CRITICAL SUCCESS FACTORS OF DIGITAL FABRICATION IN A BUILT ENVIRONMENT

Conclusion

Use of digital fabrication in construction industry has helped in understanding project life cycle and better project delivery. It has helped to modify the future of all three industries – Architecture, Construction and Engineering.

The impact of these technologies on users’ behavior is being considered on a large scale as the relation between construction process and human behavior is evolving.

Aim

The research aims at exploring critical success factors of digital fabrication in a built environment in architecture and construction industry.

Objectives

To know the drivers of the digital fabrication.

To examine the implementation issues of digital fabrication in small-medium scale firms.

To understand the nascent growth of digital fabrication in architecture and construction industry.

To explore the future of digital fabrication.

Methodology

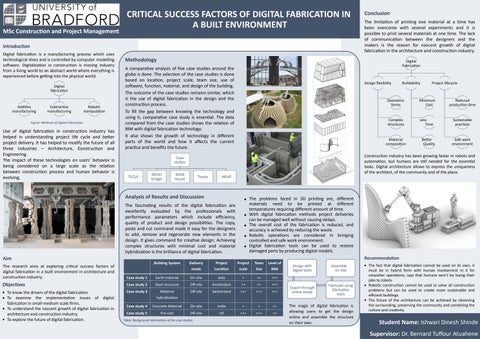

A comparative analysis of five case studies around the globe is done. The selection of the case studies is done based on location, project scale, team size, use of software, function, material, and design of the building.

The outcome of the case studies remains similar, which is the use of digital fabrication in the design and the construction process.

To fill the gap between knowing the technology and using it, comparative case study is essential. The data compared from the case studies shows the relation of BIM with digital fabrication technology.

It also shows the growth of technology in different parts of the world and how it affects the current practice and benefits the future.

Case studies

Analysis of Results and Discussion

The fascinating results of the digital fabrication are excellently evaluated by the professionals with performance parameters which include efficiency, quality of product and design possibilities. The copy, paste and cut command made it easy for the designers to add, remove and regenerate new elements in the design. It gives command for creative design; Achieving complex structures with minimal cost and material hybridization is the brilliance of digital fabrication.

The problems faced in 3D printing are, different materials need to be printed at different temperaturesrequiringdifferentamountoftime.

With digital fabrication methods project deliveries canbemanagedwellwithoutcausingdelays.

The overall cost of the fabrication is reduced, and accuracyisachievedbyreducingthewaste.

Robotic operations are considered in bringing controlledandsafeworkenvironment.

Digital fabrication tools can be used to restore damagedpartsbyproducingdigitalmodels. Design with

The limitation of printing one material at a time has been overcome with several experiments and it is possible to print several materials at one time. The lack of communication between the designers and the makers is the reason for nascent growth of digital fabrication in the architecture and construction industry.

Digital Fabrication

Design flexibility

Buildability

Project lifecycle

Geometric forms

Minimum Cost

Reduced production time

Complex structures

Less Time

Sustainable practices

Material composition

Better Quality

Safe work environment

Construction industry has been growing faster in robots and automation, but humans are still needed for the essential tasks. Digital architecture allows to express the uniqueness of the architect, of the community and of the place.

Recommendation

The fact that digital fabrication cannot be used on its own, it must be in hybrid form with human involvement in it for smoother operations; says that humans won’t be losing their jobs to robots.

Robotic construction cannot be used to solve all construction problems but can be used to create more sustainable and efficient buildings.

The magic of digital fabrication is allowing users to get the design online and assemble the structure ontheirown.

The future of the architecture can be achieved by observing the surrounding, preserving the community and combining the culture and creativity.

Student Name: Ishwari Dinesh Shinde

Supervisor: Dr. Bernard Tuffour Atuahene

fabrication Additive manufacturing Subtractive manufacturing Robotic manipulation

Digital

Building System Delivery mode Project Location Project scale Team Size Level of BIM Case study 1 Earth material On-site Italy + ++ +++ Case study 2 Steel structure Off-site Amsterdam ++ ++ +++ Case study 3 Material hybridization Off-site Switzerland +++ +++ +++ Case study 4 Concrete Material On-site India + + ++ Case study 5 Pre-cast Off-site UK +++ +++ ++

digital tools Export through online mode Fabricate using fabrication tools Assemble on-site

Table: Background information of the case studies

Figure: Methods of Digital Fabrication

TECLA

MX3D bridge DFAB House Tvasta ARUP