JEREMY SHAW

HRIA National President

It's vital that we continue working together to remain the preferred option in times of need.

JEREMY SHAW

HRIA National President

It's vital that we continue working together to remain the preferred option in times of need.

IN JANUARY, SEVERAL AUSTRALIAN MEMBERS MADE THE TRIP TO LAS VEGAS FOR THE ANNUAL AMERICAN RENTAL ASSOCIATION SHOW, AND IT DIDN’T DISAPPOINT.

RENOWNED FOR IT’S LARGER than life food and entertainment, our US counterparts played host to the ARA show over five days, with more than 700 exhibitors, dozens of keynote speakers and around 10,000 attendees. After the show, a small group travelled from Las Vegas to Los Angeles and visited several hire companies over the course of two days, which was a great learning experience. A big thank you to all involved in making this trip happen.

Living and working in South-east Queensland, I witnessed, firsthand, the effects of ex-Tropical Cyclone Alfred. As the first major cyclone to hit Southern Queensland in more than 50 years, equipment rental companies were called on to supply back-up power, traffic management, lighting, pumps and cleaning equipment. While the event didn’t cause

as much damage as anticipated, many thousands of businesses and individuals were affected by fallen trees, power outages the flooding that followed. HRIA members were in a good position to support impacted communities throughout this incident; and the spirit of collaboration among businesses is one of our industry's strongest assets.

The National Office is in the planning phase for the second annual Leadership Conference, scheduled for the Gold Coast in September. This conference targets SME leaders, who would benefit from the experience of our keynote speakers, delivering focussed content such as time management, recruitment and technology innovation.

In June, we welcome everyone to the Melbourne Convention and Exhibition Centre for HIRE25. The National Office has been working incredibly hard over many months to put together a world class show. Congratulations to all the finalists in the Hire Industry Excellence Awards. We look forward to another great event!

Finally, I’d like to thank our outgoing HRIA Vice President Tony Symons for his service to the hire industry over many decades and for several years working on the National Board as WA State President and more recently, as Vice President. It has been a privilege to sit alongside Tony at many board meetings and have him contribute to our strategic plan and initiatives.

I extend my gratitude to interim Vice President, David Schurman — Executive Manager at Kennards Hire — who joins the board for the remainder of 2025, bringing more than 10 years’ hire industry experience from both here in Australia and overseas. We look forward to working with David through the year and hope to make the position permanent at the November AGM.

WHAT’S IT TAKE TO SURVIVE AND THRIVE IN BUSINESS FOR 140 YEARS? A COMMITMENT TO CONTINUOUS GROWTH, INNOVATION AND STEADFAST SUPPORT FOR AUSTRALIAN INDUSTRY.

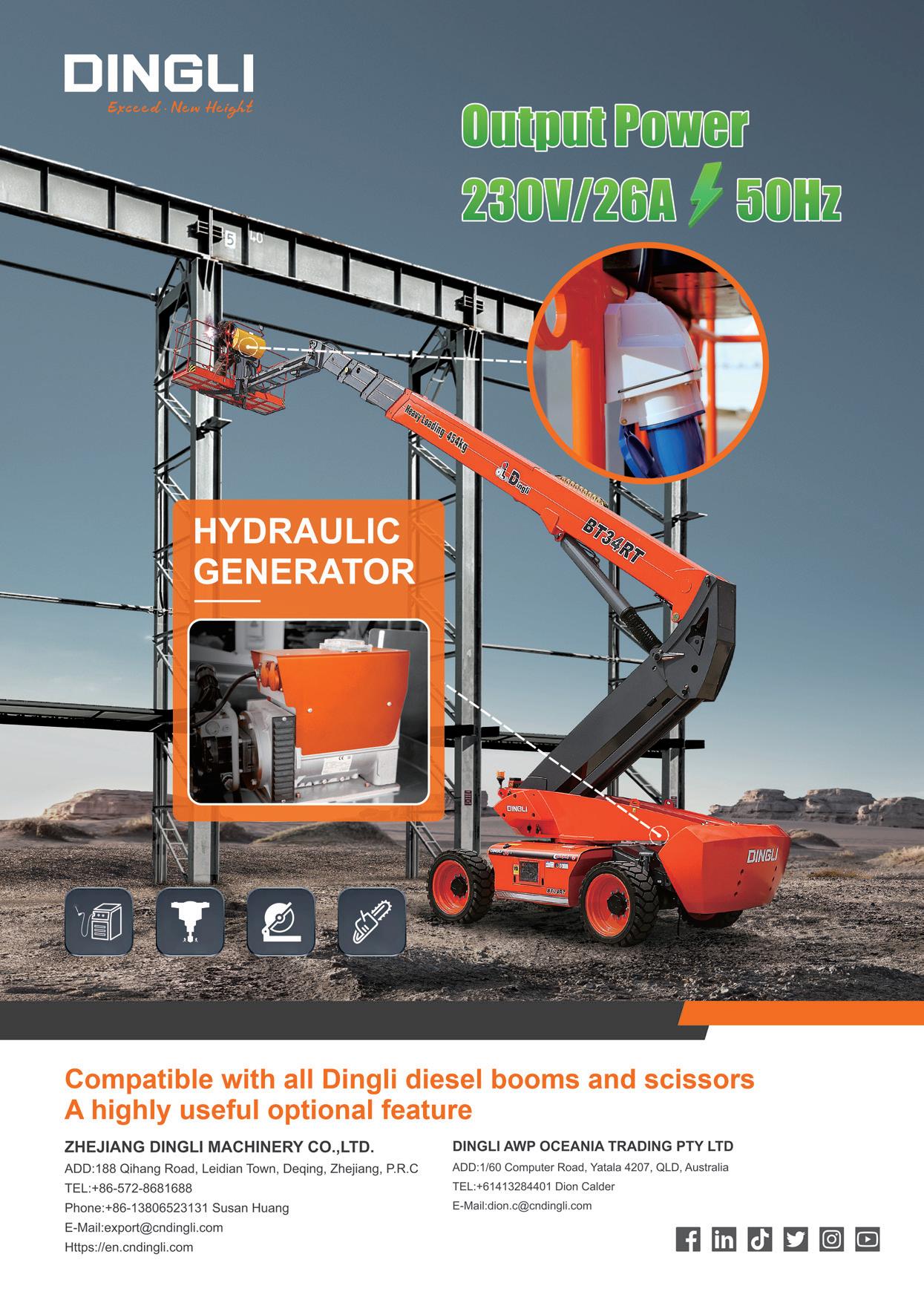

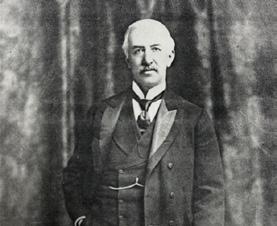

FROM ITS MODEST BEGINNINGS in 1885, Coates has grown into a powerhouse of the Australian equipment hire industry.

Coates CEO Murray Vitlich acknowledges just how far the company has come in 140 years.

“Since our founding in 1885, Coates has continually evolved, driven by the commitment of delivering innovative solutions and creating lasting value for our customers,” says Murray.

It’s a philosophy that’s seen Coates emerge from a 19 th -century start-up in Victoria to mid-century pioneers of the equipment rental business across Australia, and ultimately to the largest equipment hire and solutions provider in the country today.

“We’ve faced challenges, embraced new technologies, and expanded into new markets,” says Murray, “but one thing has remained constant: our unwavering dedication to excellence and servicing our customers.”

The Coates story began when John Coates, an English gas and hydraulic engineer, established John Coates & Co Ltd in Melbourne. The year was 1885 and the company began importing and supplying heavy machinery to the Victorian goldfields. John Coates was also a Director of the Melbourne Hydraulic Power Company, and

“We’ve faced challenges, embraced new technologies, and expanded into new markets – but one thing has remained constant: our unwavering dedication to excellence and servicing our customers.”

Murray Vitlich

For 140 years, Coates has delivered innovative solutions for customers who have helped build Australia.

advantage in the breadth and depth of our product and service offering.”

With the convenience of a ‘one-stop shop’, Sheridan says Coates can support the entire project lifecycle.

“The biggest pain point for many of our customers is the complexity of juggling so many different suppliers, jobs, equipment and people,” she says.

“When we demonstrate the comprehensive value and support we bring to their entire project, it means reduced stress, complexity and risk for our customers.”

“That’s why we want to be top of mind when key decision-makers are looking for support at every stage of their projects.”

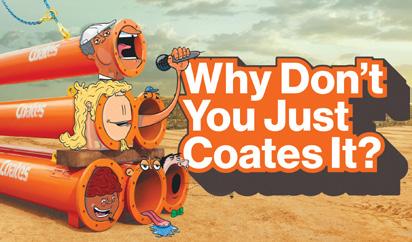

It’s now become the genesis for Coates’ new brand campaign, timed to celebrate its milestone anniversary. Launched in March, the integrated brand campaign asks the question, “Why don’t you just Coates it?”

Sheridan says the campaign is designed to raise awareness of Coates, not just as a service provider, but as a dedicated partner that supports its customers at every stage of their projects.

“At Coates, we’re proud of our Australian heritage,” says Sheridan.

“As Australia’s largest equipment hire and solutions provider, it’s our job to lead the industry and our customers into the next era. Our new campaign perfectly encapsulates how far we’ve come and where we’re headed together.”

Drawing inspiration from Coates’ rich legacy, Murray Vitlich and his team are looking to the future ahead.

“Each chapter of our story has been shaped by the hard work and innovation of our employees, the trust and support of our shareholders, and the loyalty of our customers,” says Murray.

“It is because of them that Coates is where it is today, and it is with them that we will continue to forge ahead into an even brighter future.”

‘Why don’t you

just Coates it?’ Coates’ latest brand campaign.

In 2025, Coates’ team of nearly 2000 employees located at more than 145 branches and offices throughout Australia, continue to push the boundaries of innovation, sustainability, safety and service excellence.

Murray says it will ensure Coates remains an industry leader for generations to come.

“With our customers, people and communities, we will make the next 140 years even more remarkable than the last.” T

Alex Schuessler, SmartEquip Founder & President of International Group

says. “There's real-time coverage with self-updating service documentation and operator guides, as well as always-current parts catalogues, front-ending highly simplified parts purchasing.”

Furthermore, the system integrates seamlessly with the fleet owner’s own inventory systems: “When you click on the interactive parts catalogue, our solution tells you which of these parts already exist in your own stock or inventory, alongside showing external sourcing and pricing information of your suppliers,” says Alex. “It is a fully streamlined, seamless process.”

SmartEquip is entirely agnostic regarding where a company sources its parts. “Our platform does not dictate where you purchase your parts,” says Alex. “That decision is obviously the business owner’s, and we care only that your employees can accurately identify the right parts and order them quickly, thus freeing up time for technicians to be repairing equipment, rather than chasing information and filling out paperwork.”

This combined focus on simplicity, accuracy, and speed embodies the Total Cost of Ownership (TCO) mind-set which led to the founding of SmartEquip in March of 2000. Unlike other solutions emerging at that time, during the “dot-com” revolution, SmartEquip’s focus went far beyond the transactional boundaries of e-commerce, by looking at the far richer area of operational efficiency improvements.

“You save cost on parts, by ensuring the right part is bought from the right source at the right time, certainly. However, you generate far greater savings by reducing a service technician’s time needed to conduct a repair,” he adds. “And finally, and most impressively, if you are able to reduce the time of a repair by four or five hours,

you have just improved equipment uptime by the same amount! Given the absence of variable cost, whatever additional revenue you generate at that point, for example via one more rental, is essentially pure profit,” says Alex.

“So yes, parts and especially service cost savings are substantial. And yet, it’s the additional equipment availability which is by far the most valuable part.”

Alex says companies new to the solution quickly see the benefits to be gained.

“For many of our customers, depending on fleet composition and average age, annual parts expenditure is around two per cent of the original fleet acquisition cost,” says Alex. “It is quite standard that rental companies using SmartEquip can reduce this amount by five to 10 percent.”

“Where it becomes more interesting is that service cost (between internal and externally outsourced labour) also runs about two percent. And here SmartEquip’s savings can be anywhere between 30 to 75 percent! That is a high multiple of what you can achieve by looking to purchase the cheapest part.”

“Finally, fleets that use SmartEquip typically have a four-percentage-point greater financial utilisation than those that do not. This revenue impact usually dwarfs the parts and service cost savings. Taken as a whole, you have just revolutionised your entire equipment lifecycle.”

To learn more about the SmartEquip platform, stop by for a chat at HIRE25, Stand 34 in the Exhibition Hall (4-5 June) or visit www.smartequip.com to request a demonstration.

In today’s digital world, leveraging data and productivity platforms to get a competitive edge in the hire industry is essential. SmartEquip and Rouse provide rental fleets, dealers and contractors with the market intelligence, data insights and technical tools needed to improve decision making, optimise processes and reduce costs throughout the lifecycle of equipment ownership.

Rouse and SmartEquip provide cutting-edge platforms so you can:

• Minimise overall costs for service, maintenance and repair of your fleet.

• Maximise ROI return on investment (ROI) of your machines through revenue performance measurements and fleet optimisation.

PETER LANCKEN AM, FORMER CEO OF KENNARDS HIRE, HAS BEEN INDUCTED INTO THE

IT’S ONE OF MOST prestigious awards in the global rental industry — the ARA’s Rental Hall of Fame, an honour created in 2000 to recognise individuals who’ve changed the trajectory of the equipment and event rental industry. To make the cut, you must be an outstanding industry leader who’s made a substantial and lasting impact on the industry’s success and growth at the national and/ or international level.

In January 2025 at an ARA ceremony in Las Vegas, former CEO of Kennards Hire, Peter Lancken, was one of three new inductees to the Rental Hall of Fame. ARA CEO Tony Conant said their contributions had left a lasting mark on the industry inspiring growth and innovation across the rental community.

Peter's only the second Australian to have received the honour, joining his great friend and colleague, Andy Kennard, who was inducted in 2002.

“It was pretty special,” says Peter, “there’s really no higher honour in this industry.”

It’s an industry that’s been Peter’s life — and in his DNA — for more than four decades. Initially training as a civil engineer, his hire career began in 1978 with formwork and scaffolding company, GKN. He moved to Southern California to set up GKN’s rental business and in just four years under his management, it grew to a US$50 million business.

On returning to Australia, he became Managing Director of GKN Australia, a position in which he remained until 1994. “It was 18 years of ‘getting my feet wet’ in the world of hire and it was a marvellous experience,” he says.

With GKN looking to divest its business in Australia, in 1994, Peter negotiated a deal with Andy Kennard to buy the balance of GKN rentals. That was the point where he decided that working for Kennards Hire would be a great opportunity, taking on the role of Managing Director of the Kennards Group in 1995.

Peter’s vision was to take the Kennards Hire brand and develop a network of branches around the country. From the moment he joined the business, he was a hands-on operator overseeing their growth into an iconic Australian brand with an extensive national footprint with more than 70 branches. Under his leadership, Kennards Hire twice won the HRIA’s ‘Hire Company of the Year’.

DDiesel generato

Japanese Denyo’s diesel generators are renowned as being the most reliable and fuel efficient generators with premium Kubota and Isuzu engines. From construction and mining to civil engineering and backup power. Denyo generators produce optimal power to meet a variety of user needs and rental applications. They are designed for extreme hot and cold conditions with compact, robust canopies designed to be lifted, moved and truck mounted. The simple analogue controls make them a favourite in construction and mining sites. With low noise, low fuel consumption, high quality electricity, maintenance accessibility and parallel operation.

We also stock self bunded Fuel Tanks fully baffled ranging in size from 500L to 30,000L. Also, diesel fuel trailers.

“It’s not often you come across someone who has the passion that Peter has. His contribution to both the Australian and international hire industry has been invaluable. Kennards Hire would not be the business it is today without his experience, fortitude and dedication.”

Brendan Fleiter, Chairman, Kennards Hire. (2016 - 2024)

Peter was also instrumental in building and instilling a strong Kennards Hire culture and a unique set of values. “People at Kennards Hire really believe in our values,” he says. “They believe in our vision and that this is a great place to work.”

Yet Peter's enthusiasm for the hire and rental industry extends beyond Kennards Hire. He’s played a key role in building the reputation and influence of the industry as President of the NSW Hire Association between 1996-2004, a founding director of the HRIA in 2000 and Vice President and board member of the HRIA between 2000-2009. In 2006, Peter was awarded Life Membership of the HRIA.

In the 1990s, Peter joined the ARA and is now a benefactor of the ARA Foundation. In 2003, he was a founding member of the Global Rental Alliance which raises the profile of equipment rental worldwide while increasing the membership value of the respective associations. He was awarded an ARA Meritorious Service Award in 2007 for his significant contribution and demonstrated leadership. In 2008, Peter was a founding member of the Global Rental Alliance International Business Leadership Program and in 2014, was honoured with an ARA Award for Service to the Industry on an international level, one of the highest accolades in the equipment rental industry. Peter was also the first person outside of the US to receive the ARA Award.

In 2020, Peter received the Order of Australia honour for his significant service to the equipment hire and rental industry in the community.

After stepping down as CEO of Kennards Hire in 2009, Peter joined the Kennards Hire board and held the role of Chairman from 2012-2017. He remains a non-executive director of the Kennards Group.

Peter continues to contribute significantly to the fabric of the broader Australian business community. He’s Chairman of Scully RSV, a business he developed from the ground up, and serves as Non-Executive Chairman of Acrow Formwork and Scaffolding, a national leader in the construction industry, which has returned him to his roots in hiring formwork and scaffolding.

Now aged 70, Peter attributes his long career to a passion for the industry. “It’s a privilege to work within a sector that continues to see the economic and employment opportunities the hire and rental industry provides in Australia and internationally,” he says. “, I can look back and be proud of what I’ve achieved but what’s made it so special are the incredible people I’ve met over the journey. They’re some of the best in the game and honestly, I've never had a day where I've said, ‘I don't want to do this’.”

As for his Rental Hall of Fame award, Peter insists it will take pride of place next to Andy’s in Kennards Hire’s head office in Seven Hills (NSW).

“That’s where it belongs,” says Peter. “I may have accepted this great accolade, but it’s Kennards Hire and the Kennards Hire people who made it happen.” T

Predator Industrial batteries are reliable and provide long service life, making them the optimal choice for businesses.

The comprehensive range has sizes to suit all popular floor cleaners, pallet trucks, elevated work platforms and more.

OVER THE LAST YEAR WE’VE SEEN AN INCREASE IN THE LEVEL OF MERGERS AND ACQUISITIONS WITHIN THE HIRE AND RENTAL INDUSTRY. GIVEN THE MATURITY OF THE INDUSTRY THIS COMES AS NO SURPRISE. INDEED, IT IS NOT UNREASONABLE TO EXPECT FURTHER CONSOLIDATION ACROSS THE SECTOR IN THE FUTURE.

WHEN THE OWNERSHIP OF AN organisation transitions, considerable change typically follows. This often causes disruption both internally and externally. An area that is sometimes tricky to manage is what a change in ownership means for a company’s brand name.

Recent activity in the hire sector has seen a variety of approaches to treating a brand following acquisition. One method, the ‘co-branding’ approach, contrasts with fully retaining, or indeed, expiring a brand name. Unsurprisingly, this begs the question as to what the best way to manage a brand is once an acquisition has occurred?

The good news is there is no wrong or right approach. As with many aspects of marketing, strategies can flex to the specifics of an industry and ideal solutions are often found in the grey rather than being in a binary black or white context.

Whether the industry experiences further consolidation over the coming year remains to be seen. For any company considering an acquisition, a question that needs to be considered is how to manage a company’s brands once the deal has gone through? From a marketing perspective new brand owners need to decide between running a house of brands or a branded house. Sometimes it helps to look outside of our immediate industry to see how such issues have been approached in the past.

The branded house approach means sticking to one brand across all the products or services within the organisation. BMW is a useful example of a brand that’s done this. Whether the company is offering a small hatch, an SUV or a luxury limousine, every vehicle wears the BMW brand.

In contrast to BMW is the Unilever approach. Unilever offer many products under a broad portfolio of brands. Think household brands like Dove, Rexona, Omo, Flora and Magnum. Unilever believes the best way to drive relevance with its target audience is by having a house of brands.

Managing a brand portfolio, in its most simplistic form, is about choosing between a ‘House of Brands’ or a ‘Branded House’; no one size fits all. But, investing in an array of brands that fail to connect with your customers is a surefire way to burn profit.

When companies are acquired, the real question to be considered is this: How can the maximum, possible value be extracted from the newly merged entity’s brand portfolio? What approach is best? Be like BMW and have a brand that signifies the same thing for everyone? Or, be like Unilever, with a house of brands, and have something for everyone?

Fundamentally it comes down to a choice between business efficiency (Branded house) or business focus (House of brands). Three factors will inform the decision. What drives relevance with your customers? What makes you stand apart from your competition and what generates trust for your company? Looking at the future state of your brand portfolio with this criteria is useful when determining how many brands to maintain following mergers and acquisitions.

Nick Foley is the Director of Intangify and has led the strategy for some of the world’s most recognised brands. If you would like to get in touch, email nick@intangify.com.au or go to intangify.com.au

T owards the global energy transition, we provide the widest range of hybrid and environmentally friendly products: lighting towers,

THIS YEAR HAS SEEN A RECORD NUMBER OF ENTRIES INTO THE BEST NEW PRODUCTS CATEGORIES FOR ACCESS, GENERAL, SOFTWARE & SERVICES

APS Power Instagrid ONE Stand #98

Atlas CEA B-Air 185-12 Stand #96

Crommelins Battery-Powered Rammer Stand #62

EP Equipment TCL101 Stand #115

Flextool Mikasa MCD-T18H-PLUS Stand #39

Instagrid One

Globe Power Survivor SeriesRemote Stand #64

Husqvarna A25 - Air Cleaner Stand #32

Kaeser MOBILAIR M250e-power Compressor Industry 4.0 Stand #50

Makinex Concrete Grinder Stand #74

Manitou MT 730 H Stand #33

PowerLink BES14S Microgrid Energy System Stand #93

Pramac Generac GRW67P Hybrid Generator Stand #66

RoyPow 15kW / 33kWh Portable Power Storage Systems Stand #87

SiteHQ SmartWall Stand #156

Wacker Neuson SM50 mini Loader Stand #116

FOR HIRE AND RENTAL BUSINESSES, CARBON MANAGEMENT ISN’T JUST ABOUT COMPLIANCE — IT’S FAST BECOMING A CRITICAL COMMERCIAL REALITY.

HE HIRE AND RENTAL

Tsector constantly evolves and innovates their product and service offerings to meet the needs of customers they support. All sectors of the economy are under increasing obligations to track and reduce their carbon footprint, and those expectations are passed onto supply chains.

For small and medium hire businesses, that brings a new reality: if you can’t measure and manage your carbon impact, you may lose existing customers and miss out on future opportunities. This focus on sustainability also offers a major opportunity to improve efficiency, reduce costs, and future-proof your business.

Why carbon now?

Governments, investors and broader stakeholders are demanding action. Large Australian entities are now required to report on climate-related risks under the mandatory climate-related financial disclosure regime. These standards align with global frameworks and will eventually apply to thousands of entities.

Even if you’re not directly covered by the mandatory reporting, your customers and other stakeholders may be. They will require your emissions data to fulfill their reporting obligations. That means if you’re supplying gear to a contractor working on a major project, you may be asked to provide your specific carbon emissions data related to your products and services.

The Brisbane 2032 Olympic and Paralympic Games organisers have publicly stated that the Games will be “climate positive”— not only aiming for net zero but going further by removing more carbon than they emit. This commitment has real implications for all contractors and suppliers associated with the games and the development of related infrastructure — including for hire and rental providers.

Any company bidding to work on Olympicrelated infrastructure or event delivery must now show how it will reduce emissions and achieve sustainability goals. Whether you supply generators, site sheds, access equipment or event structures, being able to provide carbon data and offer lower-emission options is a prerequisite to do business.

If you can’t provide emissions data—or don’t offer low-emissions equipment—you could be excluded from project sites.

Carbon emissions (CO₂-e), are produced through the burning of fossil fuels, use of electricity and other business activities. In the hire and rental industry, they typically fall into three categories:

ire and ental ndustry ssociation

Hiring gives you access to a huge range of the latest equipment. Trial new equipment and ensure you are always using the right equipment for your job.

ENSURE EFFICIENCY

When you hire you are speaking to experts who can help you choose the right equipment for your job. Once the job is complete the equipment can be returned, no need to worry about whether that piece of equipment will ever be used again.

CONTROL COSTS

Don’t worry about machine maintenance costs or tying up your capital. Hiring equipment is also fully tax deductable which makes good business sense.

SAVE TIME

Hiring means you don’t have to spend time updating and maintaining machinery. Get instant access to the equipment you need when you need it.

SAVE MONEY

Owing equipment is expensive. By hiring you will always have access to the latest equipment without worrying about repairs, upgrades and borrowing costs.

SAVE SPACE

No need to worry about storage sheds, yards or equipment sitting idle. Hiring means you can return the equipment as soon as you are finished using it.

SAVE THE ENVIRONMENT

Equipment that is purchased often sits idle for long period of time. People are increasingly conscious of their carbon footprint therefore hiring makes sense for the environment as well as your business.

ENSURE SAFETY

When you hire, the equipment comes inspected and ready to go, ensuring it always up to standard and meets regulations.

PROTECT YOUR STAFF

All hired equipment is thoroughly checked prior to each hire and electrically tested and tagged as required.

SERVICE

When you hire you don’t need to worry about delivery, spare parts, accessories and more

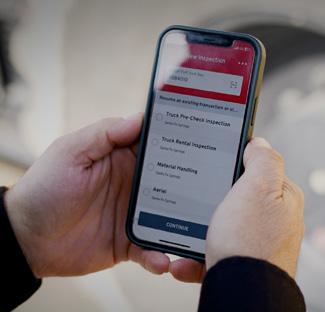

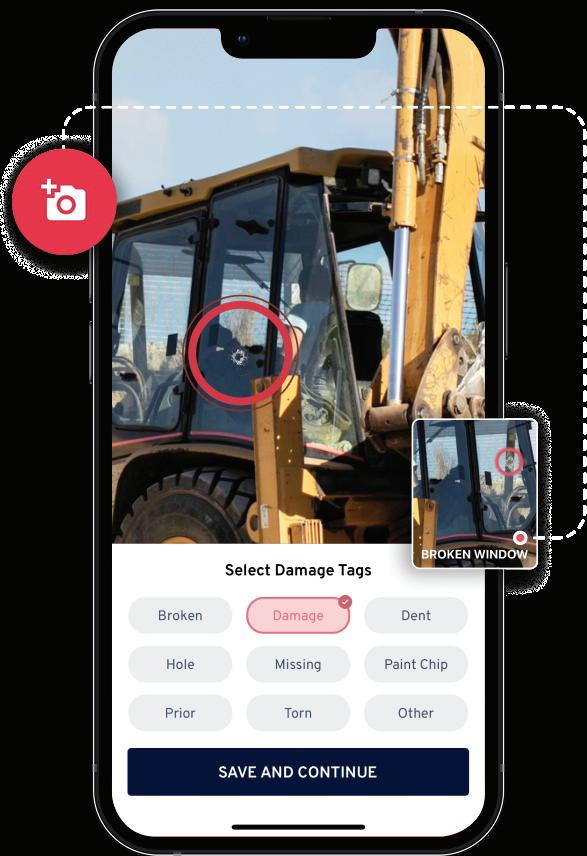

MOST EQUIPMENT, TRUCK, AND AUTO RENTAL COMPANIES LOSE MONEY ON DAMAGE THEY CAN’T PROVE. RECORD360 HELPS THEM GET IT BACK.

WE MAKE IT EASY TO document asset conditions before, during, and after a rental with photos, videos, and digital signatures that are stored and time-stamped in one place. Rental teams use Record360 to resolve disputes faster, reduce turnaround time, and get more out of every asset. For companies like Synergy Equipment, that consistency matters. “We’re big enough to take care of you and small enough to know you. Record360 uses that motto as well,” says Jamie Sawyer, Corporate Trainer.

Behind the scenes, we’ve been quietly rewriting what’s possible in rental tech. In just the past year, our product has taken major leaps forward. AIpowered blur detection now flags blurry photos automatically and has already caught over 8 million of them. OCR technology reads VINs in a snap. Our redesigned unit pages make complex histories instantly clear. And new tools like inline photos, an open API, and a dedicated development portal are reshaping how inspections connect across systems. This kind of progress doesn’t just improve workflows. It transforms them.

Across industries, rental teams that are seeing stronger returns and smoother operations tend to focus on a few key things:

1. They stop relying on paper. Paper gets lost. It’s hard to track, hard to share, and easy to dispute. Teams that digitize inspections and records not only save time, they build trust with customers and insurance providers alike.

2. They document every asset, every time. Inconsistent documentation opens the door to revenue loss. The most effective teams make inspection part of the process, not an afterthought. Clear, visual records at pickup and drop-off protect both sides of the transaction.

3. They shorten the turnaround window. Faster inspections mean faster rentals. By streamlining how assets are checked in and out, top teams reduce downtime and move equipment, vehicles, or trailers back into circulation quickly.

4. They make accountability easy. With photo evidence, timestamps, and digital signatures all in one place, questions about damage or misuse are easier to answer and resolve. That clarity keeps operations running smoothly, even when challenges come up.

Whether you’re trying to cut damage costs, speed up inspections, or get more out of your team’s time, the right tools make all the difference. Record360 gives you a faster way to work, a clearer way to document, and a smarter way to protect your bottom line.

Find out how Record360 works at record360.com or email salesau@record360.com

JOHN GLOVER EWPA President

2025 HAS MARKED A PIVOTAL YEAR FOR THE ELEVATING WORK PLATFORM ASSOCIATION (EWPA) AS WE CONTINUE TO LEAD THE INDUSTRY IN IMPROVING SAFETY STANDARDS, TRAINING QUALITY, AND INDUSTRY ALIGNMENT WITH THE LATEST REGULATORY FRAMEWORKS.

In January, the AS 1418.10:2025 MEWP Design Standard was released. This new standard is a significant step forward in elevating design expectations for MEWPs across Australia. We anticipate seeing machines built to this standard enter the market later this year or early 2026.

Following this, in April, the AS 2550.10:2025 MEWP Safe Use Standard was released.

In response, the EWPA Technical Director is currently updating the EWPA Good Practice Guide to align with these changes. This revised guide will undergo review by the Board of Directors and is expected to be published by the end of May 2025. This resource continues to support safe, compliant MEWP operations across all sectors.

We anticipate seeing machines built to [the new AS 1418.10] standard enter the market later this year or early 2026.

One of the EWPA’s strategic pillars is improving operator safety by ensuring access to comprehensive, quality training. We’re proud to announce the launch of the revised EWPA Yellow Card Program, which reflects the latest updates in industry standards and feedback from extensive stakeholder consultation.

Key highlights of the new Yellow Card training program include:

• Industry-Driven Development and Consultation: Developed with input from industry leaders and end-users to reflect realworld expectations and needs.

• Stronger Safety Foundations: Incorporates a Pre-Work Assessment focused on Language, Literacy, and Numeracy (LLN), ensuring all participants are set up for success and safety.

• Thorough Testing and Review: The new program has undergone multiple draft reviews, a pilot rollout in November 2024, and a full impact evaluation in March 2025 to ensure it meets the highest standards.

• Standards Aligned: The updated course aligns with the newly released AS 2550.10:2025 and the nationally recognised unit of competency RIIHAN301E, ensuring maximum compliance and relevance.

• Trainer Readiness: Over 200 EWPA Accredited Trainers across the country have received new training resources and attended a CPD webinar, ensuring they are ready and equipped to deliver the updated course.

As we move forward, the EWPA remains committed to driving safer outcomes and building industry confidence through standards leadership, best practice guidance, and world-class training delivery. b

WHEN VICTORIA’S ‘BIG BUILD’ PROGRAM NEEDED SPECIALIST ACCESS EQUIPMENT FOR MELBOURNE’S WEST GATE TUNNEL PROJECT THEY TURNED TO KENNARDS HIRE.

The West Gate Tunnel Project is building twin tunnels under the Yarra River. Once complete, it’s expected to deliver a vital alternative to the West Gate Bridge, remove thousands of trucks off residential streets and provide quicker and safer journeys for commuters. The project is a partnership between the Victorian Government and Transurban and is being built by a joint venture of CPB and John Holland.

Much of the access equipment used onsite is supplied by Kennards Hire. They also supply crib sheds, power tools and other smaller equipment. So when the project needed to source some of the largest boom lifts available in the country, Kennards Hire was top of mind.

For CPB John Holland Site Superintendent, Unakea Taiki (JJ) it was a ‘no brainer’.

“Whenever I need equipment, Kennards Hire have delivered it then and there, no questions asked,” says JJ. Kennards Hire now supply two x 215ft boom lifts, 10 x 180ft boom lifts and two x 135ft boom lifts to the project. They’re being used to move unique steel structures into place over the vehicle entry and exit points of each tunnel and the ventilation building.

With the steel structures built around 100 meters away from where they’ll finally be fixed to the portal structure, two cranes are used to move each piece into place. One crane picks up the pieces from where they’ve been built and transfers them to another crane mid-air, which then moves the structure into place at a height of up to 50 metres (approximately 160 feet) above ground and bolted to the structure.

Kennards Hire’s 180ft boom lifts facilitate the mid-air transfer of the structures and are then used to bolt the structures to the portals.

Kennards Hire have supplied some of the biggest

Kennards Hire’s 180ft boom lifts facilitate the mid-air transfer of the structures and are then used to bolt the structures to the portals. The two 215ft boom lifts are used to position and fix the structures over the ventilation building, at a height of more than 60 metres (approximately 200 feet).

Kennards Major Projects Victorian Manager, Cody Rowan, says the project was a great opportunity to showcase Kennards Hire’s access capabilities on one of the biggest and most visible civil construction projects in Melbourne.

“We knew we could supply the equipment and provide training but what gave us a point of differentiation was offering a dedicated project manager to the project.”

While the ability to supply the biggest boom lifts in the country was JJ’s priority, so too was access to Kennards Hire’s service and support capabilities, and training for the project’s boom lift operators.

“[Kennards Hire Project Manager] Richard is onsite every week to check on the equipment and the project,” says JJ.

“I'll give him unrealistic deadlines, where I need a piece of equipment in the next hour or two and it’s always been supplied. If there’s an issue with anything, I know I can call him and someone will be there within the next half an hour.” b

JLG INDUSTRIES IS TAKING ITS OFFERING TO THE NEXT LEVEL, EXPANDING BEYOND ITS RENOWNED ACCESS EQUIPMENT TO BECOME A TRUE SOLUTION PROVIDER FOR THE HIRE AND RENTAL INDUSTRY.

With new product categories, expanded services, and local manufacturing, JLG is making it easier than ever for businesses to get the equipment and support they need from a single trusted partner.

For decades, JLG has been a market leader in access equipment, with an established presence across Australia. Now, the company is broadening its reach and range, with the reintroduction of telehandlers, a range of mini dumpers, and new lighting towers, made here in Australia.

“Our goal is to be a total solutions provider for our customers,” says Scott Daly, General Manager — JLG APAC. “Whether it’s new machinery, service, spare parts, or application-specific solutions, we want our customers to be able to come to us for everything they need.”

JLG is also investing in materials handling and earthmoving, thanks to recent global acquisitions that will further strengthen its product range. This move will allow the company to provide greater support to a wider range of industries, including civil construction, landscaping, mining, and infrastructure projects.

JLG has made significant strides in expanding its hybrid lighting tower offerings, giving customers a greener choice across multiple product lines, which are all Australian made and designed in Port Macquarie.

JLG also provides a refurbishment service that allows existing diesel JLG lighting towers to be

converted into hybrid units. This gives customers the flexibility to upgrade their assets for improved efficiency and reduced environmental impact without the need for full replacement.

JLG is continuing to invest heavily in aftermarket support, expanding its team of in-house technicians and field service mechanics across capital cities and regional areas. JLG employs its own experts in-house to ensure customers receive the highest level of support.

“Having a strong team of skilled people is just as important as having the right equipment,” says Daly. “We’re focused on making sure our customers get the best service possible.”

JLG is growing to better support hire and rental businesses

JLG’s diversification is already underway, with many of the new product lines available now and further expansions rolling out over the next 12–18 months. For hire and rental businesses, this means greater convenience, more product choices, and a trusted partner that continues to evolve with the industry.

“At the end of the day, we want to be easy to do business with,” Daly says. “By expanding our range and strengthening our service capabilities, we’re making sure our customers can rely on JLG as their total solutions provider.”

According to the European Rental Association's (ERA) report on the impact of digitalisation, companies worldwide are increasingly integrating digital tools to enhance efficiency, safety, and compliance. This shift is not only improving day-to-day operations but also helping businesses reduce machine downtime and streamline fleet management. In Australia, these global trends are being mirrored, with local solutions emerging to meet industry-specific challenges.

One of the biggest changes comes in how operators access equipment documentation. In the past, they relied on paper manuals. Now, solutions like Haulotte’s MyCompanion allow users to access up-to-date machine-specific information, simply by scanning a QR code. This ensures that operators always have the latest instructions and safety guidelines to hand, reducing the risk of misuse due to outdated information.

“Having the right information at the right time is critical for both safety and efficiency,” says Keith Clarke, General Manager of Haulotte Australia. “MyCompanion removes the hassle of misplaced manuals and gives users instant access to troubleshooting guides, instructional videos, and other key resources.”

Digital tools aren’t just improving accessibility; they’re also making fleet management easier. Keeping track of multiple machine models across a rental fleet can be challenging, but MyCompanion

simplifies the process. Businesses can purchase QR code stickers separately and apply them to their entire Haulotte fleet, making machine registration quick and seamless. This allows for fast updates and ensures compliance across all equipment without the burden of paperwork and manual tracking.

Telematics solutions like Sherpal are also facilitating fleet management by providing real-time data on machine location, usage, and diagnostics. Sherpal ERA reporting uses predictive maintenance to reduce unexpected breakdowns, reducing maintenance costs across the industry. Remote monitoring allows operators to detect potential issues before they escalate, extending equipment lifespan and ensuring better resource allocation.

For service teams, digitalisation has significantly reduced the time spent diagnosing issues. MyCompanion allows operators to quickly identify error codes and follow troubleshooting steps, leading to faster repairs and less downtime. “Previously, even minor issues often required a service call, which meant lost time and added expenses,” Clarke explains. “Now, operators can resolve many common faults themselves, keeping projects on track.” When combined with telematics systems like Sherpal, which remotely monitor machine health and alert operators to service needs in advance, businesses can achieve even greater efficiency.

As digitisation streamlines operations, improving safety and increasing productivity, the Hire industry will be better positioned to meet evolving industry standards and customer expectations. The implementation of tools like MyCompanion and Sherpal reflects a broader commitment to smarter, more connected equipment management.

For more on machine digitization, visit haulotte.com.au/en_AU/mycompanion

UP UNTIL JUNE 30

Free SHERPAL for 1 year*

Free FASTN safety system or 1 year free servicing**

*Sherpal watch - **Includes OEM-scheduled servicing at branch locations only

SJ45 AJ+ AND SJ60 AJ+ ROUGH TERRAIN ARTICULATED BOOMS REMAIN SIMPLE AND RELIABLE, WHILE OFFERING A COMMON SPECIFICATION RANGE WITH DIESEL, ALL-ELECTRIC AND HYBRID-ELECTRIC MODELS. A SUSTAINABLE CHOICE FOR RENTAL.

HYBRID ELECTRIC BOOMS

ALL ELECTRIC BOOMS

EQSS has been at the forefront of secondary guarding innovations, initially for booms and more recently, for scissor lifts.

The introduction of OverWatch in 2020 was a game-changer for contractors and hire companies providing a much-sought after solution to entrapment risks on scissor lifts. With the release of OW9 earlier this year, the device now provides even greater operator protection while allowing increased operator freedom and range of movement in the platform.

Australian companies have driven the widespread implementation of secondary guarding. Industry leaders, such as Coates, Onsite, Skyreach, and CPB played a crucial role in advocating for these safety measures and influencing best practice. These companies have demanded safety systems that are effective – that provide protection to the operator in all modes of operation, that cannot be disabled or bypassed, that will stop the machine to prevent a fatality; not simply accept a tick and flick response.

Australia has one of the highest adoption rates of scissor lift secondary guarding. Paul Rankin, chief operating officer for Loxam Powered Access Division in the U.K., has called on the industry to accelerate the implementation of secondary guarding on scissor lifts, advocating for industry-wide collaboration to improve safety standards. Some companies are rising to this challenge, with major contractors such as BAM UK & Ireland introducing crush protection mandates company wide.

The urgency for greater adoption is reinforced by recent fatal incidents in Queensland involving scissor lifts. These tragic events serve as a reminder that we must come together and take action to protect our workers and make our worksites a safer place.

State regulators have taken steps towards this with both Queensland WorkSafe and Victoria WorkSafe having guidance on the adoption of secondary guarding devices for MEWPs in scenarios where the risk of entrapment exists.

At a national level, new editions of the Australian Standards AS/NZS1418.10 AS2550.10 for MEWPs were published earlier this year. The changes were introduced in response to recommendations from coronial inquests, significant incidents, advances in

technology, and current international standards and industry guidelines.

Within the AS2550.10 Safe Use standard, updated recommendations include precautions against crushing. The guidance covers working near overhead or adjacent crush hazards and identifies the increased risk of operator entrapment. The recommendations include travelling with the platform lowered, considering ground conditions, and equipping MEWPs with effective operator protective devices where a crush risk exists.

The risk of crush incidents leading to tragic outcomes is well known. Worksites are urged to add secondary guarding where there is a crushing risk to operators.

BRETT O'HARA INTERIM HRIA EVENTS DIVISON PRESIDENT

In the last few months we’ve seen:

• record crowds in South Australia to watch the first event of the UCI World Tour, the Tour Down Under

• more than 1.1 million fans watching the world’s best tennis players at the Australian Open over 15 days

• the LIV Gold tournament in Adelaide which attracted 100,000 fans over three days

• record crowds in Sydney watching the Sail GP

• more than 460,000 fans at the Formula 1 GP in Melbourne over four days, and

• a quarter of a million people heading to Avalon to get their adrenaline hits at the Australian International Airshow. Of course, behind every great event, our members are making it all possible. It’s also often the first introduction for many young people into the unique work of the events industry and the diversity of jobs on offer. From building temporary structures and marquees, laying temporary flooring and providing furniture, catering equipment, air conditioning, power supply, toilets, temporary fencing, access equipment and general equipment, there’s a world of opportunity on offer. And where else can you be part of a team that brings memorable, one-off, perhaps even life-changing experiences to literally millions of people. It’s why we love what we do. Our industry’s biggest event, HIRE25, is now just around the corner. As part of the program for Events members, Harry the Hirer will be hosting a tour and function at our Brooklyn facility. Hope to see you there! T

AS THE 2024/2025 SUMMER EVENT CALENDAR WINDS DOWN IN THE SOUTHERN STATES, THE TRANSITION TO EVENTS IN THE NORTHERN STATES BEGINS.

What continues to amaze me about our industry is the willingness of our members to invest in world-class equipment to meet the expectations of clients.

Events provide the perfect opportunity for businesses to showcase their products and services in a more personal way and engage with clients in a unique setting. More and more events are also providing opportunities for hirer’s outside of the traditional party/event hire companies.

Members have been involved in thousands of events this season, catering to the smallest weddings and private parties through to local community events bringing people together in celebration, right up to some of the biggest public events held around the country.

"Of course, behind every great event our members are making it all possible. It’s also often the first introduction for many young people into the unique work of the events industry and the diversity of jobs on offer."

100% AUSTRALIAN OWNED, AND STILL 100% AUSTRALIAN ENGINEERED TOUGH, ONE OF AUSTRALIA’S OLDEST, MOST ICONIC AND TRUSTED OEM BRANDS HAS JOINED THE HRIA IN TIME FOR HIRE25.

Engineer and Inventor, Owen Cox realised his dream with his first machine the Cox Mowmobile — with its 26” deck and just 6 hp.

Owen founded an Australian icon and an Australian industry, with machines now with deck sizes up to 72” and engines up to 40 hp.

Established in Brisbane in 1954, COX celebrated its’ 70th Birthday last year. “COX ‘doing it right’ is down to a combination of many things,” said Chris.

“For sure it’s the toughness that comes from a fully fabricated steel deck. Pressed metal is cheaper, but nothing beats properly engineered and fabricated heavy-duty steel... sure, it’s more expensive to manufacture, but it makes for the strongest decks, which is well-suited to the Hire market.”

“COX’s swing-back blades, fitted as standard, oversize wheel and tyre combos, powerful engines with generous fuel tanks and comfortable seats are designed so you can mow all day.”

“COX have always been a regional brand, where their toughness enables our engineering to prove COX’s metal on those larger family blocks.”

“Since Covid, we’re seeing more families moving to city fringe and regional Australian towns.” said Chris.

“These families need yard care equipment, and COX has the best range available. Heavy-duty ride-ons and zero turns, push mowers and cylinder mowers, scarifiers, log splitters, chippers, generators and pressure washers,” said Chris, “All engineered tough for Australia’s unique conditions.”

“For those customers wanting to use a machine once or twice a year, or those establishing themselves in a new home or community, who need to be budget conscious, hiring a scarifier or log splitter makes a lot of sense.

“For contractors who need a temporary fill-in machine or an additional machine quickly, hiring is the best option,” said Chris.

“If you’re a hire company, you need your machines to be built tough and hassle free to operate. Once it’s hired out you need the machine to work first-time, every time, and be problemfree for the full hire period.”

“COX has the largest dealer network of any mower and machinery brand in Australia with sales, service, parts and repairs at over 200 locations across Australia,” said O’Leary.

As for what the future holds, Chris said: “What about fully autonomous zero-turn mowing at over 20 km/hr? That’s a footy field and in-goal areas every 15 minutes.”

To discover the range Cox has to offer, visit them on stand #172 at HIRE25.

AS THE HIRE AND RENTAL INDUSTRY CONTINUES TO DEMAND SMARTER, MORE VERSATILE AND COMPACT EQUIPMENT, MERLO HAS ANSWERED WITH A LINE-UP PURPOSE-BUILT FOR PRODUCTIVITY, DURABILITY AND OPERATOR EASE. THIS YEAR AT HIRE25, VISITORS TO STAND 57 WILL GET UP CLOSE WITH OUR STANDOUT PERFORMERS IN THE HIRE SECTOR: THE TF27.6 AND P27.6 TELEHANDLERS, ALONGSIDE OUR COMPACT POWERHOUSE—THE MERLO CINGO TRACKED CARRIER.

The TF27.6 and P27.6 telehandlers are part of Merlo’s Compact Telehandler range—machines that pack serious capability into a size that’s ideal for hire fleets. Weighing under 5 tonnes and standing under 2 meters high, these machines are tailor-made for tight sites, from urban construction zones to landscaping jobs.

The TF27.6 offers all the premium features you'd expect from a Merlo: 2.7-tonne lift capacity, 6-meter reach, hydrostatic transmission, and class-leading comfort with an enclosed, air-conditioned cab. It’s designed for operators who spend all day in the seat and need the job done efficiently and safely. Its versatility makes it an easy hire win—from builders and tradies to facility managers and event contractors.

The P27.6, slightly more stripped down for simplicity, still delivers Merlo’s renowned reliability and safety systems. It's a no-fuss solution for general material handling—easy to transport, intuitive to operate, and low-maintenance, which means more time on hire and less time in the yard.

For smaller load applications and tight access sites, the Merlo Cingo tracked carriers offer a unique edge. Whether it's moving material across uneven terrain or operating with attachments like dumpers, augers or mini-loaders, the Cingo is a hire-ready solution for a broad range of industries including landscaping, construction, demolition, arbor, and events.

These compact carriers are engineered with highperformance petrol engines and intuitive controls, making them perfect for both professional contractors and DIY users. Their small footprint and low ground pressure make them ideal for indoor and turf-friendly tasks—an increasingly important consideration for modern worksites.

All Merlo machines are engineered with the hire and rental industry in mind. Durability, simplicity, and serviceability are key. The TF27.6, P27.6, and Cingo models are all built to be easy to transport, intuitive to operate, and quick to maintain—maximising hire uptime and minimising headaches for owners and users.

Merlo is manufactured 100% in-house in Italy and backed by over 60 years of engineering experience, innovation heritage, quality, and reliability.

GROUNDBREAKING INNOVATION REPRESENTS MORE THAN JUST A NEW PRODUCT: IT'S A DEFINING STEP IN THE INDUSTRY'S JOURNEY TOWARDS DECARBONISATION, ENERGY, AUTONOMY AND OPERATIONAL EFFICIENCY.

Dutch infrastructure company Van Doorn, one of the first to trial the prototype, had initial doubts. But the B-Air quickly proved itself by running an entire work shift without compromise. Quiet, emission-free, and highly mobile, the unit helped maintain productivity while aligning with their environmental goals.

Remko van Piggelen of Perslucht Wilda, the dealer who partnered with Atlas Copco to pilot the prototype, emphasized how the B-Air fills a significant market gap. “Our customers work in locations where plug-in electric units just don't cut it. The B-Air meets the demand for a fully mobile, battery-powered solution.”

This success is part of Atlas Copco's broader mission. Having already released the plug-in E-Air VSD range in 2018, the B-Air represents the next leap — removing all dependency on external power. Whether it's road construction, crash barrier work, or fibre optic cable installation, the B-Air brings a new level of freedom to the field.

The B-Air 185-12 also significantly reduces noise pollution (operating at just 61 dB at 7 meters) and operating costs, making it a smart choice for urban environments, indoor applications, and sustainability projects.

“Our goal is simple,” says Maarten Vermeiren, Product Marketing Manager for Sustainability and Digitalisation at Atlas Copco. "We aim to offer diesel-free alternatives for every user, and the B-Air is a bold step in that direction.”

Aimed squarely at accelerating the transition to a lowcarbon economy, the B-Air 185-12 eliminates the need for diesel and external electricity sources, thanks to its integrated 57kWh lithium-ion battery. This means complete mobility and zero local emissions — all while delivering the same productivity and performance expected from a traditional diesel unit.

With advances in energy storage and a growing global push toward sustainable solutions, Atlas Copco has made the vision of a fully battery-powered compressor operating independently on remote job sites a reality.

As clients focus on reducing emissions, Atlas Copco continues to lead by example, offering clean, efficient, and high-performance alternatives. The B-Air is not just a product, it's a commitment to a future where sustainability and productivity go hand in hand.

In the words of Richelle E. Goodrich, “The direction you choose to face determines whether you're standing at the end or the beginning of the road.”

With the B-Air 185-12, Atlas Copco is unmistakably choosing the beginning — and driving us all toward a greener tomorrow.

IN THE BUSINESS OF CONCRETE FINISHING, A CONCRETE POWER TROWEL IS ONE OF THE KEY PIECES OF EQUIPMENT YOU’LL NEED TO CREATE A FLAT AND LEVEL CONCRETE FLOOR. WHEN COMPARED TO THE PROCESS OF HAND TROWELLING, IT WILL MAKE ANY CONCRETING JOB EASIER, AND GIVE YOUR WORK A HIGHQUALITY, PROFESSIONAL FINISH.

Once you’ve made the decision about which type of power trowel is right for your business and application, you’ll need to choose your machine. Look for a power trowel from a reputable brand, with a reliable engine that will last the distance. Check the safety features. Make sure the operation is simple. Look at the comfort factor — are the hand grips or the seat ergonomic and easy to adjust? Consider whether a lifting hook is a necessary addition. For the construction trade professional, having the right equipment can make every job easier, of better quality and more profitable. Flextool is here to help you to find the power trowel you need.

Flextool has a huge selection of walk-behind and ride-on concrete power trowels, as well as replacement blades and pan floats in a wide range of sizes.

Investing in a concrete power trowel isn’t cheap, so you need to get it right.

One of the main decisions will be whether to purchase a walk-behind power trowel or to invest in a ride-on trowel machine. For residential projects, a walk-behind should do the job, as the slabs are likely to be limited in size. Walk-behind power trowels provide easy portability and manoeuvrability in smaller spaces. If you’re doing regular medium to largescale commercial projects — upwards of 500-600 square metres at a time — a ride-on power trowel will be well worth the extra investment. A ride-on power trowel has more power, increased weight and a wider finishing path, so a single operator will be able to achieve a higher quality floor in less time, leaving you free to move on to the next job.

The latest all-new Flextool ProFinish Series 2 WalkBehind and Flextool ProFinish Series 4 Ride-On Power Trowel models introduce enhanced operator features such as ergonomic controls, optimised weight distribution, practical water bottle holders and more, because small details can make a big difference on the job site. Plus, improved serviceability and durability features make this range perfect to endure the high demands of the hire and rental industry.

Whatever the demands of your business, Flextool has the right concrete power finishing equipment for the job.

When it comes to concrete power finishing, Flextool ProFinish has been a trusted choice for professional contractors, delivering the performance and reliability needed to get the job done right. Now, we’ve taken this proven range and made it even better. Built with the user in mind, the all-new Flextool ProFinish Series 2 Walk-Behind and Flextool ProFinish Series 4 Ride-On Power Trowels combine durability, precision, and innovation to ensure the best possible flat floor results are achieved on every slab. The latest models introduce enhanced operator features such as ergonomic controls, optimised weight distribution, practical water bottle holders and more, because small details can make a big difference on the job site. Plus, improved serviceability and durability features make this range perfect to endure the high demands of the hire and rental industry.

CAPABLE OF HANDLING HEAVY LOADS IN TIGHT SPACES, DIECI’S NEW APOLLO 20.4 SMART TELEHANDLER IS PROVIDING BOTH STRENGTH AND SAVINGS TOGETHER IN ONE POWERFUL MACHINE, MAKING IT A HIGHLY VERSATILE MACHINE FOR ALL HIRE CUSTOMER MARKETS.

Operators working in confined or small areas where materials need to be quickly moved, lifted, transported or stored, demand equipment and special-function vehicles that are more compact, efficient, highly manoeuvrable and safe to use.

Dieci National Sales Manager, Bob Mules said the Apollo 20.4, “has been designed specifically to deliver highperformance and effortless manoeuvrability in tight spaces, without compromising on power or precision.”

“This 37kW Kubota engine-powered product was only released recently. Rapid sales indicate a clear need in the market for the new machine.”

Giving out 25kph, the advanced engine and transmission deliver an unbeatable combination of power and efficiency.

Three steering modes: 2-wheel, 4-wheel and crab steer — make for smooth navigation and responsiveness even when carrying full loads.

Despite the telehandler’s compact dimensions, Bob said it provides several features designed to improve operator comfort.

The cab is roomy and ergonomically optimised, ensuring comfort even during extended periods of use, while there is an updated dashboard contributing to a more intuitive and efficient operating experience.

The controls, including a proportional joystick, are designed for ease of operation, reducing fatigue and allowing precise handling of the telehandler. The cab has large windows, providing excellent visibility in all directions, enhancing safety and convenience.

“Dieci engineers have added patented features that simplify maintenance. The Apollo brings strength and savings together in one powerful machine,” Bob said.

“Weighing 4300 kilograms unladen, the telehandler has a robust boom that can handle heavy loads up to 2000 kilograms to an impressive height of 4.35 metres, while its horizontal reach is 2.57 metres,” he said.

“The fork has a swivel angle of 133o with a gradeability of 56 per cent, providing the lift capacity of a hydraulic forklift with the reach and elevation of a crane.

“A wide range of attachments let the Apollo take on multiple tasks with a single machine, making it ideal for construction tasks such as moving materials, lifting heavy

loads to elevated positions, handling scaffolding, and assisting in building structures,” Bob said.

“Making sure sales, parts and service functions are integrated, Dieci aims to provide the best possible customer experience, whether they are buying one or 20 machines.

“Dieci has a commitment to customisation to suit market needs and has a proven record in specialised products that are supported by a strong national parts and service network.”

AS BUSINESSES ACROSS AUSTRALIA STRIVE TO BECOME MORE ENVIRONMENTALLY RESPONSIBLE, THE INTRODUCTION OF STRICTER SUSTAINABILITY REGULATIONS IS SET TO CREATE BOTH CHALLENGES AND OPPORTUNITIES.

KAESER Compressors Australia is ready to assist businesses at every stage of their sustainability journey, whether it’s as simple as cutting back energy use or as complex as meeting international targets such as the United Nations' Sustainable Development Goals (SDGs).

True to KAESER’s philosophy of “More compressed air for less energy”, KAESER products are designed to operate with exceptional energy-efficiency and ecofriendliness. Beyond this, KAESER minimises the use of valuable environmental resources throughout production, distribution, and service.

In addition to energy efficiency, KAESER provides advanced ancillary services, including Air Demand Analysis (ADA) and K-Air remote monitoring. These services help businesses improve uptime, conserve resources, and implement circular economy practices by extending product life times and reducing reliance on fossil fuels. For businesses working to reduce carbon emissions or adopt comprehensive sustainability strategies, KAESER’s offerings are specifically tailored to support these objectives.

To meet its commitment to sustainability, KAESER has developed a forward-thinking, organisation-wide concept: Rethink. Research. Reduce. Repair. This approach integrates sustainability into every step of product development and operations. From the design stage to maintenance and logistics, KAESER ensures that environmental responsibility is embedded across the entire lifecycle of its products.

• Rethink: Sustainable product development requires new approaches. KAESER equips employees with Design Thinking skills at the Hasso Plattner Institute to develop innovative, resource-efficient solutions.

• Research: With over 100 years of expertise, KAESER utilises advanced simulation, calculation tools, and prototype validation to create highly efficient, dependable, and eco-friendly compressed air systems.

• Reduce: Recognising that the most resource consumption occurs during long-term operation, KAESER prioritises energy efficiency to ensure minimal environmental impact. Packaging materials have also been adapted to more eco-friendly choices, significantly reducing its carbon footprint.

• Repair: Maintenance-friendly design is evaluated and optimised by its Service Technicians to extend product lifecycles and reduce waste.

KAESER’s headquarters in Germany has set ambitious sustainability goals with aims to reduce direct emissions (Scope 1) and indirect emissions (Scope 2) by 80% by 2030 (compared to the base year 2019). Indirect emissions from the upstream and downstream value chain (Scope 3) are also estimated to decrease by 15% over the same period.

As businesses face growing expectations for responsible practices, KAESER Compressors Australia is prepared to guide them in reducing energy use, enhancing operational efficiency, and meeting regulatory requirements. KAESER offers custom solutions designed to meet unique needs and support meaningful progress toward sustainability.

For more on Kaeser’s sustainability solutions, visit: au.kaeser.com/company/sustainability/resourcesaving-product-development/

At KAESER, our approach - Research, Rethink, Reuse and Repair - ensures that we minimise resource consumption from the ground up. Every step, from product development to production and maintenance, is designed with environmental responsibility in mind. Learn more at au.kaeser.com/company/sustainability or speak to us at HIRE25 stand 50

AUSSIE PUMPS’ CHIEF ENGINEER, JOHN HALES, TELLS US HOW AUSSIE IS GOING IN SUPPORT OF HIRE WITH A GLIMPSE OF THE FUTURE.

“When we built the first Scud 15-16 years ago, we launched a sleek design with no ‘sharps’ and weight distribution for the machines to be highly manoeuvrable,” said John Hales.

“We fit oversized Bertolini pumps with a huge, finned crankcase and a gear box drive, which means the pump runs at 1450 rpm but still produces 4,000 psi pressure, that can last for decades.”

“We go to extraordinary lengths to make sure it’s safe and attractive to the renter. They like the beefy Bobcat-style design, that’s a bit like a racing car. The complete frame and base is all stainless steel. It’s organic as hell”, said Hales.

“We know that the hire industry is exceptionally sensitive about the safety of the products being hired. It’s vital the customers who rent them know what they’re doing.” Aussie have gone to major efforts to make the unique Scud design easy to push around, well balanced and capable of being used stress-free, on construction sites.

Several years ago, the Standards Association issued a ruling that high pressure cleaners should be divided into Class A & B categories. Operators of Class A machines were not required to have RTO certification but Class B operators did.

Aussie caution on introducing Class B machines into a hire fleet. “Yes, they have more grunt and you can rent them for more, but if anything goes wrong, and the operator doesn’t have certification, both the hire company and the operator can be in serious trouble,” said John.

“Class A machines on the other hand, don’t require certification. Our Scud 400 and even our Ultra 4,000 psi 20 lpm Scud are Class A.”

Aussie Pumps offer a simple one-page summary of the classification to help customers decide what’s right for them.

Aussie offer a complementary Safety Training Course, built around their unique knowledge of operator issues within a range of trades. “We know what can go wrong and our course goes a huge way towards reducing the possibility of injuries. We recommend all hire operators renting pressure cleaners should do the course and even put their staff through it. It only takes around half an hour and is worth every second!”

For comprehensive advice and documentation on safety, technology and Triplex pumps call the Aussie Hire team 02 8865 3500. aussiepumps.com.au.

GEOTRENCHER IS HERE HELPING BUSINESSES SAVE TIME, EFFORT, REDUCE UNNECESSARY RISK AND MAKE MORE MONEY BY MAKING TRENCHING TASKS EASIER FOR IRRIGATION, PLUMBING, NBN, ELECTRICAL AND FENCING PROJECTS.

Husband and wife team, Olivia and David McNabb operate the distribution and service for Geotrencher, handheld trenchers from NZ.

“The Geotrencher products gives us a lot of joy!” said David. “We love getting feedback from people in the irrigation and landscape sectors, when they first use the Geotrencher.”

As such a small operation, the McNabbs struggle to get the word out about their product range and how they can add value to end users. Having recently joined the HRIA, they look forward to seeing how the HRIA membership can give them greater market reach, with HRIA’s networks allowing them to communicate the credibility of their products and back-up service.

The Geotrencher is an adaptor or conversion to quick cut or concrete saws — not chainsaws. This gives the 400mm, 500mm or 700mm bars a longer life in the dirt that the old chainsaw versions did not have. Being able to cut 36mm or 58mm wide opens up a lot of applications for both easier

access or transport of the tools or quicker installation than a backhoe or mini digger.

“We get a kick out of the many uses or hacks that people share with us when using the trenchers, such as using to channel under footpaths to run lines, trenching hard up against buildings, doing a double cut to remove grass, removing trees or cutting out Agapanthus!”.

David says that they had a call from one customer telling them the machine has even helped them finish their apprenticeship. Others tell them: “Without this machine, [customers] would not take on these types of jobs,” which is just the kind of feedback they believe hire companies look for when adding new equipment to their range.

“We are getting requests every week to hire these trenchers which, alone, we cannot keep up with,” added David, “so our website now points customers to where they can hire them”.

To find out how Geotrencher can help stock, advertise and manage hires visit www.geotrencher.com.au

Record360 helps you capture equipment condition with confidence, before and after every hire. With time-stamped photos, e-signatures, and mobile inspection checklists, rental teams reduce damage disputes by up to 60% while recouping 5–10x their monthly spend.

Built-in AI blur detection ensures every photo is sharp, so there’s no room for doubt. See it in action and drop by our stand: salesau@record360.com

See Record360 live at HIRE25 in the Point of Rental Booth