HYDRALADA INCLINOMETERCALIBRATION PROCEDURE

BPE inclinometer requires calibration;

1. Initial fitment to the chassis.

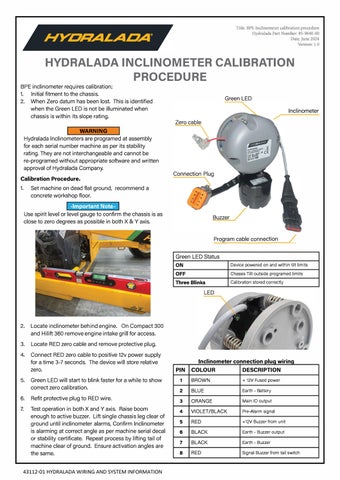

2. When Zero datum has been lost. This is identified when the Green LED is not be illuminated when chassis is within its slope rating.

WARNING

Hydralada Inclinometers are programed at assembly for each serial number machine as per its stability rating. They are not interchangeable and cannot be re-programed without appropriate software and written approval of Hydralada Company.

Calibration Procedure.

1. Set machine on dead flat ground, recommend a concrete workshop floor.

Use spirit level or level gauge to confirm the chassis is as close to zero degrees as possible in both X & Y axis.

2. Locate inclinometer behindengine. On Compact 300 and Hilift 360 removeengineintakegrill for access.

3. Locate RED zero cable and remove protective plug.

4. Connect RED zero cable to positive 12v power supply for a time 3-7 seconds. The device will store relative zero.

5. Green LED will start to blink faster for a while to show correct zero calibration.

6. Refit protective plug to RED wire.

7. Test operation in both X and Y axis. Raise boom enough to active buzzer. Lift single chassis leg clear of ground until inclinometer alarms, Confirm Inclinometer is alarming at correct angle as per machine serial decal or stability certificate. Repeat process by lifting tail of machine clear of ground. Ensure activation angles are the same.

Device powered on andwithin tilt limits

Chassis Tilt outside programedlimits Three Blinks Calibration storedcorrectly

Inclinometer connection olua wirina