helping us to realise our vision of accelerating the circular economy through waste management and processing.

Belgium

Pre-treatment of plastics in Willebroek started

Steam network ECLUSE 2 in Antwerp construction phase

Ireland

Waste-to-Energy plant in Cork permit phase

FOSTER in Ghent construction phase

WAN in Antwerp started

Dranco takeover

Northern Ireland

Belfast Waste-to-Energy plant permit phase

UK

Rivenhall in Essex construction phase

NESS Waste-to-Energy Facility in Aberdeen started

How does MSW make a difference in Belgium?

MSW Belgium offers sustainable, reliable and flexible total solutions for a wide range of waste streams, ranging from residual and packaging waste to bio-organic streams and even wood waste. In addition, customers not only gain access to advanced waste treatment technology, but Indaver also strives for indepth cooperation with public and private partners for the recovery of energy and materials. In order to market this unique approach more effectively, MSW Belgium recently launched its new business model, IndaNova.

“During an event in the restored Handelsbeurs in Antwerp, we showed 150 guests how we put our vision of circular value creation from waste into practice with IndaNova.”

Alain Konings, Director of Sales & Marketing MSW Belgium

For more info on MSW Belgium, visit our website.

IndaNova in 3 promises

IndaNova stands for an approach that focuses not only on waste but also on the production of circular raw materials and low-carbon energy. This business model will therefore play a key role in achieving the ambitious climate goals for 2050.

#1 With a passion for knowledge-sharing

We are an open and transparent knowledge hub for sustainable waste management – not only internally but also externally. We share our extensive knowledge and experience with students, researchers, industrial partners, governments and other stakeholders. Consider, for example, how MSW Belgium plays an active role in organisations such as Belgian Waste-to-Energy and CEWEP. But we are also participating in feasibility studies on the reuse of plastic food packaging.

#2 Near our network

Indaver brings together organisations from various sectors to achieve ambitious targets. By establishing connections with both public and private parties, Indaver creates a broad network that shapes the circular economy. Strategic collaborations with Port of AntwerpBruges, FINEG, BESIX and Maatschappij Linkerscheldeever, among others, show the power of mutual trust and cooperation.

#3 Always progressive

For the waste streams we process today, we use the most modern techniques and we constantly adapt our installations when there are new, better insights in the technological field. MSW Belgium also invests in technologies and infrastructure for future waste streams. An example: we are preparing for the transition from fluorescent lamps to LED lamps in consultation with management bodies.

Highlights from 2024 (MSW Belgium)

FOSTER: unique public-private partnership

Indaver and BESIX – together FOSTER – have been given the green light for the construction and management of a high-tech sludge incineration plant. It will process two-thirds of the sewage sludge of all domestic wastewater in Flanders – so of 4 million inhabitants. During processing, the installation will extract green energy and bottom ash from the sludge. In a second phase, client Aquafin plans to recover phosphorus from the residues.

During

ENERGY - WASTE - MATERIALS

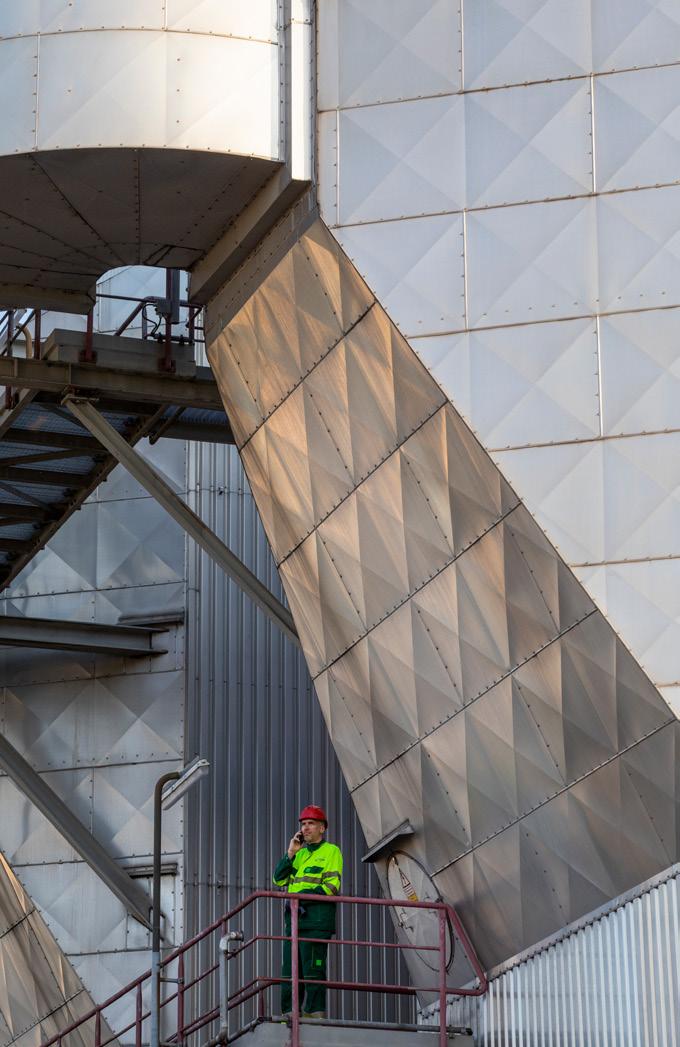

ECLUSE 2: challenging expansion of steam network

Through a tunnel under the Scheldt, ECLUSE 2 will transport the recovered energy, in the form of steam, from the Waste-to-Energy plants of Indaver and SLECO to the Evonik company. The tunnel is an essential link in achieving sustainable, circular and climate-neutral chemistry in an industrial symbiosis on both riverbanks.

The benefits of ECLUSE 2:

Less fossil fuels, more renewable energy

Less CO2 emissions

Less nitrogen emissions

Implementation of energy and climate objectives

Less energy loss

“One of the most important reasons we can achieve ECLUSE 2: trust between all partners. And from that trust, we worked together on this project in a very open atmosphere. Together we have overcome difficulties. Everyone has contributed to this.”

Bart Verschueren, Sustainability Manager Energy & Utilities at Evonik

Successful first year for Antwerp North Heat Network (WAN)

The most ambitious heat network in Flanders is running at full speed. The Boortmalt malting plant – which accounts for 90% of the consumption – can thus save the equivalent of the natural gas consumption of 10,000 households. From 2025, a residential network will also be linked to WAN and it will allow schools, public buildings and 3,200 households to heat their homes sustainably.

“Today, we save around 30,000 tonnes of CO2 per year thanks to Indaver’s residual heat. The fact that we could just find the solution in the neighbourhood was an eye-opener.”

Giovanni Vercammen, Chief Energy & Technology Officer at Boortmalt

Further valorisation of bottom ashes

By carefully washing, sieving and cleaning bottom ashes from our Waste-to-Energy installations, Indaver turns them into raw materials for various applications. In 2024, we took important steps in the further

reprocessing of increasingly high-quality materials from bottom ashes. For example, we have recently started extracting precious metals from the fine fraction of bottom ashes and are close to working together to use recyclate for BENOR-labelled materials.

Taking agility and solidarity to a new level

MSW stands for reliable and flexible service. This will enable us to cope with the larger volumes of PMD waste that will arise as a result of better responses from companies and citizens. But we also prove our reliability and flexibility by assisting competitors in the event of force majeure

For example, in 2024 we processed exceptionally large volumes of waste due to the temporary permit freeze at ISVAG. The contractual overflow from ISVAG to Indaver is 35,000 tonnes per year, but at the end of 2024 we were processing a volume that was twice that amount. We also helped out competitors who were struggling with technical breakdowns due to explosions of nitrous oxide cylinders. And our PMD sorting installation provided continuity during the temporary closure of a competitor.

Arrival of the tunnel drill in Antwerp for the construction of the longest microtunnel in Belgium below the river Scheldt - as an extension of ECLUSE.

How does MSW make a difference in the Netherlands?

In the Netherlands, the focus of our waste and materials management is on two types of waste.

#1 Organic Flow Solutions

In the Netherlands, Indaver processes bioorganic waste into high-quality compost. We do this in four composting facilities for organic waste (Alphen aan den Rijn, Nieuwdorp, Oude Pekela and Rotterdam-Europoort) and six for green waste (Moerdijk, Nieuwdorp, Vagroen Oldekerk, Rijpwetering, Vagroen Groningen and Voorschoten).

With compost of ever-improving quality, we give the soil back its natural nutrients and close the cycle. From the remaining fractions, we then make biomass. In this way, only a small residual fraction ends up in the landfill.

#2 Solutions for non-recyclable and mineral streams

MSW Netherlands stores residual flows that cannot be recycled, reused or incinerated at one of its two operational landfills, Stainkoeln and North and Central Zeeland. Indaver first and foremost ensures that all customers within its working area are assured of a continuous and safe landfill capacity.

In addition to our landfill activities, we clean and supply mineral raw materials within the circular economy. We mediate for our customers between supply and demand in the field of soil, sludge, rubble and other reusable building materials. With our knowledge, extensive network and independent position, we are able to do this in the most efficient and effective way possible. In addition, we have five temporary storage facilities in the Netherlands.

The landfill in North and Central Zeeland is being sealed.

At Rotterdam-Europoort, we make compost of an ever-increasing quality.

Highlights from 2024 (MSW Netherlands)

Preparation for a new office in Stainkoeln

A well-thought-out and designed office can be a powerful lever to boost productivity, creativity, and team spirit. And that is exactly what we are going for with our new office in Stainkoeln. Important: the building will have an energy rating of A+++.

New markets for high-quality compost

High-quality compost can serve as a peat replacement. For example, there is a market in the Netherlands for potting soil with peat substitutes. Moreover, compost offers an ecological advantage as the extraction of peat is very sensitive to emissions. We are now adapting the production processes to be able to produce specific compost products for agriculture, potting soil and tree cultivation, among other things.

Smaller and smaller residual fractions to landfill

At our Europoort location in Rotterdam, we have succeeded in going from 10% to 5% residual flow. The key to success: a new screening line. Thanks to this sieve line, we can largely convert residual flows into biomass of consistent quality. We sell that biomass as a clean energy source and only the last 5% residual flow goes to landfill – a considerable improvement!

How does MSW make a difference in Ireland?

Municipal Solid Waste (MSW) management and specifically black bin waste management in Ireland, has undergone a significant transformation in recent years, evolving from a system heavily reliant on landfill, to a more integrated approach emphasising recycling, energy recovery and sustainability.

In 2022, Ireland generated 3.19 million tonnes of MSW and recycled 41% of it. That’s roughly 342kg of waste per person. When we have removed the recyclable material, we are left with residual waste, that needs to be processed or disposed of. This is where waste-to-energy facilities come in.

By sending residual waste to Meath Wasteto-Energy (WtE) Facility for treatment and energy recovery, we can divert waste, that would otherwise go to landfill. Our Meath facility processes over 200,000 tonnes of MSW annually, which is delivered by private collectors and state agencies from locations throughout Ireland. The facility generates enough energy to sustain its own operations, and also to export approximately 18 MW of electricity, enough to provide power to about 42,000 homes.

The installation in Meath ensures safe and compliant thermal recovery of waste. It operates at a minimum temperature of 850°C and is equipped with an extensive flue gas cleaning system. All emissions are monitored in real time and available here.

Indaver Meath is the first of only 2 WtE facilities to be developed in Ireland and has operated very successfully since 2011. It is considered critical infrastructure In Ireland. Alongside these dedicated thermal recovery facilities, waste is also co-processed at cement kilns and accepted at the 3 final operating MSW landfills.

Because Ireland has a deficit in treatment capacity for residual waste, there exists a dependency on export of refuse derived fuel or “RDF” (fuel derived from residual MSW) to other countries to be processed. Approx 300,000 tonnes of RDF are exported from Ireland per year. Indaver has been an active party for several years in the export of waste to our long-standing business partners in Sweden, Germany and elsewhere, where waste will be used as a fuel to generate electricity and district heating and cooling.

The Waste-to-Energy facility in Meath produces energy for about 42,000 households annually.

How does MSW make a difference in the United Kingdom?

In Aberdeen, Indaver manages the NESS Waste-to-Energy Facility, which is owned by three local authorities in Northeast Scotland. The facility processes around 150,000 tonnes of household waste annually and recovers both electricity and heat. The electricity is fed into the national grid, while the heat is supplied to surrounding communities via a local district heating network.

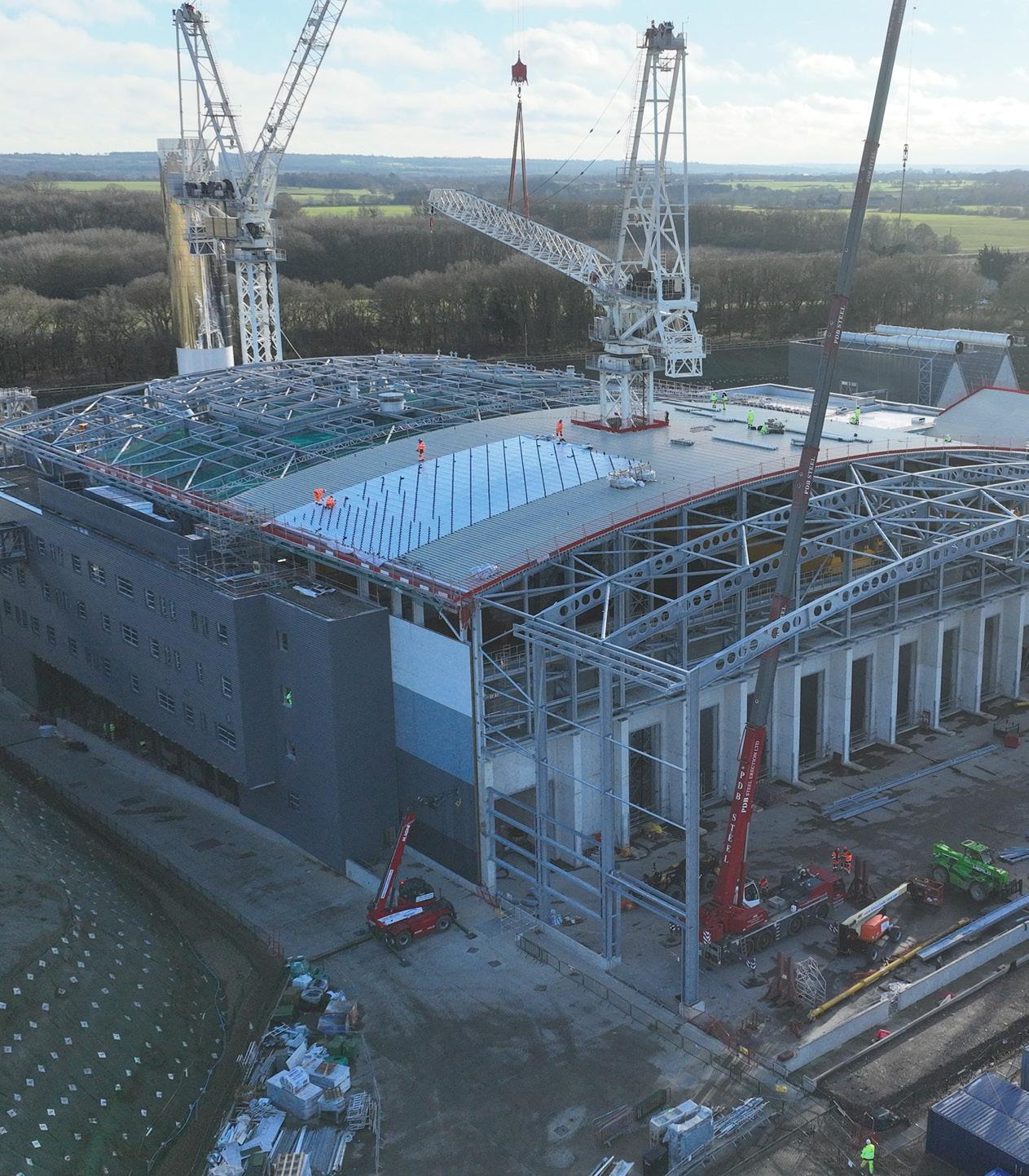

In Essex, east of London, Indaver is constructing the Rivenhall Waste-to-Energy facility, which will process 595,000 tonnes of non-recyclable household and similar commercial waste each year. This facility will be crucial for treating these waste streams locally, rather than sending them to landfill or exporting them to other regions. Importantly, Indaver plans to recover enough energy during the waste treatment process to power 130,000 households.

An overview of the construction works at the Rivenhall site.

Plastics2Chemicals (P2C): from complex to circular plastics

Our state-of-the-art installation in the port of Antwerp is, of course, the most visible aspect of Plastics2Chemicals (P2C). But we go beyond the construction and operation of an installation to chemically recycle complex plastics into new, high-quality building-blocks for industry. For example, in 2024 we opened a plant for the pre-treatment of plastic waste and we also provide logistics services, such as storage and transport. In short, we take care of every step in the chain.

Indaver Separation Technologies (IST): tailormade sludge dewatering

Sludge from production processes or a water treatment plant can seriously disrupt a company’s primary processes, resulting in high costs and possibly a production stoppage or environmental incident. To avoid this, IST offers tailormade solutions through mobile and fixed installations.

By separating production sludge or water purification sludge into water and solids, the clean water can be returned to the cycle. In addition, the material value of the dewatered sludge can be put to good use, for example in agriculture.

Shared services support business lines and units

Health & Safety offers support and follow-up in the field of health & safety.

Corporate Sustainability supports and coaches the business lines in the fields of sustainability, continuous improvement and innovation.

HR takes care of the sustainable employability and well-being of all employees within Indaver.

IT/BIS ensures the automation and digitisation of processes and all kinds of applications.

Communications is responsible for Indaver’s internal and external communication.

Financial Administration plays a crucial role in ensuring Indaver’s financial stability and growth. This finance department also includes the roles of legal affairs, insurance and purchasing.

Supply Chain is responsible for the entire logistics and administrative chain of waste: from the customer to the processing centre.

Engineering is responsible for the design and construction of new projects or modifications to existing installations.

Read more about P2C

Read more about IST.

The European Green Deal as a guide

The World Economic Forum’s Global Risks Report 2024 shows that the main challenges for the next 10 years are ecological in nature. This also applies to Europe. To help turn the tide, Indaver is focusing on three of these ecological challenges: the climate crisis; the raw materials and energy crisis; and the ecosystem crisis.

Climate crisis

Global warming is making itself felt more and more in daily life every year. For example, 2024 was 1.6°C warmer than the average for the period 1850–1900. It is the first calendar year to break through the symbolic threshold of 1.5 degrees, and that by a large margin. There is only one possible conclusion: greenhouse gas emissions must be drastically reduced. Indaver wants to play an exemplary role in this.

Raw materials and energy crisis

Europe urgently needs to become more self-sufficient in strategic and critical raw materials. This is necessary for a number of reasons, including to achieve the climate and sustainability goals. Indaver contributes to this by recovering high-quality materials and sustainable energy from various waste streams.

Ecosystem crisis

Europe’s ecosystems are under pressure from persistent pollution – think of the loss of biodiversity and the risks of Substances of Very High Concern for the environment and people. Indaver is taking the lead in this area, too. Our circular vision and our decisive actions protect the ecosystems by keeping food and material cycles clean.

In 2019, the European Commission presented the European Green Deal: a roadmap to move towards an environmentally sustainable, climate-neutral, and fully circular economy by 2050. This challenging ambition has brought with it a lot of amended and new legislation in recent years – a trend that continued in 2024.

Stricter legislation complements

our strong

decisiveness

New legislative initiatives continue to shape our sector at breakneck speed. As long as they are clear, objective, achievable and the same for all, we embrace these rules and goals for a better Europe. In fact, we see opportunities to make a difference for our customers with our decades-long policy of continuous improvement and innovation. For example, our rotary kiln ovens are among the absolute best in Europe, both in terms of sustainable destruction of hazardous waste and for material and energy recovery.

Green Deal objectives

0% net greenhouse gas emissions by 2025

Decoupling economic growth from the use of raw materials

Making sure no one is left behind 9 strategies

In response to the rapidly changing legal context, Indaver makes regular adjustments.

After all, in our social role we contribute directly to several strategies of the European Green Deal.

Transforming the economy of the EU for a sustainable future

EUROPEAN GREEN DEAL

How Indaver contributes to the European Green Deal: climate and energy

The legislation to stimulate the decarbonisation of European society affects both our own operations and our ambition to focus with even greater intensity on energy generation from household and industrial waste streams.

Renewable

Energy Directive III (RED III)

What?

RED III is the 3rd version of the European Renewable Energy Directive and aims to accelerate the energy transition. For example, there is a binding target for the share of renewable energy: (at least) 42.5% by 2030.

Why relevant?

The directive contains a definition of ‘residual heat’ that the Antwerp North Heat Network (Belgium) and ECLUSE (Belgium), among others, must meet. This allows us to sustainably valorise this residual heat.

Energy Efficiency Directive (EED)

What?

The Energy Efficiency Directive (EED) sets out rules and obligations regarding primary and secondary energy consumption. In 2024, the European Commission published recommendations on financing energy efficiency.

Why relevant?

Heat networks that are fully fed with residual heat are recognised as ‘efficient’ and even ‘carbon-neutral’ through a recent Recommendation Document. In short, Indaver’s heat networks enable companies to reduce their Scope 2 emissions.

Emission Trading System (ETS)

What?

Industrial companies that fall within the scope must surrender one emission allowance for every tonne of fossil CO2 emissions. They can buy and trade those emission rights.

Why relevant?

The outcome of the European decision-making process on the place of waste processing within the ETS is still uncertain, but we do expect an impact. Today, only our E-Wood power plant is covered by the ETS system because of the use of biomass. Our Waste-to-Energy installations could also fall under the ETS regime from 2028 onwards.

Effort Sharing Regulation (ESR)

What?

The ESR sets a national target for each Member State to reduce greenhouse gas emissions from sectors not covered by the Emission Trading System (domestic transport, buildings, agriculture, small industry & waste). All relevant actions must be included in the National Energy and Climate Plan (NECP).

Why relevant?

The waste management sector is currently covered by the ESR system. Sometimes there are additional measures to reduce the environmental impact. For example, the German federal government has been levying a CO2 tax on thermal waste treatment plants since 2024.

EU Taxonomy

What?

The EU Taxonomy is a classification system that clarifies which activities are sustainable by virtue of their contribution to environmental objectives. The system prevents greenwashing by setting clear criteria for the share of turnover and investments that may be included.

Why relevant?

The classification system recognises that our rotary kiln ovens provide an essential social service. This is because they are the final link in the circular economy by destroying hazardous substances and thus keeping the cycle clean. This is a recognition of the sustainability of our activities in this area.

Carbon Removal Certification Regulation (CRCR)

What?

In December 2024, the ‘Regulation establishing a certification framework for permanent carbon removals, carbon land management and carbon storage in products’ was published. In this way, the EU wants to create a positive climate effect and prevent greenwashing.

Why relevant?

If the voluntary certificates for carbon removals and soil emission reductions break through, this could be an opportunity for efficient and effective carbon removal from our industrial processes, contributing significantly to EU climate neutrality by 2050. After all, CO2 capture and storage counts as permanent carbon removal.

How Indaver contributes to the European Green Deal: the circular economy

The EU is in the process of redesigning the legislative framework for the transition from a linear to a circular production and consumption model. As an enabler and gatekeeper of the circular economy, we make sure to keep our finger on the pulse and inform our customers about the (upcoming) legal framework.

Waste Shipment Regulation (WSR)

What?

The objective of this legislation is to protect the environment and human health from the adverse effects of the international transport of waste. This includes a ban in principle on the export of waste outside the European Union.

Why relevant?

From 2026, the revised WSR introduces a further tightening of the waste export ban outside the EU and of intra-EU traffic with destination ‘Disposal’ (disposal vs recovery). In addition, the new WSR also provides for a substantial digitisation of the notification procedures.

Waste Framework Directive (WFD)

What?

The Waste Framework Directive, which has been in force since 1975, sets out the legal framework for the treatment of waste in the EU. In 2024, a review got underway focused on textiles and food waste.

Why relevant?

The Framework Directive includes concepts and definitions within waste management, such as definitions for waste, recycling and recovery. In addition, it also establishes a priority order in the so-called waste hierarchy: prevention, preparation for reuse, recycling, other recovery applications (e.g. energy recovery), and disposal. The directive thus forms the basis for many of our decisions.

Critical Raw Materials Act (CRMA)

What?

The CRMA aims to ensure that the EU has access to a secure and sustainable supply of critical and strategic raw materials. This is important to achieve the European objectives on climate and digitalisation.

Why relevant?

One of the key goals of the CRMA is that by 2030, at least 15% of the annual consumption of critical and strategic raw materials must come from local recycling processes. This offers an opportunity for Indaver, which has been specialising in the recovery of high-quality materials from various waste streams for years.

Packaging & Packaging Waste Directive (PPWD)

What?

The EU published the revised PPWD in January 2025 with the goal of harmonising packaging standards at national and European level, reducing packaging waste as much as possible, and promoting the reuse and circularity of packaging materials.

Why relevant?

The PPWD includes provisions for the use of recycled content in plastic packaging for the first time. Although the calculation method has yet to take shape, the development of the P2C project gives Indaver a unique asset to help customers achieve the targets.

Towards a circular economy

Need for extra recycling capacity

Targets for the recycling of plastic packaging in the EU:

How Indaver contributes to the European Green Deal: zero pollution

As part of the European Green Deal, the EU wants to reduce air, water and soil pollution to a level that is no longer harmful to humans and our natural ecosystems. This legislation contributes to this.

Industrial Emissions Directive (IED)

What?

Need for high-quality recycling

Targets for recycled content (from post-consumer waste) in plastic packaging in the EU:

Important: because we are selling more and more materials on the raw materials market, quality specifications and product standards are also coming into focus, such as REACH to control the risks of chemical substances.

The directive has been in force since 2010, with the aim of reducing and controlling harmful emissions from industrial activities, thereby protecting our air, waters and soil.

Why relevant?

Through this legislation, the EU sets rules to prevent and, where that is not possible, limit emissions into air, water and soil. Specifically, IED contains, for example, operational requirements, emission limit values and monitoring and compliance requirements for thermal waste treatment plants.

BREF (Best Available Techniques Reference Documents) for waste incineration

What?

The BREF for waste incineration plays a crucial role within European legislation, especially with regard to the Industrial Emissions Directive. The BREF document describes a number of general Best Available Techniques (BAT) that apply to all waste incineration plants, regardless of the type of waste they are processing. In addition, BAT is also given for waste incineration plants that treat specific types of waste, such as household, medical or hazardous waste.

Why relevant?

This BREF has a direct impact on the management and operation of Indaver’s waste incineration plants. We closely follow all requirements, introduce necessary changes and always work in accordance with the BAT.

BREF FOR LANDFILLS IN THE MAKING

The European Agency for Research on Industrial Transformation and Emissions has started the development of the BREF landfills. Indaver is looking forward to the outcome of the European BAT study and we welcome the proposal to ensure equal responsibility among all partners in our sector.

Our international presence

Indaver is active in 9 European countries. There, we manage and operate installations and many other sites that keep material chains closed and safe. Through our targeted investments and acquisitions, we are systematically expanding our radius of action, as well as our capacity to efficiently recover energy and materials from various waste streams.

Waste-to-Energy plants

Our Waste-to-Energy installations extract energy from nonrecyclable waste.

Doel (BE), Meath (IE), Aberdeen (UK), Rivenhall (UK, under construction), Ghent (BE, under construction)

Hazardous waste plants

Our specialised incineration plants neutralise hazardous waste at a high temperature and generate maximum energy. Hamburg (DE), Biebesheim (DE), Antwerp (BE)

Recycling

Our high-tech installations recover valuable materials, such as precious metals, solvents, ferrous and non-ferrous metals and plastics.

Inda-MP (BE), Solvents (UK, BE), P2C (BE), IndaChlor (FR), PMD sorting (BE), bottom ash treatment (BE), Indaver Relight (BE), ARP (NL)

Composting

Our installations process organic and green waste into valuable raw materials and sustainable energy. the Netherlands

Transfer

stations

Transfer stations for the safe, temporary storage and processing of waste.

All Indaver countries

Sustainability reporting according to the CSRD

To make the European Green Deal a success, it is important that consumers, banks, governments and other players can more easily compare organisations when it comes to sustainability performance. The new Corporate Sustainability Reporting Directive (CSRD) enables this level of reliable and transparent comparison. The directive does this by requiring all in-scope companies to publish annual sustainability reports that meet strict standards – the European Sustainability Reporting Standards (ESRS).

In 2026, our parent company, Katoen Natie, will issue a first CSRD-compliant report on fiscal year 2025, to which Indaver will actively contribute. In line with this, we will also continue to publish our own sustainability report. This edition is a so-called transitional edition and already contains aspects from the joint CSRD report.

A new chapter in a long tradition

The CSRD has a much broader target group than its predecessor, the Non-Financial Reporting Directive (NFRD). As a result, more than 50,000 European organisations will have to report on sustainability from 2026 – many for the first time. However, Indaver already has a long tradition in sustainability reporting, with the publication of our first annual report more than 20 years ago.

This means that with the arrival of the CSRD, we are mainly building on what we have already been doing. Below is an overview of some important new revisions that we implemented (partly) in this report for 2024.

What were we doing before CSRD?

Structure of the report

Reporting according to the 17 Sustainable Development Goals and GRI standards

Materiality

Determination of materiality based on own evaluations and stakeholder engagement

Data

collection

Data collection for material topics, from training hours to mass balances of installations

Transparency

Internal determination of targets and associated action plans

What’s new with CSRD?

Beyond the CSRD...

Joining the SBTi

Reporting according to the ESG format and the relevant ESRS

Determination of materiality according to principles of double materiality as described in ESRS 1 and 2

In addition to the mandatory CSRD requirements, Indaver is also continually raising the bar for itself. For example, we want to score better and better for EcoVadis, and we recently also endorsed the Science Based Targets initiative (SBTi). By the end of 2025, we are aiming for a comprehensive decarbonisation plan, including short- and longterm targets, which we will then submit to the SBTi for validation.

Expansion and deepening of data collection, especially for the carbon footprint (fleet, forklifts, etc.)

External publication of targets and associated action plans

CO2 calculations for customers

We help our customers with their CSRD reporting via our own tool for calculating CO2 emissions. For example, we can share how much the emissions were for a certain volume of waste according to a certain processing method, just like data for transport. This provides customers with reliable data for their own report on Scope 3 (category 3.5: waste generated in operations). We also provide them with information about avoided emissions associated with the volume of waste they deliver (Scope 4).

Our emissions laboratory at Doel.

Double materiality: the key to effective reporting

The concept of double materiality is central to the CSRD and combines two perspectives: impact materiality and financial materiality. The latter perspective is new and requires Indaver to analyse how sustainability issues affect our financial performance. The advantage is that it allows us to better anticipate risks and opportunities that may affect our financial health in the short, medium and long term.

In 2024, much attention was paid to the execution of our double materiality analysis (DMA), including the determination of our impacts, risks and opportunities (IROs). Although in previous years we assessed materiality on the basis of various sources and stakeholder feedback, those analyses did not meet the requirements of the CSRD.

Sustainability reporting according to the CSRD - Towards a solid foundation for reporting in 6 steps

Towards a solid foundation for reporting in 6 steps

Step 1: Scope and pre-selection topics

After determining Indaver’s main activities and value chain, we drew up a longlist of sustainability issues that are close to our strategic objectives. We did this on the basis of the ESRS Guidance Documents. More specifically, we selected 14 of the 18 topics listed.

Step 2: Stakeholder Consultation

We consulted our main internal and external stakeholder groups through direct discussions or indirect methods (such as desk research).

Suppliers and partners

Employees of Katoen Natie

Customers

Research and knowledge institutions

Sector federations

NGOs

Business partners

Investors and analysts

Regulators and policymakers

Subsidiaries of Katoen Natie

Step 3: Materiality analysis

Based on all the input collected, we confirmed and scored the 14 material topics on which we will report. The topics are evenly spread across Environmental, Social and Governance. To illustrate: all ESRS apply to Indaver, except for ‘ESRS S4 – consumers and end users’, because they are too far down our chain, both upstream and downstream.

topics

Climate change mitigation Employee health &

Hazardous substances & materials Working conditions & employee well-being Sustainable & resilient supply chains

Pollution prevention & reduction Diversity, equity and inclusion

Marine & inland biodiversity Workforce’s social rights

Resource use & circular economy

Workers in the value chain and human rights

Engagement with local communities

Step 4: Determination of Indaver’s IROs

& service innovation

By identifying and scoring all impacts, risks and opportunities (IROs), we better understand how sustainability issues affect our financial results and vice versa. Double materiality is therefore not only a basis for effective reporting, but also a valuable tool for our business strategy and business models.

FIRST QUALITATIVE ASSESSMENT OF INDAVER’S IROS

Environmental topics

Important: this assessment is based on interviews with senior staff and various advocacy groups, which we assume may represent larger stakeholder groups. In the next step, an (external) validation round will follow in which we will have both the topics and exact scores validated.

Social topics

Social topics Environmental topics

For a full description of our material impacts, risks and opportunities, please go to CSRD Benchmark.

Governance topics

Governance topics

Step 5: Central data collection

Although we are very active in the field of sustainability, the CSRD requires us to collect and maintain much more data centrally. That is why we are now consolidating data that was previously not always centrally recorded for various reasons. Think, for example, of data on the application and retention of permits that were only available locally until recently.

Step 6: Targets and action plans

Once we understand in detail where we currently stand and have identified areas for improvement, we can set specific goals to guide our future efforts. We will continue to work on this in 2025 so that we can share them in our next sustainability report.

“We have been measuring and communicating our sustainability performance for years – either because customers asked for it, or because we consider it ‘good business’ ourselves. With the CSRD as a catalyst, we are now shifting up a gear. Not only because we have to, but especially because we believe in the benefits of mapping out impacts, risks and opportunities associated with sustainability topics even more specifically. With the insights, we are improving our contribution to an increasingly cleaner, circular and just society.”

Corrinne Goenee, ESG-manager

Our contribution to the Sustainable Development Goals

In the context of our sustainability strategy, Indaver attaches great importance to transparent reporting and international alignment. The Sustainable Development Goals (SDGs) of the United Nations are an important frame of reference in this regard.

Our material themes are carefully determined through our materiality analysis and reflect the sustainability priorities of Indaver and its stakeholders. In the attached table, we show how our activities contribute to specific SDGs. For example, the most important SDG for us is SDG 12 - Responsible consumption and production. Needless to say, this objective fits perfectly with Indaver’s mission.

Next to these leading SDGs, we also make a reference to secondary SDGs in this report, such as SDG 15 – Life on land.

SDG 3: Good health and well-being

SDG 4: Quality education

SDG 6: Clean water and sanitation

SDG 7: Affordable and sustainable energy

SDG 8: Fair work and economic growth

SDG 9:

Industry, innovation and infrastructure

SDG 11:

Sustainable cities and communities

SDG 12:

Responsible consumption and production

SDG 13: Climate action

SDG 17: Partnerships for the goals

Indaver’s commitment

We promote a proactive safety and health culture in the 9 countries where we have facilities.

Lifelong learning is a prerequisite for sustainable employability of employees at Indaver.

For customers, we treat wastewater so that it can be reused. To reduce our own water footprint, we make maximum use of rainwater, commit to reusing internal wastewater streams and optimise our processes.

By recovering energy from waste, Indaver contributes to European energy goals.

As an international group with 2,306 employees, we promote economic productivity through diversification, technological modernisation and innovation.

Indaver stimulates innovation both inside and outside its own company walls. Moreover, we support industry in tackling new challenges related to raw materials.

We supply energy to industry and residential areas, while also effectively protecting our ecosystems.

Indaver is creating a pure circular economy. With our core activities, we limit the impact of waste on people, climate and the environment, while also going full steam ahead with positive impact.

Indaver has a Carbon Management Plan with 6 focus areas to pursue Science Based Targets.

We actively seek external partners to put our mission around sustainable waste management into practice.

Environmental

A healthy planet through sustainable waste management

At Indaver, we consider it our social duty to actively contribute to the quality of life on the planet. We use the European Green Deal and the Clean Industrial Deal as a compass for this. Through these action plans, the EU aims to make our society more sustainable by rethinking technologies, production processes, consumption patterns and our way of living.

Indaver is ideally placed to work within a new, fundamentally different system. After all, we are already recovering high-quality materials and energy from waste and thus protecting our ecosystems. In other words, our approach to waste is already providing valuable solutions to some of the biggest challenges facing Europe, such as material scarcity, energy dependence, climate change and environmental pollution.

Reducing our carbon footprint

Why important?

Last year, 2024, was the warmest year on record. What’s more, 2024 was the first calendar year to break through the symbolic barrier of 1.5 degrees of warming compared to the pre-industrial period (1850-1900) –that is a first for planet Earth, and an ominous warning. The warming of 1.5 degrees is not yet structural, but scientists expect it to be so around 2030.

In the Paris Climate Agreement, the EU agreed with 200 countries to keep structural global warming ‘well below two degrees, and preferably at one and a half degrees’. The latter goal seems a long way off, but it remains important to strive for every tenth of a degree less warming because every tenth means a less severe impact in the form of extreme weather conditions. Indaver is doing its bit to achieve Europe’s climate targets.

Our objectives and approach

Indaver is ambitious in terms of climate action, but we operate in a particular sector. While waste disposal is crucial to keeping the environment and our material chains clean and pure, it also leads to emissions. During the incineration of waste, CO2 is inevitably released from the waste itself. For our other emissions – e.g. from fuel and purchased electricity – we are aiming for a significant reduction, just like other industrial sectors.

How does our sector differ from other industrial sectors in terms of carbon footprint? We zoom in on the differences per scope in this chapter.

Scope 1

Remarkably high share of (unavoidable) emissions from waste

The focus of our carbon footprint is on Scope 1, the greenhouse gas emissions that arise in or through our installations and vehicles. This mainly concerns the CO2 that is released from waste during incineration. This translates to an estimated 95% of our Scope 1 emissions being unavoidable, because we cannot replace waste with an alternative.

Our Scope 1 emissions are therefore directly proportional to the volumes of waste generated by society, as well as the composition of that waste. In fact, the more installations we start up to carry out our essential social role, the greater our Scope 1 – and therefore carbon footprint. Only carbon capture & storage or carbon capture & utilisation could offer amelioration in this regard, but the technology is not yet advanced enough to roll it out on a large scale in our industry. In addition, its implementation would immediately encounter limitations, such as available infrastructure.

Scope 2

Limited emissions thanks to self-generation

With a 1% share of our total carbon footprint, our Scope 2 emissions are rather limited. This is largely due to the energy that we recover and use ourselves in the thermal treatment of non-recyclable waste. For example, we use part of the energy recovered in our incinerators in Belgium, Germany, Ireland and the United Kingdom to fuel our own buildings and processes.

Scope 3

Much smaller than most industrial sectors

Emissions from our upstream and downstream value chain represent a small share of our total carbon footprint and consist mainly of purchased products and services, such as outsourced processing and transport. This is atypical, because for most industrial players Scope 3 is by far the largest factor in the total carbon footprint – about 75% on average, according to the Carbon Disclosure Project.

It is important to mention that our Scope 1 and 2, as well as the outsourced processing within our Scope 3, form part of our customers’ Scope 3. We pass on the necessary calculations to them, so that they can report truthfully on the impact of their waste.

Scope 4

High share of avoided emissions

Scope 4 is a new concept within CO2 accounting to refer to avoided emissions. More specifically, Scope 4 is defined by the World Resources Institute as ‘emissions that are avoided when an organization uses a product to replace other goods or services; with the same function but with a lower CO2 intensity’.

Scope 4 does not count as a carbon-reduction measure or the achievement of Science Based Targets. It is also not yet a mandatory scope to report on, e.g. within the CSRD. But this new dimension does help to build a more comprehensive overview of Indaver’s contribution to the carbon footprint of society as a whole. For example, Indaver avoids many emissions through energy and material recovery from waste.

Boortmalt uses green energy from Indaver’s thermical treatment of waste thanks to the Antwerp North Heat Network.

Carbon Management Plan for a CO2-neutral Indaver

Based on the unique nature of our carbon footprint, Indaver has developed its own Carbon Management Plan. This includes 6 qualitative focus areas that are discussed in detail in this section.

In line with our commitment to the Science Based Targets initiative (SBTi), in 2024 we started to further refine and expand this plan. By the end of 2025, we aim to have submitted our decarbonisation targets, timeline and KPIs to the SBTi for validation.

In the making: Science Based Targets

Our commitment to the SBTi means that Indaver wants to draw up a decarbonisation plan that is in line with the targets necessary to limit global warming to 1.5°C, as set out in the Paris Agreement. More specifically, we are working on reduction targets for the short and long term.

What are we going to do in 2025?

Create a complete and validated inventory of our emissions within Scope 1, 2, 3 and 4 to create a baseline model.

Identify ongoing and potential decarbonisation activities through a bottom-up approach.

Develop a strategy and action plan for decarbonisation.

“We are fully committed to improving our carbon footprint in all Scopes. However, due to the specific nature of our Scope 1 and 4 emissions, a successful journey depends to a large extent on collaborations with partners throughout our value chain. We will take the lead in this and work out an ambitious but realistic plan for ourselves. The ultimate goal: to be CO2 neutral by 2050.”

Karl Vrancken, Chief Sustainability Officer

Our projects and initiatives in 2024

For many years, Indaver has had a Carbon Management Plan for managing and reducing CO2 emissions related to our facilities and the treatment of waste. We are currently further developing and quantifying that plan.

In our plan, we identify 6 focus areas that will help to reduce CO2. Some of these focus on the short term, others on the longer term.

Focus area 1

Destroying waste materials to reduce their impact

As gatekeeper of the circular economy, there is an important responsibility for Indaver to keep hazardous waste out of the cycle. Our rotary kiln ovens in Belgium and Germany are essential for this. These furnaces also destroy various hazardous substances, such as HFCs (hydrofluorocarbons). These are mainly used in refrigeration systems and have a high Global Warming Potential (GWP). By destroying these substances, we help to prevent them from contributing to global warming. Our

site IndaChlor (France) also destroys waste materials, such as tetrachloromethane, a harmful substance with a very high GWP, during the recovery of chlorine.

It goes without saying that we always keep these installations in prime condition and improve them whenever possible. For example, in 2023 we replaced a rotary drum in one of our furnaces in Antwerp (Belgium), while in 2024 we introduced several improvements to our installations in Hamburg and Biebesheim (Germany) to ensure we continue to meet the strictest environmental requirements.

Focus area 2

Avoiding emissions by keeping carbon in the chain through recycling