ISSN: 2321 9653; IC Value: 45.98; SJ Impact Factor: 7.538 Volume 10 Issue XI Nov 2022 Available at www.ijraset.com

ISSN: 2321 9653; IC Value: 45.98; SJ Impact Factor: 7.538 Volume 10 Issue XI Nov 2022 Available at www.ijraset.com

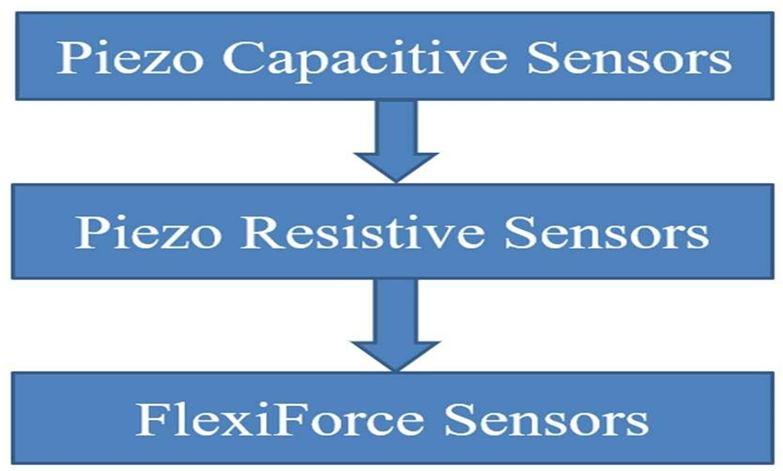

Abstract: Occlusal load, contact sequence and location are necessary parameters for the study of dental biomechanics, simulation, and clinical treatment planning. There is a huge demand for dental implants, which could accurately and precisely become a substitute to natural teeth, in human beings. To select the most appropriate material for implants as well as designing an artificial tooth, it is important to understand the force exerted by the human jaw while in the process of mastication. To achieve this, there are multiple attempts as well as iterations done through various steps and circuit arrangements, primarily through piezoelectric sensors here. This happens to be the one of the most appropriate ways to measure and quantify the bite force of a tooth. After iterating with charge amplifiers, piezo capacitive and piezo resistive circuit arrangements, moving ahead with the FlexiForce measurement kit and using the A201 sensor which provided with the stable and consistent output for static as well as dynamic loading.

Keywords: Flexiforce kit, Piezoelectric sensors, occlusal load

Mastication is one of the processes in living beings, which influences the digestion process. During this process, there are forces exerted by the teeth on the food particles which may vary according to the consistency and type of food being consumed. In the Dental field, there are several instances where the original teeth are damaged because of several reasons like accident, cavity, or poor hygiene. In those particular cases, artificial teeth, i.e., implants or just dental caps are used to do the function of the original teeth. These components have the similar parameters to that of an actual tooth. In terms of design and material properties, as well as the strength. The materials must be appropriate in terms of the force that the teeth exert to successfully aid in the chewing process.

Every type of tooth has a specific function and arrangement; therefore, they have different and unique characteristics. The object of this communication is to discuss the use of quartz, in dentistry, to monitor biting forces quantitatively and to give details of a transducer assembly. This investigation was conducted to correlate biting force magnitude to the degree of mouth opening (i.e., vertical dimension) and different mandibular positions. A quartz disc with a diameter of 6 mm can withstand approximately 2600 N without fracture when compressed between two flat parallel planes. For the research of masticatory biomechanics and simulation, three occlusal characteristics are necessary: contact location, load, and sequence. The polling procedure can make polymers that don't ordinarily have piezoelectric characteristics. The polymer is heated until the molecules may freely migrate. The molecules (electric dipoles) are aligned along the axis of the applied electric field after being subjected to a high electric field. The polymer is then cooled under a continuous electric field to keep the dipoles from reverting to their random configuration. The amount of piezoelectric activity produced is determined by the amount of heat applied. The produced charge varies in proportion to the strain and is independent of the strain frequency, hence piezoelectric films may be employed as force gauges in general. To prevent interference with natural occlusion, a tiny cross section and great flexibility are desirable. These are critical design parameters for occlusal contact sensors that are accurate. Vinylidene fluoride polymer covered with silver ink is used to make piezo films. The film's composition should not be damaging to health because it will only be used in a therapeutic environment for a short time.

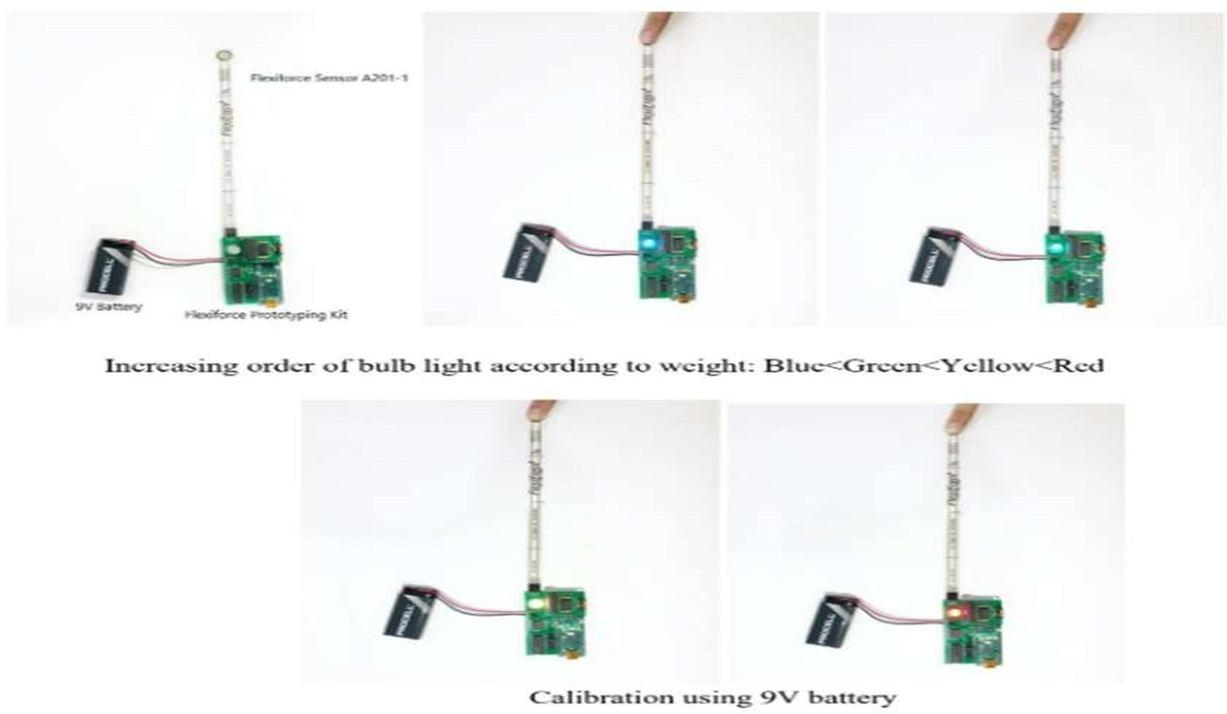

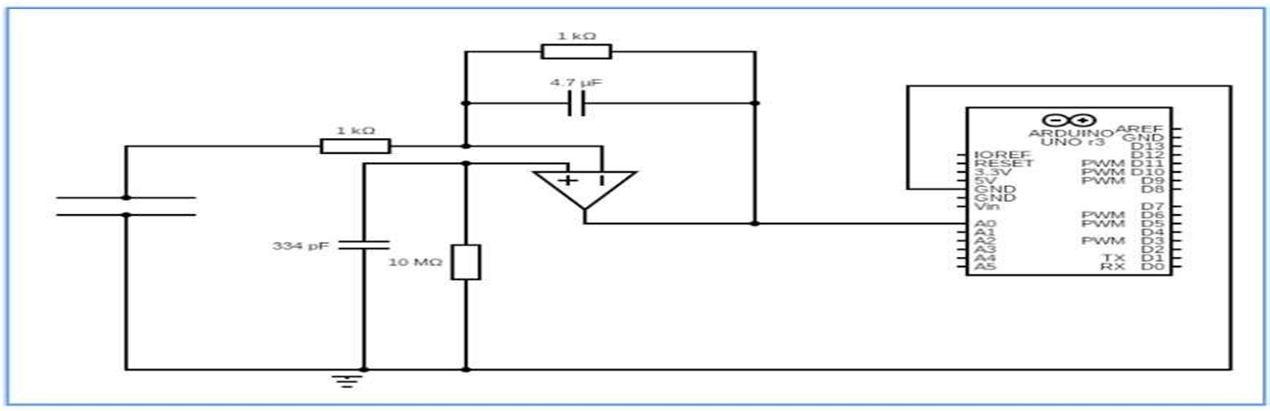

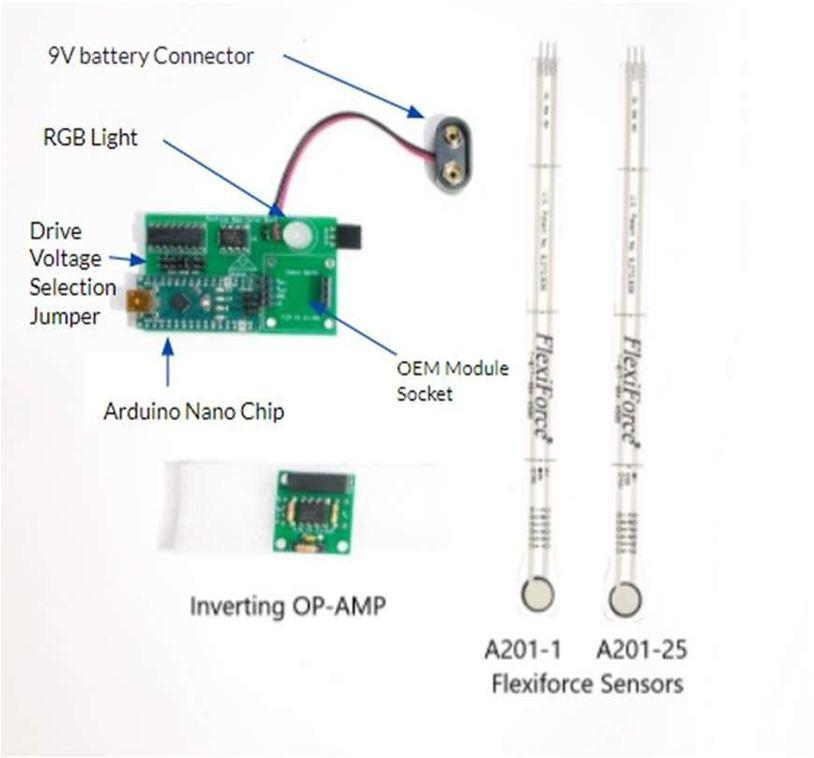

Flexi Force sensor (here used is A201) are the piezoresistive sensors. When the load is applied on the sensing area of the sensor, the resistance value changes in the inverse proportion to the force applied. It can be used for static and dynamic frce measurement. When the piezoelectric sensor is directly connected to ADC of Arduino with using resistor the output is very low, it gives maximum value of 2.97V at weight of 2000g.

ISSN: 2321 9653; IC Value: 45.98; SJ Impact Factor: 7.538 Volume 10 Issue XI Nov 2022 Available at www.ijraset.com

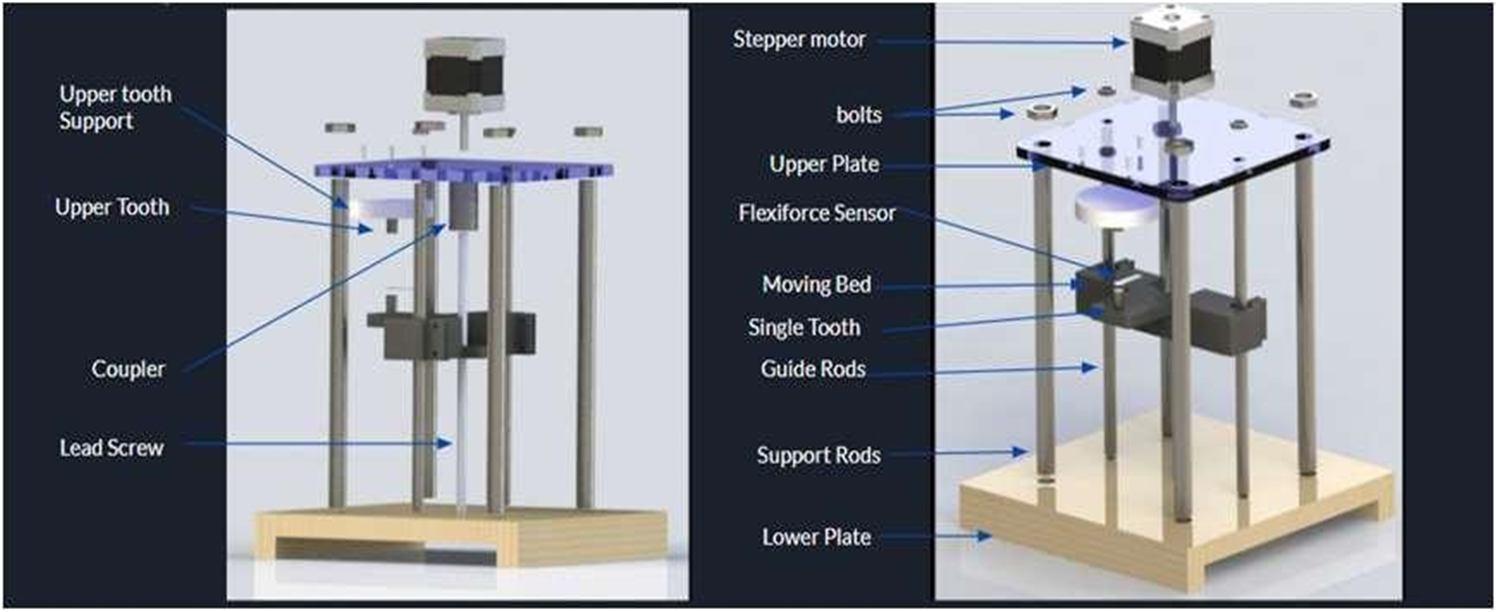

The setup is developed by taking in consideration the actual human jaw. Here, it involves an imitation of an individual tooth surface. The upper and lower tooth put together; it is an artificial arrangement where there is a vertical movement of the spanner. There are four rods that support the entire setup. Along with additional two guiding rods that help in the movement of the spanner. A motor is mounted on the top to power the rotational movement of the spanner through the coupler by lead screw. In such a way the movement of the teeth can be replicated.

ISSN: 2321 9653; IC Value: 45.98; SJ Impact Factor: 7.538 Volume 10 Issue XI Nov 2022 Available at www.ijraset.com

The FlexiForce sensor is a flexible, ultra thin printed circuit that may be readily incorporated into a wide range of applications. The FlexiForce force sensor can measure force between practically any two surfaces because of its paper thin design, flexibility, and force measuring capabilities. Sturdy enough to withstand the harshest conditions. The force sensing characteristics of FlexiForce are superior. Compared to other thin film force sensors, it has better linearity, hysteresis, drift, and temperature sensitivity. The sensor’s “active sensing area” is a0.375" diameter circle at the sensor’s end. The sensors are made up of two substrate layers. Polyester film makes up this substrate (or Polyimide in the case of the High Temperature Sensors). A conductive substance (silver) is put to each layer, which is then followed by a layer of pressure sensitive ink. After that, adhesive is utilized. To construct the sensor by laminating the two layers of substrate together the silver circle that sits above the "active sensing region" is defined by pressure sensitive ink. Silver spreads from the sensory region to the rest of body.

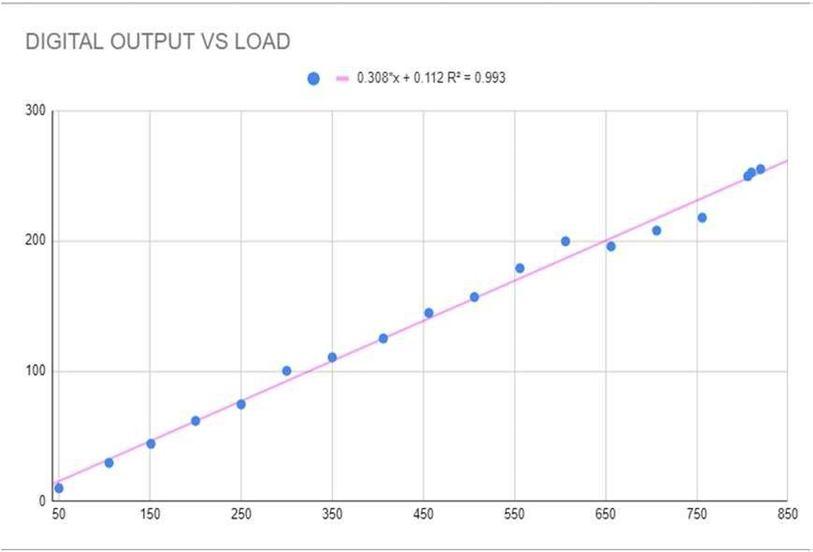

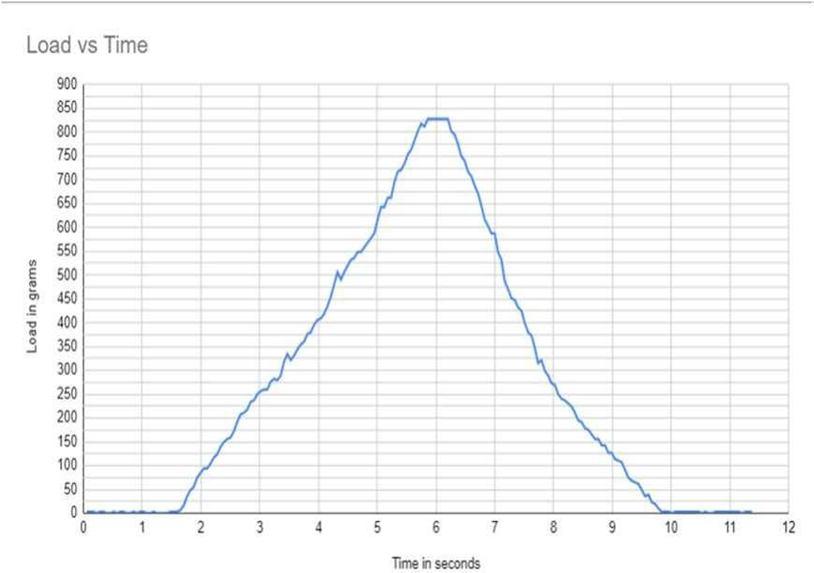

Taking in consideration the boundary conditions as 0 255 Here are the recorded values by the FlexiForce Sensor. Moving ahead, the second graph is of the cycle of dynamic loading. Analysis of different factors affecting the measurements.

ISSN: 2321 9653; IC Value: 45.98; SJ Impact Factor: 7.538

Volume 10 Issue XI Nov 2022 Available at www.ijraset.com

1) The values from the FlexiForce sensor are stable

2) The measurements vary accordingly with the loading

3) There is a small effect of environmental conditions as well

4) The graph plotted provides the information of the force values

5) The sensor is successfully conditioned and calibrated

1) The dynamic loading on the tooth surface gives a linear graph

2) The values of the force are stable in a particular range

3) The loading, when done in a cycle, varies similarly for unloading

4) The artificial arrangement successfully resembles the actual one

5) The data can be utilized in dental prosthetics

6) It can be used in the R&D of materials used dental caps

7) The data can be utilized to improve the chewing experience

8) The values can be used to design artificial teeth

[1] www.wikipedia.com

[2] www.sciencedirect.com

[3] www.explainthatstuff.com

[4] www.flexiforce.com

[5] www.azoforce.com

[6] www.tekscan.com