The difference made The Circular Future Fund

A £1 million innovation fund to boost the circular economy

As a global society we use more natural resources than the biosphere is capable of regenerating. We need to rethink our relationship with products & materials, and rapidly transition to more circular models of production & consumption if we are to reduce our ecological footprints.

At the John Lewis Partnership we have a proud history of designing & manufacturing products that can be loved for and last a lifetime. However, as a trusted retailer, we recognise the role we need to play in driving the required shifts across industry and society.

That is why we were so excited to establish The Circular Future Fund in collaboration with the brilliant team at Hubbub. We wanted to provide a source of funding that could stimulate novel thinking and enable products or services that could deliver transformational change.

We were amazed at the volume and quality of applications, and the four winners were absolutely worthy of the funding they received. It has been brilliant to see the progress they have all made since their initial presentations.

When developing the fund, we committed to openly sharing the results of the projects to enable others to build on and amplify their impact. I am delighted that we are now able to publish this report and I hope it is only the beginning of the impact that each of the winning projects will have.

George Barrett

Partner & Sustainability Manager (Circular Economy), John Lewis Partnership

George Barrett

Partner & Sustainability Manager (Circular Economy), John Lewis Partnership

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

What’s in store

The Circular Future Fund: The ambition and how it worked

The projects: A snapshot of success

DAME: Making menstrual cups mainstream

Pip & Henry: Redesigning children’s shoes to last

Scottish Library and Information Council: Establishing lend and mend hubs in Scottish libraries

University of Leeds: Innovating technology to enable polyester to be recycled again and again

How can we create a circular economy?

3 4 6 19 8 12 15 23

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

The Circular Future Fund: The ambition and how it worked

Step 1 – Rethinking waste

The Circular Future Fund aimed to support trailblazing ideas and innovations to boost the transition towards a more circular economy.

It called for pioneering new approaches to challenge the outdated ‘take, make, dispose’ model, whether that be rethinking waste with new products or materials, finding creative ways to shift consumer mindsets or developing new business models and services. Focus areas included food, textiles and household products, services, and technology.

Step 2 – Launching the fund

In partnership with Hubbub, the John Lewis Partnership launched the £1 million fund in November 2021. It was open to businesses (under 5 years old), charities, social enterprises, academic bodies, and Community Interest Companies.

4

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

Step 3 – Identifying innovation

The fund offered grants of between £150,000-£300,000, with 245 applications received. This shows the huge demand for creating a circular economy and a need for funding. The winning projects were selected by a Grant Panel in Spring 2022.

Step 4 - Convening a Grant Panel of experts

The Grant Panel consisted of eight experts on different aspects of the circular economy and the grant criteria. They reviewed the eight shortlisted applicants at a Grant Panel day, where those shortlisted pitched their ideas – and the final four high-quality, innovative projects were chosen.

Amir Goshtai, Director of Financial Services, John Lewis Partnership – John Lewis expert

Archie Mason, Director of Innovation, True – Retail Innovation expert

Besma Whayeb, Founder & Director, Ethical Influencers – Customer expert

Emma Walsh, International Partnerships Director, FoodCloud – Food expert (previously, now Climate and Nature Innovation, Barclays)

Step 5 – Getting going

Dr Jack Barrie, Research Fellow, Chatham House – Circular Economy expert

Jenny Dadd, Grants Manager, Environment (lead) & Built Heritage - Esmée Fairbairn Foundation (previously, now Funding Manager Lead - Our Natural World) - grant giving expert

Marija Rompani, Director of Sustainability & Ethics, John Lewis Partnership – John Lewis expert

Trewin Restorick, CEO, Hubbub – Grant Panel Chair (previously, now CEO, Sizzle)

The four projects ran for 12 months from Summer 2022, and reported regularly to Hubbub to monitor their progress and seek support with challenges.

5

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

The projects: A snapshot of success

£1M

fund to find innovative circular economy ideas

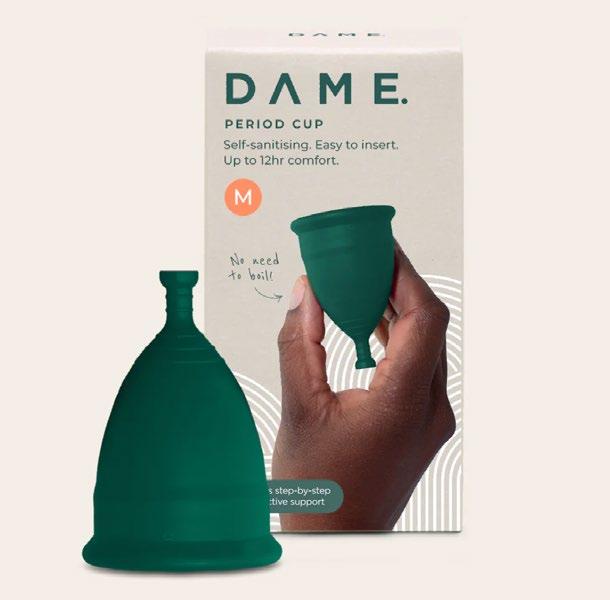

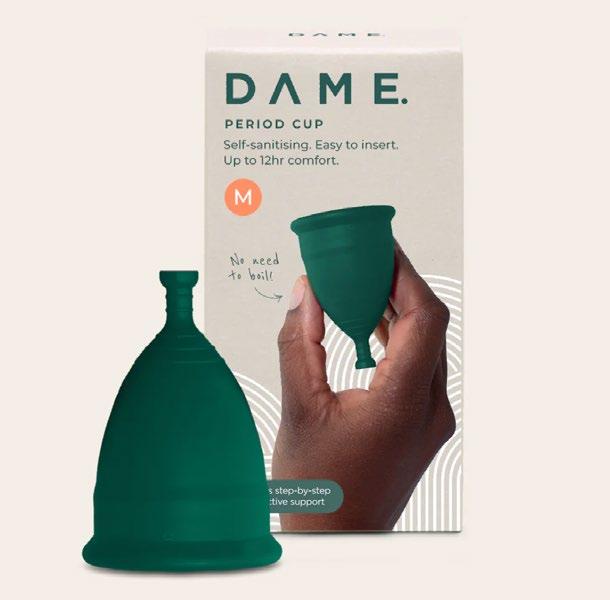

DAME

Helping menstrual cups go mainstream

applications 245

4

• New reusable self-sanitising cup created, generating 99x less carbon over its lifetime (compared to boiling a traditional cup)1. Avoiding the need for 2,860 single-use period products over each cup’s ten year lifespan.2

• Myth-busting menstrual cup user guide, featuring influencer Hayley Morris, viewed 4,500 times per day.

Pip & Henry

Redesigning children’s shoes to make them last longer

• Three concepts to create expandable shoes that can be more easily recycled.

• Huge insights to help challenge the status quo of the footwear design industry.

6

innovative, impactful, and interesting projects identified! THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

Scottish Library and Information Council (SLIC)

Establishing ‘lend and mend hubs’ in Scottish libraries

• 9 hubs created, potential for at least 2000 mending workshop participants a year.

• 5t CO2e saved from furnishing hubs with reused furniture.3

• Creating a model for other libraries to follow.

The University Of Leeds

Innovating technology to enable polyester to be recycled again and again

• Revolutionary new dyeing process significantly reduces energy, water, and chemical usage.

• Proven that dyes can be removed from polyester – enabling dye, water, and fabric to be recycled with huge potential environmental benefits.

• Bonus discovery that their technology also works on other fabrics.

7

THE CIRCULAR FUTURE

| THE DIFFERENCE MADE

FUND

DAME Aims

1 2

To innovate to break down the barriers to using a menstrual cup, (originally) through:

• Developing a personalised digital assistant to learn about behaviour and barriers to help users find the right product - and stick with it.

• Creating a menstrual cup starter kit of various shapes and sizes and an easy take-back service to encourage people to give it a go.

To increase cup usage through a successful communications campaign to reach new people to adopt menstrual cups.

8

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

DAME’s project to make menstrual cups mainstream

• DAME is a business aiming to make periods positive for people and planet.

• The circular sustainable period product - the menstrual cup - has existed for decades... yet it remains a niche product that only 5% of people with periods use4. There’s a tsunami of plastic waste generated by periods as we flush away over 1.5-2 billion of disposable period products in the UK each year5 A mainstream menstrual pad alone is made of 90% plastic6

• DAME gained insight on the barriers to cup use, through surveys and a small user group trial – identifying the main concerns as comfort, leaking, inserting a menstrual cup and cleaning it.

• They had a theory that better guidance could help more people try and stick with menstrual cups. 91% of 100 people with periods who’d never used a menstrual cup, said clearer instructions and a user guide would encourage them to give it a try. And half of the fourteen trial participants trialling a traditional cup for the first time, stayed with a cup after two periods, when they were given support on how to use it.

• DAME explored having a starter kit of different shapes and sizes and easy take-back service for unused cups. However, this proved complex with challenges around sterilising cups and identifying a suitable reuse or resale route for used and returned cups, that could also minimise waste.

• Instead, DAME focused on designing out waste by providing better guidance on cup sizing and support with adopting cups, to remove the need to trial multiple sizes.

• DAME also created an innovative new cup, applying self-sanitising technology used on medical equipment to remove the need to boil or sterilise cups. DAME’s self-sanitising period cup launched in June 2023 and has achieved several ISO standards to prove its safety and effectiveness. It was a finalist in the Pure Beauty Wellness Awards 2023.

• They worked with influencer Hayley Morris to develop a range of videos and tips to answer common questions and concerns, delivered in Hayley’s accessible and sisterly signature style.

9

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

The difference made

Suite of tips and videos available for anyone to help breakdown concerns about menstrual cups – averaging 4,500 views per day.

Early indications are that around half of cup purchases are from new cup users, with around a third being existing cup users, suggesting that the self-sanitising technology is more attractive than other cups.

Over one cup’s 10-year lifetime it could prevent 2,860 plastic disposables.7

If cleaned in cold water as advised, the self-sanitising cup can contribute 99x less carbon emissions over its lifetime, compared to boiling a traditional cup8.

Learnings and challenges

• DAME’s insight trial suggested there may be large unmet demand for menstrual cups, if people are given the right support, compared to the 5% that currently use cups.

• A big challenge was finding a model that reduced waste at the core, so focusing on getting the right fit in the first place is built into the cup’s product information.

What’s next?

DAME are making the user guide content freely available for educators to help get teenagers to try and stick with cups – and many organisations have already expressed an interest in it.

They are also exploring partnerships with charities such as Bloody Good Period, to see if the cup could be provided to those experiencing period poverty through their established national network of distribution centres.

DAME will continue to capture feedback on their user guide and FAQs, to make continual improvements to overcome common questions and concerns about menstrual cups.

It is hoped self-sanitising cups will become more common, helping to address cleaning and hygiene as one of the barriers to cup use.

10

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

The DAME cup will be proven to be one of the most innovative period products in the last decade. This technology uses materials proven in scientific testing to be self-sanitizing, reducing the largest barrier to cup use for the eco-conscious and those who care about moving towards environmentally friendly sanitary care. The reusable cup has been shown to be a convenient, safe, comfortable option for menstruation when used correctly. The DAME cup is directly addressing the stigma around reusable period products and is an exciting step forward in women’s health.

The comprehensive video guide usefully goes through each step chronologicallymaking it both informative and less overwhelming for new users. The FAQs … make the introduction to period cups less daunting.

11

Find out more visit DAME’s website THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

- Dr Stephanie Kuku, health technology advisor

- Maddie Yu, Youth Board, DAME

Pip & Henry Aims

To complete a feasibility study into extending the life of children’s shoes and reducing the number of shoes going to landfill, by exploring two solutions to disrupt the children’s footwear industry:

1 2

An expandable shoe that grows with a growing child’s foot.

Design of a shoe that can be more cleanly separated into their component materials and therefore recycled more effectively.

12

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

Pip & Henry’s project to redesign children’s shoes

• Pip & Henry is a business that creates stylish, comfortable, and responsibly produced shoes for children.

• The project aims to address the wasteful industry of kids’ shoeson average a young child replaces its shoes every four months with a staggering 85% of those shoes ending up in landfill9. Splitting each outgrown shoe more cleanly into high quality materials could also aid recycling.

• Pip & Henry’s research and development project began with identifying suitable R&D partners from product and footwear designers to materials experts and manufacturers.

The difference made

• They have developed not just two (as originally planned), but three concepts to work towards their vision of an expandable shoe and shoe that’s easier to disassemble.

• Each idea has been through an extensive product development process from creating prototypes to refining the design and materials and identifying suitable manufacturing partners to create the relevant moulds or tools.

Pip & Henry hopes to challenge the status quo of footwear manufacturing techniques and inspire others to change, through use of their insights and three potential new designs which they plan to either launch themselves or license to others.

They are capturing several learnings including:

More in depth knowledge about footwear manufacturing methods and their environmental impacts.

Understanding of material innovations that can significantly reduce the environmental impact of shoes.

Recycling capabilities in the footwear industry, and how to design better for end-of-life recycling.

13

THE

FUTURE FUND | THE DIFFERENCE MADE

CIRCULAR

Learnings and challenges

Pip & Henry had hoped to create a capsule collection of their new designs in 2023 and while they have made huge progress this is now due in 2024, due to the complexity of shoe designs and the various stages of research and development needed. As above, the project’s learnings will offer extensive insights to help make the footwear sector more circular.

Securing additional funding was another anticipated challenge, which they have achieved by securing a £100k Innovate UK grant to continue through to 2024. The biggest challenge ahead is securing patents to launch their own capsule collection, plus licensing or commercialising elements of their shoe technology.

The solutions we’re thinking of aren’t easy, but we’ve built some fantastic partnerships with designers, innovation consultants, manufacturers, materials experts etc...and together we hope to launch concepts that could be truly game changing from a sustainability perspective for the footwear industry.

- Louise Crawley, Head of Product & Innovation

What’s next?

I’m genuinely excited about the progress we’ve been making at Pip & Henry. And that’s not just from a product perspective, but because of the impact our product will be able to have. It is hard to overstate the current waste there is in the kids shoe market and I firmly believe that this innovation - both increasing the lifetime use of every shoe, and enabling easier recycling - has the potential to fundamentally change things for the better.

- Magnus Willis, NED Pip & Henry

Launch of Pip & Henry’s children’s footwear capsule collection in 2024.

Exploring licensing concepts, to help scale their circular shoe innovations.

Collaborating with the footwear manufacturing and recycling industries to share their learnings and insights to maximise the project’s legacy.

1414

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE Find out more Visit Pip & Henry’s website

Scottish Library and Information Council (SLIC)

Aims

Create a network of 8-10 lend and mend hubs in public libraries across Scotland to support communities to repair, reuse, rent and upcycle everyday items.

Build a support community to educate and upskill library users in the circular economy.

15

1 2 THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

SLIC’s plan to create lend and mend hubs in libraries

• SLIC is an independent advisory body the Scottish Government, that supports the Scottish library and information sector through funding, advice and guidance including projects and partnerships to benefit libraries and Scotland’s population.

• The Scottish public are familiar with borrowing from libraries (visiting them 40 million times each year), but don’t always have the skills or opportunity to embed the circular economy into how they use household goods and clothing.

• The concept builds on libraries as community hubs and spaces of responsible lending and learning, plus helps adopt Scandinavian best practice and SLIC’s track record of innovation including providing free community access to equipment like 3D printers.

• SLIC began by identifying nine varied Scottish libraries to establish lend and mend hubs through a competitive application process. All have agreed to maintain the hubs until at least January 2026 and will offer equipment,

workshops, and tools free of charge to overcome cost barriers for the public.

• Community consultations helped get buy-in from the community - receiving 410 responses. They identified demand for textile tools such as sewing machines and workshops for mending, while for lending people wanted seldom used items such as drills, carpet cleaners and even slow cookers.

• A new hub brand helps make the hubs easily recognisable across Scotland and beyond. All hubs have been fitted out using reclaimed and upcycled materials.

• Each hub has a ‘lend and mend hub champion’ trained in the circular economy, mending equipment, and lending collection.

• Links have been made with 30 partner organisations across the hubs to support the development of educational programmes and workshops to upskill communities to help them repair, reuse, upcycle and recycle items. A further 16 partner organisations are involved at individual hubs.

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

The difference made

Since opening, the hubs have been inundated with requests for workshops and have had to set up a waiting list. Early indications suggest hubs have the potential to reach at least 2000 people per year through sewing and mending classes alone. As well as supporting the circular economy, the hubs are also tackling social isolation.

The hubs were fitted out with circularity in mind. Using 31 repurposed office desks, 7 meeting tables and 102 chairs saves over 5t CO2e compared to buying new10

Learnings and challenges

• SLIC faced some delays due to a combination of COVID affecting library staff resource, plus procurement and health and safety challenges all delaying finalising

I wasn’t leaving the house after the pandemic – this has given me a purpose to leave my house and meet likeminded people with similar interests – I was nervous at first, but the tutor and group are great, and I am keen to get involved in other classes.

- Class participant

- Anonymous, Public consultation feedback

partnership agreements with libraries. However, this was overcome with determination, seeking external advice and best practice for health and safety in existing repair settings.

• The commitment to using repurposed furniture and upcycled materials took longer than expected but was essential to the ethos of the hubs.

• There’s been huge interest from the Circular Economy network in Scotland as well as communities demonstrating interest in the potential role of libraries in enabling the circular economy. This also led to additional exciting partnerships:

• The University of Glasgow, who created a film about clothing usage called the Fabric of Society, which has been shown across the hubs to raise awareness of the impact of fast fashion.

• Glasgow Wood who created bespoke pegboards for the hubs using highquality ply that was used as part of Kenya’s display at COP26 in Glasgow.

17

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

This is what libraries are meant for!

What’s next?

Rollout of the lending collection, workshops and an education programme at the 9 hubs.

A full evaluation due in Winter 2023/24, will explore the benefits for library users, including how the hubs help public understanding of the circular economy and what a scalable model might look like.

SLIC will then create a toolkit, disseminated through workshops, to share their learnings and help other library services across the UK replicate their approach.

With the ongoing cost of living crisis, the lend and mend hubs have the potential to support families to make more sustainable choices. Libraries are trusted community spaces without agenda and have an opportunity to provide a space where communities can take action through practical everyday solutions locally.

The introduction of training sessions and educational workshops will allow people to gain skills and develop knowledge to help promote the circular economy and widen our impact on increasing environmental challenges.

- Team Manager, Libraries and Archives

It has been great working with the lend and mend project [to] see such a fantastic ambitious idea become a reality. The project has worked brilliantly in partnership with many organisations.

- Share and Repair Network Scotland Coordinator

18

Find out more Visit SLIC’s website

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

- Marion Kunderan, Head of Programme, SLIC project team

The University of Leeds

Aims

• To create a pilot prototype to demonstrate a circular textile system for polyester. Where novel switchable solubility dyes can be applied and removed from polyester using innovative CO₂ technology to separate dyes from fabric, more specifically:

1 2 3

To demonstrate the ability to colour and de-colour polyester fibre in three primary colours.

To demonstrate that de-coloured polyester fibre can be recycled and turned into new fibre and re-coloured to achieve the same performance as virgin fibre.

Quantify the economic and environmental benefits to enable scaling.

19

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

The University of Leeds’s idea to make polyester circular

• Builds on research by The Leeds Institute of Textiles and Colour, working alongside the Wolfson CO2 Laboratory in the School of Chemistry. Currently there is no true circularity in the polyester industry because the dyes in polyester mean it cannot be easily removed, which prevents it being recycled back into new virgin polyester fibre. Polyester is the world’s most common textile fibre and yet only 15% of polyester produced is made from recycled polyester (mostly from plastic bottles)11

• The University of Leeds’s innovation created new novel ‘switchablesolubility’ dyes that enables them to be switched from water-soluble to water-insoluble to colour and de-colour polyester.

• The process uses only CO₂, water, heat, and pressure using existing dyeing infrastructure. Existing dyeing methods use polluting chemicals and are energy and water intensive – while their technology enables the dye, water, and fabric to be recycled.

• They have created 100g of primary colour dyes and used the dyes in combination to produce a full colour wheel, despite challenges overcome. The fabric and dye is stable under home washing conditions.

• The research team also proved that 85% of the dyes can be removed (enough to enable fabric and dye recycling) with their decolouration process, without wasting any fibre.

20 THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

The difference made

The introduction of the new CO₂ technology delivers a truly circular process that has the potential to recycle directly and mechanically some of the 57 million tonnes of polyester fibre produced globally each year.12 A full lifecycle analysis will measure the possible environmental impact of both the dyeing and decolouration, but the current potential benefits of the technology are:

Reuses the dye – currently, no dye can be recycled from standard dyeing processes. 2.2 million tonnes p.a. are lost to inefficiencies in the dyeing process.13

Recycles the water - 520 billion litres p.a. are used in the dyeing process which could potentially be reused and recycled14.

Uses less energy - reduced water heating from recycling water, could reduce CO2 emissions by 25-30g CO2e per garment15.

Removes polluting auxiliary chemicals - 150kg of chemicals per tonne of polyester would not be needed16, as no auxiliary chemicals are needed.

Enables fibre-to-fibre polyester recycling – much of which isn’t currently recycled.

Learnings and challenges

• The team faced challenges with equipment malfunctions, material costs and hazards to develop the technology, but these were all overcome.

• The lifecycle and economic analysis of the technology is still planned but delayed as quite complex – dependent upon the final optimised process.

• The research led to two surprising discoveries:

• Firstly, revealing that 99.9% of all dyes could be removed from polyester, not just their new novel switchable dyes.

• Secondly removing dyes from nylon and PLA also showed some success using this process, as did denim meaning indigo dye and denim could potentially be recycled.

• These additional findings could prove very impactful to reduce the impact of existing textiles, creating more circularity.

• The team’s hypotheses around the potential of CO2 technology to extract their new dyes were proved correct. Having demonstrated a circular system resulting in both recyclable textiles and dye, the technology can now be optimised.

21

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

What’s next?

The University of Leeds will next take the technology to pilot scale by trialling on industrial equipment, working with industrial partners to stress test the technology.

A full life cycle analysis will then be undertaken to establish the environmental benefits.

Additional funding from The University of Leeds will help explore commercialising the technology to maximise its reach and impact. Early conversations with brands and industry partners are very positive.

Further discussion with retailers and recyclers will help identify the best way to collect garments from the public for recycling.

Meanwhile the team will continue to share their new discoveries about dyes and their learnings with the sector.

It has been an incredible journey working on this project since its inception. I have always felt very lucky to work on something that functions so effectively and could have such a huge environmental impact. Now that the project is reaching the commercialisation stage, I am very excited to witness and be a part of something that could create a global change in the textile industry.

The results speak for themselves, and I am proud to have been a part of developing this exciting and potentially pivotal innovation. Presenting the work…was a great experience and the reception was fantastic. We received so many enthusiastic questions from the audience the moderator had to call time, and we were discussing the technology for the rest of the conference.

22

– Nathaniel B. Crompton, Research Fellow at The University of Leeds

- Dr. Harrison Oates, Research Fellow at The University of Leeds

Find out more Read University of Leeds blog THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

How can we create a circular economy?

The four Circular Future Fund winners, while ranging from business to academia and from periods to polyester, had some common factors that made their projects successful. To create a circular economy at the pace and scale needed, we recommend other organisations trying to make an impact in designing out waste, also consider these factors.

Innovation

Gain insight

Building a circular economy requires identifying the barriers to change. All four projects had a period of insight gathering or in-depth research from identifying material properties to behavioural barriers and motivations, to help inform innovation.

Challenge the status quo

Designing out waste means challenging existing thinking, technology, and habits. The Circular Future Fund winners identified opportunities to do things differently combining innovation from different sectors, to be brave and determined to identify new ways of operating.

As a young brand that genuinely wants to make footwear circular, we always had a strong vision for what we wanted to achieve. But this grant really propelled our ambitions, giving us the resources to get into the depths of material research, understand the complexities around the physics of what we would design, find ways to create operationally feasible solutions to the problem - all while keeping the customer at the heart of everything we’ve developed.

- Jeroo Doodhmal, Founder & CEO, Pip & Henry

23

THE CIRCULAR

FUND | THE DIFFERENCE MADE

FUTURE

Fund innovation

Gaining insight and challenging the status quo is time consuming and costly, beyond the means of many businesses and organisations’ day to day operations. Additional funding helps find and support innovation that might not otherwise have happened.

Collaboration

Partner up

Embedding a circular economy needs everyone to work together, combining new ideas and expertise to move up the waste hierarchy. Collaboration between business, the public and third sector, is essential to build circularity into everything we do. All four winners are partnering with other organisations and sectors to realise their ideas.

Share learnings

Like The Circular Future Fund, trials or new ideas should share their learnings to help make the transition to a circular economy faster and inspire and enable others to act, learning from what does and doesn’t work. The winners will continue to share learnings with their sectors to increase their impact and the legacy of their projects - which has only just begun.

As a small dynamic business with impact at its core, we’re constantly looking at ways to push the boundaries of what’s possible but often lack the resources. The grant has provided us with the bandwidth to innovate on product design and performance, and to spend time sourcing partners willing to switch up their current supply chains. In this way, we’ve been able to merge the dynamism of a small business with the clout of a larger business in order to drive real change in the category.

- Alec Mills, Co-Founder, DAME

24

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

It has been amazing to see the progress that all four winners have made over the past two years, and this shows the potential change that can be generated by grant funding and collaborations between organisations of different sizes and structures.

- George Barrett, Partner & Sustainability Manager (Circular Economy), John Lewis

Inspire and influence

Bring the public along with you

The public – you and me and everyone we know – will need to get on board with the circular economy. From understanding why we need to do things in new ways, to the roles we can play, like choosing products and services that prevent waste. The four winners have created tangible examples of the circular economy in action, helping the public get involved in fun ways, that also benefit their lives. They communicate the co-benefits for everyone and have plans to share their stories far and wide, in an accessible way that the public can get on board with.

Influence others

To create a circular economy at the pace and scale needed, we need to influence business, policymakers by highlighting successes, opportunities, and learnings. As well as influencing each other to help make people willing and able to take action that’s good for the environment and for everyone.

Innovation and collaboration are the catalysts for achieving a circular economy. The Circular Future Fund is

critical in this respect by

empowering and inspiring innovative British companies to develop groundbreaking circular business models which can serve as a beacon for others.

25

- Dr Jack Barrie, Research Fellow, Chatham House (and circular economy expert on the Circular Future Fund Grant Panel)

THE CIRCULAR FUTURE FUND | THE DIFFERENCE MADE

Huge thanks to:

The four Circular Future Fund winners, for their creativity, dedication, and tenacity to overcome challenges and deliver true innovation.

The Grant Panel for giving up their time to provide their insights and expertise to identify the winners.

John Lewis and Partners for their commitment and identifying 10p plastic bag charge funding to support innovation in the circular economy.

Hubbub for running the fund.

Footnotes and sources

1 Based upon independent analysis by Climate Partner, a traditional cup boiled would use 41.9514 kg CO2e over 10 years if boiled for 7-10 minutes, versus washing a DAME cup in cold water would use 0.4357 kg CO2e.

2 Assuming 22 disposables per cycle and 13 menstrual cycles per year, so 286 disposables/ year/ per person.

3 Based on FIRA Study into the Feasibility of Benchmarking Carbon Footprints of Furniture Products 2011

4 ‘UK Feminine Hygiene and Sanitary Protection Products Market Report 2021’ Mintel

5 Marine plastics: pollution policy and position statement, 2015, Marine Conservation Society.

6 Calculation by Natracare 2018

7 Assuming 22 disposables per cycle and 13 menstrual cycles per year, so 286 disposables/ year/ per person.

8 Based upon independent analysis by Climate Partner, a traditional cup boiled would use 41.9514 kg CO2e over 10 years if boiled for 7-10 minutes, versus washing a DAME cup in cold water would use 0.4357 kg CO2e.

9 Centre for Sustainable Manufacturing and Reuse/ recycling Technologies (SMART) Loughborough University (2007), Recycling of Footwear Products, A position paper.

10 Based on FIRA Study into the Feasibility of Benchmarking Carbon Footprints of Furniture Products 2011

11 Textile Exchange, 2021, Preferred Materials and Fibre report

12 maia research, 2021 - Global Polyester Fiber Market Report 2021. Customized report

13 Burkinshaw, S.M. Fundamentals of Dyeing. In: Physico chemical Aspects of Textile Coloration. 2015, pp.153165.

14 Burkinshaw, S.M. The Role of Water in Aqueous Dyeing. In: Physico‐chemical Aspects of Textile Coloration. 2015, pp.81-152.

15 The actual saving is likely to be significantly more. This value is simply based on reduction in energy use by not having to heat the dyebath from room temperature each time. Further savings are also possible based on embedded carbon in chemicals used, effluent treatment, recycling and post dyeing water washes, but these are much harder to quantify at this stage.

16 Koh, J. Dyeing with Disperse Dyes. In: Hauser, P.J. ed. Textile Dyeing. IntechOpen, 2011.

26

George Barrett

Partner & Sustainability Manager (Circular Economy), John Lewis Partnership

George Barrett

Partner & Sustainability Manager (Circular Economy), John Lewis Partnership