3.4Initialoperation

Note:Inordertoheatthewaterinthepool(orhottub),thewaterpumpmustbe runningtocausethewatertocirculatethroughtheheatpump.Theheatpumpwillnot startupifthewaterisnotcirculating.

Afterallconnectionshavebeenmadeandchecked,carryoutthefollowingprocedure:

1SwitchonthewaterpumpCheckforleaksandverifythatwaterisflowingfromandtothe pool.

2ConnectpowertotheheatpumpandpresstheOn/Offbuttonontheelectroniccontrol panel.Theunitwillstartupafterthetimedelayexpires(seebelow).

3Afterafewminutes,checkwhethertheairblowingoutoftheunitiscooler

4.Whenyouturnoffthewaterpump,theunitshouldalsoturnoffautomatically,ifnotadjust theflowswitch

5.Allowtheheatpumpandthewaterpumptorun24hoursadayuntilthedesiredwater temperatureisreachedTheheatpumpwillstoprunningatthispointAfterthis,itwill restartautomatically(aslongasthewaterpumpisrunning)wheneverthepoolwater temperaturedrops1degreebelowthesettemperature

Dependingontheinitialtemperatureofthewaterinthepoolandtheairtemperature,itmay takemanyhoursorevenmorethanonedaytoheatthewatertothedesiredtemperature.A goodpoolcovercandramaticallyreducetherequiredlengthoftime

WaterFlowSwitch:

Itisequippedwithaflowswitchtopreventtheheatpumpofrunningwithinadequatewater flowrate.Itwillturnonwhenthepoolpumprunsandshutsoffwhenthepumpshutsoff.Ifthe poolwaterlevelismorethan1maboveorbelowtheheatpump’sautomaticadjustmentknob, yourdealermayneedtoadjustitsinitialstartup.

Timedelay-Theheatpumphasabuilt-in3-minutestart-updelaytoprotectthecircuitry andavoidexcessivecontactwearTheunitwillrestartautomaticallyafterthistimedelay expires.Evenabriefpowerinterruptionwilltriggerthistimedelayandpreventtheunitfrom restartingimmediatelyAdditionalpowerinterruptionsduringthisdelayperioddonotaffect the3-minutedurationofthedelay.

3.5Condensation

Theairdrawnintotheheatpumpisstronglycooledbytheoperationoftheheatpumpfor heatingthepoolwater,whichmaycausecondensationonthefinsoftheevaporator.The amountofcondensationmaybeasmuchasseverallitersperhourathighrelativehumidity Thisissometimesmistakenlyregardedasawaterleak.

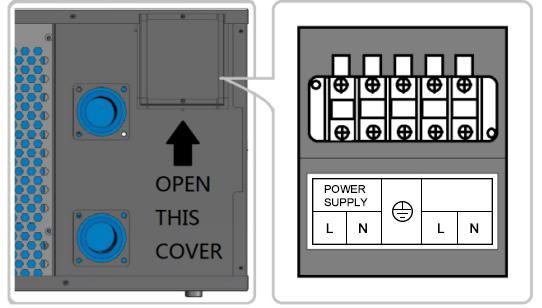

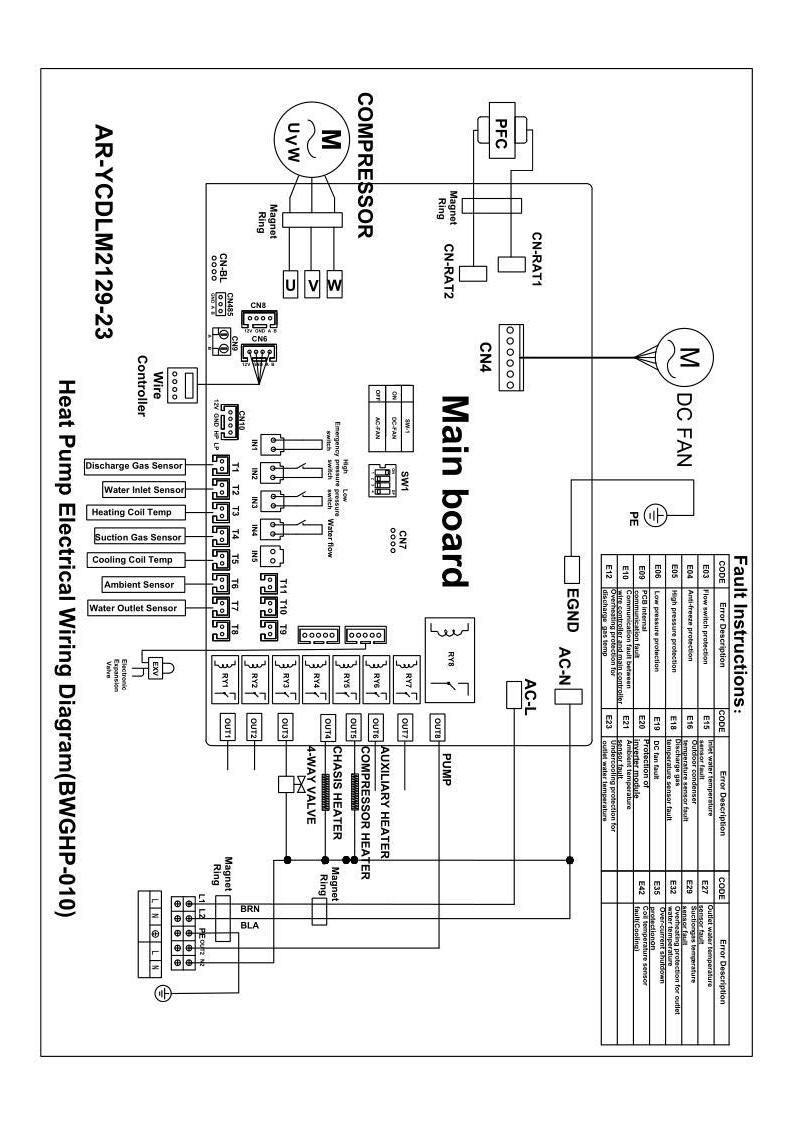

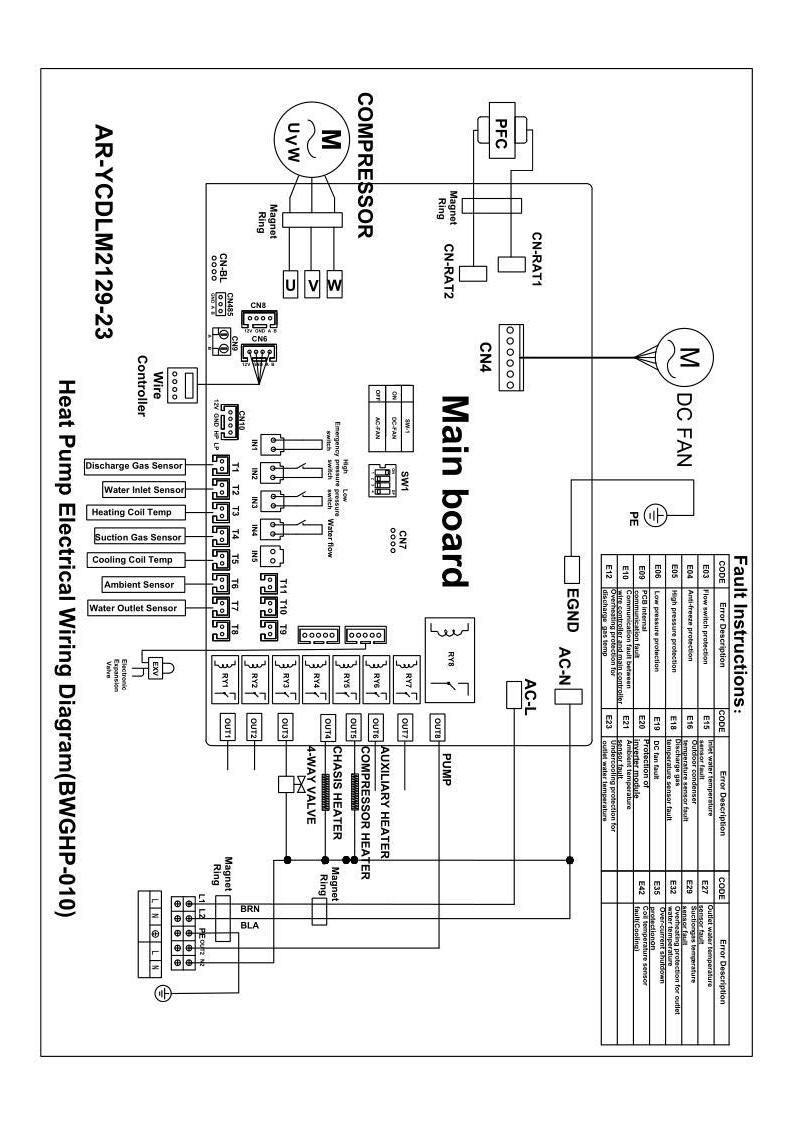

4.ElectricalWiring

NOTE:

(1)Theaboveelectricalwiringdiagramsareonlyforyourreference,pleasesubjecttheheat pumptothepostedwiringdiagram

(2)Theheatpumpmustbeearthedwell.Earthingtheunitisstillrequiredtoprotectyou againstshortcircuitsinsidetheunit

Disconnect:Adisconnector(circuitbreaker,fusedorun-fusedswitch)shouldbelocated withinsightofandeasilyaccessiblefromtheunitThisiscommonpracticeoncommercial andresidentialheatpumps.Itpreventsremotely-energizingunattendedequipmentand permitsturningoffpowertotheunitwhiletheunitisbeingserviced

5.Controller’sOperations

LEDDisplayController

5.1Overview

◎Thecontrollerisspeciallydesignedfortheheatpump,withfeaturesasbelow:

Heatingandcoolingmode;

Couldshowandchangetherunningandsettingparametersofthesystem,easy forusertoinstallandtest;

Withautomaticprotectionandfaultwarningfunction;

Withstrongsystemprotectionfunction,likecompressordelayprotection,high pressure,lowpressure,sensorprotection,waterflowdetect,andetc;

Thecommunicationdistancebetweentheheatpumpunitandwirecontroller shouldbelessthan100metersThecommunicationportisRS485;

Stronganti-interference,stableperformance.

5.2BasicModelofSystemControlChart

◎SystemChart

◎ControlPrinciple

Theheatpumprunsaccordingtothewirecontroller’sorder

Thewirecontrollercouldchangetherunningparametersandsendtherunning parameterstotheheatpump

Theheatpumpcoulddetecttherunningconditionandsendtheinformationorfault tothewirecontroller

HeatPump

WireController

◎BasicIcons

1.Whenit’sunderheatingmode, turnson

2Whenit’sundercoolingmode, turnson

3.Whenit’sunderdefrostingmode, turnsonandtwinkles

Whenit’sunderoffstatus,thedisplayshowsthecurrenttime

◎KeyOperatingInstruction

1)""KeyOn/Off

Whenit’sinotherinterface,pressthisbuttonshortly,itwillgobacktothemain interface.

Inthemaininterface,pressthiskeytoturnon/off

Inthemaininterface,pressthiskeyfor5secondstosetthetimer,whenhouron nixietubeflashes,youcansethourof"Timeron",thecorrespondingiconof"Timer on"flashes,press","tosethour.Whenfinishingsetting,presskey"" shortlytogotosetminuteof"Timeron",press","tosetminute.Whenfinish setting,presskey"Mode"togotosethourof"Timeroff",thecorrespondingiconof "Timeroff"flashes,press","tosethour.Aftersettingfinished,presskey"" shortlytogotosetminuteof"Timeroff",press","tosetminute.Aftersetting, presskey""andreturntothemaininterface,iftherelativelightison,itmeans thatthecorrespondingtimerissetsuccessfully

TimerCancel

Whenthetimeon"Timeron"and"Timeroff"issame,timeriscanceled.

5.3WireController

Attheinterfaceofsetting"Timeron"or"Timeroff",presskey""for 5seconds,"Timeron"or"Timeroff"canbecanceledindividually

Whentherelativelightisoff,itmeansthistimeriscanceled.

2)""KeyMode

Whentheheatpumpison,pressthiskeyshortly,youcanshiftdifferentmodes: heatingmode,coolingmode(Whentheheatpumpispoweredbythespa,the coolingfunctionwillonlybeavailablewhentheactualwatertemperatureislower thansettemperatureonthespacontroller).

Whentheheatpumpisoff,pressthiskeyshortlytosetthetime,4nixietubesare twinkling,atthistime,presskey""shortlytosetthehour,presskey","to setthehourWhenfinishing,presskey""shortlyagaintosettheminute

Whenfinishing,presskey""toreturntothemaininterface

3)""KeyPlus

Whentheheatpumpison,inthemaininterface,pressthiskeytoincreasethe settingtemperature

Whenit’sinmanualfrequencymode,inthehomepage,pressthiskeytoincrease thesettingfrequency

4)""KeyMinus

Whentheheatpumpison,inthemaininterface,pressthiskeytodecreasethe settingtemperature.

Whenit’sinmanualfrequencymode,inthehomepage,pressthiskeytodecrease thesettingfrequency.

5)""Key"POWERFUL"

Whentheheatpumpison,pressthiskeyshortlytogointopowerfulmode.

6)""Key"SMART"

Whentheheatpumpison,pressthiskeyshortlytogointosmartmode

Underoffstatus,pressthiskeyfor5secondstochangethetemperatureunit between℃and℉

7)""Key"SILENT"

Whentheheatpumpison,pressthiskeytogointosilentmode

Presskey""for5seconds,andenterintotheunitstatusparameterinquiry, presskey","toviewtheparameters,presskey""toexitparameter

8)StartingElectricHeaterManually

Presskeys""+""atthesametimefor5secondstoturnon/offthe electricheatermanually

9)EnforcedDefrosting

Whentheconditionsofenteringenforceddefrostingaremet,press""and""at thesametimefor5seconds,thenitenterintoenforceddefrostingmode.

Whenenteringintodefrosting,heatingmodeicon" "appears.When exitingfromdefrosting,modeiconrecovertonormaldisplay

10)RecovertoFactoryDefault

Bybuttonoperation:presskeys""+""atthesametimefor5seconds andenterintouserparametersmode,thecurrentparameterisreturntemperature Thenpresskeys""+""atthesametimefor5secondsandwired controllerrecoverstofactorydefault.Atthistime,buzzerwillalarmtwice continuously,andallparametersrecovertofactorydefault

query InquiryCode Descriptions DisplayRange 01 Inletwatertemp -20~99℃ 02 Outletwatertemp -20~99℃ 03 Ambienttemp -20~99℃ 04 Dischargetemp 0~125℃ 05 Suctiontemp -20~99℃ 06 Outercoiltemp -20~99℃ 07 Innercoiltemp -20~99℃ 08 MainEEVsteps 09 AssistantEEVsteps / 10(A) Compressorcurrent 11(B) Radiatortemp 12(C) DCbusvoltage 13(D) Compressoractualrotatespeed 14(E)DCfanmotoractualrotatespeed

11)Systemparametersetting

Press""+""for5secondstoenterthepasswordinterfaceforsettingthe parameters.Thenpress""or""toenterthepassword.Press""to changethedigitofthepassword.Afterfinishingthelastdigit,press""to confirmthepassword

6.SystemParameters:

Parameter Code ParameterName SetRange FactorySetting 1 ReturnDifferencefor TargetWaterTemp 1~18℃(2~36℉) 1℃(2℉) 2 SetTempinCoolingMode 8℃~35℃(46~95℉) 27℃(81℉) 3 SetTempinHeatingMode 5℃~40℃(41~104℉)40℃(104℉) 4 CompensationValueofInletWaterTemp-5℃~15℃(-9~30℉) 0℃(0℉) 5 DefrostingCycle 20MIN~90MIN 45MIN 6 DefrostingStartTemp -9℃-1℃(1630℉) -3℃(27℉) 7 DefrostingTime 5MIN~20MIN 8MIN 8 TemptoQuitDefrosting 1℃~40℃(33~104℉)20℃(68℉) 9 Differencebetween AmbientTempandCoilTemp toStartDefrosting 0℃~15℃(0~30℉) 5℃(10℉) 10 AmbientTemp.toStart Defrosting 0℃~20℃(32~68℉) 17℃(63℉) 11 ElectronicExpansionValve's WorkingCycle 20S~90S 30S 12 OverheatDegreeinSmart/ PowerfulMode -5℃~10℃(-9~20℉) Dependson ActualModel d(13) ExhaustGasTempof ElectronicExpansionValve 70℃~125℃(158~257℉)95℃(203℉) 14 ElectronicExpansionValve's StepsduringDefrosting (SetValue*10=ActualSteps) 2~45 Dependson ActualModel 15 ElectronicExpansionValve's MinSteps(SetValue*10=ActualSteps) 5~15 10 16 ElectronicExpansionValve's WorkingMode 0Manual/1Auto 1 17 ManualStepsof ElectronicExpansionValve (SetValue*10=ActualSteps) 2~45 35

Note:Intheabovetable,theactualvalueoftheelectronicexpansionvalveand theairspeedis10timesoftheparameterdisplayedvalue.Forexample,whenthe P20defrostexpansionvalveopeningdegreeshows30,theactualvalueatthistimeis 300steps;whenP30fanmanualrotationspeedshows80,theactualvalueatthis timeis800.Whenthevalueismorethan100,Arepresentsfor10,Brepresentsfor11, Crepresentsfor12,andDrepresentsfor13.

7.Troubleshooting

7.1Systemprotection/errorindication

18 OverheatDegreeinCooling Mode -5℃~10℃(-9~20℉) Dependson ActualModel 19 Reserved / / 20 ElectronicExpansionValve's WorkingModeWhenCooling 0=WaterTemperature 1=Supercooling 1 21 WaterPump'sWorkingMode WhenTargetTemperatureReached 1=NonStop/2=Stop 3=Intermittent 3 22 Fan'sWorkingMode 0=Auto/1=Manual 0 23 Fan'sManualControlSpeed (SetValue*10=ActualSpeed) 0-99 (SetValue*10=Actual Speed) 80 (Set Value*10=Actual Speed) 24 AmbientTemptoStart AuxiliaryElectricHeater -20℃~20℃(-4~68℉)-20℃(-4℉) 25 AuxiliaryHeating FunctioninDefrosting Mode 0Non/1Yes 1

ErrorcodeErrordescriptions Solutions Er03 waterflowfailure Checkwaterflow/switch Er04 winteranti-freezing Waterpumpwillrunautomatically forfirstgradeantifreeze Er05 highpressurefailure 1Dischargeredundant refrigerantfromheatpumpgas system 2Cleanthewaterexchangeror waterfifter Er06 lowpressurefailure 1.Checkifthereisanygas leakage,re-filltherefrigerant 2.Replacethefilterorcapillary Er09 communicationfailurebetweenDisplay andPCB 1Checkifthecommunication connectionwirebetweendisplay andPCBisdisconnectedorhas poorcontactChangethewireor

Er10 communicationfailureoffrequency conversionmodule(alarmwhen communicationbetweendisplayand PCBaredisconnected)

menditifyes

2CheckifPCBordisplayis damagedChangethe correspondingpartifyes

ChangePCB

Er12 excessiveexhausttempprotection1.Replacethecompressor dischargetemperaturesensor

2.Reconnectorcleancompressor dischargetemperaturesensorand wrapitwithinsulationtape

ReplacethecontrollerorPCBoard

Er15

Waterinlettemperaturefailure

Checkorchangethesensor

Er16 externalcoiltemperaturefailure Checkorchangethesensor

Er18 exhausttemperaturefailure

Er19 DCFanmotorfailure

Checkorchangethesensor

1CheckifDCfanmotoris

damagedChangeitifdamaged

2CheckifDCfanmotoroutput

portonPCBhasoutputChange PCBifnooutput

Er20 Abnormalprotectionoffrequency conversionmodule

Er21 ambienttemperaturefailure

Er23 toolowcoolingoutletwatertemp protection

Er27 wateroutlettemperaturefailure

Er29 Returngastemperaturefailure

Er32 Toohighheatingoutletwater temperatureprotection

Er35 Compressorcurrentprotection

Solveitaccordingtothesubsidiary errorcodesinthefollowingtable.

Checkorchangethesensor

Checkwhetherthewaterflowor watersystemisjammedornot

Checkorchangethesensor

Checkorchangethesensor

Checkwhetherthewaterflowor watersystemisjammedornot

1Checkiftheincomingvoltage supplyistoolow,ifso,repair

2Checkifthecompressoris overloadedandrepair

3Checkwhetherthethermalrelay isdamaged,ifso,replace

Er42 internalcoiltemperaturefailure

Checkorchangethesensor

◎E20faultwilldisplaythefollowingerrorcodesatthesametime,theerrorcodeswill switchevery3secondsAmongthem,errorcodes1-128aredisplayinpriority

Whenerrorcodes1-128don’tappear,thenerrorcodes257-384canshow. Iftwoormoreerrorcodesappearatthesametime,thendisplayerrorcodes accumulation.Forexample,16and32occuratthesametime,display48.

Error Code Name Descriptions Solutions 1 IPMOver-currentIPMModuleproblem Replaceinverter module 2 compressor synchronous abnormal Compressorfailure Replacecompressor 4 reserved -- -8 compressor outputphase absent Compressorwiring disconnectedorpoorcontact Checkingcompressor inputcircuit 16 DCbuslow voltage Inputtoolowvoltage,PFC modulefailure, Inspecttheinput voltage,replace module 32 DCbushigh voltage Inputvoltagetoohigh,PFC Modulefailure Replaceinverter module 64 Radiatorover temperature Mainunitfanmotorfailure,air ductblockage Inspectfanmotor,air duct 128Radiator temperatureerror Radiatorsensorshortcircuit oropencircuitfault Replaceinverter module 257communication failure Invertermoduledoesn’t receiveorderfrommain controller Inspectionthe communication wiring=betweenmain controllerandinverter module 258ACInputphase absent Inputphaseabsent(Three phasemoduleiseffective) Inspectioninputcircuit 260ACInput over-current Inputthreephaseimbalance (threephasemoduleis effective) Inspectioninputthree phasephasevoltage 264ACInputlow voltage Inputlowvoltage Inspectinputvoltage 272CompressorHigh pressurefailure Compressorhighpressure failure(reserved) 288IPMtoohigh temperature Mainunitfanmotorfailure,air ductblocked Inspectfanmotorand airduct 320Compressorpeak currenttoohigh Compressorlinecurrenttoo high,thedriverprogram doesn’tmatchwith compressor Replaceinverter module 384PFCmodule over-temperature PFCModuletoohigh temperature

MalfunctionsObservation

LEDwirecontroller shows nodisplay

LEDwirecontroller displaystheactualtime

Reasons

Nopowersupply

Solutions

Checkwhethercableandcircuit breakerareconnected

Heatpumpunderstandby status Startupheatpumptorun

Heatpumpis notrunning

Water temperatureis coolingwhen heatpumpruns underheating mode

LEDwirecontroller displaystheactual watertemperature

1Watertemperatureis reachingsetvalue,heat pumpunderconstant temperaturestatus

2Heatpumpjuststartsto run

3Underdefrosting

1.Verifywatertemperaturesetting 2Startupheatpumpafterafew minutes

3LEDwirecontrollershoulddisplay "Defrosting"

LEDwirecontroller displaysactualwater temperatureandnoerror codedisplays

1Chosethewrongmode

2Figuresshowdefects

3Controllerdefect

1Adjustthemode

2ReplacethedefectLEDwire controller,andthencheckthestatus afterchangingtherunningmode, verifyingthewaterinletandoutlet temperature

3Replaceorrepairtheheatpump

Shortrunning

LEDdisplaysactualwater temperature,noerror codedisplays

1FanNOTrunning

2Notenoughair ventilation

3Notenoughrefrigerant

1.Checkthecableconnections betweenthemotorandfan,if necessary,theyshouldbereplaced

2Checkthelocationoftheheat pump,andeliminateallobstaclesto assureagoodairventilation

3Replaceorrepairtheheatpump

2Checkthetitaniumheatexchanger carefullyifitshowsanydefects

1Checkthelocationofheatpump, andeliminateallobstaclestoassure agoodairventilation

2.Replaceorrepairtheheatpump

7.2OtherMalfunctionsandSolutions(NodisplayonLEDwirecontroller)

waterstains Waterstainsonheat pumpunit 1Concreting 2.Waterleakage

1Noaction

Toomuchice onevaporator Toomuchiceon evaporator

8.Maintenance

(1)Youshouldcheckthewatersupplysystemregularlytoavoidtheairenteringthesystem andoccurrenceoflowwaterflow,becauseitwouldreducetheperformanceandreliabilityof theheatpump

(2)Cleanyourpoolsandfiltrationsystemregularlytoavoidthedamageoftheunitasaresult ofadirtyorcloggedfilter

(3)Youshoulddischargethewaterfromthebottomofthewaterpumpiftheheatpumpwill stoprunningforalongtime(speciallyduringthewinterseason).

(4)Onanyothermoment,youshouldcheckiftheunithasenoughwaterbeforetheunit startstorunagain

(5)Aftertheunitisconditionedforthewinterseason,itispreferredtocovertheheatpump withthespecialwinterheatpumpcover.

(6)Whentheunitisrunning,thereisalwaysalittlewaterdischargeundertheunit.