ABOUT ME

MY NAME IS IAN...

A multi award winning first year BSc (Hons) Product Design student at Nottingham Trent University and a student member of the Institution of Engineering Designers.

After spending 11 years in the Royal Air Force as a General Technician Workshops manufacturing aircraft components, I decided to seek out new challenges and opportunities to make a difference in the world of design.

A critical thinker with a keen eye for detail and ensuring sustainability is in all my designs, either through materials or function. Constantly pushing my boundaries to broaden my knowledge and skill set to better make my designs a reality. I have a huge passion for CAD software and producing as accurate renderings as possible within KeyShot.

2021-2025 - Nottingham Trent University BSc (Hons) Product Design

2011-2014 - MOD St Athan No 4 School of Electro Mechanical Engineering

2003-2008 - North Kesteven School

GCSE - 11

EDUCATION: SKILLS:

Technical Detailing

Problem Solving Organisation

Time Management Communication

CAD Modelling CAD Rendering

SOFTWARE:

ILM Level 3 - Leadership and Management NVQ Level 3 - Fabrication and Welding NVQ Level 3 - Machining Level 3 Apprenticeship in Engineering IOSH Managing Safely Level 2 - IT User Skills ECDL Extra Solidworks CSWA

QUALIFICATIONS: AWARDS:

Gold and Sponsor award Starpack 2022 Gold award winner for Mattii Labs

CONTENTS

NAME E-CARRY

INTRODUCTION

DESIGN CRITERIA

REFREAMED BRIEF

A 4 week project tasked with designing a product that only uses corrugated cardboard to replace single use plastic.

Must be made from corrugated cardboard to replace single use plastic

Must be easy to assemble and break down to recycle

Must be able to be easily adopted by other brands

Should be easy to expand and scale

Design and develop a replacement for shrink wrap plastic around drinks can multipacks.

The average american consumes 5 cans per week.

Brazilian consumes 2 per week

European consumes 2 per week

1 can per week for a Chinese consumer

cans per week for a Japanese consumer

THE SOLUTION

Design and develop a replacement for single use plastic on

and

with corrugated

that can

Underside of the E-Carry was made the same width, this was to add extra support but also aid in the manufacturing process to reduce

The handle was made to pass through each other. This was to ensure the product would stay together but also give added strength and

The rear side cut outs were made circular rather than having the crenelations, this allows for larger cans to be inserted into the E-Carry

Modelling the E-Carry using the sheet metal tool within Solidworks, allowed a net design for the product to be generated.

DEVELOPMENT

BRANDING

The logo for the E-Carry was designed in a way that would communicate its ability to be reused as well as recycled.

It has been inspired from the recycling logo with the endless cycle approach and coloured green to give visual understanding that the product is recyclable.

USER INTERACTION

Within the internals of the E-carry is a storyboard of how the product is assembled. By using the graphic approach means the communication isn’t limited by language barriers.

TECHNICAL

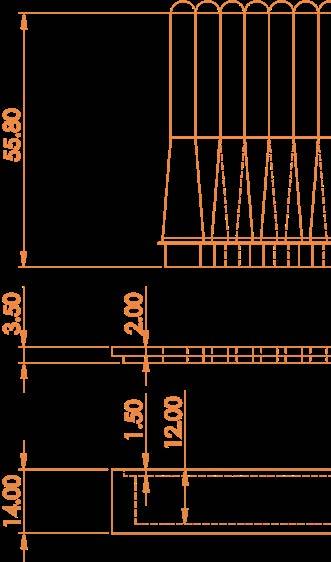

The E-Carry has been designed in a way to minimise waste during the manufacture process. A common width for sheet corrugated cardboard is 220.98cm. The product being based on this size allowed 4 across allowing the E-Carry to fit 16 per meter with minimal waste.

MATERIAL

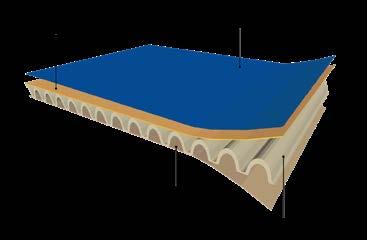

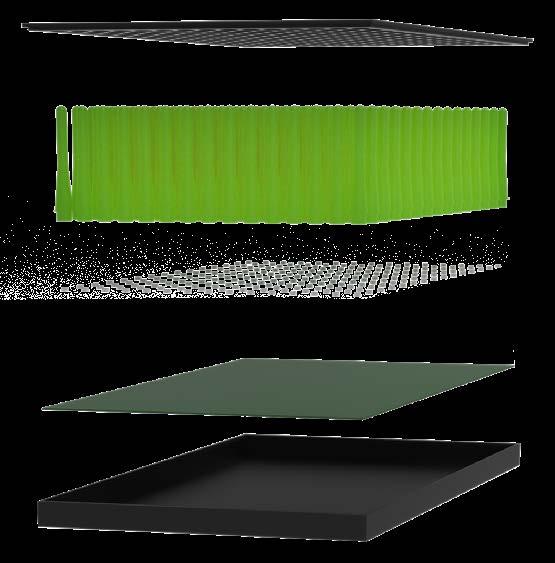

With the makeup of corrugated cardboard being made from sustainable materials already it fits very well with the sustainable nature of the product. The outer and inner layers of the cardboard for the E-Carry are made from 140GSM Kraft paper and the internal fluting is size D (2.3mm) made from waste paper.

NORSK

NAME

MODULAR SHELVING

INTRODUCTION

REFREAMED BRIEF THE PROBLEM

A 5 week project set around the challenge of designing a product to be manufactured from aluminium extrusion.

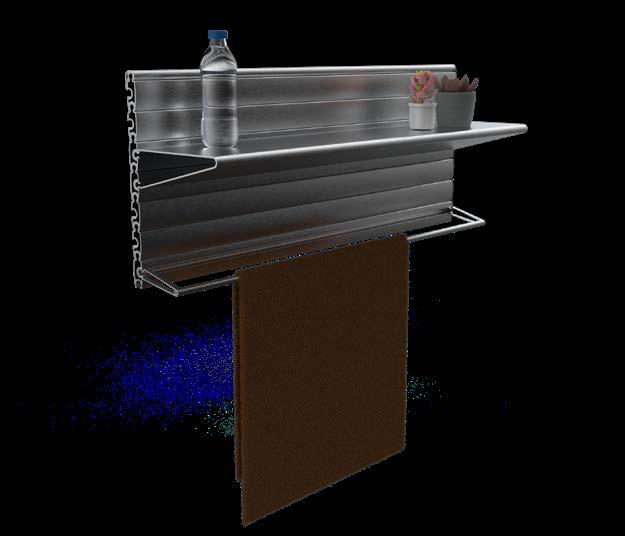

Flats within the UK have minimal floor space. Furniture takes up a large amount of this, and vertical shelving solutions require a large number of holes to be drilled into the wall.

Design and develop an aluminium extruded modular shelving solution, for use within a small home environment, the product must use minimal wall fixings without reducing function.

DEVELOPMENT

Profile becomes a solid profile due to the limitations of manufacture

Removed internal structure to allow use of solid die, reducing costs

Built in weak point to allow extrusion

compress around hanging section

DIE DESIGN

Hydro machinery can press 13kg per meter of extrusion.

Per meter of the main body extrusion (on left) weighs 1.2kg, meaning the machine can push 10 extrusion sections simultaneously.

TECHNICAL DETAILS

Main body of the assembly has been designed with extrusion manufacturing considerations in mind. No sharp edges to reduce friction during the process.

Even wall thickness to reduce the chance of distortion.

The extrusion uses a hollow die profile to extrude through, with the die having the space for 10 extrusions to be manufactured at once.

FINAL DESIGN

FUTURE

NAME AIM

INTRODUCTION

DESIGN CRITERIA REFREAMED BRIEF

A 1 week design sprint challenge, with the goal of designing a product for prehabilitation care.

Elective (non-emergency care) has suffered due to the COVID-19 pandemic. Many patients waiting much longer than the 3 month goal. Prehabilitation care is required to minimise pain and support the patients mental wellbeing during this wait.

Improve a knee patients comfort and minimise pain whilst they await their surgery date.

DUE TO COVID-19

WHEN ELECTRO MUSCLE STIMULATION IS USED

SPENDS

MENTAL

FINAL DESIGN

After the initial shape and function of the product was decided upon, the final design had two main elements.

Pain rating buttons for the user to log their pain level before and after treatment.

Visual graph of users pain level to allow them a visual understanding of the treatments affect on their pain level, which can directly affect the users mental well-being.

DESIGN PROCESS

MATTII

NAME

ILLUMII

INTRODUCTION

REFREAMED BRIEF THE PROBLEM

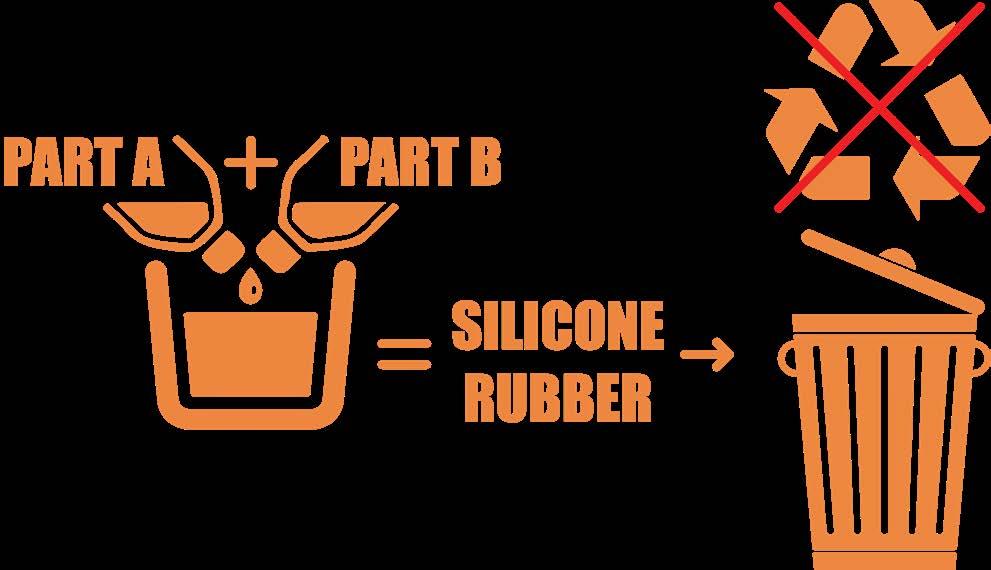

A 4 week individual project set by Mattii Labs to up cycle disposed silicone fingers into a new project.

Thousands of silicone fingers are disposed of during the manufacture of aircraft. These fingers cannot be recycled therefore end up at landfill.

Up cycle the disposed silicone fingers supplied by Mattii Labs, into a sensory product aimed at those with autism/anxiety.

RESEARCH

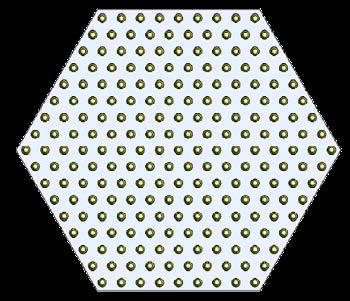

Hexagonal panel would be too large and difficult to manufacture with the amount of fingers required.

DEVELOPMENT

but could be too small for effective

Using a diamond shape allows creative freedom when mounting and also gives a larger size for a sizeable sensory feedback when used on the go.

20mm Spacing

15mm Spacing

FINAL DESIGN

Diamond shaped panels with a 10mm spacing between the centres of each finger, this ensures the sensory response it at it’s highest.

10mm Spacing

SALE

THANK YOU