1 minute read

FABRICATION CUSTOMIZATION: PROTOTYPING

A Building’s Handshake - Project 2

(Third Year Fall, 2021)

Advertisement

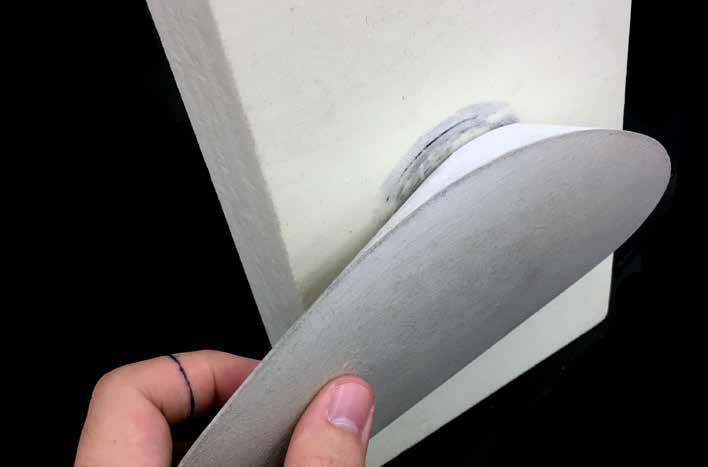

Project 2 shifts from the purely subtractive process of Project 1 into the hybrid process of mold making and casting. This new fabrication process prompted a different approach and warranted a reaximination of the handle as an object. Such a handle became an experiment in how it could both stand alone as an individual architectural work as well as add to the architecture upon which it operates.

Considering the operation and tactility of the handle in tandem with the intention for it to be an individual object became a point of interest. It begs to scrutinize the idea of comfort through an examination of intentional discomfort. Discovering how the perception of the object changes as the individual discovers its operability became a point of interest.

As the project entailed for us to create a two-part mold to cast our handles in, my initial concept proved unfeasible with the resolution achievable with our stock. Even just the parting line itself proved too complex and the mold quickly became extremely difficult to model even digitally.

My second concept proved feasible to mill but faced many additional challenges in casting. The hand held portion of the handle was too thin and often cracked or broke on release from the mold. On my third casting attempt I decided to try rockite in place of plaster and this thin section of the handle broke off and became lodged within the mold.

Class Collective Models

With my third attempt, I further simplified the geometry in an attempt to create a form which has an organic elegance, yet is contructed from abstract and industrial shapes. The resulting form reads much more easily and proved simpler to mold. Setting the parting line deeper into the mold and lining it with modeling clay prevented leakage. The simpler geometry also allowed for much cleaner casting and release, helping prevent breakage and cracks.