ARCHITECTURE PORTFOLIO

HYUNJUNG PARK

DETAILED, SUSTAINABLE, LIVING-CENTERED DESIGN

CONNECTION COMMUNITY CENTER

(DEEP ENERGY RETROFIT)

PROJECTS

INNOVATION’S

(3D PRINTED RESIDENTIAL)

1161 1161

1161 WESTON

(MID-RISE RETAIL & RESIDENTIAL)

(MASS TIMBER OFFICE)

ELECTRONICS LTD. (INDUSTRIAL PLANT & OFFICES)

HYUNJUNG ARCH’S HOUSE (RESIDENTIAL)

CONNECTION COMMUNITY CENTER

Specialization: Transformation of Existing Building for Reuse

Main Material: Existing Steel, Brick, Aluminum Panel

Date: Sep. 2024

Course: Drafting & Detailing 5,6

Duration: 8 months

Used Software: Revit/ Sketchup/ Twinmotion/ Illustrator/ Photoshop

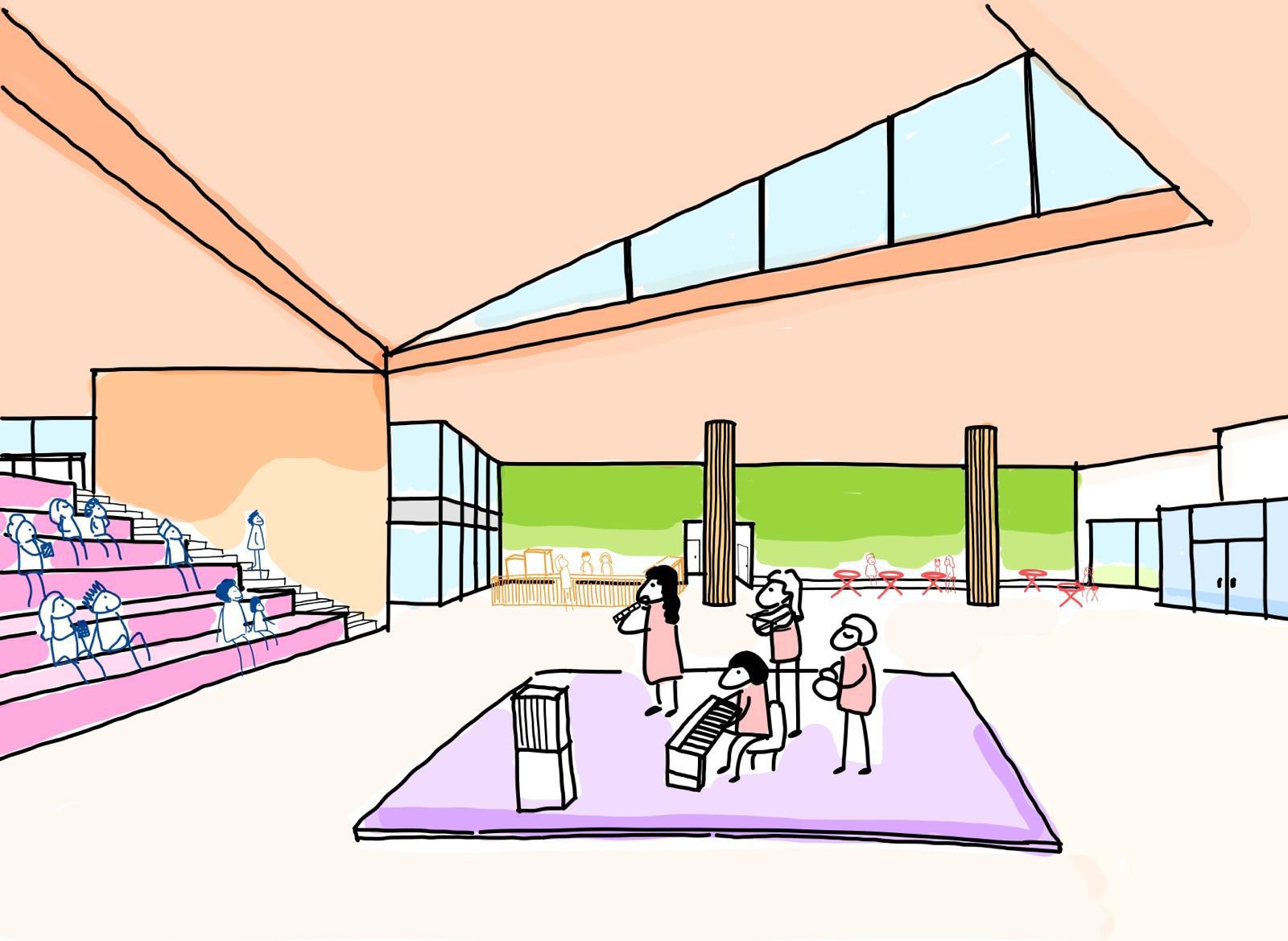

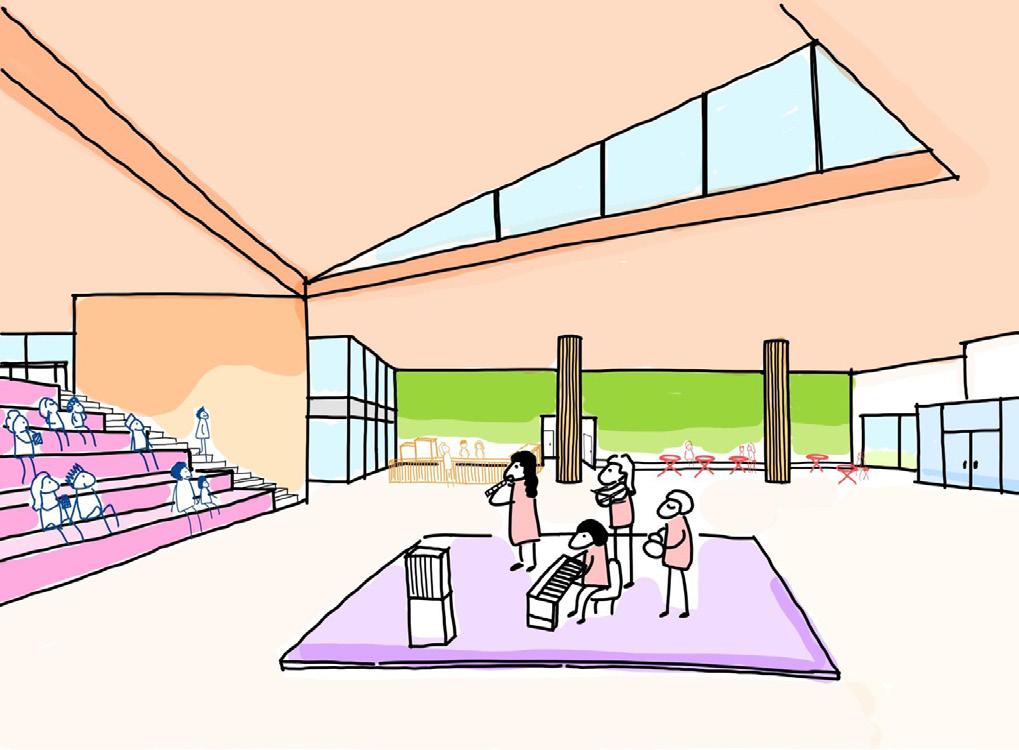

This project retrofits the Humber Academic Center as a Deep Energy Community Center, focusing on sustainability and human connection. The primary concept, “Connection,” fosters relationships between people and nature beyond traditional community facilities.

Located at 110 Carrier Drive in an industrial zone, the building integrates a thoughtfully placed garden on the east side, away from loading docks and truck activity. The design minimizes shadows by limiting the southern section to one story, ensuring optimal sunlight, especially in winter.

Through passive design strategies and energy-efficient systems, this project promotes environmental sustainability while enhancing user experience.

West View (Entrace)

Outdoor Sustainability Elements

Ground Source Heat Pump Bioswale

Rain Garden & Permeable Pavement

Efficient Irrigation System

Local Plants & Xeriscaping

Architectural Sustainability Strategies

Green Roof & Reflective Roof

Sawtooth Roof (for Natural Light)

Solar Shading on the South Face

Fabric Sun Protection on Curtain Wall

Solar Panel

Connection with “people” and utilmately with “nature”

Community Garden (Platform for education)

Community Engagement

Interior Space Planning

User’s Perspective in mind

Allow users to see the Interior Activities rather than the Industrial Surroundings Feel Interconnected rather than Isolated

Eco-Friendly Interior Design

Green Wall in Food Court & Dining Area

Sliding Windows at the Back of Building (for Air Circulation)

Radiant Ceiling Panel

Energy Recovery Ventilatior (ERV)

Low Flow Fixture

Sustainable Design Strategies

DESIGN DEVELOPMENT & PRESENTATION

ALL HVAC EQUIPMENTS FOR REUSE

FOR REUSE

DEMOLITION NOTES:

1. EXISTING CONDITIONS ARE TO BE VERIFIED ON SITE PRIOR TO STARTING DEMOLITION/ NEW WORK. IF SITE CONDITION DIFFERS FROM DRAWINGS. NOTIFY PRIME CONSULTANT.

2. REFER TO CIVIL, STRUCTURAL, MECHANICAL AND ELECTRICAL DRAWINGS FOR ADDITIONAL INFORMATION AND AREAS OF DEMOLITION AND NEW CONSTRUCTION WORK.

3. REFER TO HAZARDOUS SUBSTANCE REPORT FOR LOCATION AND REMOVAL OF HAZARDOUS SUBSTANCE PRIOR TO STARTING ANY DEMOLITION/ NEW WORK.

4. EXCEPT DEMOLISHED STEEL COLUMN, REMAINING EXISTING STEEL COLUMN TO BE REFURBISHED AS NEEDED AND COVERED AS SPECIFIED IN PROPOSED DRAWINGS.

5. REMAINING EXISTING FOUNDATION WALL AND FOOTING TO BE VERIFIED AND REINFORCED AS REQUIRED FOR STRUCTURAL LOADS.

6. REMAINING EXISTING GROUND FLOOR SLAB TO BE REFURBISHED

7. DEMOLISH EXISTING UPPER FLOOR SLAB WITHOUT DAMAGING ADJACENT STRUCTURAL ELEMENTS.

8. DEMOLISH ALL EXTERIOR WALL WITHOUT DAMAGING ADJACENT STRUCTURAL ELEMENTS.

9. DEMOLISH ALL EXISTING EXTERIOR DOOR, FRAME AND ANY ASSOCIATED SIDE LITES, TYP.

10. DEMOLISH ALL EXISTING CEILING FINISH AND EXISTING LIGHT FIXTURES TO BE DECONSTRUCTED AND SALVAGE FOR REUSE.

11. DEMOLISH ALL EXISTING WINDOW AND TRIM.

12. DEMOLISH EXISTING SHAFT WALL WITHOUT DAMAGE TO ADJACENT FLOOR.

13. DEMOLISH EXISTING STAIRWELL AT ALL LEVELS, INCLUDING STAIR, RAILINGS, AND ALL ASSOCIATED COMPONENTS.

14. DEMOLISH EXISTING INTERIOR WINDOW, SILL AND TRIM. DEMOLISH WALL BELOW WINDOW OPENING TO FLOOR LEVEL.

15. DEMOLISH EXISTING ROOF EXCEPT FOR THE ROOF STRUCTURE.

16. SALVAGE ALL EXISTING CORRIDOR BENCHES AND BENCH WALL FASTENERS WITHIN THE EXTENT OF RENOVATION, INCLUDING BUT NOT LIMITED TO THOSE SHOWN IN THE DEMO DRAWINGS. STORE BENCHES FOR REINSTALLATION.

17. SALVAGE ALL ELECTRIC VEHICLE CHARGERS FOR REINSTALLATION IN NEW WORK.

18. SALVAGE ALL STREET SIGNS FOR REINSTALLATION IN NEW WORK.

DESIGN DEVELOPMENT & PRESENTATION

AQUATICS

AQUATICS

GYMNASIUM

GYMNASIUM

MULTIPURPOSE SPACE

AQUATICS

MULTIPURPOSE SPACE

COMMON & ADMINISTRATION AREAS

GYMNASIUM

COMMON & ADMINISTRATION AREAS

LOBBY/ FOOD AREA

MULTIPURPOSE SPACE

LOBBY/ FOOD AREA

DOUBLE HEIGHT SOCIAL HUB

COMMON & ADMINISTRATION AREAS

DOUBLE HEIGHT SOCIAL HUB

LOBBY/ FOOD AREA

SITTING STAIR

SITTING STAIR

DOUBLE HEIGHT SOCIAL HUB

TREE

TREE

SITTING STAIR

TREE

Ground Floor Circulation Diagram

1. EXISTING CONDITIONS ARE TO BE VERIFIED ON SITE PRIOR TO STARTING DEMOLITION/ NEW WORK. IF SITE CONDITION DIFFERS FROM DRAWINGS. NOTIFY PRIME CONSULTANT.

2. REFER TO CIVIL, STRUCTURAL, MECHANICAL AND ELECTRICAL DRAWINGS FOR ADDITIONAL INFORMATION AND AREAS OF DEMOLITION AND NEW CONSTRUCTION WORK.

3. REFER TO HAZARDOUS SUBSTANCE REPORT FOR LOCATION AND REMOVAL OF HAZARDOUS SUBSTANCE PRIOR TO STARTING ANY DEMOLITION/ NEW WORK.

4. EXCEPT DEMOLISHED STEEL COLUMN, REMAINING EXISTING STEEL COLUMN TO BE REFURBISHED AS NEEDED AND COVERED AS SPECIFIED IN PROPOSED DRAWINGS.

5. REMAINING EXISTING FOUNDATION WALL AND FOOTING TO BE VERIFIED AND REINFORCED AS REQUIRED FOR STRUCTURAL LOADS.

6. REMAINING EXISTING GROUND FLOOR SLAB TO BE REFURBISHED

7. DEMOLISH EXISTING UPPER FLOOR SLAB WITHOUT DAMAGING ADJACENT STRUCTURAL ELEMENTS.

8. DEMOLISH ALL EXTERIOR WALL WITHOUT DAMAGING ADJACENT STRUCTURAL ELEMENTS.

9. DEMOLISH ALL EXISTING EXTERIOR DOOR, FRAME AND ANY ASSOCIATED SIDE LITES, TYP.

10. DEMOLISH ALL EXISTING CEILING FINISH AND EXISTING LIGHT FIXTURES TO BE DECONSTRUCTED AND SALVAGE FOR REUSE.

11. DEMOLISH ALL EXISTING WINDOW AND TRIM.

12. DEMOLISH EXISTING SHAFT WALL WITHOUT DAMAGE TO ADJACENT FLOOR.

13. DEMOLISH EXISTING STAIRWELL AT ALL LEVELS, INCLUDING STAIR, RAILINGS, AND ALL ASSOCIATED COMPONENTS.

14. DEMOLISH EXISTING INTERIOR WINDOW, SILL AND TRIM. DEMOLISH WALL BELOW WINDOW OPENING TO FLOOR LEVEL.

15. DEMOLISH EXISTING

FITNESS

FITNESS

MULTIPURPOSE SPACE

MULTIPURPOSE SPACE

COMMON & ADMINISTRATION AREAS

COMMON & ADMINISTRATION AREAS

OUTDOOR PATIO/ GREEN ROOF

OUTDOOR PATIO/ GREEN ROOF

DOUBLE HEIGHT AREA

DOUBLE HEIGHT AREA

SITTING STAIR

SITTING STAIR

Upper Floor Circulation Diagram

Garden View

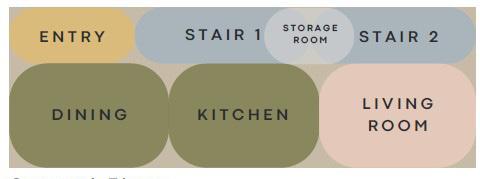

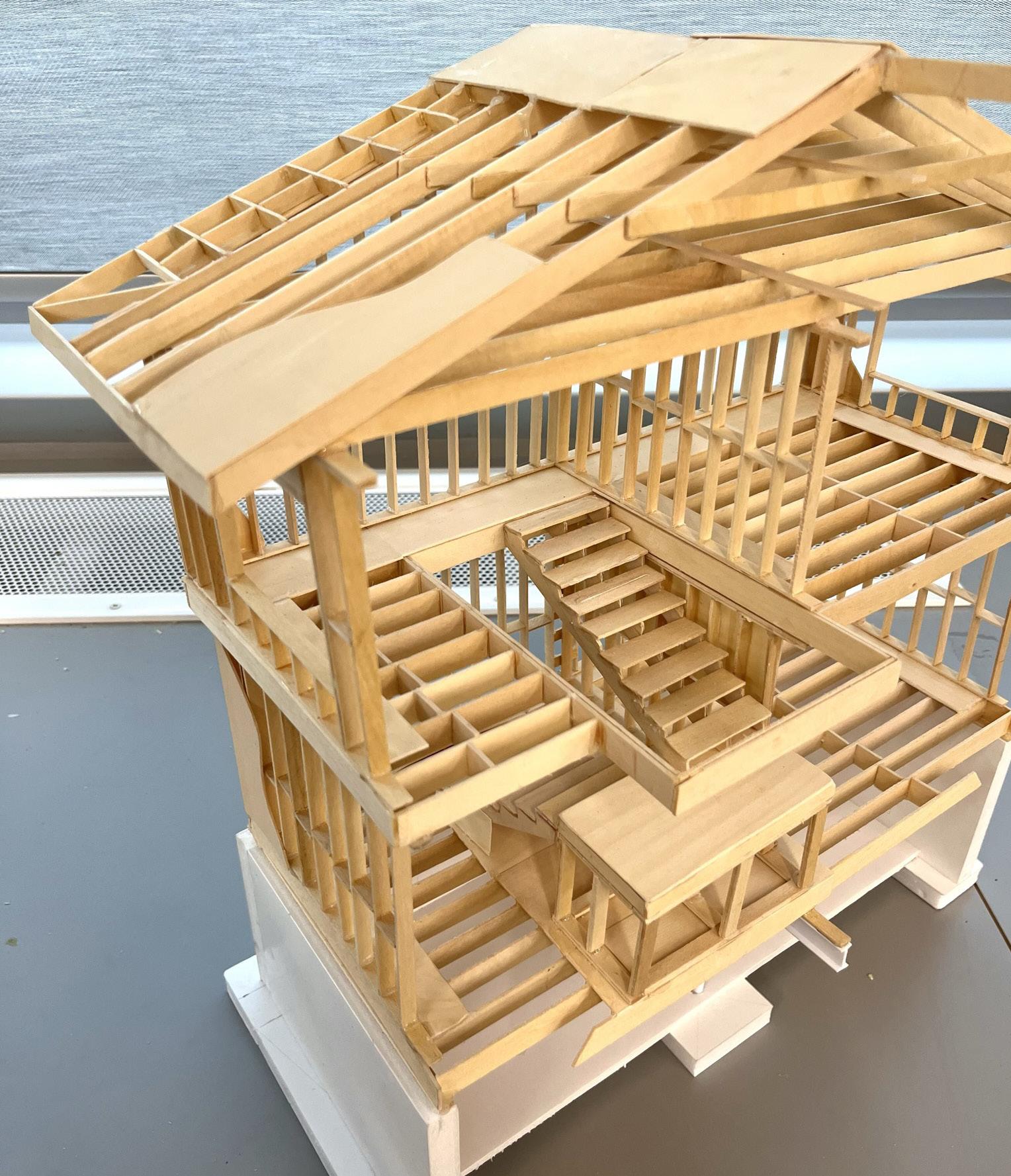

INNOVATION’S 3D PRINTED NARROW HOUSE

Main Material: Lavacrete (Cement-based material),

Geopolymer, Recycled aggregates

Date: Sep. 2024

Course: Special Project

Duration: 4 months

Used Software: Revit/ Twinmotion/ Illustrator/ Photoshop

This project explores the potential of 3D printing technology in residential design by creating a sustainable narrow house for a family with two children (ages 10 and 15). The design maximises space efficiency while ensuring comfort and functionality in a compact footprint.

Using 3D printing reduces construction waste, shortens building time, and lowers labor costs. Additionally, the automated printing process minimize material transportation, lowering the project’s carbon footprint.

This approach demonstrates how 3D printing can offer affordable, eco-friendly housing solutions for urban environments.

Block Diagram

Basement

Ground Floor

Second Floor

Third Floor

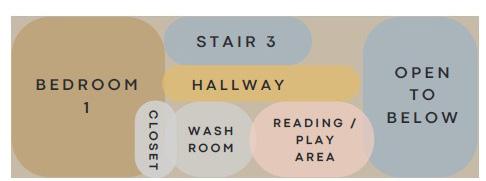

Second Floor Plan

Third Floor Plan

CORRIDOR WASHROOM

CORRIDOR KITCHEN

GARAGE

1161 WESTON RETAIL & RESIDENTIAL BUILDLING

Main Material: Precast Concrete Panel

Date: Jan. 2024

Course: Drafting & Detailing 4

Duration: 4 months

Used Software: Revit/ Twinmotion/ Illustrator

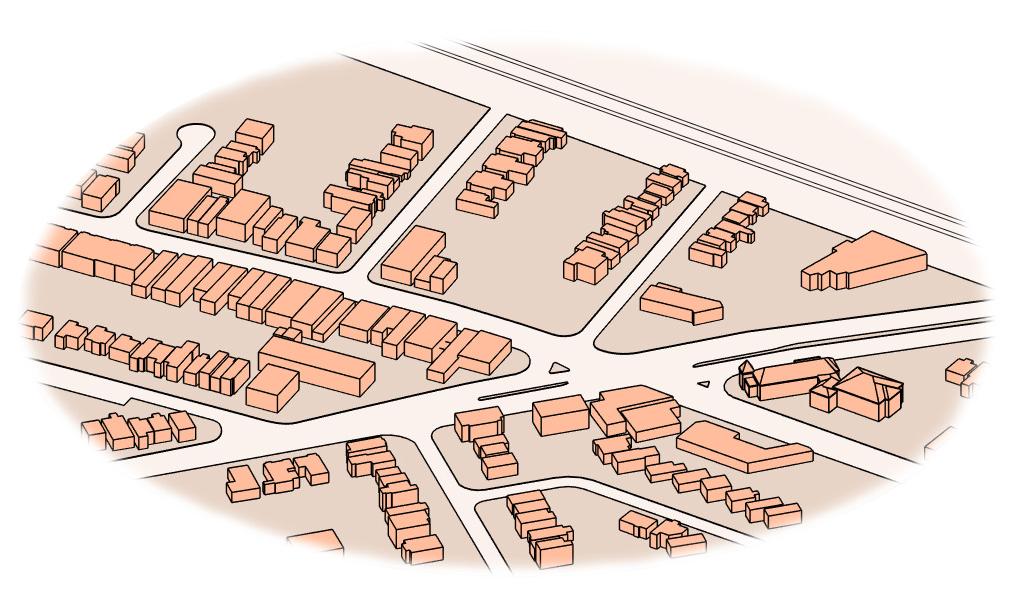

Located in the Mount Dennis District, it is shaped by careful site analysis and zoning considerations. The building is oriented based on sun, wind, and view studies, with optimized glazing on the south side, shaded by solar devices to support passive heating and natural daylighting.

The exterior features a precast concrete rainscreen system composed of three different finishes, referencing the textures and colors of surrounding buildings to harmonize with the local context.

Furthermore, this project activates the community with the ice/roller skating rink located in northwest of the building, retail shops on ground floor and shared amenities on the fifth floor. It not only welcomes mixed income families but also gets engaged with existing neighbors.

Circulation Diagram

Mechanical Penthouse (within angular plane)

5.25m setback for patio place 1.25m setback for balcony

80% of R.O.W Width (Weston Road)

27m/ 8 storey Max building height

Photovoltaic Panels on Roof

2.5m setback above laneway

2.75m setback for balcony

5.6m height below cornice line 11m/ 4 storey streetwall

80% of R.O.W Width (Hollis Street)

RESIDENTIAL

COMMERCIAL

COMMERCIAL

RESIDENTIAL

RESIDENTIAL

COMMERCIAL

COMMERCIAL

COMMERCIAL

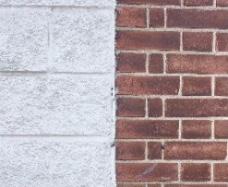

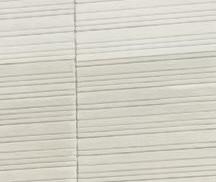

Elements, Materials, Textures of Surrounding Environment

Vinyl Siding Red Clay Brick

Aluminum Siding Wall Painting

Green Curtain Wall Stone Block White Pattern Tile

Conc. Wall Arched Window

Orange Color Stucco Brick to Conc. Block Pattern

Solider Brick Pattern Bay Window

Window & Parapet Frame

Exterior Wall Design

Custom Tiles Dark Grey Brick Blue Black & Painted Brick Red Brick & White Conc. Block

CORNICE LINE

Seasonal Daylight and Solar Shading Strategy

Summer Sun Spring & Autumn Sun Winter Sun

Summer Sun Spring & Autumn Sun Winter Sun

Double Glazed Windows To Prevent Heat Loss

Building Envelope Concept

Horizontal Sun Shading Devices For Summer Sun

Beige Precast Concrete Panels

Beige Polyurethane Concrete Molding

White Aluminum Entrance Canopy

Precast Sandwich Concrete Panels

BlueBlack Precast Concrete Panels

Red Clay Bricks On Precast Concrete Panels

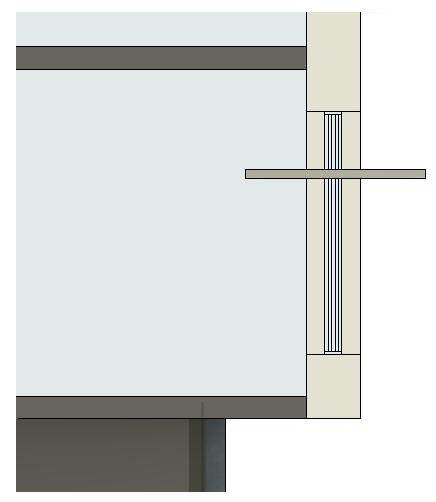

Suspended Soffit Detail

MIXED-USE RETAIL & OFFICE BUILDING

Main Material: Mass Timber (NLT, Glulam)

Date: Sep. 2023

Course: Drafting & Detailing 3

Duration: 4 months

Used Software: Revit/ Autocad/ Twinmotion/ Illustrator/ Photoshop

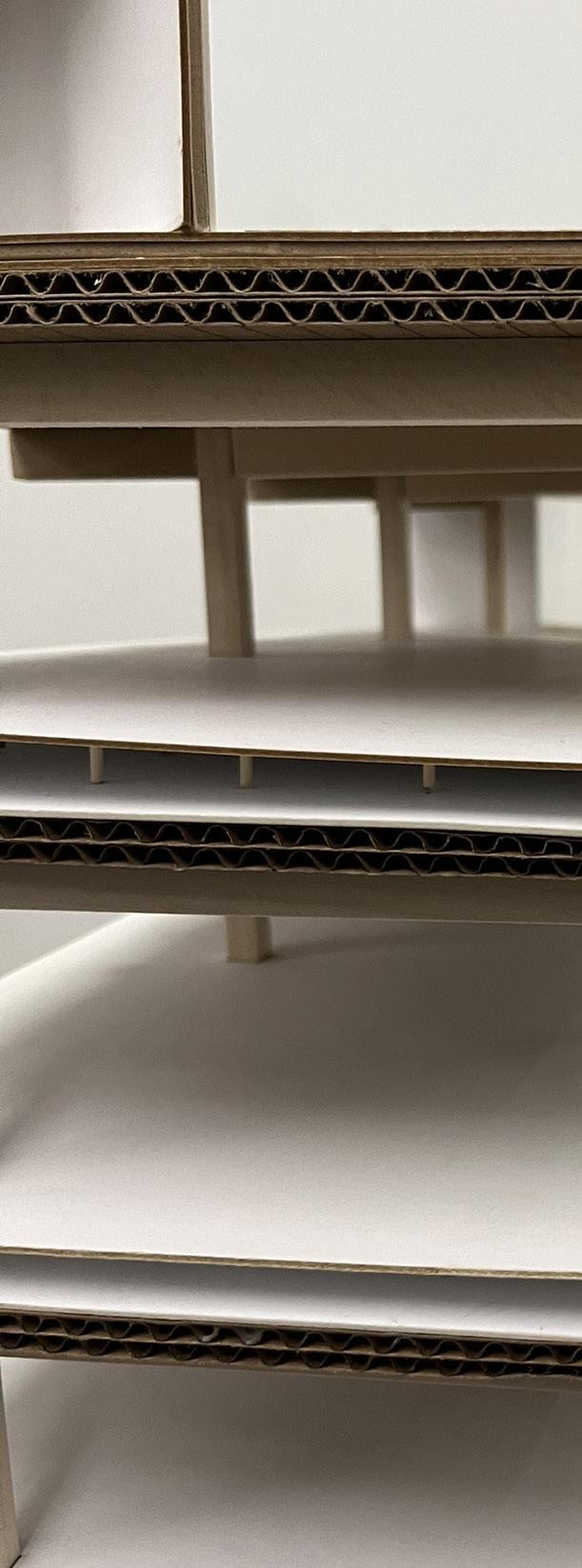

A mixed-use commercial building at the northwest corner of Main Street and Forest Boulevard, with one level of retail, four storeys of office space, and underground parking for 75 cars.

The structure incorporates mass timber for its columns, beams, and floor slabs excluding the ground floor and parking level. The exposed wood surfaces throughout the office levels are designed to promote occupant well-being, with research showing positive effects on productivity, comfort, and stress reduction.

The building is oriented to maximize sunlight on the southeast side, allowing natural light to reach interior spaces while helping reduce reliance on artificial lighting and lowering heating demands.

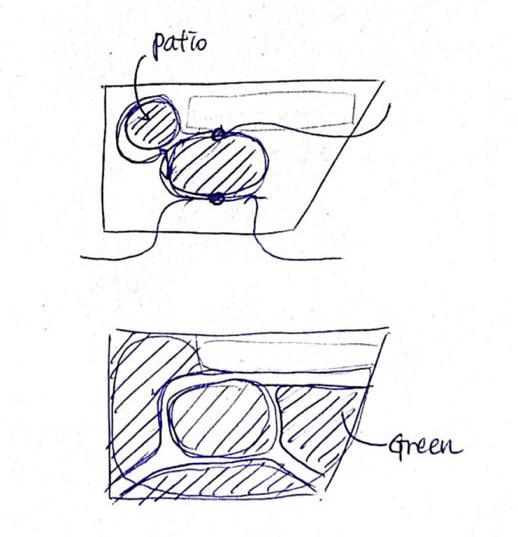

Parti Diagrams

Concept Diagram

CONCEPT DIAGRAM

SDS ELECTRONICS LTD.

: INDUSTRIAL PLANT & OFFICES

Main Material: CMU, Steel

Date: May. 2023

Course: Drafting & Detailing 2

Duration: 4 months

Used Software: Autocad/ Illustrator

A sustainable facility for an electronics company, incorporating skylights, solar panels, a green roof, and passive shading strategies to reduce energy demand and maintain indoor thermal comfort.

A central courtyard with trees sits at the heart of the building, creating a calming green space that can be viewed from both the showroom and the laboratory. This integration of nature into the interior enhances visual connection and brings a sense of openness to the working environment.

The employee facility extends to an outdoor patio, offering a comfortable space for breaks and informal gatherings.

3

ASSEMBLY LEGEND

EPOXY FLOORING - 125 CONC. SLAB - 0.15 POLY. D.P.C - 50 XPS INSULATION

150 GRANULAR FILL

REFLECTIVE ROOFING MEMBRANE - 100 TAPERED XPS INSULATION - ELASTOMERIC MEMBRANE AIR BARRIER (TREMCO, ExoAir 120) - 13 PLYWOOD - 40 STEEL DECK 5 6 - DIMPLE BOARD - 390 REINF. CONC. FOUND'N WALL - 50 EPS INSULATION

- INTERIOR FLOOR FIN. (V.A.T.) - 125 CONC. SLAB - 0.15 POLY. D.P.C - 50 XPS INSULATION - 150 COMPACTED GRANULAR FILL 8 - 90 x 57 BRICK VENEER WITH 10 MORTAR GAP - 25 AIR SPACE - 100 PIR RIGID INSULATION (XTRATHERM) - 0.15 ELASTOMERIC MEMBRANE AIR BARRIER(TREMCO, ExoAir 120) - 190 x 190 C.M.U. BLOCK WITH 10 MORTAR GAP - 22 MET. FURRING CH. @ 400 O.C. - 16 G.W.B. - INTERIOR FLOOR FIN. (V.A.T.)

(XTRATHERM) - 0.15 ELASTOMERIC MEMBRANE AIR BARRIER(TREMCO, ExoAir 120) - 190 x 190 C.M.U. BLOCK WITH 10 MORTAR GAP - 22 MET. FURRING CH.

65 CONC. SLAB REINF. WITH W.W.M.

600 O.W.S.J @ 500 O.C. - LAY IN ACOUSTIC TILE IN SUSPENDED T-BAR SYSTEM WALL MOULDING ANGLE

TEXTURED CEMENT BOARD FIN.

16 EXT. GRADE G.W.B.

22 MET. FURRING CH. @ 400 O.C.

38 CARRYING CH. @ 1200 O.C.