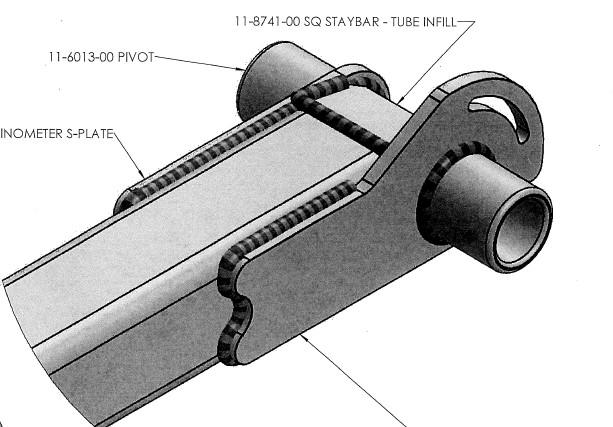

LEVELLING BAR ASSEMBLY PROCEDURE

BeforecommencingmanufactureconfirmwithHydraladathecorrectsizeRHSrequiredforthemodelof machine.COMPACTMODELS-40x40x4MAXIMODELS50x50x4

ALLWELDS5MMCONTINUOUS

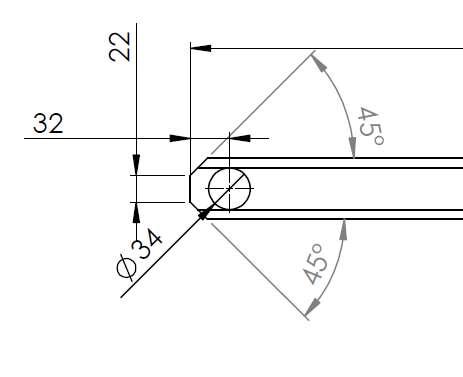

1.Drill34mmhole32mmfromoneendofRHS.ThiswillbetheCageendoftheStarbar Cutendsat45deg(asperdrawing)

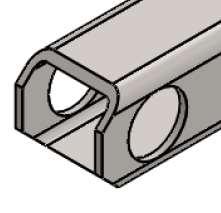

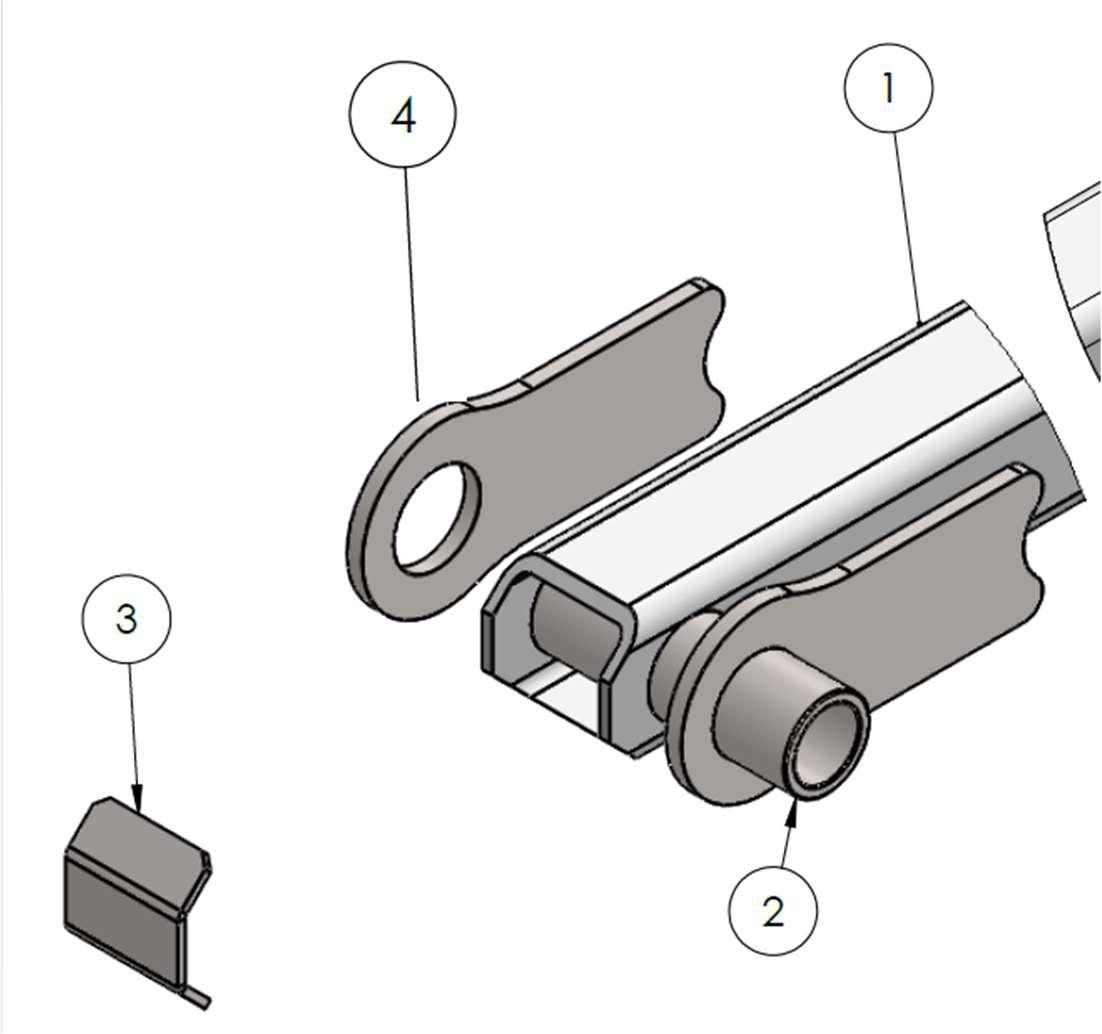

1. STAYBAR STD RHS

2. 11-6006-00 PIVOT PIN TUBE

3. 11-6266-00 SQUARE STAYBAR -END CAP

4. 11-6022-00 PLATE, STAYBAR SIDE

2. Insert pivot pin tube and centre in RHS

Attach, Side-Plates, tack weld in position.

Fit End cap

Weld all components

3.FitbusheswithLoctiteretainingcompoundtobothendsandreamwith¾”reamer.

4.TemporaryfittoCageandwithchromepivotpin.Liftcageandholdinpositionwithcagefloorlevel.

5.Atchassisendtemporaryfitadjustableendpiecetochassiswithpivotpin.

6.MarkStaybarRHSlengthtofitinsidethepivotpintube.CutstaybarRHStosize

7.WithcagelevelandkeepingthestaybarRHSgapthesamealongtheboomtackweldtheendsonto thestaybar.

8.Fullylowerandraisetheboomandmakesurethegapatthechassisendisstillpresentanduniform. Adjustasrequired.

Danger:

Donotentercageforthisoperationmanuallypushspoolatcontrolvalvetoraiseandlowerboom.

Chassis end adjustable assembly

9. Fully weld side-plates to RHS, weld infil plates onto Pivot tube.

10. Paint

11. For Maxi model Hydralada fit support clamp and idler at mid-point of Leveling Bar

These idlers can be fitted to earlier model machines, or additional idlers if desired. To fit an idler to an undrilled boom, mark two holes in the boom, opposite one another, and 45mm below the top face of the RHS section of the boom. These must be tapped to a 16" UNC thread.

ToadjusttheIdlerassembly,assembletheidlerassembly,leavingtheclampboltsonthe levellingrodalittleloose.SupportingtheLevellingRodsothatisparalleltotheboom,move theidlerclampalongthestaybarintothepositionwheretheincludedangleformedbythe levellingrodlevellingrodpin-idlermount(Angle‘Y’),andthelevellingrodlevellingrodpinboom-masterpin(Angle‘X’)arethesame.TightentheclampboltsontheLevellingRodto15 ft/lbs.

12.SetInclinometeractuatorheightasperstabilitycertificate.