Start of the new construction

New phase towards quality and environment

ISSUE 12 FEB. 2023 INSPIRATIONMAGAZINE

2 INSTORE inspiratiemagazine Next Generation displays at EuroShop! Visit us at hall 4, booth 4C27

We’re truly underway now! The first work on the construction of our new building has started. The groundwork has begun and the first contours of the building are becoming increasingly visible.

The construction of our new building and the relocation signify a new phase within our company, in which sustainability and technological developments are central. To implement this, we’re investing massively in our machinery; our graphic production line is being completely renewed. More about that later in the magazine.

Negotiations for a new automatic punching machine and laminating machine are in full swing. This way we will soon be able to start work in Roermond with a completely new production line and be ready for the future.

We have not been idle in the field of display innovations either. Our 2 Second Display series has been renewed and we would like to put this series in the spotlight again. Because with core values such as sustainability, speed, convenience and simplicity, this is a display series that is highly versatile and that definitely stands out on the shop floor.

Martijn Hol

3 INSTORE inspiratiemagazine

4 Frog leaps: we are making big leaps 6 Holbox - trusted and innovative at EuroShop 8 Responsible materials 9 Expect Excellence 10 2 Second Display series 11 2 Second ELLIPSE Display 12 2 Second HANG-IN Display 13 2 Second RETAIL Display 14 Holbox Poland goes Holcomplet! 16 Quality and environmental respect 18 Next level in our printing process 20 Holcomplet 22 Always Caring 24 Social and responsible entrepreneurship is in Holbox’s DNA 26 Display tips: don’t’s & do’s 27 Materialpassport of the display 28 Creative, recyclable packaging 30 All-in-one display solution 32 “Eventually I’ll become redundant” 34 New printing press 35 Colophon

ISSUE 12 FEB. 2023

Preface

Frog leaps: WE ARE MAKING BIG LEAPS

Fully automated warehouse

GETTING THE JOB DONE

We are in the phase of getting our hands dirty! The administrative work is out of the way, which means that the work on the plot can really begin! The ground has been prepared for construction and in January we started with the earth-moving operation: raising and levelling the ground. Now the contours of the building are really becoming visible and the new building is starting to come to life!

An automated warehouse is a warehouse in which the storage, movement of goods is automated. Its purpose is to increase the efficiency, accuracy and speed of logistics activities. This results in increased productivity and better management of inventory and logistics activities.

Certification

“BREEAM Excellent”

A BREEAM Excellent certificate is a recognition for buildings that have delivered exceptional performance in terms of sustainability and environmental impact. Not only does this certificate indicate that a building is energy efficient, but it also takes into account the health and well-being of its users and the environment.

Completely energy-neutral

Three thousand solar panels will cover the roof of the new building in Roermond. In order to comply with energy neutrality, as much energy as possible will be produced in daylight hours. But we are also already working on storing this energy in so-called battery containers. Through these hubs, energy-neutral production can also take place outside of daylight hours. So the building and the situation can be adapted to what is optimal for us.

Perfect humidity at 50%

Controlling the humidity in a business environment is important for the comfort and health of employees, as well as for the protection of electronic equipment and materials.

Optimal humidity varies between 30 and 60%. The new building will have a humidity of 50%.

Stay informed of developments and follow the realisation of our new building on our website:

HOLBOX IS RELOCATING FROM ECHT TO ROERMOND.

5

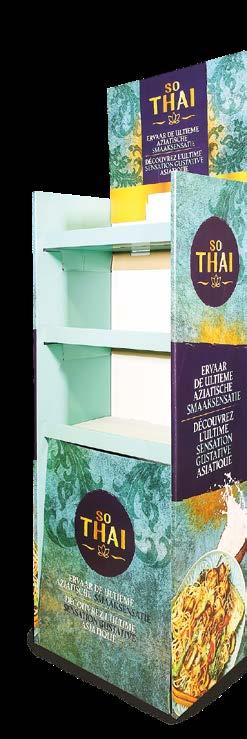

Holbox - trusted and innovative at EuroShop

Yellow is the new green

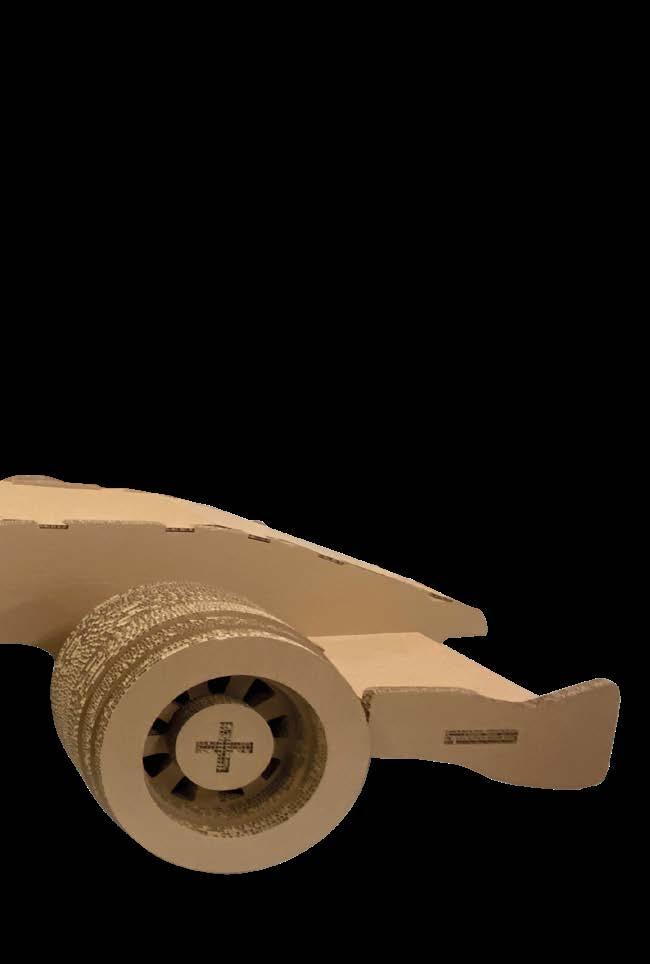

Of course, 100% sustainable displays are possible! Holbox proves this again with a stand made entirely of cardboard and where you can discover the latest developments and innovations in the field of cardboard displays.

We are constantly working on environmentally conscious displays so that we can pass on a green planet to future generations.

Our creative team of 15 designers guarantees surprising, ecological designs every day. Thanks to our ingenuity, the sustainable displays we develop are always of high quality and environmentally friendly. And with the unique and patented design from Holbox you can also expect fully recyclable displays, which are furthermore delivered as compact as possible. This means that we all save on transport and emissions for (an even) better environment.

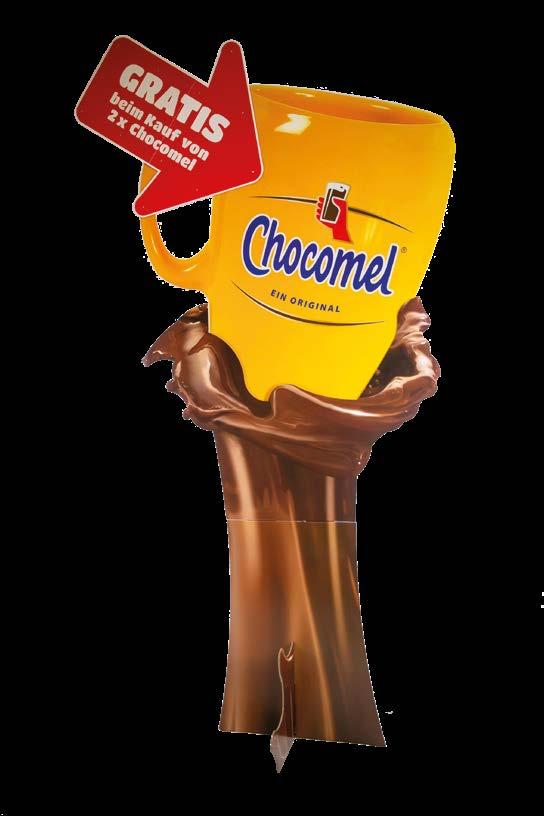

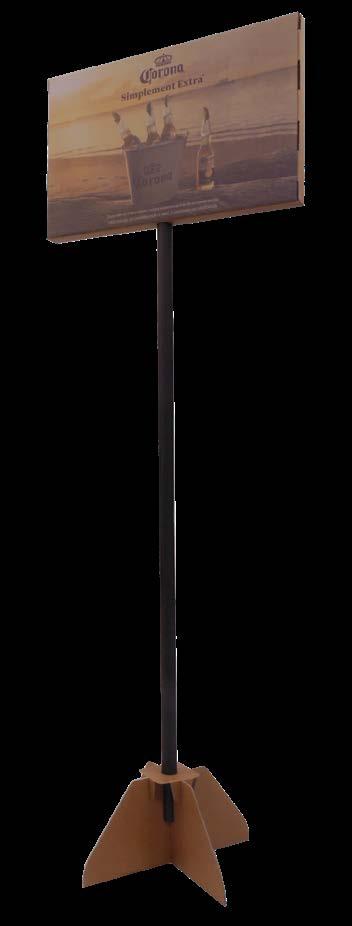

Shop decoration

Cardboard shop fitting offers an environmentally friendly and affordable solution for shops that want to create a professional look. It is adaptable, light and easy to move, enabling shops to make changes quickly and efficiently.

EuroShop visit us in hal 4, booth 4C27

You can also contact us for the decoration of your own exhibition stand. In our Holbox Shop Direct webshop you will find the most creative and distinctive products to make your stand out.

7 INSTORE inspiratiemagazine

Exhibition stand

THAT YOU WANT TO HAVE COMPLETELY CUSTOMISED; WE CAN DO IT!”

Responsible materials

Grass paper

When it comes to the use of materials, we are always looking for new possibilities. Using grass paper is one of them. Grass paper consists of 30 percent grass and 70 percent recycled paper. This way, as a company, you not only work as green as grass, you at the same time give your displays a unique look and feel.

Kraft paper

The rough and durable nature of kraft paper has made it a popular choice in recent years. It is a porous, sturdy paper and very suitable for biodegradable and recyclable displays.

Expect Excellence

For more than 45 years, we have been committed to achieving maximum sustainability for our products, the highest quality and offering the best possible service. Our production process is designed for nothing less than excellence. And this ranges from initial inquiry to actual placement in the store. Get to know our unique service.

Inquiry

As a family business, Holbox prides itself in personal contact and a warm welcome. Therefore, when you need information, we’ll be happy to sit down with you and find the best solution together.

Design

Production

Our production process is as smoothly as our displays unfold. And since all production is carried out in-house, we can easily adjust and produce the top quality you want and need at lightning speed.

Installation

Experience the power of a professional product. Our displays unfold effortlessly. They are the most durable on the market and remain strong and beautiful for a prolonged period of time.

Let our creators think along with you

Holbox guarantees craftsmanship. Curiosity and ingenuity are in our DNA. More carrying capacity, fewer CO2 emissions or more display space: we surprise you with new ideas.

Delivery

At Holbox, you can expect highly competitive delivery times. Thanks to our know-how and smart delivery solutions, your display will always arrive on time and in top condition.

A professional display creates new opportunities. Our folding masters are happy to think along with you to come up with the best possible solution for your unique situation. www.holboxdisplay.com

9 INSTORE inspiratiemagazine 01 02

03 04 05

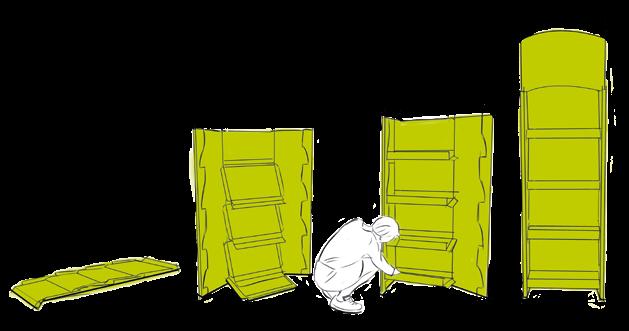

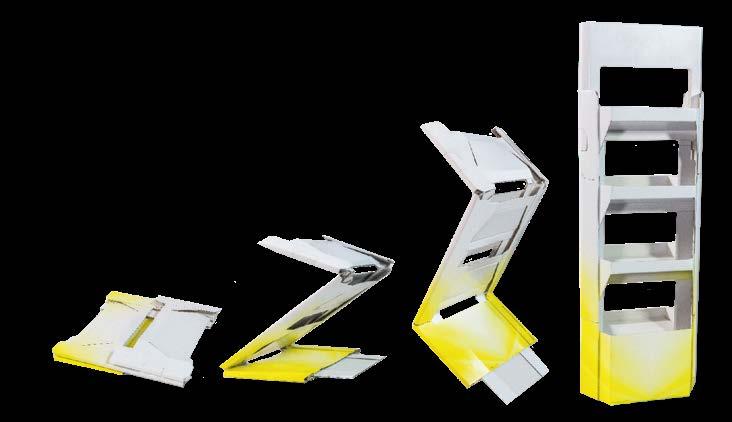

No time to waste!

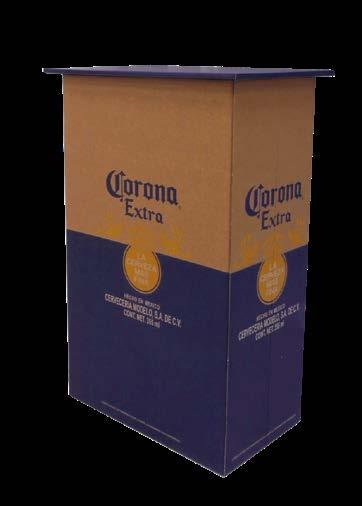

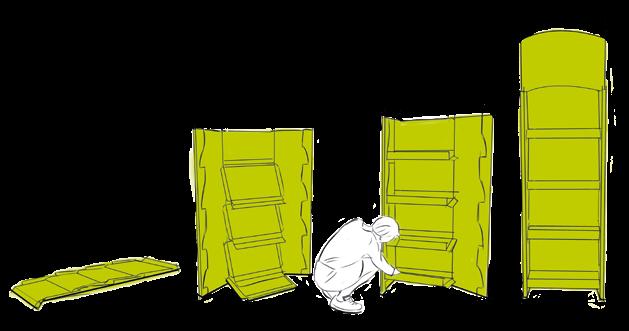

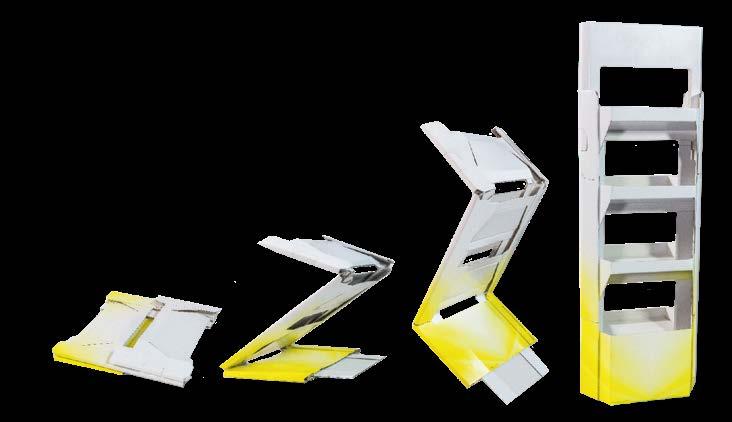

When it comes to speed and convenience, our creative folding masters have developed a series of displays that meet these core values, our 2 Second Display series.

The advantages of our 2 Second Display series:

• Easy and flawless setup in 2 seconds

• Fast delivery

• Handy and small packaging

• Wide range of possibilities

• Fewer transport movements

10 INSTORE inspiratiemagazine

Patentnummer: EP 3205240 Patentnummer: EP 3 586 684

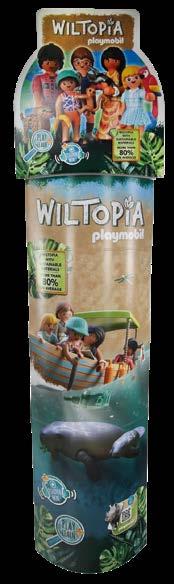

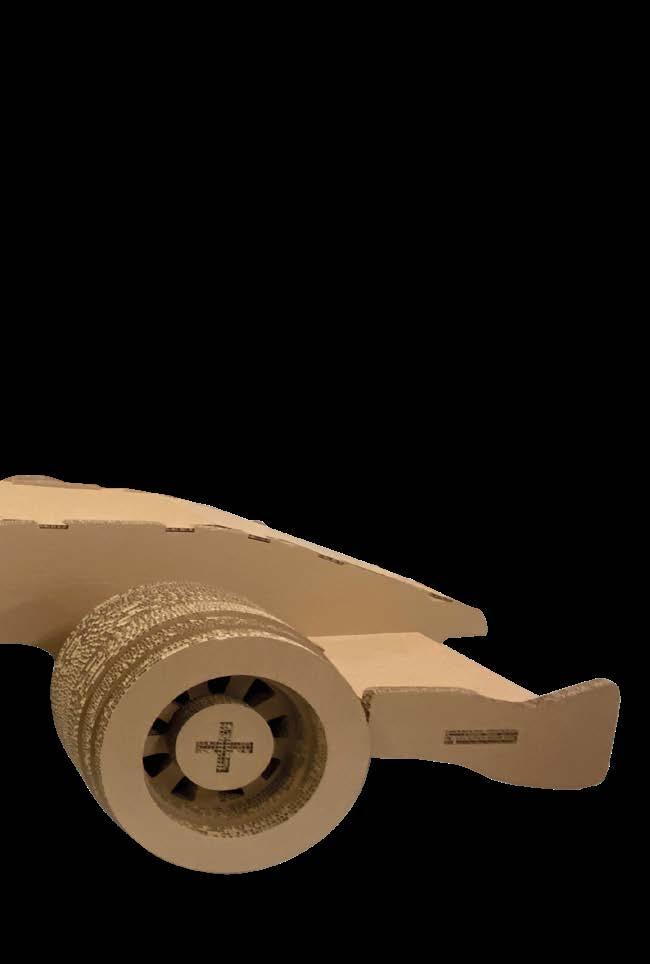

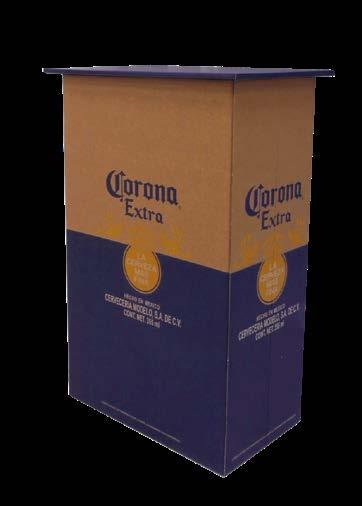

ELLIPSE

The 2 Second ELLIPSE Display is unique, because:

• it can be set up instantly

• it comes in a handy and small packaging

• it offers various variants and options with creative expansion options

• it can be ordered in our webshop at a minimum of 1

11 INSTORE inspiratiemagazine Scan the QR-code

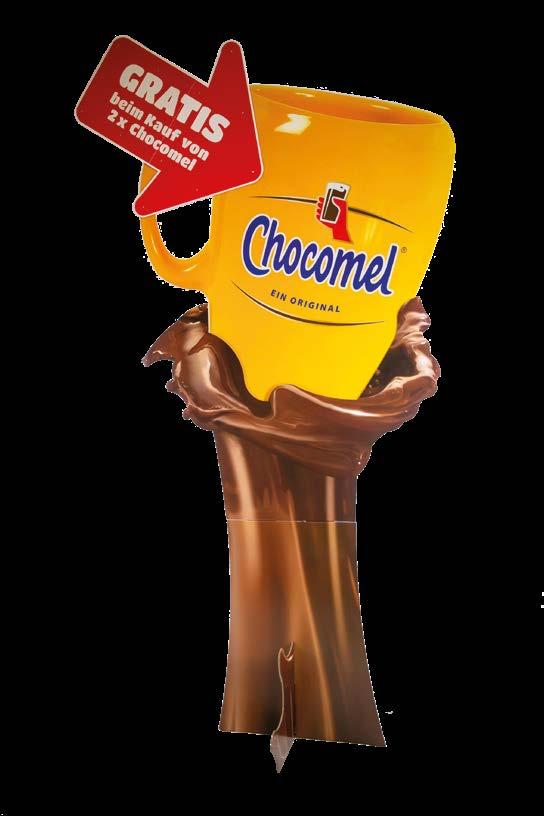

FEATURED

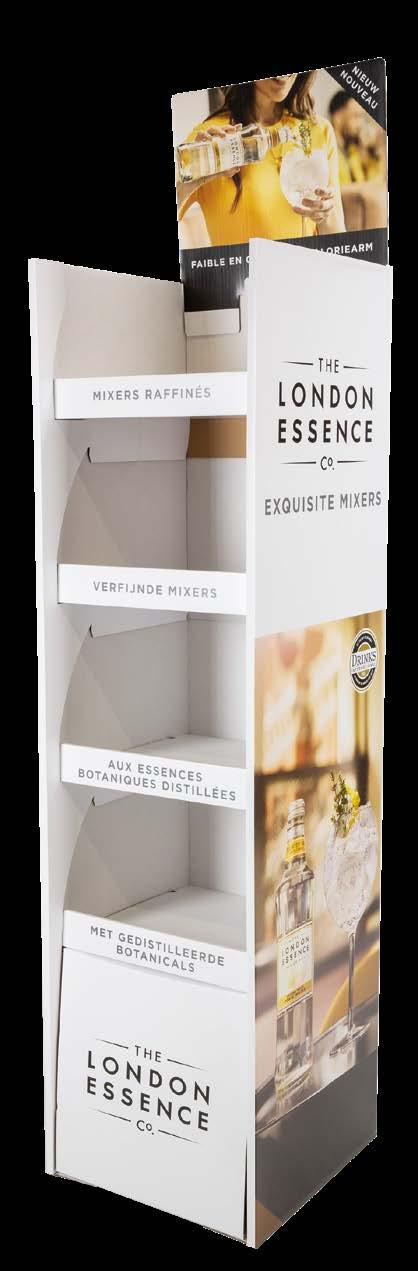

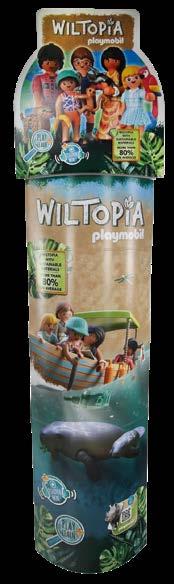

The 2 Second HANG-IN Display is unique, because:

• it has a total load capacity of up to 150 kg

• its setup is fast and easy

• it is a 100% sustainable, biodegradable display

• it has a patented construction: EP 3205240

• one package, one storage location needed

12 INSTORE inspiratiemagazine

Scan the QR-code FEATURED

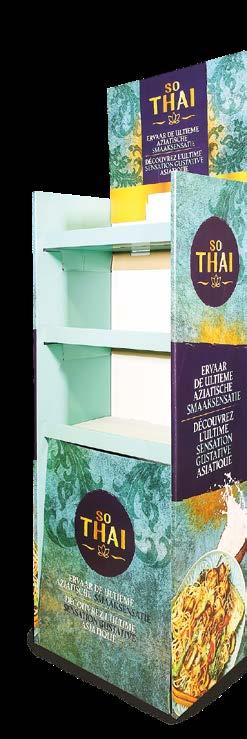

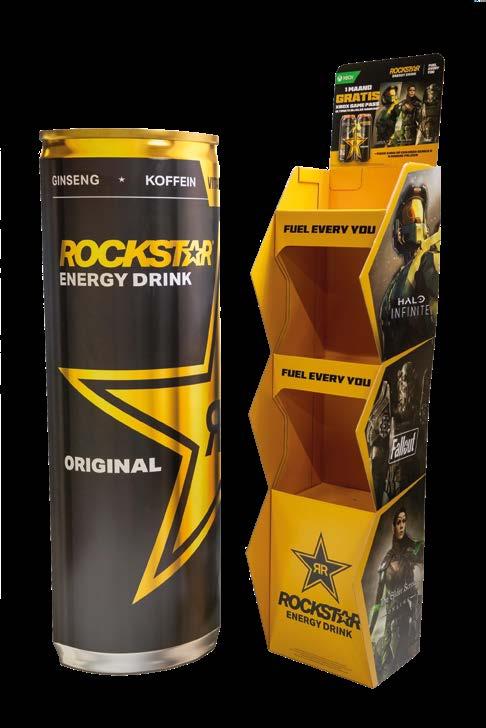

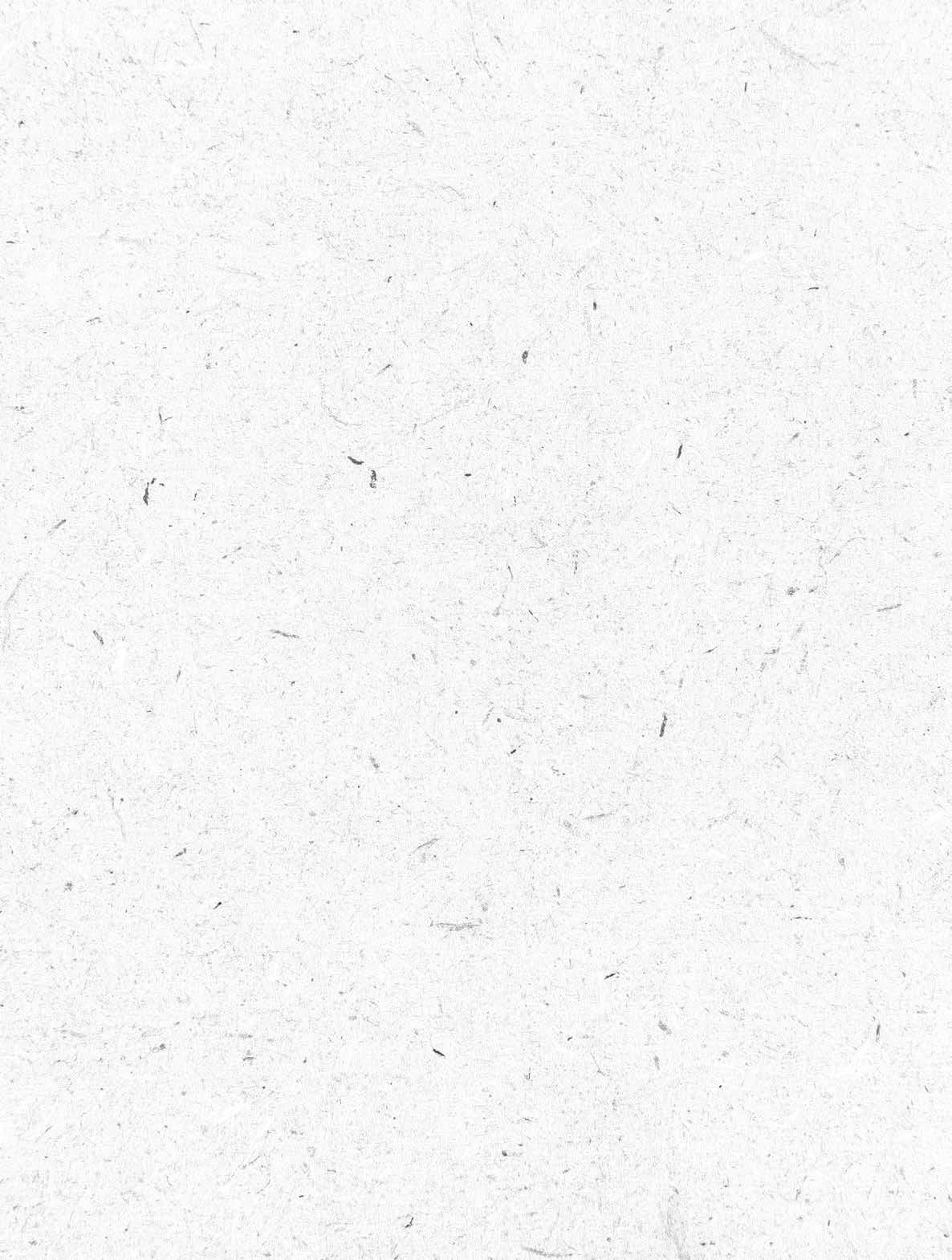

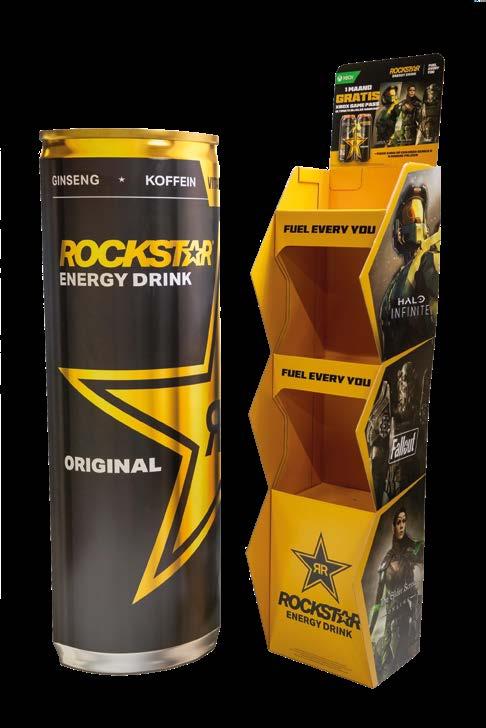

The 2 Second RETAIL Display:

• Powerhouse between the displays

• A product display in just 2 seconds

• From 5 trays, our hexagonal version carries up to 100 kg.

• Patented display: Patent application: PL 394309 A1 | RCD 001840489-001

• Just put the display on the ground and it will set up quickly and flawlessly.

Due to its folding construction, the 2 Second RETAIL COMPACT Display can be transported as a small, compact package.

13 INSTORE inspiratiemagazine

Scan de QR-code Scan the QR-code 850 mm 780 mm compact and strong

FEATURED

14 INSTORE inspiratiemagazine

“ONE COMPLETE SOLUTION FOR THE PRODUCTION OF CARDBOARD DISPLAYS”

Holbox Poland goes Holcomplet!

Our new factory in Poland has been operating for a year now and focuses on offering complete product design, production and co-packing of cardboard displays for European customers.

The doubling of the area of the property has led to more opportunities for co-packing. This allows us to really fully unburden our customers and take the design, production and delivery of the displays completely out of their hands. The building has many more loading and unloading docks, which means that many more loads can now be loaded and unloaded simultaneously. This is a significant improvement.

Sustainability is high on the agenda for the future, with investments of LED lighting and solar panels in order to be more independent of energy.

This is an important aspect, since sustainability is essential part of Holbox.

In terms of investments, there is no standstill either. In the past year two new Century punching machines were purchased and installed, allowing us to work more efficient, faster and provide an even better service to our customers. With the focus on Holcomplet and co-packing, Holbox Poland is strongly committed to offering a complete solution for the production of cardboard displays, from design to delivery. n

15 INSTORE inspiratiemagazine

“SUSTAINABILITY AND HOLBOX ARE CONNECTED WITH EACH OTHER”

Holbox is a leader in sustainable production. A decade ago, for example, the company developed an offset press together with KBA that applies water-based lacquers and thus replaced harmful UV lacquers. Sustainability AND quality are in our DNA.

Quality and environmental respect

Frank van den Munckhof, who has been responsible for quality at Holbox for more than a decade, agrees. “With our sustainability efforts we are proactively working on the future. Quality control has a lot more to do with sustainability than you might think at first.”

Testing

Displays are not blindly put into production. They are subjected to extensive testing first. “Imagine that in the supermarket it turns out that a display is not strong enough after all, or that the adhesive doesn’t hold well. In a worst-case scenario, everything has to be retrieved, repaired or produced again. That costs raw materials and equipment”, Frank explains. That’s why we test our displays extensively, including a weight and transport test. A weight test involves the display being completely filled with heavy weights for a number of days. The display is then subjected to a transport test, because we want to make sure that a filled display reaches its destination in a proper condition. This means the display is filled and put on transport, after which it spends a full day in one of our trucks. Upon return, we check the display and, if necessary, we further optimise it, so that it can withstand transport without damage.

Guaranteeing quality

As regards any findings or mistakes we encounter during testing, we’re looking for a solution that is fed back to the various departments, including the studio. They convert these into design rules, which are applied by the designer when designing a display. That way the same mistake cannot be made twice.

“If we

didn’t do that and just started

producing, we would find out that something is wrong halfway through production. In that case too everything has to be redone and we’ll be throwing away material. This way we guarantee the quality of our displays and prevent wastage of resources, materials and the need for extra transport, while contributing to sustainability at the same time.”

Testing of raw materials

All important raw materials for the display, such as corrugated cardboard, the paper that is used on it, the glue, inks and varnishes are all extensively tested first. The same applies to grass paper. “First it must be clear whether this material can also be used in production. Can it be printed? Can it be laminated? How do the creasing lines fold? Can it be glued? These and more questions must be answered first. It’s looking for the right balance. Durability is a good thing, but it must be properly tested first.

Holbox is on the case

In the field of innovation, Frank is now working on, among other things, optimising the method of palletising and making it more predictable, in order to avoid unnecessary transport movements.

He is also working on replacing plastic packaging materials, which are used for packaging small parts that are part of a display, with a recyclable material.

“The change in sustainability is really something of the last five years. Holbox is on the case. The company is working hard on it and really is a trendsetter in the field of sustainability.” n

17 INSTORE inspiratiemagazine

Next Level in our printing process

In recent years, Holbox has made the printing process even more environmentally and user-friendly. This process has many advantages.

AGFA Energy Elite Eco

The Energy Elite Eco printing plate that Holbox put into service some time ago is one of the flagship products within Agfa’s ECO³ range. This positive-working thermal printing plate offers an unprecedented run length of up to 600,000 prints. In combination with the Arkana ECO³ plate processor, which uses Agfa’s revolutionary cascade system, just 10 litres of fluid are sufficient for up to 15,000 square metres of Elite Eco plate. Because

the processor is equipped with an extremely compact developer tank, less frequent topping up is required and the overall consumption of chemical fluids reduces dramatically. The benefits for Holbox are as follows: less transport, less storage space, less cleaning and fewer empty bottles. In short, the company’s printing activities are more profitable, more environmentally friendly and even more user-friendly.

18 INSTORE inspiratiemagazine

TERRAWET lacquers

Inks and lacquers are also subject to increasingly stringent requirements. This is why Holbox uses fast-drying, water-based TERRAWET coatings with high wet and dry blocking resistance for its displays. This type of coating does not contain bisphenol A, mineral oils, heavy metals and plasticisers and is therefore ideal for a wide range of applications. It meets the certification standards, guidelines and regulations for the safety of toys and food and is therefore both food-safe and toy-safe.

Bio inks

Inks are another area characterised by rapid innovation and development. Holbox has already started to use WIFAC’s ELEMENTS TERRA MAGNA organic inks. This is a fully organic and high-quality ink range based on 100% vegetable oil. This ink is not only cobalt-free, it contains less than 1% mineral oils and is mainly made from reusable raw materials. This organic ink offers significant advantages. For example, it is suitable for all types of paper and cardboard and, because of its density, consistent drying characteristics and high

scratch resistance, the TERRA MAGNA ink is ideal for simplex and duplex printing and the latest generation of printing presses.

So Holbox’s use of the AGFA Elite Eco printing plate, TERRAWET coatings and organic inks from WIFAC is not only good for the environment, it also ensures excellent printing quality. Sustainability and quality combined, that’s what Holbox is all about. n

19 INSTORE inspiratiemagazine

20 INSTORE inspiratiemagazine

Holcomplet

The indispensable link in your supply chain

By choosing Holbox, you are not only choosing for sustainability and knowledge, but also for unmistakable, creative and smart designs without losing sight of functionality. If so desired, we can take care of the entire process from A to Z: from the creative process in which the POS material is created to the setting up and filling of the displays, quality checks, and the logistic process to the DCs, so that your display can go straight to the shop floor. This creates a very fast time-to-market.

Reliability of supply

Despite all facets of sustainability and quality taken into account, we continue to produce super-fast. We can guarantee a delivery time of 14 working days!

Full-service partner

Because we have all disciplines under one roof, we can guarantee fast lead times and know exactly how to set up the displays professionally and fill them with your products. This also prevents displays from being set up incorrectly, or not at all, on the shop floor.

We provide full-service logistics and end-to-end solutions of the highest quality so that the products reach the shop floor in the most sustainable way possible. This not only saves an enormous amount of CO2, but also directly contributes to a greener world. n

21

“HOLCOMPLET: THE COMPLETE PROCESS FROM A TO Z; FROM THE SKETCH TO CO-PACKING AND DELIVERY OF THE DISPLAYS”

People are the core of Holbox; they are crucial to achieving our objectives. They are driven and knowledgeable and committed to the organisation with all their hearts. That’s why we take the best possible care of our employees.

Always Caring

22 INSTORE inspiratiemagazine

Holbox is aware that it plays an important and exemplary role in society. It wants to set itself apart as an employer where everyone is satisfied and confident whilst working on the success of the organisation. Using the differences between and talents of its employees combined with the diversity among its personnel is an important condition to achieve this.

That is why we have entered into partnerships with various foundations that help people with poor job prospects find a place to work. Enthusiastic teams that are active at our production locations in Poland and in the Netherlands are compiled of young people and adults who need support in their daily lives in organising and carrying out their daily tasks. We also work with “Vluchteling aan Zet” to help

status holders rebuild their lives here in the Netherlands. We believe everyone should be able to participate in the labour market and are therefore happy to help set up such integration projects.

The vitality of our employees is a primary concern as well. Vital employees are more productive and enjoy their work, which maximises their employability. Holbox offers a healthy and safe working environment and encourages participation in sporting activities that are not only organised by the company, but also by third parties.

Community involvement is intertwined with Holbox’ DNA. We sponsor various sports associations and music companies in the region, among other things.

Through our own Navenant Foundation, we raise money for charities through numerous activities throughout the year. In particular for Health Foundation Limburg, for research into cancer and Alzheimer’s. n

23 INSTORE inspiratiemagazine

Social and responsible entrepreneurship is in Holbox’s DNA

Holbox in Echt has grown considerably and needs more space. The family business will therefore move to a new, larger building in Roermond at the beginning of 2024. Chantal Hol and her brother Martijn Hol talk about the success of the Limburg display specialist, whose people have sustainability and corporate social responsibility (CSR) in their DNA.

text Harry van Deursen photos Raoul Limpens

Asign that says “Jan Hol Verpakking bv” adorns the windowsill in the office of managing director Martijn Hol. It refers to the early years when Holbox was still a wholesaler of corrugated cardboard boxes. “My father Jan’s wholesale box business was one big playground when I was young”, says Martijn. “The moment he became an independent entrepreneur in 1976 is something I remember well. I was eight years old. We played hide and seek between the boxes and climbed on pallets. My father never pushed me to get into the business. The decision to join the company as soon as possible was mine and mine alone.” Chantal Hol, commercial and marketing director, also started summer jobs at an early age. “I filled in as a receptionist and helped in the graphics department.” Today, brother and sister run the company together, which has become the market leader in cardboard displays. Together, they

manage 225 employees and are responsible for a branch in Poland where about 200 people work.

Niches

“We’ve always looked for niches in the market”, says Martijn. “In the early days, it was the rapid delivery of customised corrugated cardboard boxes. Due to the emergence of large corrugated cardboard factories, we switched to cardboard displays. That’s our core business now. We make it easier for customers by taking care of the entire process for point of sale material. From design to production, setting up and filling and transport of the displays, if necessary. We manage all the production processes for this ourselves.” To find the niches in the market, you have to follow that market closely, says Chantal. “The trading environment can change quickly. We noticed this during the COVID period, when only the supermarkets remained open.

Their turnovers were excellent back then. We also benefited from that.” According to Chantal, these kinds of crises make it more difficult to make forecasts, but she sees plenty of opportunities. “New markets pop up during a crisis, such as emerging B-brands. To spot these trends, we regularly make store visits to all major retailers. We have a database that allows us to look back up to 15 years.”

Sustainability

Holbox is a leader in sustainable production. Ten years ago, the company developed an offset press together with KBA that applies water-based lacquers and thus replaced harmful UV lacquers. “Sustainability is in our DNA”, says Chantal. “We’ve been using bio-inks for printing for years and only use FSC-certified cardboard. We were the first supplier to make 100% FSC-approved displays. And if the customer wishes, we can also use

24 INSTORE inspiratiemagazine

grass paper. Eco design is another strong point of ours. This means we cleverly organise the punching plates with little production waste and we give parts of the transport packaging a second lease of life by using them as the interior construction of the display. This is how you extend a product’s life cycle.” “We have various patents for this”, Martijn continues. “It mainly concerns smart constructions that enable you to make large displays with a lot of carrying capacity with little cardboard.”

No more gas

The company will move to Roermond in 2024. With 30,000 square metres, the new Holbox building will be twice as large as the old building in Echt. The new building has the highest sustainability certification: BREEAM Excellent. Martijn says: “We’re moving away from gas and want to be completely self-sufficient.

During light hours, that’s no problem because we have 3,000 solar panels on the roof. We want to install battery containers for the evening hours. In addition, there will be a kind of central highway of 250 metres with electric AGVs for internal transport. That offers a considerable efficiency improvement.”

Advancement location

The new building is also necessary for the growing number of co-pack projects realised by Holbox. Setting up and filling displays requires a lot of space. During these projects, the company also works together with asylum permit holders and people from the sheltered workshop. “We’re the most successful advancement location in Limburg for people with disabilities in the labour market”, says Martijn. “Social involvement is important to us.”

Chantal: “As an entrepreneur, you have a duty of care. Both towards

your employees and those around you. That’s something our parents taught us. Holbox therefore also organises projects for charity, such as End Polio Now, and has set up its own Navenant Foundation. On average, we donate around 200,000 euros a year.” “Making displays can be combined well with a social view of the world”, Martijn concludes.

“That feels good to us and also to our people. The nice thing about a company is that you work together with your people and your customers. And that we’re all proud of our product. That’s Holbox.” n

25 INSTORE inspiratiemagazine

“AS AN ENTREPRENEUR, YOU HAVE A DUTY OF CARE. BOTH TOWARDS YOUR EMPLOYEES AND THOSE AROUND YOU”

Display tips

This page is full of tips for making displays as sustainable and eco-friendly as possible!

Don’ts Do’s

NON-CERTIFIED PAPER AND CARDBOARD

Using non-certified paper and cardboard is not eco-friendly. The origin of the wood fibres is not known, so you have no idea how the trees were grown and harvested.

CONVENTIONAL INKS

Conventional inks contain materials derived from crude oil and are not biodegradable. They are not eco-friendly.

UV LACQUER

UV-lacquer gives printed matter an attractive finish. However, the drying process requires special UV lamps, which consume more energy.

LAMINATED PAPER

Because laminated paper is covered with a PE film, it is not recyclable. When laminated paper gets thrown away as recyclable paper, the paper and cardboard recycling process is disrupted because the film does not soak loose. In other words, the plastic coating is not biodegradable and returns to the environment as a pollutant.

PLASTIC, WOOD AND METAL

If you use other materials in the display, it is no longer fully recyclable and therefore not ecofriendly.

FSC® AND PEFC CERTIFIED

We work with raw materials from responsibly managed forests where the habitat of plants and animals is protected and the rights of indigenous peoples and forest workers are respected. The cardboard and paper used in the displays can be recycled up to 5 times.

ORGANIC INKS

In our production process, we use solvent-free printing inks, also known as BIO-inks. They are a better sustainability choice because the resources that provide the raw materials, vegetable-based oils, can be replanted indefinitely.

LOW-MIGRATION LACQUER

Choose an environmentally friendly lacquer: this is a water-based lacquer and therefore biodegradable.

DOUBLE DISPERSION LACQUER

Dispersion lacquer is a great substitute for laminated paper. It gives the printed matter a glossy look and is also much more environmentally friendly. Because this material is biodegradable, it can be disposed of in the paper recycling bin.

FULLY RECYCLABLE

Choose a 100% cardboard construction. Paper and cardboard are environmentally friendly and biodegradable materials, so everything is 100% recyclable.

Sustainability ID Material passport of the display

Scan the Sustainability ID to see the material passport of the display. This passport shows the origin of the display: which recycled and certified paper or cardboard types the relevant display consist of, which environmentally friendly inks or lacquers have the material been printed with and which waste bin does the promotional product needs to be deposited in after the end of its life cycle. Since Holbox displays do not contain any materials other than paper or cardboard, we want to make the display as transparent as possible in order to make the route to recycling, and with that a second life, as short as possible.

• Material passport: tells which recycled and environmentally friendly materials are used in the display (material, ink, etc.)

• Option to equip each display with this label

• Chain transparency

• Accountability to customer and consumer

The material passport of the relevant display and all other information is displayed immediately.

27 INSTORE inspiratiemagazine

“A SIMPLE WAY TO REPORTING TO PEOPLE AND THE ENVIRONMENT”

Display with a Sustainability ID.

The Sustainability ID on the display is small. with a smartphone

MATERIAALPASPOORT FSC/PEFC printsheet Vegetables inks Waterbased varnish Monomaterial 100% recyclable SUSTAINABILITY INFO

Creative, recyclable packaging

Material

We produce microwave offset printed packaging. Our packaging can be produced up to 600 grammes of cardboard and can be produced in various cardboard types such as B, C, E and F corrugation, BC corrugation, EB corrugation and EE corrugation. Currently, grass paper and kraft paper is a very popular packaging choice. It gives the packaging a very durable and also robust appearance.

Production

The packaging can be provided with a luxurious finish, including 5-colour printing for which we use bio-inks, migration-free lacquer and double dispersion lacquer, which gives the printed matter a brilliant appearance.

Options further include a wide choice with regard to gluing the packaging: longitudinal seam, 4-point, 6-point and auto lock gluing. Auto lock packaging features a special construction in which the bottom automatically falls into place when the packaging is unfolded. This saves handling and time.

Folding gluing machine

Our production location in Poland is fully equipped to produce high-quality packaging quickly and efficiently. For example, we operate a folding gluing machine at that location. This machine does longitudinal seam gluing, four-point gluing, six-point gluing and also glues auto lock packaging. n

28 INSTORE inspiratiemagazine

Cardboard packaging is a versatile and durable product that can be used for a wide variety of products. They are recyclable, lightweight and can be adapted to the specific needs of a product or company. The possibilities of packaging are endless.

29 INSTORE inspiratiemagazine langsnaad 4 -punts langsnaad 4 -punts 6 -punts 6 -punts autoloc k 6 -punts autoloc k longitudinal seam 4-point 6-point autolock P&P Company

All-in-one display solution

with a total display package. 01

02

off road with this striking display combination 30 INSTORE inspiratiemagazine

Impress

Present and collect

Go

03

Striking and dynamic

04 Easy, high-impact and sustainable

05 Rock solid presentation

31 INSTORE inspiratiemagazine

Melanie van Bracht guided Holbox to ISO 14001 certification

“Eventually I’ll become redundant”

Green production, with full attention to the environment and safety, has been high on Holbox’s agenda for years. To take the policy in this area to an even higher level, the company decided, among other things, to obtain ISO 14001 certification, which it achieved in 2021. However, that wasn’t the end of the process. The optimal implementation of the system in the new building in Roermond is the next step.

Melanie van Bracht, owner of consultancy firm SHE* Mel Veiligheid en Milieusupport, can still remember her early days at Holbox in 2019. She was certainly not dissatisfied with the company’s approach to safety and the environment. However, when director Martijn Hol pointed out the sustainability of the production process, she immediately came up with a challenging remark. She laughs: “I told him: prove it. That triggered him. Because even though Holbox had already done a lot of good things, there’s always room for improvement. Sustainability goes beyond the environment and complying with existing rules. It’s also about welfare and safety, for example. And having an eye for detail.”

A broader approach

She knows what she’s talking about. With her consultancy firm, Melanie assists all kinds of businesses. She also teaches Safety Science at Avans Hogeschool. She regularly involves her students in projects for which she is engaged. Including Holbox, which, in retrospect, she joined at a difficult time, in 2019, just before the COVID period. She explains that achieving ISO 14001 certification was one of the goals. “ISO 14001 focuses very specifically on a company’s environmental performance. This means having an eye for general matters concerning the environment, but also for aspects that are very specific to a company. That’s why we started making an inventory and drawing up a risk analysis and risk register. From there, you

32 INSTORE inspiratiemagazine

“IN THIS BUILDING WE’VE HAD TO TEACH EMPLOYEES

HOW TO CHANGE YEARS OF HABITS”

work towards the new situation by implementing improvements. In doing so, we also looked beyond just the environmental component and we used the opportunity to also improve other things that fall under sustainability.”

Continuity

Matters that received attention included the emergency response team, keeping emergency exits clear, the presence of fire extinguishers in the right place, the accessibility of gas pipes, and so on. As far as the environmental aspect is concerned, the handling of hazardous substances, the processing and separation of waste, the use of materials and storage, and the handling of ink, among other things, were examined. “During that process, it became apparent, among other things, that Holbox did not use FSC materials for all processes. It did use FSC cardboard, but that wasn’t always the case with paper. That was addressed immediately.” Improvements were made step by step, until certification was obtained in 2021. But that certainly wasn’t the end of the project, Melanie says. “You

then enter the next phase: ensuring that people remain alert and that everything continues to go well. This guarantees the continuity of the improvements.”

Awareness process

In the meantime, an HSE (health, safety, environment) working group had been set up, including a number of Holbox employees in addition to Melanie. One of Melanie’s students also regularly visits the company for advice. Members of the working group now make observation rounds or inspections once in a while. Visual material is among the tools used to check whether the situation is still as agreed. Melanie: “We are engaged in an awareness process; that takes time. Employees have to unlearn certain habits and learn others so they start to take something for granted and if something goes wrong they wonder how it could’ve happened. This way, you reduce the chance things turn out to be not entirely ideal during an inspection by an external party.” One point on the horizon, says Melanie, is Holbox’s move to new business premises in Roermond next year.

She will also provide guidance and advice during that process. “It’s important that you immediately do everything right during the transition. In this building we’ve had to teach employees how to change years of habits. That’s something you have to prevent during the move. With good preparation, we make sure we immediately apply the right approach, in accordance with the regulations. That the working method they’ve now learned will remain intact in the new building. Of course, checks will always be necessary, but they can eventually be carried out by the HSE working group.” She then smiles: “I’ll remain involved for the time being, but the intention is that I’ll eventually become redundant.” n

33 INSTORE inspiratiemagazine

“IT’S IMPORTANT THAT YOU IMMEDIATELY DO EVERYTHING RIGHT DURING THE TRANSITION”

New printing press

The relocation to our new building in 2024 offers plenty of room for our ambitious growth plans. The graphic production line will be upgraded as well: our partner Wifac will soon be installing a new Koenig & Bauer Rapida 164 press.

For Holbox, the upcoming move means the start of a new phase, Martijn Hol explains when announcing the plans. Sustainability plays an important role in this. With 27,000 square meters of floor space, the fully circular building will be more than twice the size of the current location in Echt. Three thousand solar panels on the roof enable Holbox to produce energy neutrally.

Partnership with Wifac

Most of the new space is used for the production and storage of displays. In order to respond well to market trends, we are seizing the opportunity this move brings for an important investment in machinery. As early as 2004, we installed our first largeformat press from Koenig & Bauer. It proved to be a turning point for our company as we had been producing in half format until then. In the past twenty years, a close partnership has

34

developed between Holbox and Wifac, which we are extremely pleased with. Wifac is now supplying us with the fourth Koenig & Bauer press.

Second Koenig & Bauer Rapida 164

The installation of this new Koenig & Bauer Rapida 164 (4-colour printing press with lacquer unit) replaces the existing Rapida 162 press. We will soon have two identical presses: the existing Koenig & Bauer Rapida 164 will be completely overhauled and will be included in the move to Roermond. This creates increased efficiency, because both presses are operated in the same way and use the same plates.

To maximise the productivity of the presses, we will also be installing a new Agfa N24 VLF CtP system,

including pallet loader, for the production of processless plates. Speed and flexibility are an absolute requirement for us to always be close to the market. These investments mean we are ready to take on the future.. n

Colophon

INSTORE inspiration magazine is a publication of Holbox BV

Loperweg 8, 6101 AE Echt

T +31 (0)475 56 95 95

E info@holboxdisplay.com

I www.holboxdisplay.com

Editorial staff Editorial board

Juliette Cober Chantal Hol

Wendy Volleberg

Sandra Heijckers

Design

Studio Done (Maureen Nikkessen)

Holbox

Inova

Photography

Stefan Gerads, Raoul Limpens, Shutterstock, Freepik

Order size

1,500 copies in 3 different languages

Paper and print

Cover: Maxi-offset, 250 grams

Inside: Maxi-offset, 150 grams

Printed with organic inks and double dispersion lacquer

Nothing from this publication may be copied and/ or reproduced, in any way, without the written consent of the publisher. Although Instore magazine has been prepared with the greatest possible care, Holbox is not liable for any mistakes in this publication.

Holbox BV is not responsible for actions of third parties, which might result from reading this publication.

35 INSTORE inspiratiemagazine

ISSUE 12

“WITH THESE INVESTMENTS WE ARE READY TO TAKE ON THE FUTURE”

Holbox BV Headquarters

Loperweg 8, 6101 AE Echt

The Netherlands

T +31(0)475 56 95 95 | E info@holbox.nl

www.holbox.nl

Offices

FR Paris

DE Köln

PL Warschau

Production

NL Echt

PL Gliwice

Webshop shopdirect.holbox.nl