CASE STUDY

RESHORING PLASTIC INJECTION MOULDING MANUFACTURING

OVERVIEW

Mars Plastics is one of the largest injection plastic moulding manufacturers in the United States. This case study outlines how they helped a US Company reshore production of their 3 products back to the United States, saving them time, money, and the aggravation of waiting for products.

BACKGROUND

Mars recently was contacted by a company through a vendor, who had built 3 product lines overseas over the years .

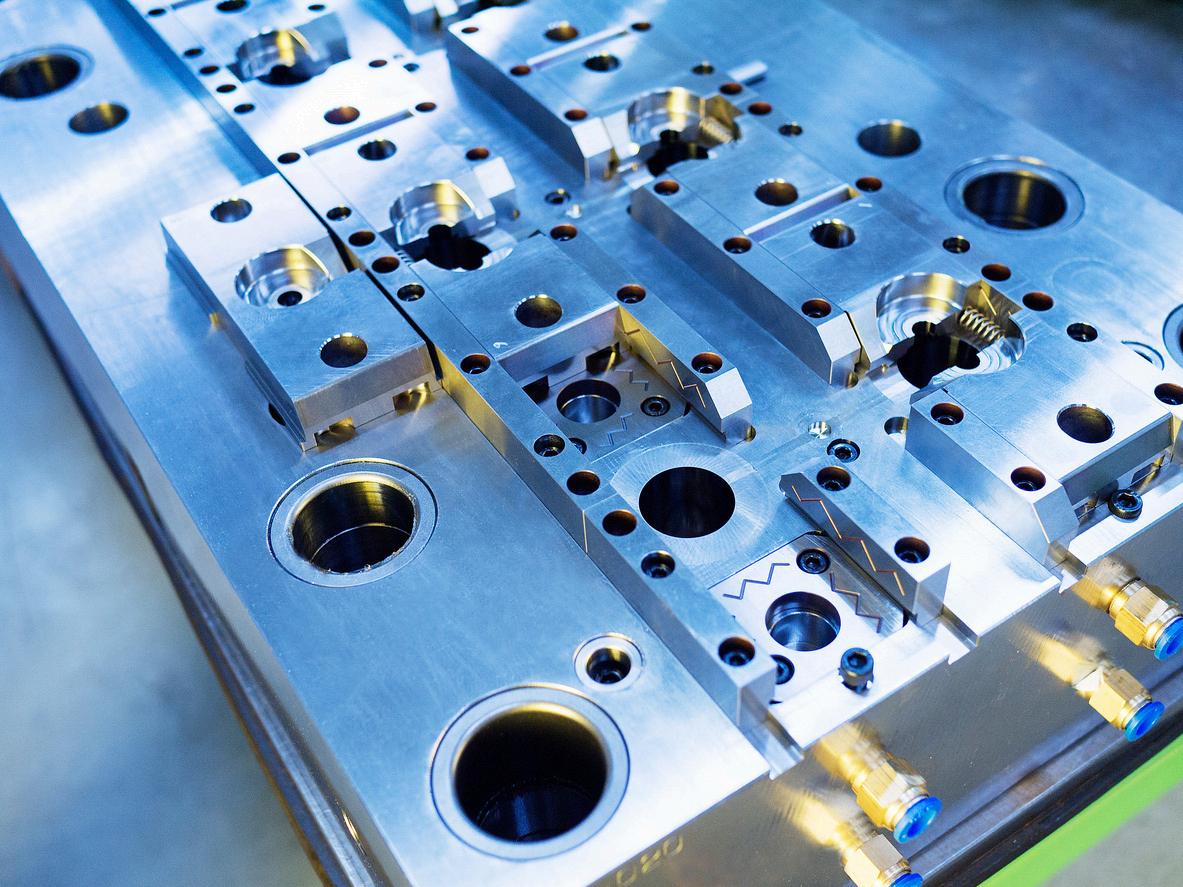

The production of these three products utilized a total of 41 tools ranging from inserts to stand alone tools. Because of the political climate and difficulties bringing parts in from China, manufacturing there has become more time consuming, expensive, and uncertain; they needed to get the tools on-shore, or back to the United States.

Adding to the challenges, this company had 4 factories producing components from multiple sized injection molding machines ranging from 24 to 500 tons.

OUR INNOVATION

Mars Plastics took over this project and made this reshoring less stressful for the customer. We had our sister company in Shenzhen gather up the tools from the 4 different facilities.

They verified to our customer what they collected, made sure it was what our customer paid for and planned on receiving. They then sampled all the tools to verify we could run them at our USA facility and produce a quality product. If they needed conversion from insert to full frames, KO patterns being adjusted, or adding cooling lines to make it easier to run, it was all done during this verification.

OUR COMPREHENSIVE SOLUTIONS

Once tools were verified they were sent in groups via boat to Mars Plastics. Mars verified and asset tagged all tools and started producing parts within weeks.

The entire process took 83 days and now the customer has a USA manufactured product that is sourced and produced quickly and inventoried for fast turn around. They no longer need to worry about financing and planning 3 months in advance for receiving product.