DG8,Icomera’sdedicateddesignandengineeringdivision,deliveredaturnkeysolutionfor NetworkRailaspartofaprojecttoconverttwoBritishRailClass153“Sprinters”into VisualInspectionUnits(VIUs).

Initsroleasleadsupplier,DG8oversawtheinstallationdesignandengineering,approvals (RIS-2700-RST),materialsupplyandinstallationwork.

TheUrgentNeedtoAddressTwoKey Challenges

ReduceRiskstoRailwayStaff

Issuessurroundingtrackworkersafetyaretreatedwith utmostprioritybyNetworkRail-theownerandinfrastructure managerofmostoftheBritishrailwaynetwork.

Currently,NetworkRailemployeesspendhundredsof thousandsofhoursontrackforswitch&crossing(S&C) inspections.However,switchesandcrossingsarethehighest riskassetintrackengineering.NetworkRailstandards requireS&Cinspectionstobecarriedoutuptoweeklyin someareas.Thisissometimesdoneduringtheday(causing disruptiontopassengerandfreightservices)butmoreoften donemanuallyatnightbyatrackengineerwhowalksalong thetrackduringapossessionandlooksattheassetusing justatorch.

ManualS&Cinspectionsbringriskstoengineeringteams. Followingseveralseriousincidents,NetworkRailsoughta proof-of-conceptwhichwoulddemonstrateaviable alternativetoon-footvisualinspections,meaningthatsome inspectionscouldbedivertedtothesafetyofanoffice.

ImproveNetworkInfrastructureManagement

Byguidingtrainsfromonetracktoanother,switchesand crossingsplayanintegralroleinthelifeoftherailway.

However,theyareverypronetowearandtearbecausetrains frequentlytraveloverthem,meaningthattheyneedtobe

monitoredandreplacedregularly.With20,000milesoftrack forNetworkRailtomaintain,that’squiteajobforitsstaffto domanuallyoutonfoot!

Everyyear,severallow-speedtrainderailmentsoccuronthe networkduetoissuesinwhichS&Careatfault.These derailmentscausesignificantdisruption¹;andtheyalso requirelargenumbersofengineeringstafftobe (re)allocatedtohelpresolvetheproblem,whichincursits ownstaffsafetyrisks,inadditiontocostandlogistical issues.

NetworkRailwerethereforekeentoimplementasolution whichwouldhelptoaccuratelydeterminethelocationofany issuesalongthetrackandensurearesilientandreliable “PredictandPrevent”maintenancestrategy.Ifsuccessful, theywouldimproveoperationalefficiencyonthenetwork, ultimatelyhelpingofferthetravellingpublicamorereliable service,whilemaintainingthenetworkatalowercost.

1

¹https://railinsider.co.uk/2020/02/01/derailed-freight-train-at-eastleigh-causes-ongoing-disruption/ Switches&CrossingsAretheHighestRiskAssetinTrackEngineering

AbouttheProject

DG8’sRoleasLeadTurnkeySupplier

Giventhepressingneedtoaddressthesetwochallenges, NetworkRailsoughtatrain-basedsolutioncapableof performingautomatedraillineinspection,whichitcould commencetestinginunderoneyear.Amulti-company projectteamwasformedtodesignandbuildaswiftsolution.

DG8,Icomera’sdesignandengineeringdivision,was assignedastheleadsupplier,responsiblefordeliveringa turnkeyserviceforNetworkRailinwhichitwouldoverseeall aspectsofprojectmanagement,design,andinstallation.

willplayasignificantimpactinsupportingthetransport industry’soverarchinggoalsofsustainabilityandcostefficiency.It’sinterestingtonotethatretrofittingnewand advancingtechnologiesaccountsforatleast60%ofDG8’s activeprojectsatanygiventime.

However,(re)designinganddeliveringonboardequipment andsystemsonolderrollingstockbringsitsownsetof challenges,theprincipalofwhichare(1)thelimitedavailable spaceand(2)theneedforintegrationforexistingonboard systems.

SupportingComplexDigitalOnboardSolutions

ToachievetheprojectgoalssetoutbyNetworkRail,theunit conversionoftheCl153swasbasedaroundintegratingthree complexdigitalsolutions:

1.Atrackconditionandgeometrymonitoringsystem enablingnon-contactmeasurementofrailroadtrack

2.Acamerasystemrecordingimagesofthetrackand uploadingthefootagebacktoNetworkRail’sVideo ManagementSystem(VMS)

3.Apositioningsystemthataccuratelytagsthedatafrom theothersystemswiththelocationonthenetwork DG8workedcollaborativelywiththeindustry-leading solutionprovidersinvolvedtoaccommodatetheir requirementsthroughintelligent,space-efficientdesign bothtothevehicleexteriorandinterior.

NetworkRailinitiallyselectedtworetiredCl153units,whichit hadleasedfromPorterbrook,tobeconvertedintoVisual InspectionUnits(VIUs)fortheproject.Aswellasbeingeasy todrive/maintainandreliabletooperate,NetworkRail’s selectionofolderrollingstocksuchastheCl153smade perfectsensegiventheiravailability,andthetighttimescale beingworkedto.

Furthermore,overthelonger-term,beingabletoextendand enhancethelifeofolderrollingtrainstocksuchastheCl153s

2

Re-engineeringOlderRollingStocktoBringBenefits

LineScanCamerasAreInstalledUnderneaththeTrain

Project Management

Design Engineering

Approvals

Material Supply Installation

TheVIUconversionunitshaveeachbeenequippedwith elevencameraswhichcanrecordthousandsofhighresolutionimagesathighspeed(eightatthefront,one underneath,andtwoattheback).Mountedapproximately 20cmabovetherail,thecamerascaptureanareaofupto 40cmwide,deliveringhigh-fidelityimages.Sincetheimage resolutionisgoodenoughtoinspect(forexample)an individualbolt,S&Ccheckscanbeperformedremotelybased ondatareceivedfromtheVIUs.

AnInnovativeHybridPowerSolution

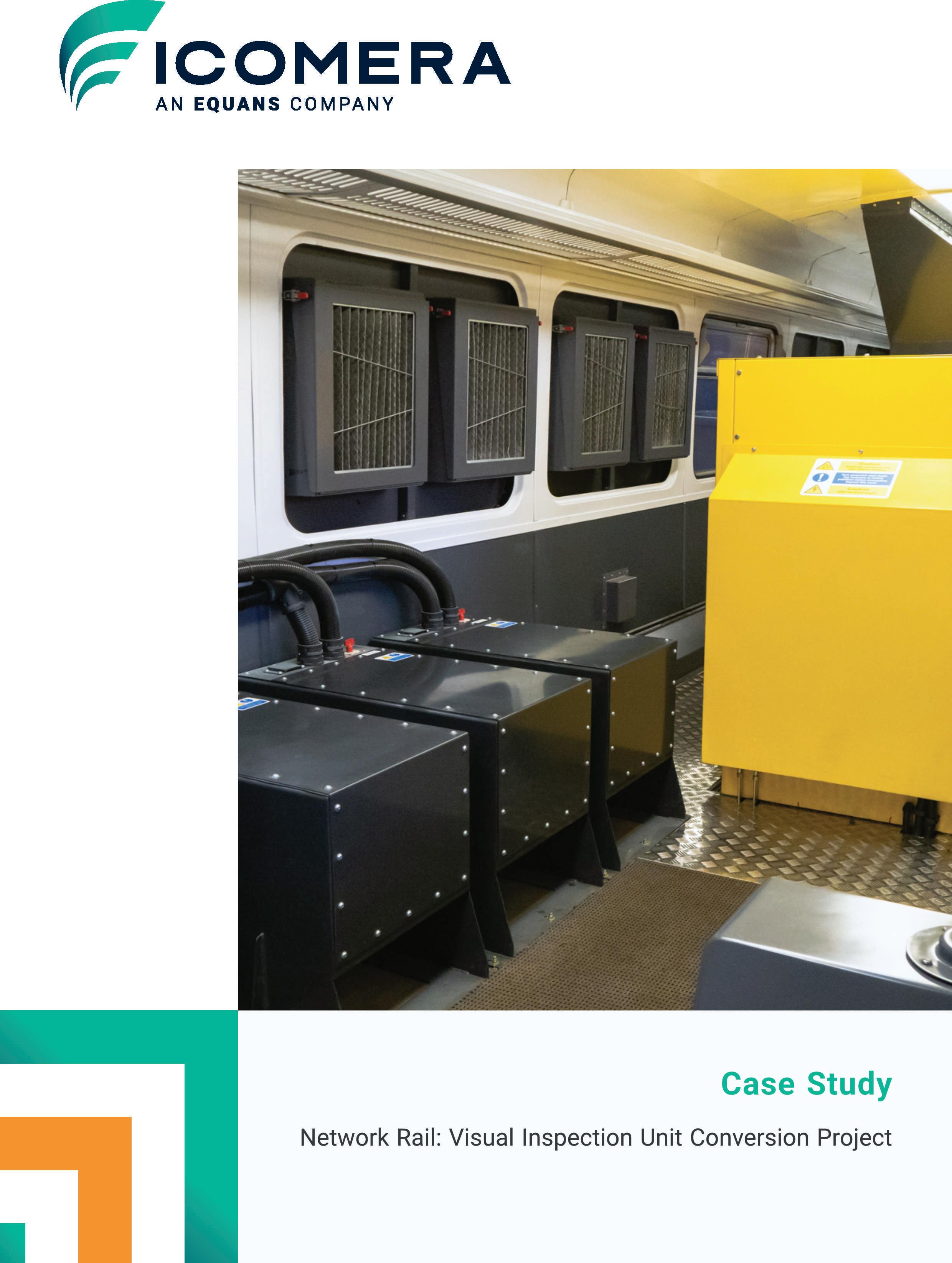

Thetrainsystemsrequiredahybridpowersourcewithmultimodecontrolstosupportrecordingwhileinservice,and post-processingwhileinsidings.DG8’ssolutionwasto installaninternalgeneratorandsupportinglithiumbatteries workingintandem.

Adistinctionwasdrawnbetweenthecritical(“essential”)and non-critical(“secondary”)onboardsystems.Thegenerator powersboththe“essential”and“secondary”circuitswhilethe trainisrunning–Butwhenthetrainisshutdownattheend ofashift,thegeneratorclosesdownandsomeservices(e.g. non-essentiallighting)areswitchedoff,whilethecritical systemscontinuetoreceiveconstantpowerviathelithium batteries.

Thelithiumbatterieshaveacapacityof600Amphours,48V, whichcanpowerthekitforapproximately3.5days.Whenthe batteriesbegintolosetheircharge,thegenerator automaticallystartsupandchargesthemuntiltheyarefull again,beforeswitchingitselfoff.Thisensuresthatthetrain remainspermanentlypoweredandreadyforoperation.

SincetheVIUsessentialsystemsarepermanentlypowered, theycanconstantlytransmitdatabacktoTheCloud;this allowsNetworkRailtoaccessthesystems24/7.Shouldthe trainbeoperatinginbadreceptionareasorworkingin tunnels,thekitisabletotransmitthedataaftertheshifthas finished.Evenafterthedriverhasgonehome,thetrain remainspoweredandtransmits.

Inrecognitionofitssuccess,theVIU conversionprojectwasshortlistedinthe SafetyandSecurityExcellencecategory atthe2023RailBusinessAwards

3

ToiletControlEquipment

KitchenAreaDesign

WhatNetworkRailSay:

“[Theproject’s]returnoninvestmentisfast,andif itsavesonemoredeathontherailwayitwillhave paidforitselfahundredtimesover.”

ProjectLead, NetworkRail

WhatWeSay:

“WorkingaspartofthisinnovativeNetworkRail project,it’sbeenapleasuretodemonstrateDG8’s capabilitiestodeliverturnkeyserviceswithinan ambitioustimeframe"

MarkHoptroff,Director, DG8DesignandEngineering

4

BatteryChargerandLithiumBatteries

ICOMERA Odinsgatan28,41103Göteborg,Sweden T+46317992100 sales@icomera.com