READY TO HELP YOU

Stack your tax credit on top of additional fall discounts of up to $16k in savings on agtech, towers and more.

Get a new Zimmatic pivot and qualify for year-end tax savings.

You may qualify for 100% bonus depreciation when you buy a Zimmatic pivot and take delivery in 2025. Now is the perfect time to invest in your operation, enhance productivity, and qualify for tax savings when you take delivery before year-end.

Consult your tax advisor to determine eligibility. Circle Z AG & Irrigation for

FLAME WEEDING AND THE PROPANE FARM RESEARCH PROGRAM

Propane-powered flame weed control is popular among ag producers as an alternative to herbicides — one that is 100% organic and up to 90% e ective against weeds. Likewise, the Propane Farm Research Program is also growing in popularity, thanks to the opportunity for farms to earn up to $10,000 per application for providing valuable data on the performance of propane-powered ag equipment. By participating in both, farmers can help improve the future of agricultural operations in ways that make them even more e cient and more environmentally friendly.

See how propane flame weeding fits your potato production schedule at propane.com/flame-weeding.

Find complete Propane Farm Research Program guidelines at propane.com/PFRP.

Published 13 times a year by Harris Publishing Inc.

SUBSCRIPTIONS:

U.S. and Possessions

$24.00 per year, International $120.00 per year. To subscribe call (800) 638-0135

Copyright 2024 Harris Publishing Inc. All rights reserved.

Reproduction in whole or in part without permission is prohibited. Back issues available at $5 per copy. Limited quantities. Publisher not responsible for content of materials submitted.

PRESIDENT Jason Harris

VICE PRESIDENT Chuck Harris

VICE PRESIDENT Ryan Harris TREASURER Clayton Ward

PUBLISHER

Jason Harris

EDITOR

Lane Lindstrom lane@potatogrower.com

ADVERTISING DIRECTOR

Rob Erickson rob.erickson@potatogrower.com

PRODUCTION

Sandon Wixom

GRAPHIC ARTISTS

Laci Thompson

CIRCULATION

Chuck Harris

IT DEPARTMENT

Chuck Harris

ACCOUNTING

Clayton Ward

Canadian Publisher’s reement No. 40606038, Customer No. 7004671.

Mailed under a standard rate mailing permit at Idaho Falls, Idaho, and at additional mailing offices.

Also Publishers of SugarProducer

NATIONAL POTATO COUNCIL (202) 682-9456 www.nationalpotatocouncil.org

FOUNDED BY Darryl Harris

CORPORATE OFFICES:

HARRIS PUBLISHING INC. 190 E 1st Street Idaho Falls, ID 83401 208-523-1500 www.potatogrower.com

POTATOES USA (303) 369-7783 www.potatoesusa.com

UNITED POTATO GROWERS OF AMERICA (801) 266-5050 www.unitedpotatousa.com

ALLIANCE FOR POTATO RESEARCH & EDUCATION www.apre.org

POTATO ASSOCIATION OF AMERICA (734) 239-8022 www.potatoassociation.org

DECEMBER 8-11

Irrigation Show

Ernest N. Morial Convention Center

New Orleans, Louisiana irrigation.org

DECEMBER 9-11

Great Lakes Fruit, Vegetable & Farm Market Expo

DeVos Place Convention Center Grand Rapids, Michigan www.glexpo.com

DECEMBER 22

Famous Idaho Potato Bowl

Albertsons Stadium Boise, Idaho www.famousidahopotatobowl.com

JANUARY 6-8, 2026

National Potato Expo

Gaylord Texan

Dallas, Texas www.nationalpotatocouncil.org

JANUARY 6-8, 2026

Dakota Farm Show

University of South Dakota DakotaDome Vermillion, South Dakota www.dakotafarmshow.com

JANUARY 9-14, 2026

American Farm Bureau Convention Anaheim, California Annualconvention.fb.org

JANUARY 10-17, 2026

110th Annual Pennsylvania Farm Show

PA Farm Show Complex Harrisburg, Pennsylvania www.pa.gov/agencies/farmshow

JANUARY 20-22, 2026

Manitoba Ag Days

The Keystone Centre Brandon, Manitoba, Canada agdays.com

JANUARY 21-22, 2026

Idaho Potato Conference

Idaho State University Pocatello, Idaho idahopotatoconference.com

JANUARY 27-28, 2026

Western Idaho Ag Expo

Canyon County Fairgrounds Caldwell, Idaho www.idahoagshows.com

JANUARY 27-29, 2026

Washington Oregon Potato Conference

Three Rivers Convention Center Kennewick, Washington potatoes.com/potatoconference

JANUARY 27-29, 2026

Michigan Winter Potato Conference

Sheraton Grand Rapids Airport Hotel Grand Rapids, Michigan www.mipotatoindustry.com/

FEBRUARY 3-5, 2026

WPVGA & UW Division of Extension Grower Education Conference & Industry Show

Holiday Inn Hotel & Convention Center

Stevens Point, Wisconsin Wisconsinpotatoes.com/events

FEBRUARY 3-5, 2026

Southern Rocky Mountain Agriculture Conference

Ski Hi Regional Event Center

Monte Vista, Colorado www.agconferencesrm.com

FEBRUARY 3-5

Spokane Ag Days

Spokane Convention Center

Spokane, Washington agshow.org

FEBRUARY 18-19

International Crop Expo

Alerus Center

Grand Forks, North Dakota www.cropexpo.com

Printed in Idaho Falls, ID by Falls Printing rob.erickson@fallsprinting.com

INTERNATIONAL POTATO CENTER www.cipotato.org

Avg

Layer

*Powerful

Avg

*An

4-3-2-11 Ca

Avg

1-1-1 16Ca 8s

Layer Manure~ DAIRY DOO~ Gypsum

*Increase

Lane Lindstrom, Editor

In many ways, the world seems to be on fire – figuratively and sometimes literally. I recently wrote in one of our other potato magazines: “It’s no secret the struggles farmers are facing today. Despite those struggles, outside forces – of which there are many – continue to wreak havoc on the industry. The world, especially the world of politics, has become increasingly more complex these days and that complexity is of great concern to the ag industry and rightfully so.”

Since I wrote that, things have not improved much and it’s easy to be pessimistic about the future of a great many things.

So, as I sit at my computer to put together the December issue of Potato Grower Magazine, I am listening to music. The title of my column, “Music Can Soothe The Savage Breast,” doesn’t exactly fit how I view music but it is the closest I could come to to describe the effect music has on me. Sometimes I just need to listen to music and think. And sometimes I just need to listen to music. Period. That phrase about music, by the way, has changed some over the years. The original quote is, “Music hath charms to soothe a savage breast.”

While country music and classic rock-n-roll are my favorite types of music, I listen to all sorts of music as evidenced by my Spotify library. One of my more recent additions is a collection of songs under the title “The Best Country Songs About Farming.” It’s great. I’ve listened to it multiple times (like right now as I write this). Many of the songs are familiar to me but some aren’t. Some I listen to fairly often, some I haven’t heard for years.

Here are a few lines from a handful of the songs that really jumped out at me as I listened to those soundtracks. Actually, there are many more than I can list here but maybe I’ll share more another time.

I make a lotta hay for a little pay

But I’m proud to say I’m a God-fearin’, hard workin’ combine driver Hoggin’ up the road on my p-p-p-p-plower

Chug-a-lug-a-luggin’ five miles an hour

On my International Harvester

MONTGOMERY GENTRY –“DADDY WON’T SELL THE FARM”

The city’s growin’ around him, but Daddy won’t sell the farm

You can’t roll a rock up a hill that steep

You can’t pull roots when they run that deep

KENNY CHESNEY –“SHE THINKS MY TRACTOR’S SEXY”

She thinks my tractor’s sexy

It really turns her on

She’s always starin’ at me

While I’m chuggin’ along

She likes the way it’s pullin’ while we’re tillin’ up the land

She’s even crazy ‘bout my farmer’s tan

JUDDS – “JOHN DEERE TRACTOR”

I’m like the John Deere tractor

In a half acre field

Tryin’ to plow a furrow

Where the soil is made of steel

How I wish I was home, mom

Where the blue grass is growin’

And the sweet country boys don’t complain

I can plow a field all day long

I can catch catfish from dusk ‘til dawn

We make our own whiskey and our own smoke too

Ain’t too many things these old boys can’t do

We grow good-ole-tomatoes and homemade wine

And a country boy can survive Country folks can survive

We didn’t know the times were lean Round our house the grass was green

It didn’t seem like things were all that bad

I bet we walked a thousand miles

Choppin’ cotton and pushin’ plows

And learnin’ how to give it all we had

As life went on and years went by I saw the light in daddy’s eye

And felt the love in momma’s hands

They kept us warm and kept us fed

My hands don’t earn me too much gold

For security when I grow old

But we’ll all be equal under the grass

And God’s got a heaven for country trash

Then out in the distance I saw through the window

A man on a tractor with a dog in a field

Oh, the dog walked just like it was smiling

The man drove like the world was all right

The tractor hummed on like a part of a song

That you sing to your children at night

His work was laid out there before him

In rows of green, his whole life was revealed

Oh, what I wouldn’t give if I could just live

Like a man on a tractor with a dog in a field

Nelson Irrigation has announced the launch of its new center pivot irrigation R65 VT and inverted R65i VT sprinklers. Designed to elevate multi-stream performance at the end of pivot systems, these new models build on the proven success of the R55 series, offering enhanced uniformity, increased coverage, and simplified installation.

The R65 VT features a narrower body and a newly optimized nozzle system, delivering focused streams that extend the effective radius even at low pressures. With a 270-degree water pattern, it ensures overlap with pivot sprinklers, boosting uniformity at the end of the iron. Both the blue and green (inverted) plates

Potato farming is tough on equipment — and that’s exactly where the Raptor Dynamic HD580 shines. Designed for rugged performance, this drone combines speed, power and smart tech to meet the demands of high-output spraying. With an 18.4-gallon tank and a spray rate of up to 10.5 gallons per minute (when equipped with upgraded centrifugal nozzles), it’s built to handle the heavy lifting across large potato plots.

Its ventilated battery system improves heat dissipation by 700 percent, keeping the drone cool and consistent during long spraying runs. The HD580’s flight control system includes a 120-degree wide-angle lens, virtual gimbal, electronic stabilization, and night vision enhancement — perfect for early morning or late evening applications when conditions are ideal for spraying.

can use the entire nozzle range.

The inverted R65i VT is engineered for ease of installation and superior debris flushing. Its specially designed inverted green plate enhances performance while minimizing clogging — ideal for systems prone to sediment buildup.

Whether used independently or paired with Nelson’s Big Gun Sprinklers, the R65 VT and R65i VT adapt to a wide range of site conditions. They’re perfect for maximizing coverage in corners or throughout the full revolution of the pivot.

Nelson Irrigation continues to lead the way in irrigation innovation by providing improved solutions to conserve resources and provide greater uniform water application for farmers.

For more information, visit R65 End of Pivot Sprinklers.

For potato growers who need reliability and precision in every pass, the HD580 delivers. It’s a workhorse in the sky, engineered to cut labor costs and elevate productivity. From blight control to nutrient application, this drone is ready to roll up its sleeves and get dirty.

For more information, visit RaptorDynamic. com.

With e-LS connect, ROPA and Fendt present a groundbreaking advancement in hydraulic communication between tractor and implement. For the first time, the system enables fully electronic communication of the required oil pressure via ISOBUS – without a separate hydraulic load-sensing control line. This marks a new level of precision, efficiency and system stability between tractor and implement.

For nearly 30 years, the communication of hydraulic oil pressure between tractor and implement has been based on a physical load-sensing line (LS). With e-LS connect, this connection is now being fully digitalized: the required oil pressure is transmitted electronically from the implement to the tractor via ISOBUS, allowing the hydraulic pump to precisely regulate the pressure needed for the desired flow rate.

As a result, components such as pressure control valves, sensors and LS signal lines become obsolete – reducing potential failure points, increasing operational reliability and simplifying the coupling and uncoupling process.

Existing Fendt tractors of the 500 Vario Gen4, 600 Vario, 700 Vario Gen7/7.1, and 800 Vario Gen5 series can be prepared for e-LS connect via software update starting June 2026.

For existing ROPA Keiler 2 RK22 machines, e-LS connect will be available through a software update beginning in 2026.

• Fully electronic hydraulic communication via ISOBUS

• No LS-hose, no contamination, no oil leakage

• Faster, more stable, and more precise response

• Reduced energy demand and lower fuel consumption

• Fewer components = greater operational reliability

• Increased comfort and driving pleasure for the operator

For more information, visit www.ropa-maschinenbau.de/.

“The Industry Leader In Vent Floor Systems”

• Better distribution of air flow

• Reduces moisture loss by up to 50%

• Low maintenance

• Quick cleanup

• Greater storage yield

• Easy storage loading and unloading for onions and potatoes

CURRENTLY BEING USED BY:

Frank Tiegs-Pasco, WA

Cleaver Storages-Hermiston, OR

Lamb Weston-American Falls

Madison Farms-Echo, OR Munn Farms-Prosser, WA

Hartley Farms-Prosser, WA

Lamb Weston-Patterson, WA

Agri NW-Plymouth, WA

Warden Hutterians-Warden, WA

Weyns Farms-Othello, WA

Vive Crop Protection has announced that Will McAndrew, a highly accomplished global finance leader with more than 25 years of experience in agriculture, has joined Vive’s Board of Directors.

McAndrew brings extensive expertise in strategy, financial planning, mergers and acquisitions, investor relations, and team leadership. Over the course of his career, he consistently delivered results by aligning financial support with long-term business growth, building high-performance teams, and driving operational excellence across complex organizations.

Most recently, McAndrew served as vice president of Strategic Financial Planning and R&D Finance for Bayer Crop Science, where he oversaw the finance function for Strategy and Sustainability. He played a pivotal role in strategic planning, portfolio prioritization, licensing, pipeline valuation, and deal support.

In addition to his corporate leadership, McAndrew served on the Board of CoverCress Inc., an innovative company developing a renewable oilseed cover crop. As Audit Committee chair, he guided financial oversight and governance during a period of rapid expansion.

“I am excited to join Vive’s Board of Directors at such a dynamic stage in the company’s growth,” said McAndrew. “Vive is redefining how chemical and biological crop protection products can be efficiently developed and delivered to farmers, and I look forward to contributing to its mission of advancing agriculture through highvelocity innovation.”

McAndrew holds a Bachelor of Business Administration in Finance from Iowa State University and an MBA in Finance from the University of Missouri–Kansas City.

For more information, visit www. vivecrop.com.

Volm Companies has announced a new dealership agreement with Flikweert Vision, an innovative solutions provider for the potato and onion industries.

Matthew Alexander, Volm’s vice president of Sales & Marketing, and Wayne DeCou, Equipment sales director, formally confirmed the deal with Flikweert CEO Martijn Flikweert during a recent trip to the Netherlands.

The strategic partnership marks an important expansion of Volm’s equipment portfolio, providing new and modern optical sorting solutions to meet the changing needs of the fresh produce industry.

Based in the Netherlands, Flikweert combines artificial intelligence and advanced camera technology to meet today’s challenges. With their innovations developed entirely in-house, software and mechanics are seamlessly integrated by a highly knowledgeable team of engineers.

Based in Antigo, Wisconsin, Volm is a leading packaging and equipment solutions provider with locations across all major growing regions. With our highly experienced team of service technicians, Volm has a trusted track record in providing quality installations, timely service, and reliable support.

Flikweert’s two new solutions, the Divider and QualityGrader, were introduced at the Fresh Ideas Showcase at The Global Produce & Floral Show in Anaheim, California.

New Flikweert Solutions

The Divider is a unique and highly accurate optical sorting machine that separates foreign objects, such as stone, wood, plastic and other debris, from field crops. Using AI technology to process up to 120 tons per hour, this solution optimizes product flow, resulting in less wear, product damage and waste down the line.

The QualityGrader offers a solution for the labor-intensive task of grading potatoes and onions. Using a combination of artificial intelligence and advanced camera technology, it can sort up to 20 tons of product per hour.

The 3600 Series Pulvi-Mulcher from Brillion features wider working widths, increased trash clearance and reduced downtime in the field. The series is available in 21’, 25’, 30’ and 36’ working widths. The 30’ model weighs 80% more than the popular WL360 for more clod crushing power. The 36’ unit is the widest PulviMulcher offered by Brillion.

3600 Series models feature 8” roller axles with heavy-duty bearings that improve reliability and reduce maintenance interruptions in the field. The design includes three rows of two-piece edge bent s-tines on overall 6” spacing. 25” of under frame clearance improves trash flow through the machine. A leveling harrow in front of the rear roller helps level ridges left by the shanks.

Simplot Grower Solutions (SGS), a division of the Simplot Company, recently marked its 80th anniversary with a celebration honoring eight decades of service to farmers across North America.

Founded in 1945 by J.R. Simplot, a farmer and visionary entrepreneur, SGS began as “Simplot Soilbuilders,” pioneering the concept of retail farm service centers. This innovation transformed how fertilizers and crop protection products were delivered to growers, laying the foundation for a legacy of agronomic support and customer partnership.

Over the years, SGS has expanded its offerings to include a comprehensive portfolio of crop nutrition, crop protection, and seed products, along with cutting-edge technologies like Simplot SmartFarm, a precision ag platform that empowers farmers with

data-driven insights. At the heart of SGS’s success is its team of Crop Advisors, agronomic experts who work closely with growers to optimize yields, manage inputs efficiently, and support long-term sustainability.

Today, SGS operates one of the largest ag retail networks in North America, with a continued focus on innovation and a commitment to serving the communities in which it operates. Idaho Governor Brad Little attended the 80th anniversary celebration and praised Simplot’s long-standing commitment to agriculture and rural communities. “We cannot do what we do in this country, which is feed the world, if we don’t have those incredible nutrients,” Little said. “Simplot is a model ambassador for the State of Idaho. They’ve never forgotten their roots and have remained committed to the farmers they serve.” For more information, visit Simplot. com and Simplotgrowersolutions.com.

Culinary Year In Review: More Foodservice Collaborations = More

Potatoes USA’s Culinary Program has been serving up success, helping launch six new potato menu items at major restaurant chains since 2024. Several new dishes won awards and even led to Twin Peaks restaurants selling 1.7 million more pounds of spuds annually.

Valent BioSciences LLC, MGK and Valent North America LLC announced they will come together under a new unified organization named Sumitomo Biorational Company LLC (SBC), a subsidiary of Sumitomo Chemical Company Ltd (SCC) in April 2026.

Based in Libertyville, Illinois, the integrated organization will serve as SCC’s Global Center of Excellence for Biorational Innovation, designed to accelerate the company’s industry-leading capabilities in providing integrated, sustainable biorational solutions derived from natural sources such as microbials and botanicals to customers around the globe.

Valent U.S.A. LLC will continue to operate separately, maintaining its focus on regional sales and marketing across the U.S., Canada and Mexico.

The new company will be led by Dr. Shinsuke (Shin) Shojima, who has been appointed president and CEO. With over 35 years of experience in a variety of senior executive roles across the Sumitomo Chemical Group, Shojima will manage the global agricultural and environmental health practices for biorational technologies. The Center of Excellence will focus on best practices and talent development, while collaboratively developing a range of products that contribute to regenerative agriculture and sustainable environmental health.

By consolidating its expertise and resources into SBC, Sumitomo Chemical can streamline operations and bring new innovations to market faster. The formation of SBC will strengthen the company’s ability to serve a wide range of markets, including agriculture, public health, forest health, professional pest control, and animal health.

This strategic integration enables SBC to:

• Expand research, development and supply chain capabilities.

• Streamline the customer experience for our channel

partners.

• Accelerate innovation through collaboration and knowledge sharing.

• Enhance global leadership and brand presence in regenerative solutions.

• Develop talent more strategically and create new career opportunities.

For regional sales and marketing, the following business units will continue serving customers:

• The Public Health and Forest Health business unit for Valent

BioSciences customers will continue doing business under the same representing brand for regional sales and marketing mainly in North America and Africa.

• The Biostimulants Business Unit and the Specialty Business Unit at the Valent BioSciences’ subsidiary Mycorrhizal Applications will be doing business as SBC for regional sales and marketing in the U.S.

For more information, visit https://www.sumitomochem.co.jp/english/.

(ED—This is Part 2 of a 2-part series on potato exports. Part 1 was our visit with Easterday Produce in Pasco, WA, and was published in the November issue and Part 2 focuses on potato exports, particularly fresh potato exports along with our visit to the Port of Seattle, a major U.S. potato export port.)

By Lane Lindstrom

Exports from the United States have been happening for hundreds of years and when it comes to potatoes, this country has been exporting them for more than a hundred years.

But while potato exports have been taking place for dozens and dozens of years, this part of the potato industry, as well as exports in general, have been in the spotlight (for good or bad) the past few months with the glare of the light squarely on agricultural products.

The reasons for that glare are many, but no one will argue that there isn’t a lot at stake for ag exports as this country has developed a fairly sophisticated and robust ag export program for dozens of commodities.

That includes potatoes from frozen to dehy to fresh.

Consider these figures for the period of July 2024-June 2025 from a recent Potatoes USA report:

• While U.S. export volumes rose for both fresh and frozen potatoes during that period, total export volume declined 3.75 percent to 3.1 million metric tons (fresh weight equivalent).

• Frozen potato exports, which represent 49 percent of

Above: These refrigerated cargo containers carry fresh and frozen potatoes to Far East Asia destinations. The Port of Seattle’s Terminal 5 has 1,500 reefer plugs where refrigerated containers can be plugged in on land.

total U.S. export volume, rose nearly 2 percent compared to the same period last year.

• Fresh potato exports rose by more than 1 percent and accounted for nearly 20 percent of all U.S. exports.

• The total value of U.S. potato exports decreased by 0.8 percent to $2.3 billion from July 2024-June 2025, compared to the same period last year, according to U.S. Department of Commerce data compiled by Trade Data Monitor.

• The overall decline in U.S. export volume was driven by dehydrated potatoes, which fell 14.4 percent, and potato chips, which fell 13.4 percent. Seed potato exports also decreased by 2.1 percent.

Nearly 7 billion pounds of potatoes and $2.3 billion are pretty big numbers. Those are, pardon the pun, no small potatoes. Zeroing in on just the fresh export market, that segment is a bit more than 1.25 billion pounds big.

In light of the current slump in the potato market, any downturn in exports – fresh, frozen or dehy – is less than welcome news. That comes into further focus from that Potatoes USA report we referenced earlier. It says, “Global potato trade has expanded since 2016, driven largely by increased exports from China and India. In 2025, the global market share of the six largest exporters was:

• European Union (EU) – 44 percent

• Canada – 20 percent

Left: The MSC Elaine is docked at the Port of Seattle earlier this year. This port, part of The Northwest Seaport Alliance along with the Port of Tacoma, is the No. 1 export port of U.S. fresh potatoes.

• United States – 18 percent

• China – 13 percent

• Argentina – 2 percent

• India – 2 percent.”

Any opportunity to increase U.S. potato exports, especially fresh potatoes, would be a boon to the industry. Just think of what opening the market in Mexico did for the U.S. potato industry. That market is now worth more than $120 million (235,041 metric tons) in fresh potato sales, which is down 11.4 percent from a year earlier, but still by far the largest export market for fresh potatoes out of the U.S.

“Mexico has grown to a $120 million a year market for U.S. growers,” National Potato Council CEO Kam Quarles said. “That really happened just slightly over three years. The ability to move that amount of potatoes into the export market like that is incredible. That’s why we keep driving forward with this program. [Exports] are to the benefit of all U.S. growers.”

Although the process of getting fresh potatoes into Mexico was long and arduous, it has paid off and the industry, led by the NPC and others, is focused on other export opportunities. That spotlight is now squarely focused on Japan, home to 124 million people.

The process to get fresh U.S. potatoes into Japan has been glacially slow, as Quarles has pointed out on numerous occasions. In late October, the NPC expressed its disappointment in the latest effort to get the Japanese market open. A NPC press release issued after President Donald Trump’s visit to Japan reads, in part, “The National Potato Council is disappointed that the U.S.-Japan agreement did not include fresh market access for U.S. potatoes. Japan has delayed this market access request from the U.S. for thirty years, including delays as recently as this month [October].”

In that same press release, Quarles said, “It is very disappointing that the U.S. was unable to use President Trump’s tariff leverage to push past Japan’s protectionism and finally open this valuable market.”

Later in that press release, Quarles did say, “Despite this disappointment, we were pleased by U.S. Chief Agriculture Negotiator-nominee Dr. Julie Callahan’s comments Wednesday before the Senate Finance Committee, where she acknowledged Japan’s delaying strategy is a non-tariff trade barrier. This has been stated by our industry for years, and we very much appreciate Dr. Callahan’s clear assessment and focused intent to open this market to benefit family farms across the U.S.”

Japan, as Quarles pointed out in his interview with Potato Grower Magazine, does not grow enough potatoes to supply its domestic use and does not allow fresh potato imports from any country. The country does allow some chipping

potatoes to enter its market.

He then reiterated just how important the Japanese market could be to U.S. growers. “Opening the Japanese market could increase fresh exports 10-15 percent for us,” he said. For the fresh market, the flagship is Japan. There is no market out there that is a short- or medium-term opportunity for us like Japan.”

He continued, “That’s not to say we’re not working on other export opportunities, but there’s nothing of the scope as Japan.”

While the NPC is working on opening the Japanese market to fresh potatoes, it is also working to keep the Mexico market open and thriving. “With Mexico, there are clearly forces that want to close that market,” Quarles said.

Quarles then stepped back to look at the fresh potato export market overall, stressing how important it is to the U.S. potato market, regardless of whether a grower ships his potatoes internationally or not.

“As an example,” he said, “Pick a figure, say $1 billion of fresh potatoes exported and all of a sudden the export market closes. Now you have a billion dollars of extra potatoes on the market you need to find a home for. That would have a rapid price reaction [on the market]. And it would be a massive reset of production.”

Conversely, take the same amount of potatoes out of the domestic market and prices could rise, etc.

“The math of this strategy is very compelling,” he said. With fresh potato exports, Quarles said, “I really do think the opportunity is great, especially if we can get Japan and keep Mexico going.”

So while Mexico is a huge export destination for U.S. fresh (and frozen) potatoes and Japan has the potential to benefit U.S. growers, there are several international destinations for U.S. fresh potatoes. Here are some of the most recent figures from the U.S. Department of Commerce for fresh potato exports:

• Worldwide: 569,070.9 metric tons worth $329,041,045

• Mexico: 235,041.7 metric tons worth $120,291,126

• Canada: 122,086 metric tons worth $61,794,032

• Central America & The Caribbean: 71,744.6 metric tons worth $57,162,339

• South America: 270.9 metric tons worth $151,997

• European Union: 7.6 metric tons worth $11,082

• Middle East & North Africa: 1,007.8 metric tons worth $946,895

• Asia: 138,287.4 metric tons worth $88,122,633

Of note with the figures listed above is that the Central America & The Caribbean dollar amount is an increase of 21.8 percent compared to the previous year while the dollar amount for South America increased 291.2 percent. However, the European Union dollars dropped 94.1 percent and the Middle East & North Africa figures 38.9 percent. Asia export sales are up 18.1 percent, led by Thailand (662.5 percent) and Vietnam (397.6 percent). El Salvador (103.5 percent), Panama (165.7 percent), Guatemala (71 percent) and Aruba (55.3 percent) led the way in export sales increases in Central America & The Caribbean.

Zeroing in on the Asian fresh potato market, partly because

of the potential in Japan as well as it being the primary destination for potatoes shipped via cargo ships anywhere in the world (which we learned during our visit to the Port of Seattle), it’s obvious this region of the world is an important destination for U.S. fresh (and frozen) potatoes. It is the second largest market for U.S. fresh potatoes in the world.

The Port of Seattle, it is part of The Northwest Seaport Alliance (NWSA), which also includes the Port of Tacoma so any export figures include shipments from both ports.

On average, 80 percent of exports from the NWSA are agricultural products, which include forest products. Hay is the No. 1 ag export from these two ports.

However, the NWSA is the No. 1 exporter of frozen potatoes and also the No. 1 exporter of fresh potatoes from the U.S. More specifically, 82.1 percent of all frozen potato products exported from the U.S. go through the Ports of Seattle and Tacoma while 74.4 percent of all fresh potato exports leave from these two ports.

The top destinations for frozen potato products shipped from the NWSA are Japan, South Korea and Taiwan. Meanwhile, the top destinations for fresh potatoes are Japan, Taiwan and the Philippines. Fifty-four percent of the fresh potato shipments are exported to Japan and Taiwan.

It should be noted that while fresh potato figures don’t always include seed potatoes (such as those figures from the Department of Commerce), there is no differentiation between fresh potatoes used as table stock and those used for chips.

If you’d rather receive this magazine in your inbox in a digital version email, let us know and we will switch it over for FREE. All we need is your email address. Contact Rob at rob.erickson@harrispublishing.com

The NWSA, as pointed out by Melanie Stambaugh Babst, director of communications for The Northwest Seaport Alliance, the top destinations for potato shipments aren’t the only destinations from the ports. Potatoes are shipped in refrigerated cargo containers (reefers) called TEUs. Stambaugh Babst explained, “There are small containers and large containers that are shipped via ocean going vessels. The small containers are 20 feet long and are called TEUs. TEU stands for 20-foot equivalent unit. The larger containers are 40 feet long and called FEUs. FEU stands for 40-foot equivalent unit. Despite there being two sizes of containers on ships, all metrics are in TEUs. So one FEU is counted as two TEUs in our cargo statistics.”

With that explanation in mind, she said that fresh potatoes going to Taiwan, Japan and South Korea account for 6,357 of the 9,453 fresh potato TEUs shipped to these countries annually. When it comes to frozen potato products, 45.4 percent of those go to Japan or 20,594 of the 45,346 frozen potato TEUs.

In 2024, NWSA frozen and fresh potato shipments totaled 54,799 TEUs. Of that total, 82.8 percent are frozen potato products and 17.2 percent fresh potatoes. However, Stambaugh Babst pointed out that the fresh export market from the NWSA has grown significantly over the years. In 2009, the NWSA exported 1,973 TEUs of fresh potatoes. That number is now 9,453 TEUs.

Of course, it doesn’t hurt that the Port of Seattle and Port of Tacoma are close to the two largest potato producing states in the U.S. That proximity to Washington and Idaho is one of the main things that helps set the NWSA apart from other ports. Stambaugh Babst also shared that the NWSA is the closest gateway by nautical mile to key Asian markets. And since 63.3 percent of fresh and frozen potatoes are destined to Japan, Taiwan, Korea and the Philippines, that’s quite an advantage. “We offer fast, reliable service to Asian markets,” she said. “All major alliances and carriers serve our gateway, including six last ports of call to serve exports.” She added, “Our team focuses on providing best-in-class

service, not to just importers, but to exporters as well. We pride ourselves on being a relatively balanced gateway between imports and exports. We have prioritized positive relationships with exporters and trade associations which helps us better serve potato and all ag producers in the U.S.”

When it comes to potato exports, especially fresh potatoes, Washington has the edge (read: location, location, location). As we pointed out in Part 1 of our potato export series, Washington state exported $33.86 million worth of fresh potatoes in 2024 to seven of the state’s top export countries.

As we also shared in Part 1 of this series, the state’s location definitely helps Washington growers who want to export overseas, such as Pasco’s Easterday Produce Company. “Being located in Washington state also provides a geographic advantage, with direct access to the West Coast ports and efficient shipping lanes to Asian markets,” Matthew Wood, Easterday Produce sales manage, said. “The Washington State Potato Commission and National Potato Council provide important policy and promotional support, but ultimately, it’s the reliability of Easterday Farms Produce Company – steady supply, climate-controlled storages and broker partnerships that manage logistics and documentation – that drives repeat business.”

While Washington state growers have an advantage when it comes to potato exports, there other potato-producing states that would love a part of the export action. But logistics and cost can be prohibitive factors, especially the farther growers and packers are from ports.

Reefers cost more to ship than dry containers, as was pointed out by Jeff Nielson, export manager for Expeditors International of Washington. A dry container, like one that would be used to ship hay in, would cost between $3,0004,000 to ship (via Salt Lake City using rail to Oakland or Los Angeles), whereas a reefer would cost $8,000 (to Seattle and being trucked to the port). Nielson said it’s those costs that make it tough for, say Idaho, to be competitive in the export market. “It’s challenging due to trucking costs,” he said.

Another challenge is getting refrigerated containers to

ship potatoes in. Many of them that might go through Idaho (or other western potato-producing states) on the way to the port are usually already filled with beef and pork from the Midwest and since the ocean carriers own the containers, they can pick and choose the cargo.

One export expert said that once potato packers have more access to refrigerated containers, “we’ll be more competitive.”

Something that may help improve the opportunities for potato packers farther inland are intermodal rail terminals, such as the one recently opened in Pocatello, ID. These facilities give ag producers closer access to rail so they can ship containerized products to ports. For Idaho, that would be the Port of Seattle and Port of Tacoma. Of course, rail cars can carry more cargo than a semi-trailer but it usually takes longer to get to the destination. From Pocatello, it could take a railcar up to four days to get to the Port of Seattle.

At the Port of Seattle there are railroad tracks right on the wharf where rail cars can be unloaded and then loaded onto cargo vessels. There are also truck unloading areas at the port, meaning they both offer easy access to be loaded onto ocean-going ships.

“The NWSA has an inland rail strategy that focuses on developing inland rail ramps to support increased agricultural exports from key inland locations,” NWSA’s Stambaugh Babst said. “We currently have three in operation, one each in Minot, ND, Pocatello, ID, and Wallula, WA. These rail hubs are operated by non-NWSA partners and Class 1 railroads.”

While fresh potato exports are an established and decent money maker for those able to export their potatoes, there are certainly are a lot of questions still remaining surrounding future fresh potato exports, such as if and when the Japan market will open, who will help fill the fresh potato needs should exports increase, can inland growers and packers make the numbers work to be profitable in the export market and the questions go on and on.

Most likely those answers will eventually come, some sooner than later.

But we go back to NPC CEO Kam Quarles’ statement about potato exports, “I really do think the opportunity is great …”

Strengthen soil quality by feeding it the power of the sea.

Our cold-processed seafood hydrolysate liquid fertilizer builds soil health by feeding beneficial soil fungi and bacteria.

Every October after harvest, hundreds of samples of Idaho seed potatoes begin a long journey to Hawaii.

Each grower-submitted sample, typically 400 tubers, is packed into a shipping container after treatment with a dormancybreaking chemical, then sent to its winter destination. By mid-November, the samples are planted in what the seed certification industry calls the winter grow out.

By mid-December, inspectors begin to examine emerged plants for symptoms associated with potato virus y, potato leaf roll virus and chemical injury. This stage of the certification process for Idaho seed potatoes is overseen by the southeast branch of the Idaho Crop Improvement Association (ICIA), led by Area Manager Alan Westra.

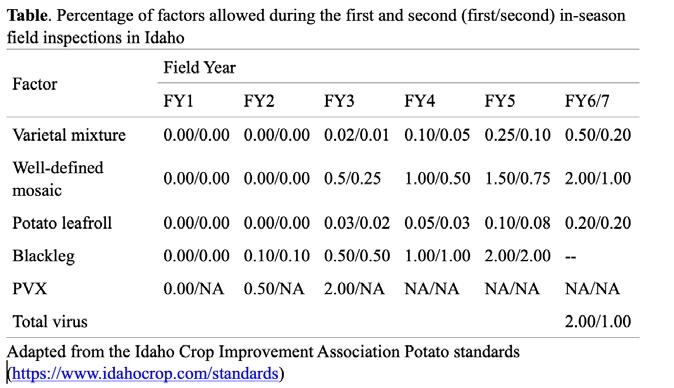

The winter grow out is one of the final steps in ensuring that seed potato lots meet the certification standards. In Idaho, seed lots that are entered in the winter grow out must have originated from approved planting stock and passed at least two in-season field inspections where conformity with disease and varietal mixture tolerances were met (see table).

In addition, the associated storage facility where the seed is to be stored must have been inspected and verified to meet requirements for cleanliness and lot separation.

A primary goal of the winter grow out is to estimate incidence of potato virus y (PVY), a virus known to cause mild or visually undetectable symptoms depending on the virus strain, potato variety, and environmental conditions. After emergence, a single leaf from each emerged plant is picked and sent overnight to the ICIA seed potato testing laboratory in Idaho Falls for analysis using an enzyme-linked immunosorbent assay (ELISA), a common serological test. Under the leadership of Lisa Tran, the lab team processes and tests hundreds of samples each season.

Despite immense efforts to obtain results quickly, the process is still long and arduous, with all testing often not completed until early February. Tran is working towards developing a method to provide results even sooner by testing dormant tubers, a method featured in a Potato Grower Magazine article (https://www. potatogrower.com/2023/07/u-of-i-grad-student).

2009 Logan LP20’ Front/Rear drives/Combo/Ez tarp

2003 Spudnik 4200 bed 20’ Electric

2001 Double L 801 20’ Front/Rear Drives/ Combo

1996 Spudnik 2100 20’ Front/Rear Drives/Elec.

1988 Double L 801 20’ Electric

1985 Logan 20’ Electric

2019 Kenworth T370 Auto w/2spd reduction, 1996 Ford L9000 Auto, Cummins 2012 Logan 22’ bed

1991 GMC Topkick Cat motor Auto Trans

1986 Pete 349 Truck with Logan 20’ bed Combo

1978 IH Tandem DS 10spd PTO, 20’ bed ready

2021 Spudnik 780 36”all chevron belts, 480 volt 3ph, remote

2005 Spudnik 560 36” 28mm BC, 480 volt 3ph, remote

2000 Wemco 36” all belt 230 volt 3ph remote all hydraulic

1999 Double L 831 36” BC Elev/49’ boom 3ph HYD Drive & Remote

1998 Double L 831 36” BC Elev./49’ boom 3ph Elec. Drive & Remote

1996 Spudnik 550 36” All Belt, remote, 480 volt 3ph

1989 Spudnik 550 36” BC Elev. 48’ Boom 3phase 480 Volt Remote Reconditioned

1991 Spudnik 525 30” All belt 480 Volt 3phase, new remote

1989 Spudnik 550 30” BC Elev. 48’ Boom 3phase VFD’s

SCOOPER

2025 Logan Scoop Pro 36” New 230 3phase Spudnik model 150 30” Reconditioned 230 volt 3ph

Spudnik 100 24” 3ph Spudnik 1000 Scoop trailer

KWIK LOCS

Neu Tech 9 lane weigher Ag Pak bagger 2 Kwik Locs Grain Treater USC LP2000 with seed wheel

For seed potato growers and buyers alike, the winter grow out results can be crucial. If incidences of PVY fall within allowable tolerances and all other certification requirements are met, the seed lot qualifies for re-certification, meaning it can be increased for yet another generation in the field. Such eligibility significantly increases the value of the seed lot.

After the winter grow out, Idaho seed lots undergo one more inspection before certification is complete: a shipping-point inspection. This step verifies that the seed meets Idaho seed potato grades, which specify tolerances for size, shape, defects (including internal and external blemishes), and specific diseases. Once all requirements are met, each container receives an official certification tag — blue, green or yellow — indicating the final grade, with blue representing the highest quality. Without a tag, the seed is not considered certified.

The winter grow out remains a vital part of the seed potato certification process. For seed buyers, reviewing seed certification records before purchasing seed is highly recommended. These records, such as summer field inspection reports, results of postharvest testing, and the North American Certified Seed Potato Health Certificate, can be obtained directly from the grower. (Duellman is associate professor of Plant Pathology and Seed Potato Extension Specialist at the University of Idaho. She can be reached at kduellman@uidaho.edu. Westra is area manager for the Idaho Crop Improvement Association. He can be reached at awestra@idahocrop.com.

2023 Lockwood Vacs Mobile 2014 Lockwood Vacs 8

ELIMINATORS

Harriston 3240 CH fingers peg belt blower sizing fingers

V 3ph 2002 Harriston 240 CH Ellis Table 480 Volt 3ph

Harriston 200 CH New13 finger roller table 480 volt 3ph

SIZER

2015 Spudnik 925 -84” Acorns, 240 Volt 3ph

2000 Spudnik 925 -72” Acorns, 240 volt 3ph

1997 Spudnik 925 72” Acorns, 480 volt 3ph Kerian 60”W x 10’ L, 4 adjustable lanes 1” to 4.5”, rib rolls

DIRT ELIMINATOR

2014 Spudnik 990 Multi Sep Dirt Elim 72” 480 volt 3ph

HARVESTERS

CROSSOVERS/WINDROWERS

2009 Spudnik 990 60”belt elev., 72” Rev/Roll Table BC picking

480 V 3ph

2004 Spudnik 995 DES 72” split picking 230 volt 3ph.

2006 Spudnik 995 72”Finger rollers, Rev/Roll table

2003 Milestone 36” hopper 60” fingers 48 belt picking table

Hang-on

1996 Milestone MSDS72 hopper 60” / 72” fingers 3ph

1998 Spudnik 900 hopper 48” Fingers 60” 230 volt 3ph

CONVEYORS -TELESCOPIC

2001 Spudnik 1255 30’’/36’’/85’ 3ph

1997 Spudnik 1255 30”/36”/85’ 1 ph

1994 Double L 820 30” x 70’ 3ph

1996 STI 30” x 70’ 480 volt 3ph

1989 Double L 810 30” x 50’ 3ph

CONVEYORS - STRAIGHT

2001

Ag-Vantage, Inc. (208) 670-1041 www.ag-vantage.com

Ag-Vantage’s Culti-Dikers are water conservation tools that create water-retaining pockets to prevent soil erosion, thus providing increased crop yields. The pockets formed can hold one-half to three gallons of water, depending on model. Culti-Dikers can be mounted to row crop planters in between the planter units or behind, depending on each grower’s specific requirements. Culti-Dikers are available in several different models and sizes to meet individual needs.

Culti-Dikers have been mounted onto planters, cultivators, grain drills and tool bars for the past 20 years. A proven water conservation tool when used in sugarbeets, corn, beans, potatoes, grains and other crops.

Kuhn North America (608) 897-2131

www.kuhn-usa.com

The new KUHN Krause Dominator 4857 boasts product features designed to provide optimal compaction removal and residue handling while reducing maintenance time. The double rank subsoil shanks mounted on narrow 18-inch spacing deliver maximum subsoil fracture. The new reversetandem rear disc conditioner produces consistent soil leveling and residue incorporation for pass-topass uniformity, while the soil conditioning reel provides final clod sizing along with seedbed soil firming. Maintenance-free features are incorporated throughout the Dominator 4857, reducing the required daily lubrication service time, placing you in the field sooner and increasing operator productivity. Working widths range from 10-foot-6 to 19-foot-6 and models are available with 7, 9, 11 or 13 shanks.

Milestone (208) 785-4285

www.milestone-equipment.com

Uncompromising attention to detail and more than 50 years of hard-earned experience have allowed Milestone to produce the most capable, highestcapacity potato-cutting system available. Milestone potato seed cutters effectively cut both long and round varieties without the need for costly retooling. Numerous innovations, including the patented Milestone Star, hydraulic sizer quick adjust, and Milestone cutting system, ensure a consistent, uniform and blocky seed piece—the key to optimal planter performance and vibrant plant growth. Several easy-

Safe-T-Pull, Inc. (701) 284-6100 www.cropshuttle.com

The Crop Shuttle is the largest, fastest and most versatile crop cart on the market. It is fully customizable, providing you up to an 800-bag capacity and discharge speeds up to 400 bags per minute. The Crop Shuttle is extremely versatile, allowing operators to use it in diverse crops such as potatoes, sugarbeets, carrots, onions, red beets, cucumbers and even corn silage.

STP Manufacturing has designed the Crop Shuttle so there is no PTO needed to power the hydraulics. The Crop Shuttle’s patented design has minimal moving parts and changing angles, meaning less buildup of debris while using less hydraulic power. The hopper rises into the air while unloading, creating the incline needed without a separate conveyor slowing down

to-use adjustments can be made while the machine is operating to help ensure the desired seed profile. Milestone’s new 84-D potato seed cutter, the newest addition to the company’s cutter lineup, represents the ultimate example of capacity, technology and raw performance.

discharge and damaging crop.

The Crop Shuttle also features a patented self-loading conveyor that allows you to unload potato seed trucks into the shuttle, giving you a 600-bag capacity to fill your planters.

Spudnik Equipment Company (208) 785-0480

www.spudnik.com

The Spudnik Belt Planter is a highspeed planter, operating at speeds of up to 6 mph, which is twice the speed of the industry conventional cup planters. For example, with an 8 Row Belt planter, you can plant 17.5 acres per hour, planting up to 210 acres in a 12-hour day compared to 104 acres with a traditional 8-row planter. Designed for precision, the belt planter ensures accurate seed placement regardless of seed type, whether cut or whole seed. Additionally, it plants based on seed weight per acre rather than seed spacing. This allows you to plan for a more accurate plant population in your field, helping your bottom line.

Parma Company (208) 722-5116

www.parmacompany.com

For nearly 30 years, Parma Company has been manufacturing heavyduty rolling harrows, packers and landplanes, to help prepare and establish the best quality seed bed. The Parma Rollaharrows and Packers come in various sizes ranging from 12-24 feet in a rigid frame and from 20-40 foot folding models. Landplanes are available in up to 30-foot widths. The 4-Bar Rollaharrow comes standard with four rows of heavyduty s-tines properly spaced to allow optimum tillage without trash buildup and plugging. Also among the standard features is a hydraulically controlled leveling bar to smooth and level the soil behind the S-Tines. The “loose fit” style front and rear packer rollers are available in various sizes and ring composites. Also available are crowfoot rollers and solid welded pipe rollers all mounted on large 2 3/16-inch shafts and heavy-duty triple lipped sealed bearings. The well-used grain drill hitch option lets the savings-conscious grower better utilize fuel and time with one pass tillage and planting. This, with the other options and features, makes the Parma tillage line of seed bed preparation the most productive tools in your farm operation.

Lockwood Manufacturing (800) 247-7335

www.lockwoodmfg.com/

Lockwood Air Cup Planters are No. 1 in the industry for seed placement accuracy. Productivity means more than being fast; it means being accurate. Lockwood’s Air Cup Planters are faster, more reliable and deliver seed spacing like you’ve touched every piece by hand. With hydraulically driven row units controlled via a GPS speed sensor, Lockwood Air Cup planters allow more accurate seed spacing and are the most forgiving planter when using cut seed. The vacuum wheel with stainless steel arms and self-cleaning urethane cups allows for faster ground speeds while maintaining planting accuracy. Plus, with individual row shutoff capabilities, you are able to maximize efficiencies when working in any field. Lockwood Air Cup planters are

T.G. Schmeiser Co. (559) 268-8128

www.tgschmeiser.com

The Next-Gen Till an’ Bedder by TG Schmeiser has been completely redesigned based on grower feedback. Starting at the bottom, we’ve built in the capability to use 20- or 22-inch ductile Schmeiser rings. Moving up, the machine now features double plated roller heads for additional strength with a massive 2-11/16-inch shaft that is held up with TILLXTREME sealed trunnion bearings. The frame has been redesigned so that the unit ships over 80 percent assembled.

The front-to-rear level system coupled with 2 rows of s-tines in front and behind the transport tires allows gauging in the toughest conditions without leaving tire tracks. Hydraulic s-tines and leveling bar are included with depth indicators standard. Wing pivots have been upgraded to 2-inch pins. The optional HD Trail Hitch has a built-in manifold for hydraulic remote extensions and is designed to haul modern drills.

compatible with optional accessories including seed monitor attachments, SureFire Accelerator Spray Kits or dry fertilizer tanks.

Brillion Farm Equipment, A Landoll Company (855) 320-0373

www.brillionfarmeq.com orwww.landoll.com

The 3600 Series Pulvi-Mulcher from Brillion features wider working widths, increased trash clearance and reduced downtime in the field. The series is available in 21-, 25-, 30- and 36-foot working widths. The 30foot model weighs 80 percent more than the popular WL360 for more clod crushing power. The 36-foot unit is the widest Pulvi- Mulcher offered by Brillion. All 3600 Series models feature 8-inch roller axles with heavy-duty bearings that improve reliability and reduce maintenance interruptions in the field. The design includes three rows of two-piece edge bent s-tines on overall 6-inch spacing. Twenty-five inches of under frame clearance improves trash flow through the machine. A leveling harrow in front of the rear roller helps level ridges left by the shanks. New to the 3631 series is the 24-inch Notched Ductile Iron wheel to provide even more clod crushing power with its heavy weight.

The Mayo Receiving Hopper is ideal for handling seed potatoes. It provides efficient receiving from loaders, trucks or pallet bins. Features include sensor speed control for desired product flow, flexible positioning and engineering for long-term use. In addition to seed handling, the Mayo Receiving Hopper provides a variety of uses in loading and unloading operations in storage facilities.

The MH 242 receiving hopper is available with a Scotts Evolution cleaning module. After the bunker floor, the machine is standard-equipped with a presentation belt, providing even better dosing. The Scotts Evolution unit itself consists of eight rollers and has the greatest possible working range, as it demonstrates excellent processing in both dry and the most challenging, wet conditions. Depending on the degree of cleaning needed, one can choose 4 ribs on these spiral rollers for ‘normal’ cleaning and 6 ribs for a more aggressive cleaning. The unit is provided with a platform on the side to ensure excellent visual inspection of the product processing.

The Potato Grower Seed Lot is where you will find seed produc ers from Manitoba to Maine, from Montana to Michigan—all con veniently gathered in one place. If you’re a seed grower interested in being a part of The Seed Lot, call Rob at (208) 521-1090.

Our isolated Northern location along with our group of 11 experienced growers have been producing exceptional seed potatoes with increased energy and the lowest possible diseases levels for over 50 years.

Our longevity and historical performance have made us a valued resource and seed potato supplier to growers across North America and the world.

With over 100 varieties including main crop and specialty selections, we invite you to give us a call to discuss how we can help you make this growing season the best one yet.

Contact Darcy Olsen for the latest info on availability of varieties & generations. Email: darcyo@epg.ab.ca

Free 1 (800) 362-9791 • Ph: (780) 447-1860

Blair Richardson, CEO, Potatoes USA

When the Potatoes USA board gathered in August, I did something I don’t often do: I spent a few minutes talking about the past. Sitting through our committee meetings that week, it struck me how much has changed over the last decade, both in the world around us and in how Potatoes USA continuously evolves to effectively increase demand for potatoes.

And right now, we are in a moment of intense change. The stability we’ve enjoyed as an industry over the last decade is feeling tested; for instance, China and India have gained a combined 11 percent of the frozen fry export market share, while the U.S.’s share has seen a modest decrease. The wheels of change feel like they’re spinning faster. These are certainly things to be concerned about, and they can be uncomfortable.

But we can’t get stuck spending too much time worrying

Focusing on the future is where I like to operate. We take the learnings from the work we’ve completed, of course, but all opportunity lies ahead of us.

about what might or might not happen in the short term. We need to stay focused on the bigger picture, on the future.

BECAUSE HERE’S WHAT HASN’T CHANGED: People love potatoes. People are eating potatoes at home and in restaurants. And more and more, people understand the many benefits of potatoes. The fundamentals of our industry remain solid. Keeping that in mind, I see the current landscape of change not as a threat, but as a wealth of opportunities. Here are a few of the opportunities I’m thinking about right now.

AND

MARKET ACCESS: The global market is arguably where we’re seeing the most rapid change, with China and India projected to increase their potato production by 11 MMT by 2030. Through research to help us most effectively tell the story of U.S.-grown potatoes, as well as a focus on our relationships with retail and foodservice operators abroad, we will find opportunities to grow international demand for U.S. potatoes with our long-standing trading partners while exploring new opportunities in countries with growing populations.

ATTRACTING INTERNATIONAL INVESTMENT:

We’re already seeing international businesses exploring the opportunity to add operations to the U.S., including Agristo, Cité Gourmande and Iscon Balaji. Agristo, a Belgium-based potato processor, has officially begun preparing the site for its first U.S. processing facility in Grand Forks, ND. This is changing the processing landscape here in the U.S., and I see more opportunity in this space that can positively impact our industry.

CULINARY MEDICINE: Perhaps more than ever, nutrition and health are part of the national conversation. People are looking for experts to trust. Through partnerships in the culinary medicine space, we can help ensure current and aspiring medical and nutrition professionals are wellversed in the nutritional benefits of potatoes, providing them

with the information and confidence to share that knowledge with their patients and communities.

STRONG DEMAND, SHIFTING DYNAMICS: While people’s love of potatoes remains constant, how, why, and where they want their potatoes are changing. With accelerated urbanization taking place across the globe, people will continue to prioritize convenience and speed. Additionally, our research shows that younger generations seek globalized flavors and food options. Luckily, potatoes are found in nearly every type of cuisine and make an

exceptional blank canvas for flavor. Our consumer-facing activations speak directly to what people are looking for in the moment, shedding light on new reasons and ways for them to purchase potatoes.

Focusing on the future is where I like to operate. We take the learnings from the work we’ve completed, of course, but all opportunity lies ahead of us. With the strong foundation of our industry and the growing global demand for potatoes, there’s no shortage of potential for what we can accomplish.

Tara Artho, Executive Director

It only took me 10 months after I moved to the San Luis Valley to stand out in a live potato field.

Miguel Diaz is on our committee and is part of a third generation family farm. He grows both seed and commercial potatoes here in the SLV. Seeing so many different varieties fully in bloom was not only beautiful, but also aromatic. I didn’t expect all the flowers to, well … smell like actual flowers. The plant could truly be ornamental if I didn’t know the real good stuff was hiding under the soil.

Miguel was kind enough to take his morning and explain some of the challenges his family was facing. It was not shocking to hear input costs, labor and lack of water were at the top of the list.

Sadly, most of those issues are out of his hands. But

something he does have control over is prioritizing soil health. He uses not only one cover crop, but a blend of several different plants, each chosen for different positive characteristics: mustard, radish and sorghum seed to name a few. It isn’t an inexpensive practice, as nothing planted on the field will be a cash crop, but the value he sees after planting potatoes on the same ground next year will be well worth it.

Personally, I never would have paired mustard with a potato, unless of course if you are talking about potato salad. In that case I am firmly on Team Mustard.

After moving from Texas to Colorado, many of my friends and family promised to visit. After all, it is beautiful here, and I love Texas, but any resident will jump at the chance to get out of the state during the oppressive summer months. So of course I had a revolving door of folks come see me in July. This was a perfect time to show them how pretty potatoes can be.

A couple of my friends from Dallas asked me a question I hadn’t heard before. “How many potatoes grow from a single plant?” This is something I would have thought was common knowledge, but growing up on a farm myself, sometimes I forget the knowledge I take for granted. Too

many folks are removed from the food chain, not because they don’t care about it, but because they have never had the opportunity to see things first hand.

My friends knew that potatoes grew underground like a root vegetable, so they assumed each plant made ONE potato like if you planted a carrot. After I told them each plant would yield around 8-10 potatoes on average, they were blown away thinking of how many potatoes would come out of just one field.

Another local grower, Brendon Rockey, had us out to visit his unique farm. Brendon grows a lot of specialty potatoes, fingerlings being one. Because they are set up differently than most, he is able to utilize alternative farming methods. When you look out at one of his lots, it quite frankly looks like a mess. The plants aren’t nice and uniform like other lots.

This is not an accident, quite the opposite! He plants barrier strips in and around his fields. This is a great way to manage pests as they are drawn to the outside of the plot and away from his potatoes. It is quite a bit more expensive and very labor intensive, but the soil health is a top priority for him. Vines are being killed, and test digs are happening. People are making sure their equipment is ready to go as soon as the weather cooperates. You can tell when September hits and that the high heat days are behind us. And it’s a good thing, because potatoes, just like me, don’t like to go to sleep when they are hot. Growers need cooler days when putting fresh potatoes into storage. The risk of disease, spoilage, and overall quality depend on it.

Twelve months later it is harvest time again, and I have made it full circle. My first official anniversary in the San Luis Valley was October 1, 2025. It has been such a fun and interesting journey to see so many angles of growing potatoes. The work, research, weather challenges, governmental red tape, and labor issues are all just a few of the moving parts that growers have to juggle.

It takes a certain type of person to be able to deal with that much uncertainty. A life in agriculture isn’t for everybody and certainly not for the faint of heart.

But if you ate today, thank a farmer.

Kam Quarles, CEO

When most Americans think of a government shutdown, they think of political posturing, point-scoring via social media memes and the general messiness of doing business in Washington, D.C.

It often seems like a distant drama that doesn’t really touch their lives. But for U.S. potato growers, and for the broader American agricultural industry, these funding lapses have real, immediate and costly consequences.

As I write this in mid-October, three weeks into the government shutdown, I think back on the missed opportunity to advance a major policy priority: U.S. potato fresh market access in Japan.

I recently traveled to Tokyo with a delegation of potato industry leaders, including Blair Richardson of Potatoes USA and former NPC President Jared Balcom, for what was intended to be a high-level trade mission. Our goal was simple: to leverage the political might of the Trump Administration to gain additional market access for America’s potato growers.

This isn’t a small opportunity. The industry estimates that full access to the Japanese market would increase our global fresh potato exports by 10 to 15 percent, injecting an estimated $150 million annually into the pockets of American potato growers and bolstering paychecks along the entire potato supply chain. It is a long-sought priority that has been languishing after three decades of frustrating trade talks, stymied by protectionism from the Japanese government.

As we flew to Tokyo earlier this month, we believed we were in the best position in years to finally get this moving. The shutdown changed that calculation. The timing of the federal funding lapse was tremendously unlucky. At the last minute, USDA

Secretary Brooke Rollins was forced to cancel her participation in our mission to Japan. While Undersecretary for Trade Luke Lindberg capably led the remaining delegation, the absence of the secretary, and the weight of her cabinet-level voice, took a significant amount of wind out of our sails.

It is an unfortunate truth that when we negotiate trade deals for American agriculture, we are never just going up against our foreign competitors. We are always up against that foreign competitor and their government. That is why comprehensive USDA trade programs are so critical – they are the leverage we need to push back against extreme tariffs, foreign subsidies and non-tariff barriers that distort the market and hurt our family farms.

The shutdown not only disrupted our current mission but also forced the cancellation of the USDA’s broader T.R.U.M.P. Trade Mission to Japan and Taiwan, which included dairy, grains, poultry, and soybean organizations. And we face the threat of a similar cancellation for a planned mission to Mexico in November.

The market access agreement with Japan is not complicated to conclude but requires a concerted push past existing protectionism. I remain optimistic that upcoming diplomatic efforts, including a visit by President Trump and the expected installation of a new Japanese prime minister, Sanae Takaichi, could finally provide the spark we need.

But we cannot afford this shutdown to drag out for more weeks (or months). This latest shutdown demonstrates that the impact of the federal government’s closure is felt far outside of D.C. and delays trade opportunities that could benefit our family farms.