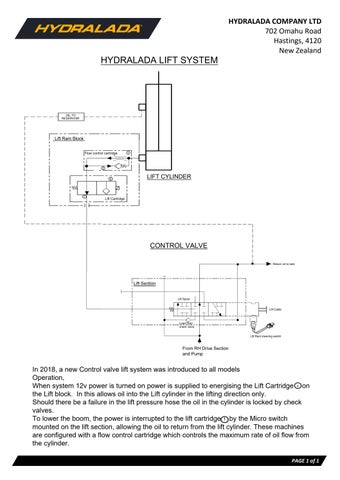

HYDRALADA LIFT SYSTEM

In 2018, a new Control valve lift system was introduced to all models Operation, When system 12v power is turned on power is supplied to energising the Lift Cartridge 2 on the Lift block. In this allows oil into the Lift cylinder in the lifting direction only. Should there be a failure in the lift pressure hose the oil in the cylinder is locked by check valves.

To lower the boom, the power is interrupted to the lift cartridge 1 by the Micro switch mounted on the lift section, allowing the oil to return from the lift cylinder. These machines are configured with a flow control cartridge which controls the maximum rate of oil flow from the cylinder.

LIFT RAM SOLENOID

PLUG Chassis Loom

WIRING CIRCUIT

LIFT RAM COIL AND CARTRIDGE On base of Lift Ram

LIFT SWITCH PLUG Chassis Loom LIFT SWITCH Normally closed (N/C)

1.With 12V power and the lift pedal in neutral power is supplied to the Coil and Cartridge at the base of the ram.

2.When the lift pedal is lowered it breaks the circuit with the LIFT SWITCH removing 12v power to the coil.

To get oil into the lift ram the LIFT RAM COIL must be energised. If not the oil must go through a flow restricter. The result of this is the engine loads up and the boom will either not lift or lift very slowly.

Fault finding causes

1. LIFT SWITCH failed in Open circui not allowing power to the coil

2. Lift ram solenoid plug not connected.

3.Coil not energising

4.Cartridge sticking

Hydraulic oil