Introduction

Hiras Ferrandino Industrial Design Engineer

Hiras Ferrandino Industrial Design Engineer

hiras93@hotmail.com

03 / 03 / 1993

Local

Dutch

Product Designer 09-2023 to 12-2023 in Den Haag

Design, development and construction of a climate box test model. Set up and apply test protocols for measuring: airflow behavior, speed and noise levels in dry and wet conditions.

Optimizing parts and material choices based on costs, production and assembly by applying different Design for X methods during the development process. Making production drawings and communicating with manufacturers and suppliers.

West 8

Assistant Designer

09-2021 to 03-2023 in Rotterdam

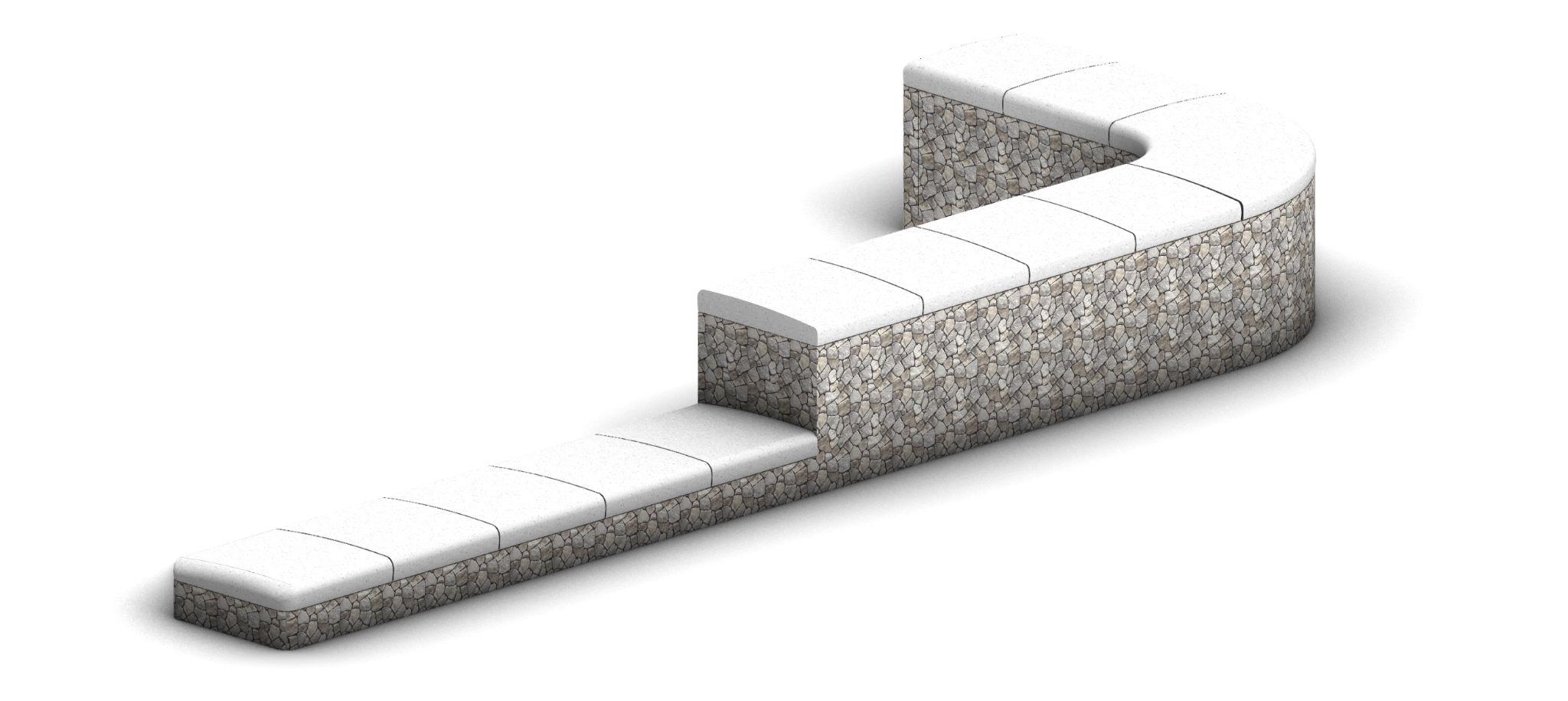

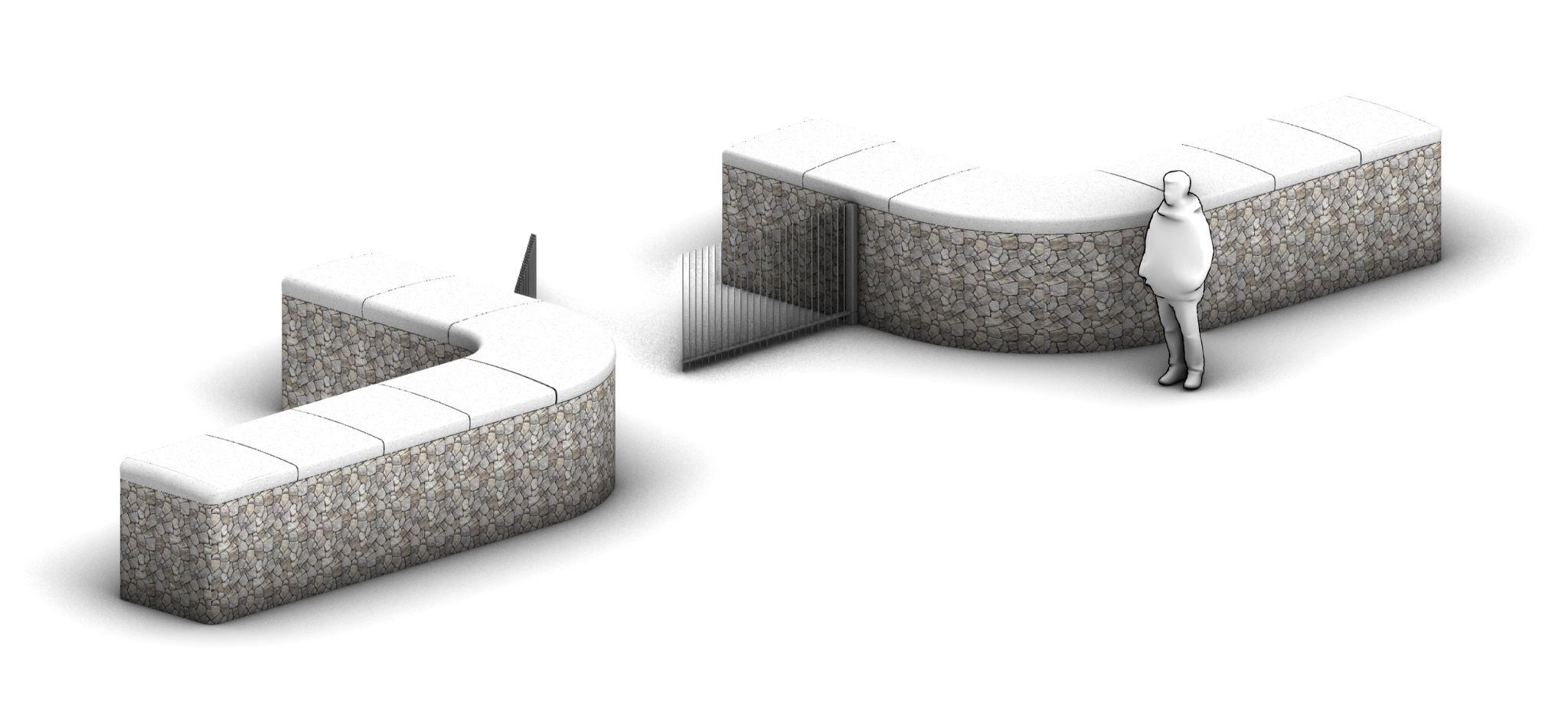

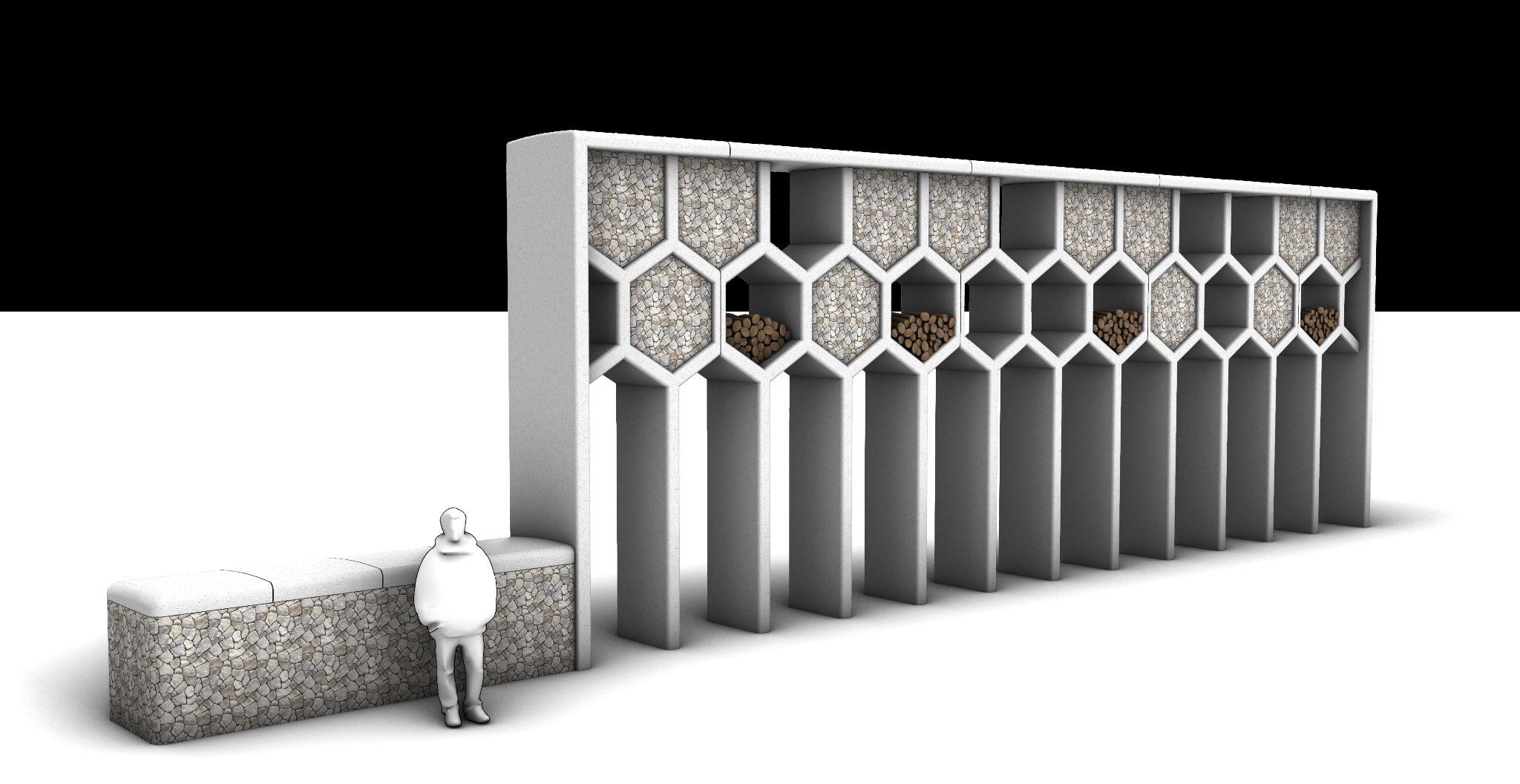

Assisted in the concept developing, designing and 3D modelling of various urban furniture elements for ongoing projects and tenders such as: sitting elements, lighting elements, planters and safety features.

Optimising modular systems of planter and sitting edges through design studies and 3D printing of 1 to 10 scale models.

Part of the design team on the collaboration project with Selux for designing and developing a new luminaire for public spaces. Preparing presentations for client meetings and communicating with manufacturers and suppliers.

West 8

Product Design Intern 02-2021 to 07-2021 in Rotterdam

Assisting in the concept development, design and 3D modeling of various urban furniture elements.

• Sketching

• Storyboarding

• User research

• Model-making

• 3D printing

• Rapid prototyping

• Rhinoceros 3D

• SolidWorks

• Onshape

• SketchUp

• AutoCad

• Adobe CS

• Ultimaker Cura

• Office 365

• Lumion

+31 (0) 616203896 Talmastraat 14, 2021CM Haarlem

linkedin.com/in/hiras-ferrandino-867521163

Hi there! I am Hiras, an Industrial Design Engineer.

I was born in Italy, but I’ve been living in the Netherlands since I was 13.

What I like most about Product Design is the ability to really bring your ideas to life, shape them into something that is tangible and that works. I think it’s remarkable that sometimes the biggest problems can be solved with something small and simple.

I like to work in the workshop with wood, metal, clay and other modelling materials but I also find new materials and the possibilities they bring very interesting. During my studies and work as a product designer also familiarised myself with 3D printing using an Ultimaker S5, experimenting with different thermoplastic and composite materials to print various scale models and prototypes.

One of the things I like to do the most in my spare time is swimming: I’ve been swimming in competitions with my club and I have participated a few times at the Open Dutch Championships.

My other interests include sports, movies, series, music and video games.

Graduated on the collaboration project with German lighting company Selux for the design and development of a new lighting fixture for public spaces. Preparing presentations for client meetings and communicating with manufacturers and suppliers.

4Littlebirds

Design & Development Intern 02-2020 to 07-2020 in Amstelveen

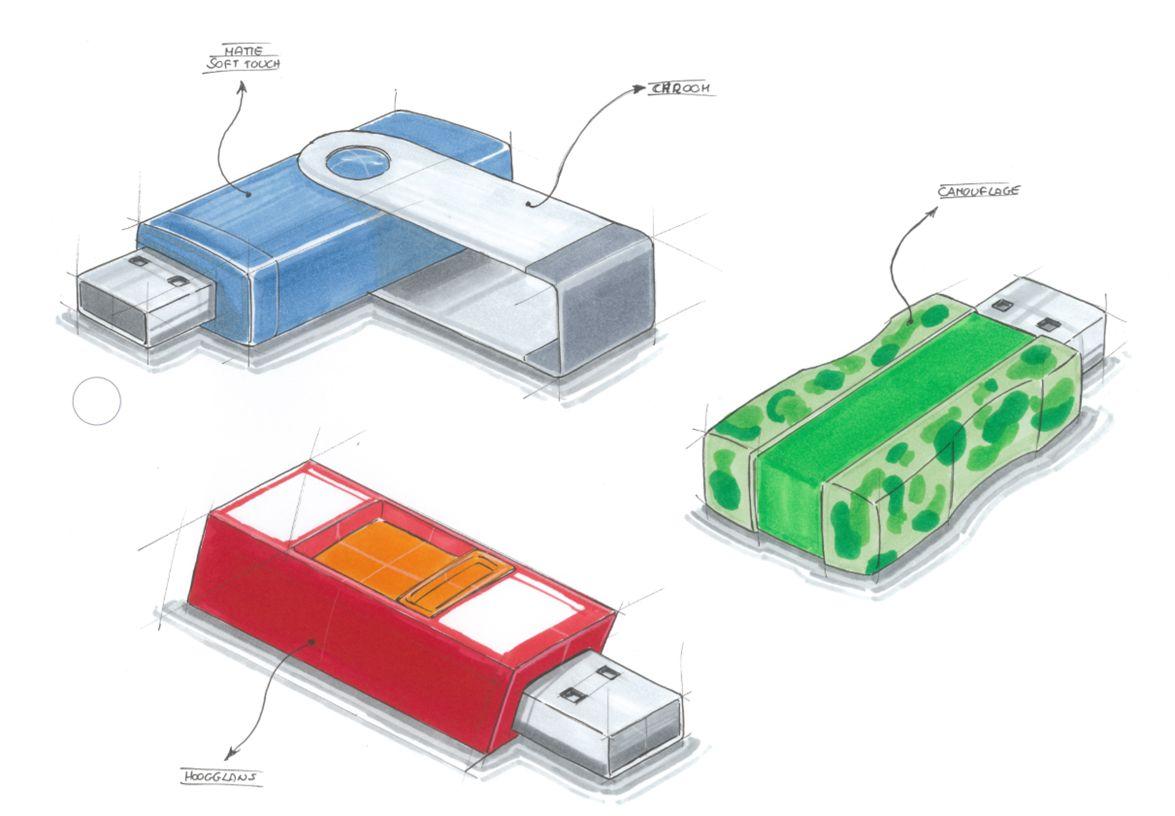

Assisted in the concept designing and developing of various brand-activation products and solutions for brands such as Jagermeister, Beefeater Gin & Absolut Vodka.

EDUCATION

2016 - 2021

Hogeschool van Amsterdam Amsterdam, Netherlands

Bachelor Engineering, Product Design

2006 - 2012

Rudolf Steinerschool

Haarlem, Netherlands

HAVO Diploma, Natuur & Gezondheid/Natuur & Techniek

2004 - 2006

Scuola Media

Ferrara, Italy

LANGUAGES

• Italian (mother tongue)

• Dutch (fluent written & spoken)

• English (fluent written & spoken)

OTHER INTERESTS

Competitive Swimming, Sports, Movies, TV Series, Drawing, Video Games

WORK PROJECTS

1. CLIMATE BOX

2. AYA LUMINAIRE

3. LIFE SCIENCE CENTER

4. CANNES COMPETITION

5. PAYSANDÚ WATERFRONT

STUDIES PROJECTS

6. DESIGN INTELLIGENCE

7. INTEGRATION DESIGN

8. PRODUCT DIMENSION

9. PERSONAL PROJECT

WORK PROJECTS

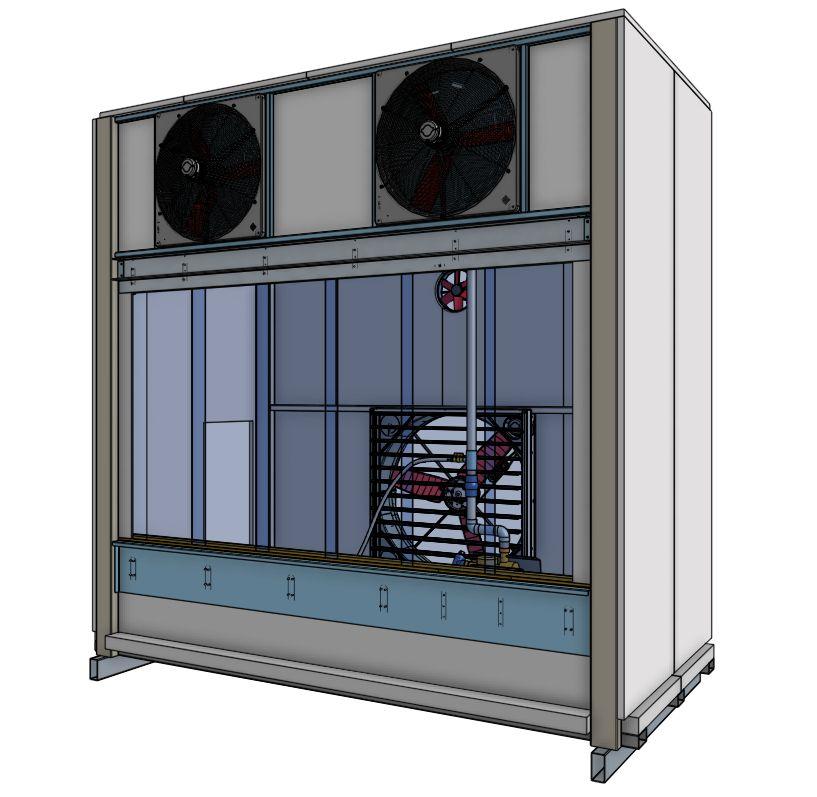

Climate Box

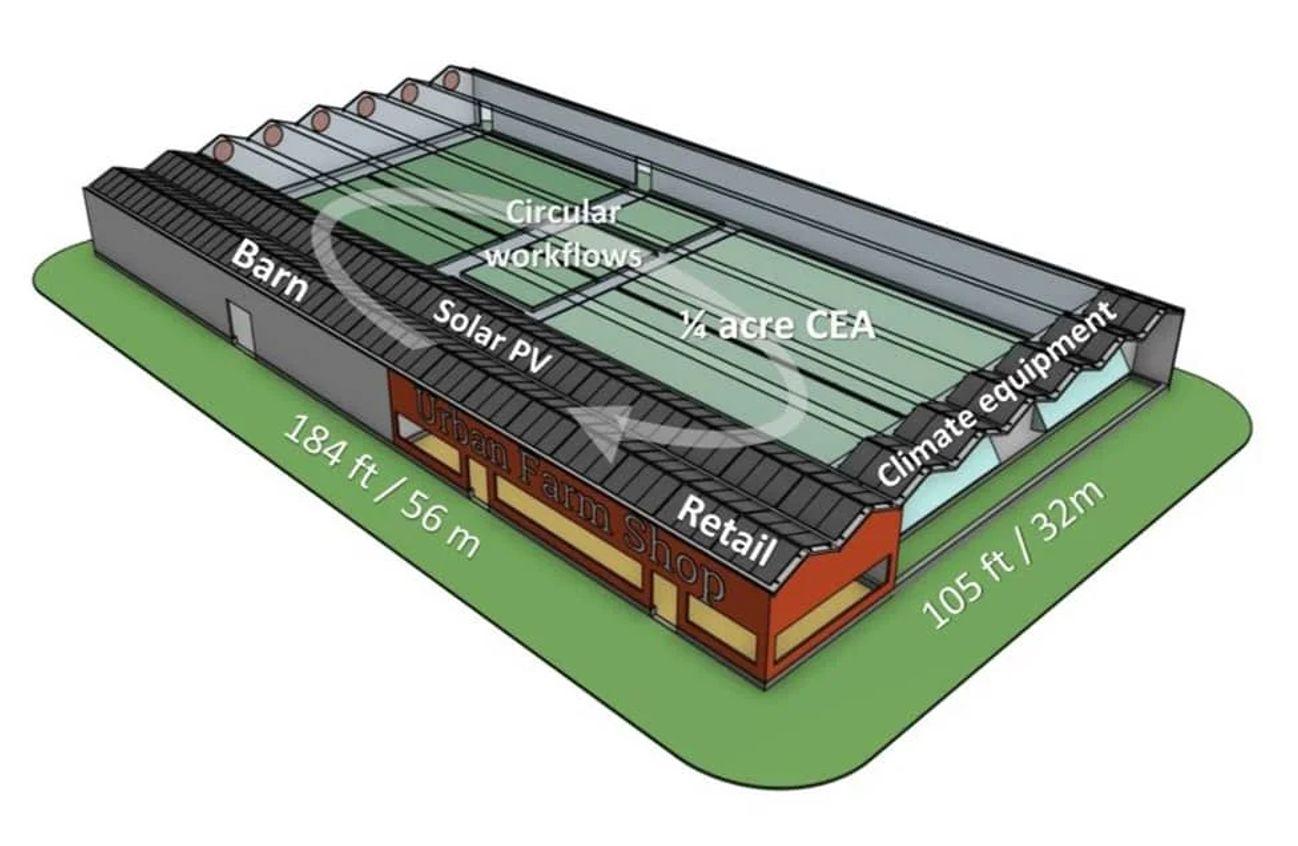

LOCAL DUTCH URBAN FARM SHOP

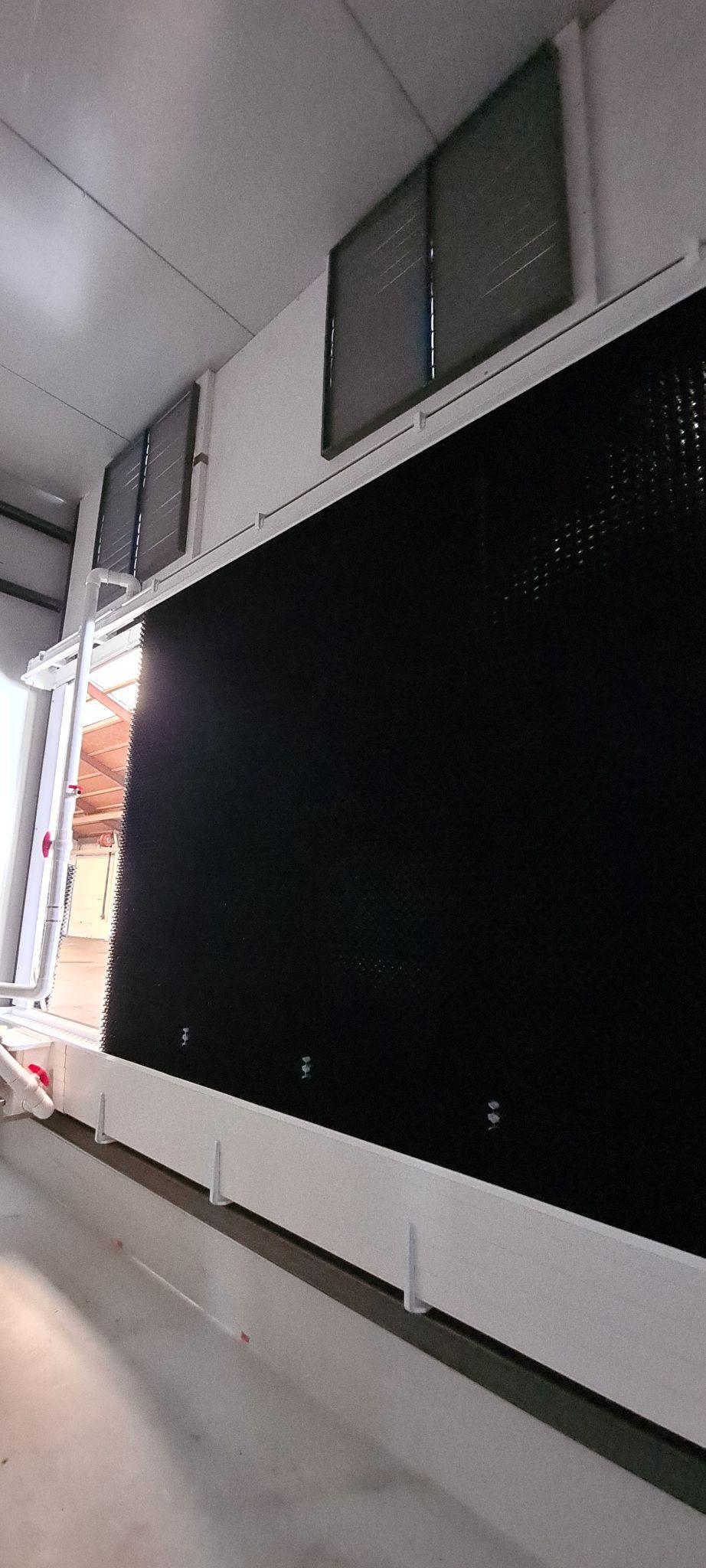

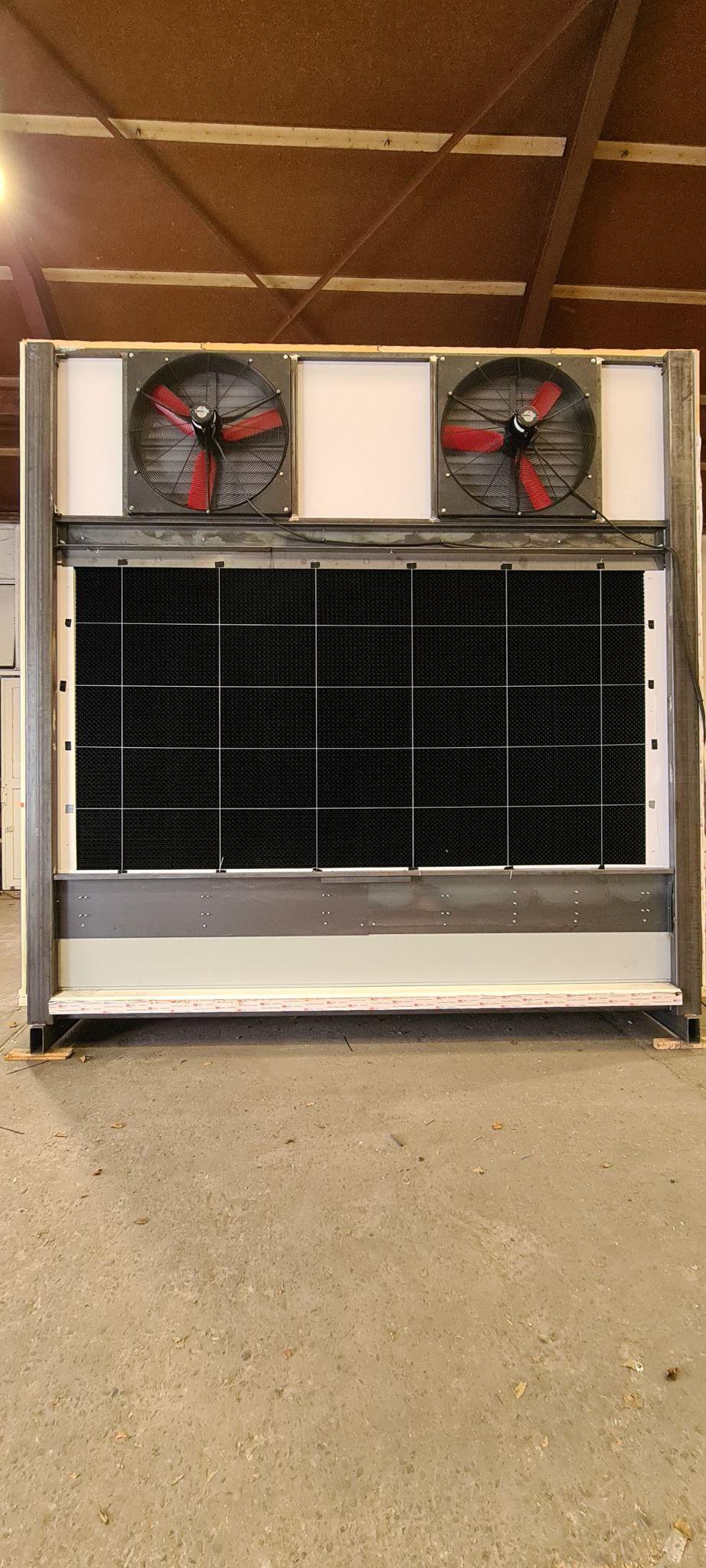

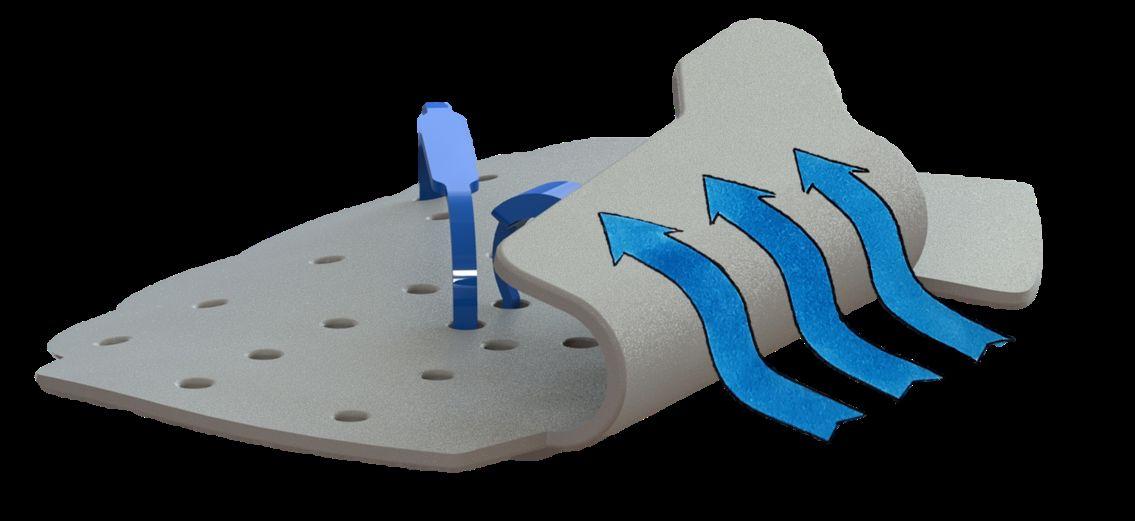

From september until the end of december of 2023 I was hired by the start-up company Local Dutch to design and build a climate box test model.

Set up and apply test protocols for measuring: airflow behavior, speed and noise levels in dry and wet conditions.

Optimizing design and material choices based on costs, production and assembly by applying different Design for X methods during the development process.

Identifying suitable production partners. Making production drawings and communicating with manufacturers and suppliers.

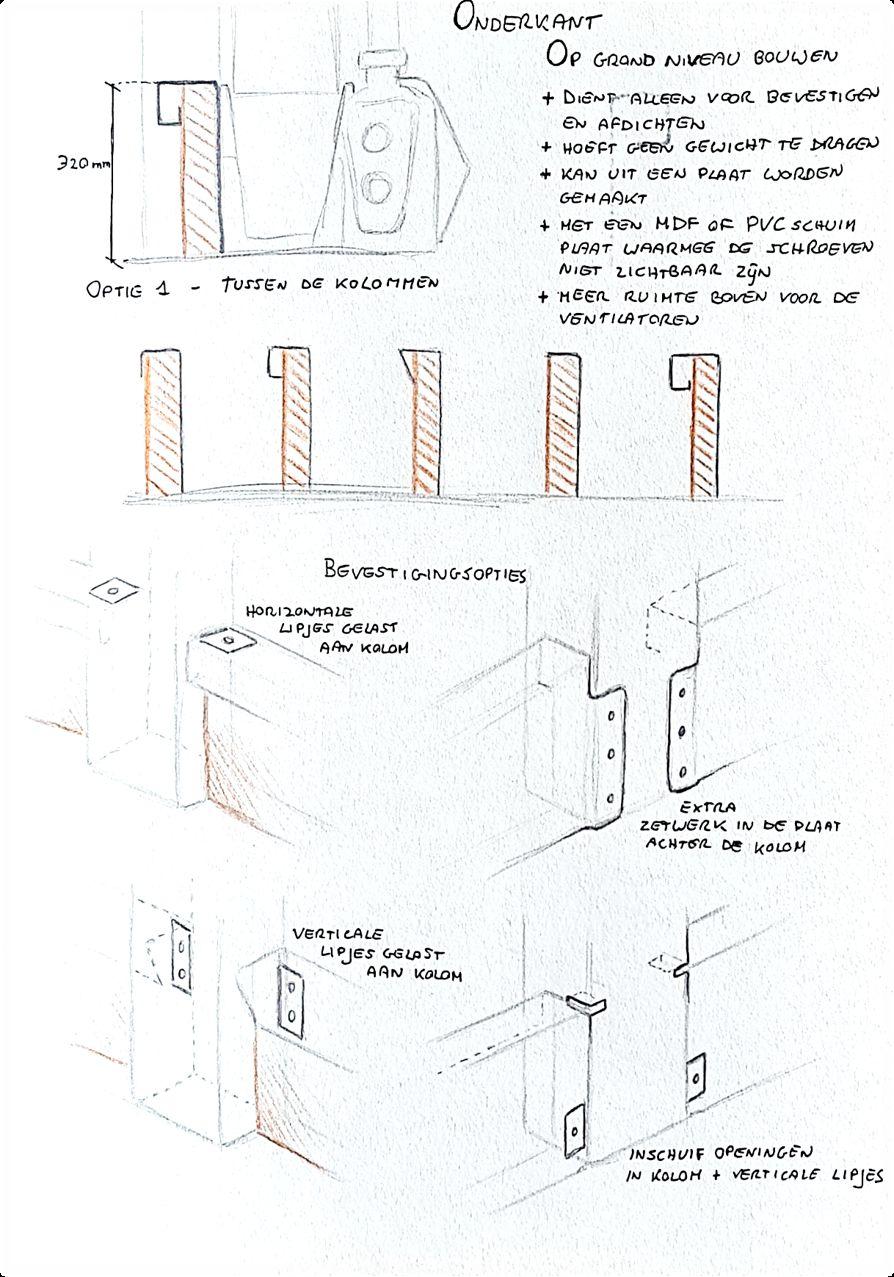

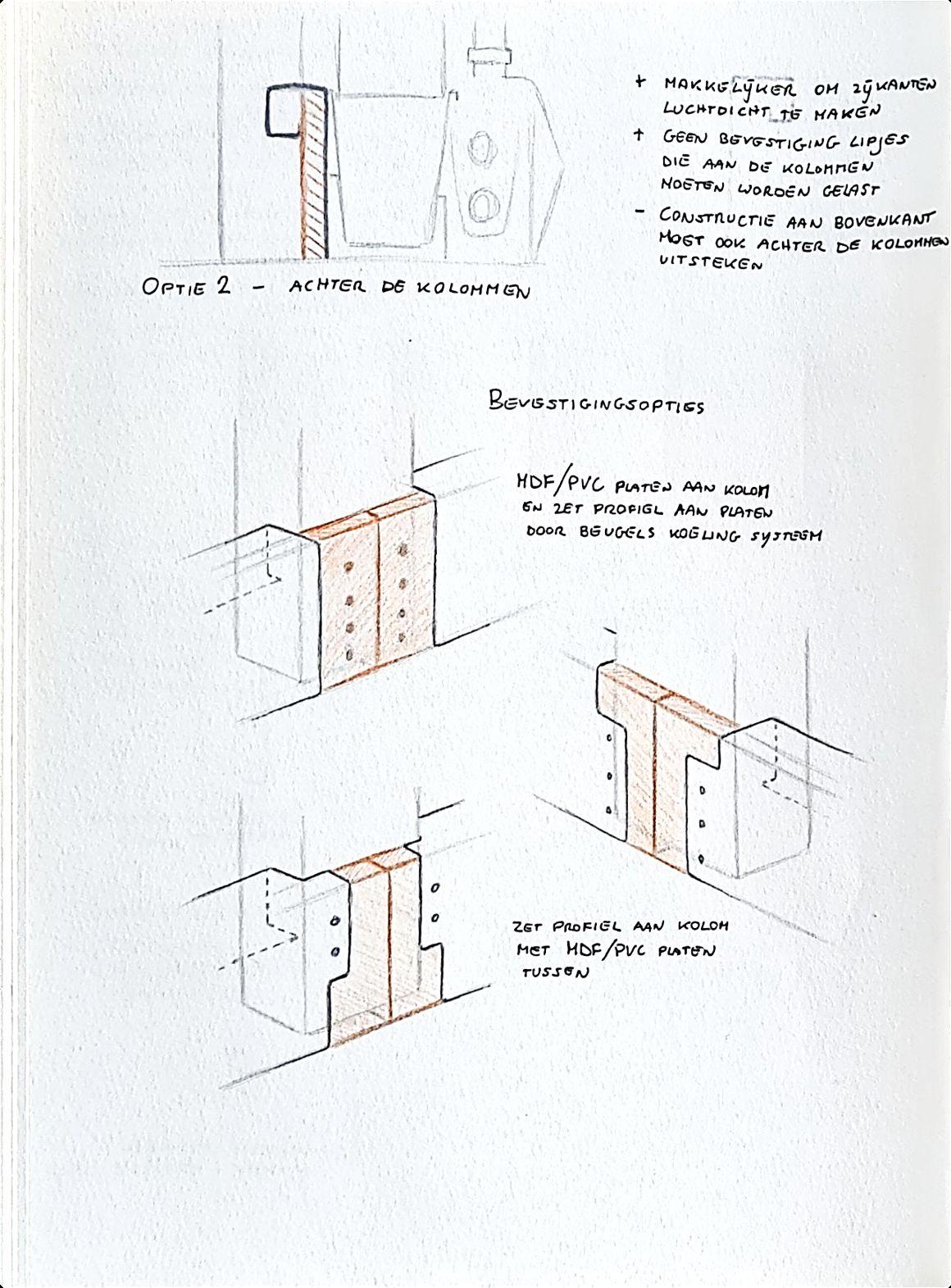

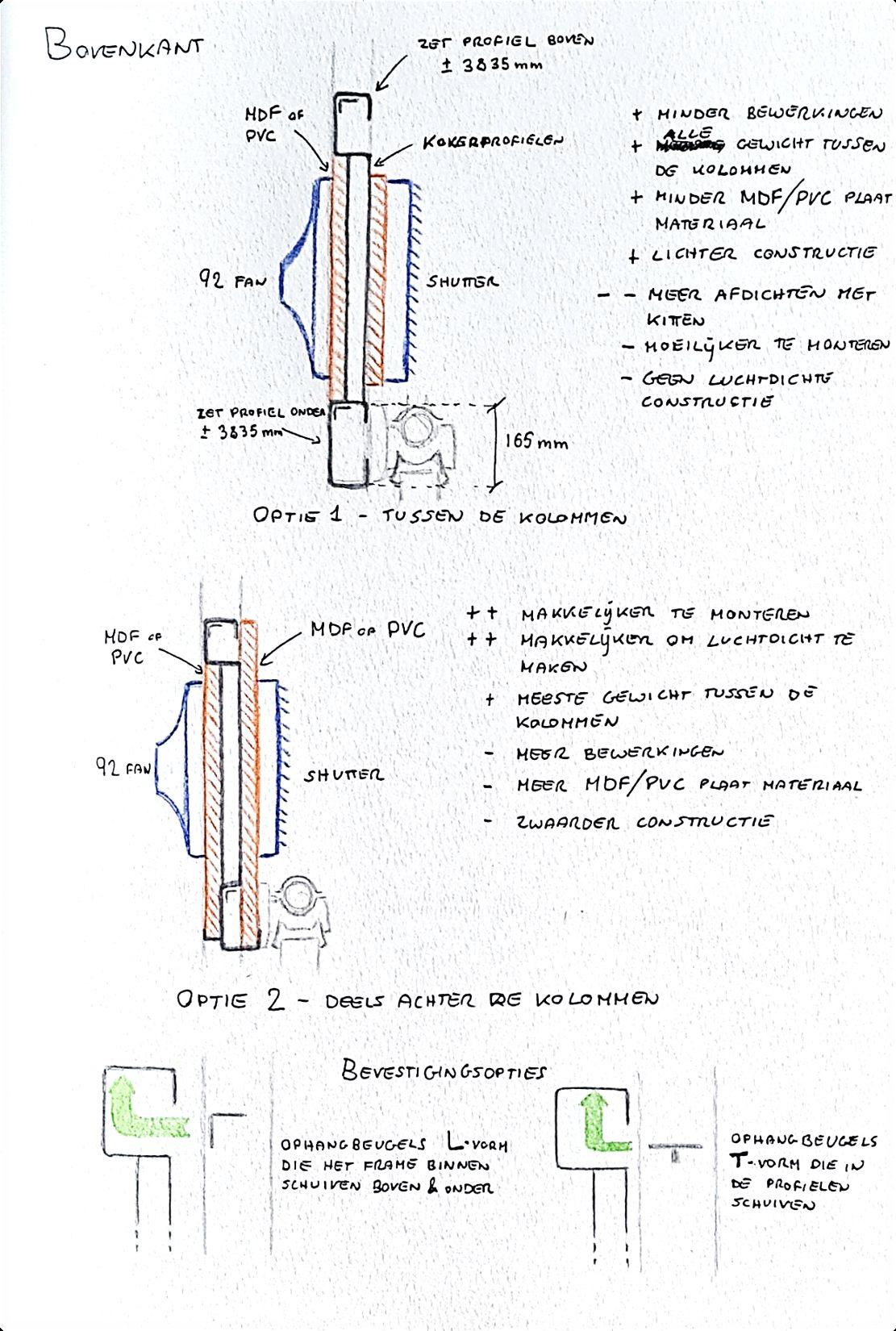

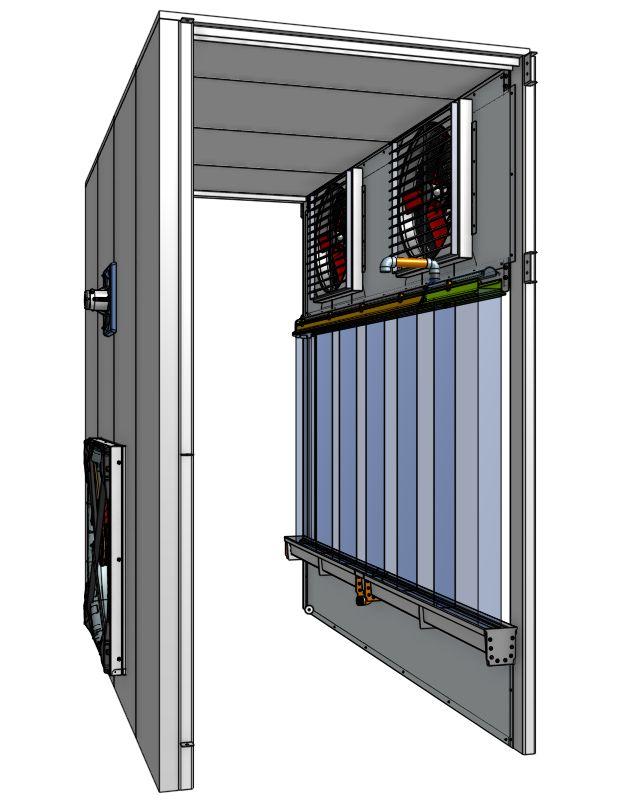

BUILDING THE PROTOTYPE

During the ideation phase, and also during the progression of the project, it was essential to make a clear list of design requirements for the to be built prototype and the 2.0 version. Some of the key requirements were:

● Upper-front structure/frame must be able to hold the weight of 2 ventilators, 2 shutters, sealing panels and the water delivery system of the padwalls while it's running

● Upper and lower front structures must be airtight

● Sealing panels must be suitable for building in greenhouses/humid working environments

● Upper-front structure/frame parts must be as light as possible

PROTOTYPE TESTING

After the working prototype was built and ready to use I designed and set up test protocols for measuring and gather data on:

● Airflow behavior

● Airspeed

● Noise levels in decibels

These tests were then carried out multiple times under different scenarios and under both dry and wet conditions.

IMPROVING THE DESIGN

Parallel to working on the prototype at our test location I would also work on the 2.0 version of the Climate box.

Optimizing the design of the different parts based on costs, production and time of assembly estimations by applying different Design for X methods during the development process.

During the project I also identified suitable production partners that could make the different parts at the desired level of accuracy and made the production drawings.

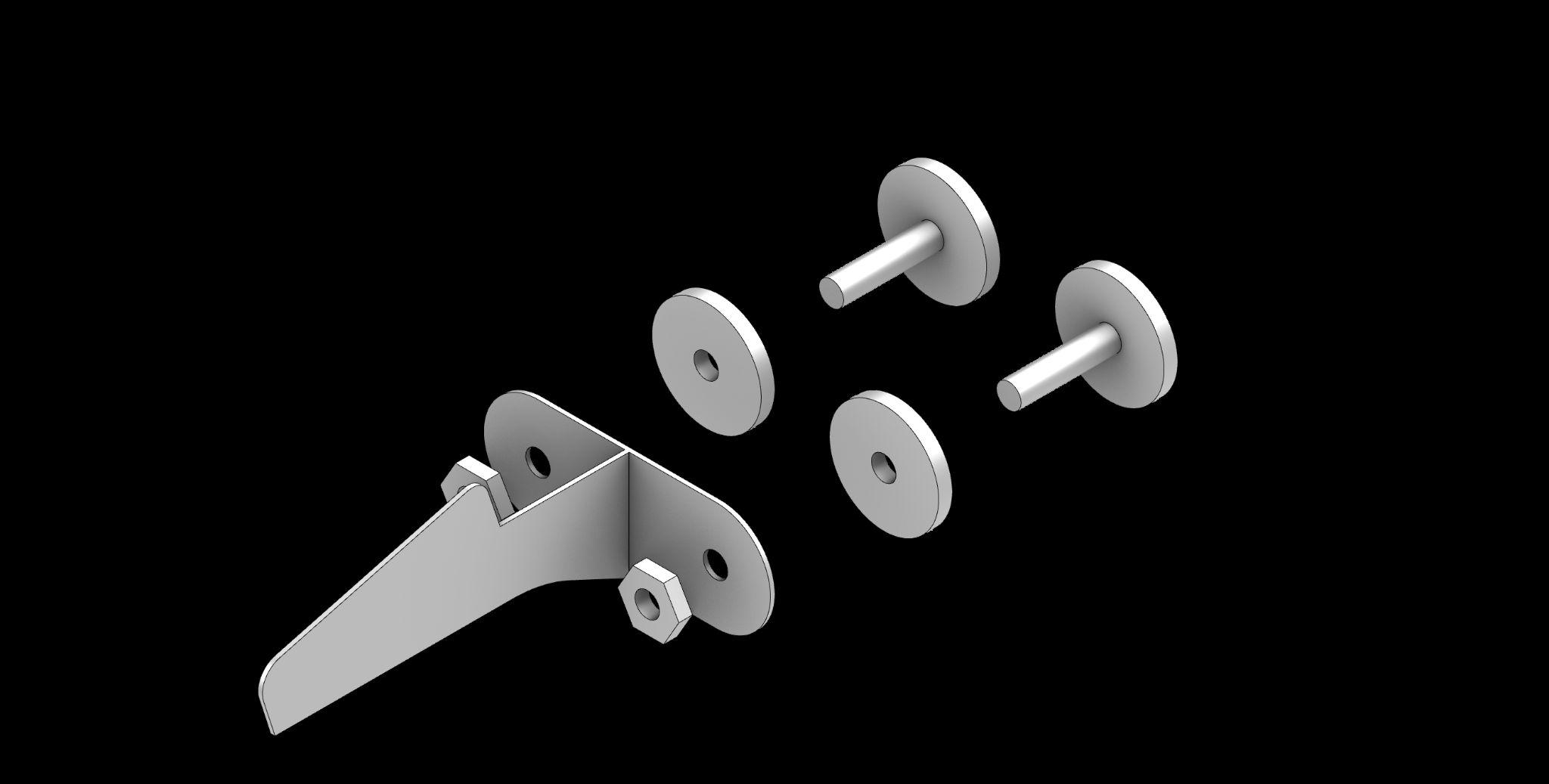

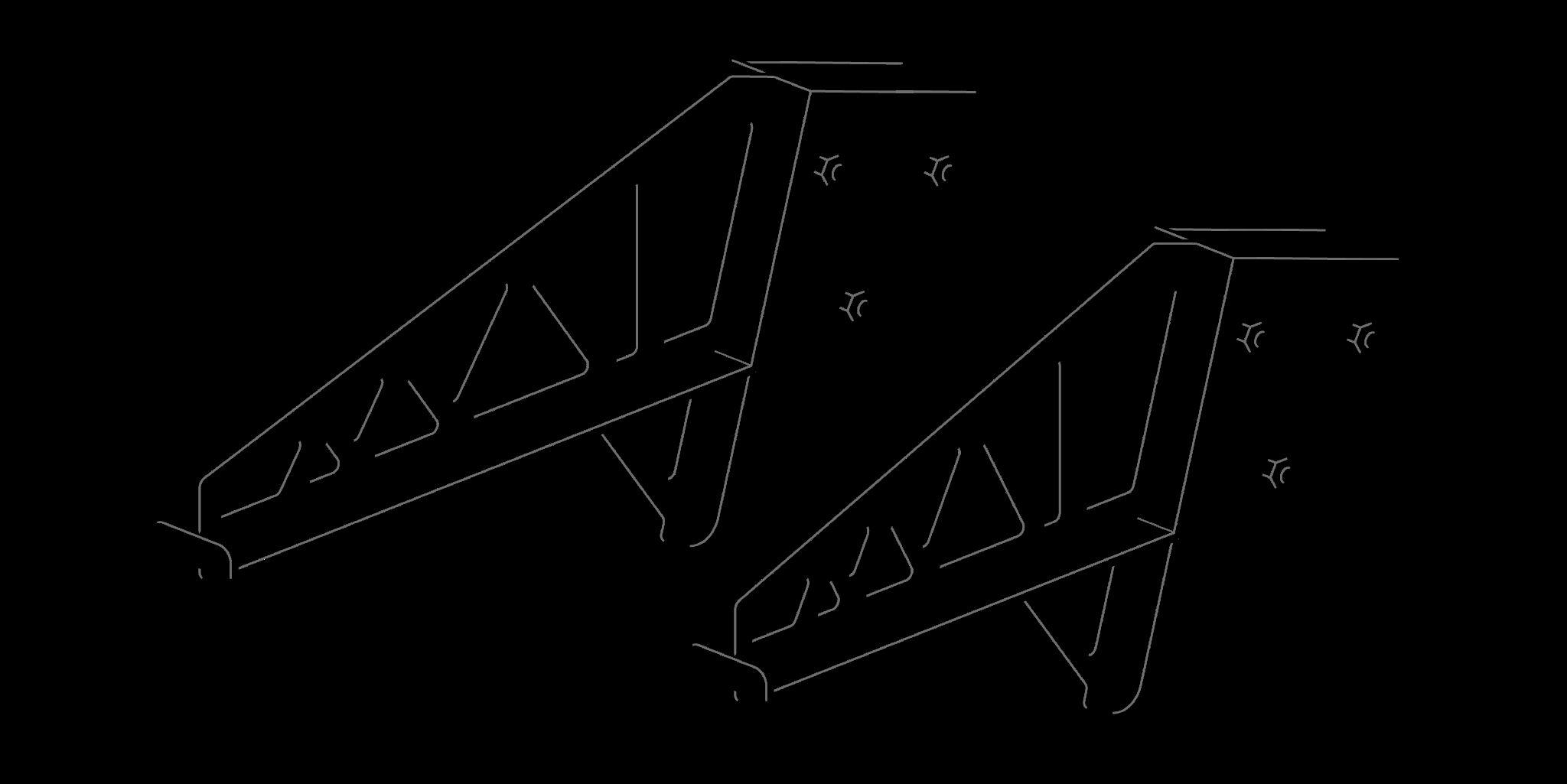

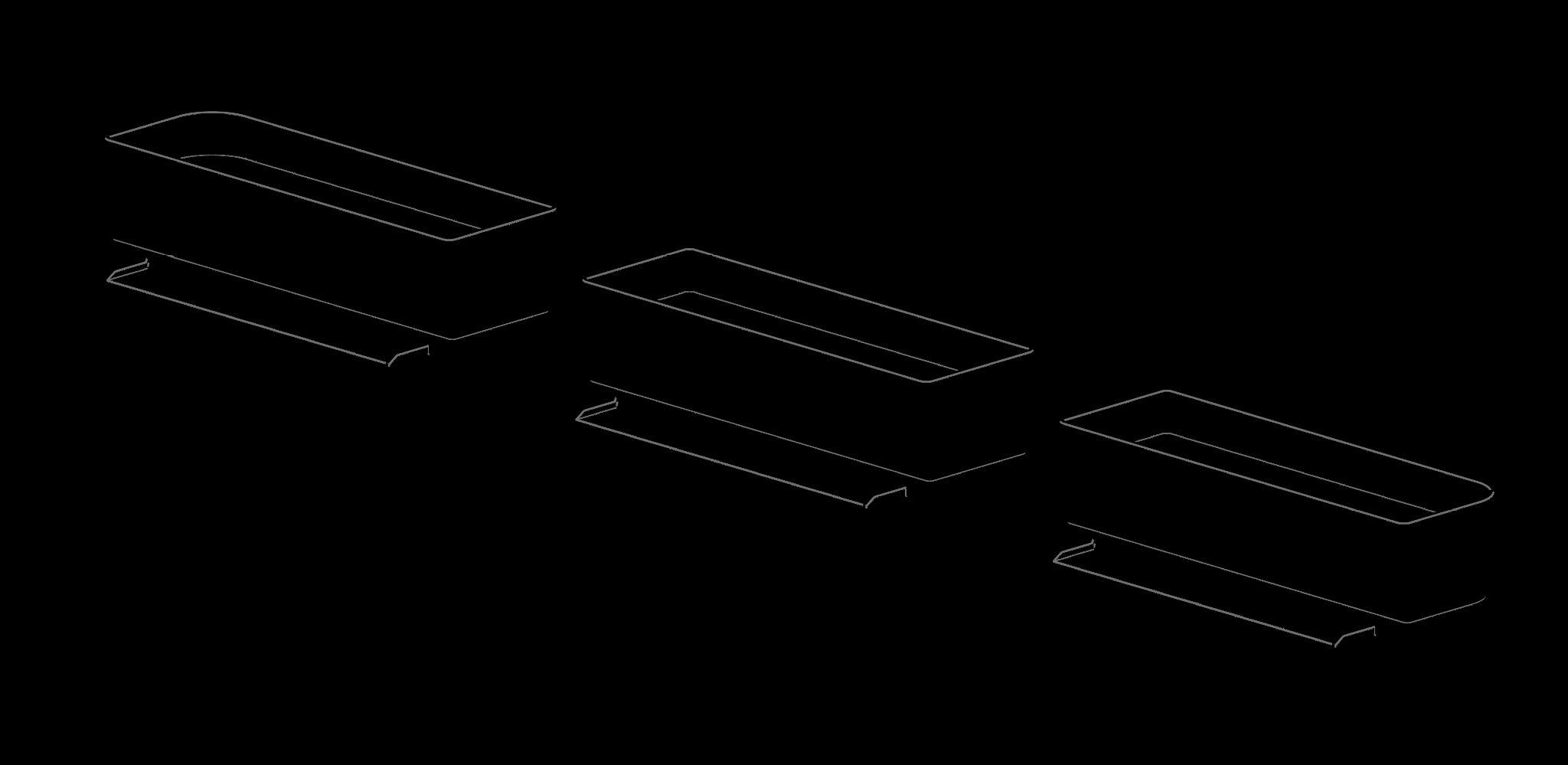

Bent sheet metal part for fixing panels and top ventilators

Alucobond aluminium panels to seal top of inner wall

Small bent sheet parts for fixing top ventilators

Bent sheet metal part for fixing panels and water delivery system of padwalls

Single Alucobond aluminium panel to seal bottom of inner wall

Standard L-profile for sealing gaps and imperfections of concrete floor

Specially designed metal gutter for supporting padwalls and drain water to tank

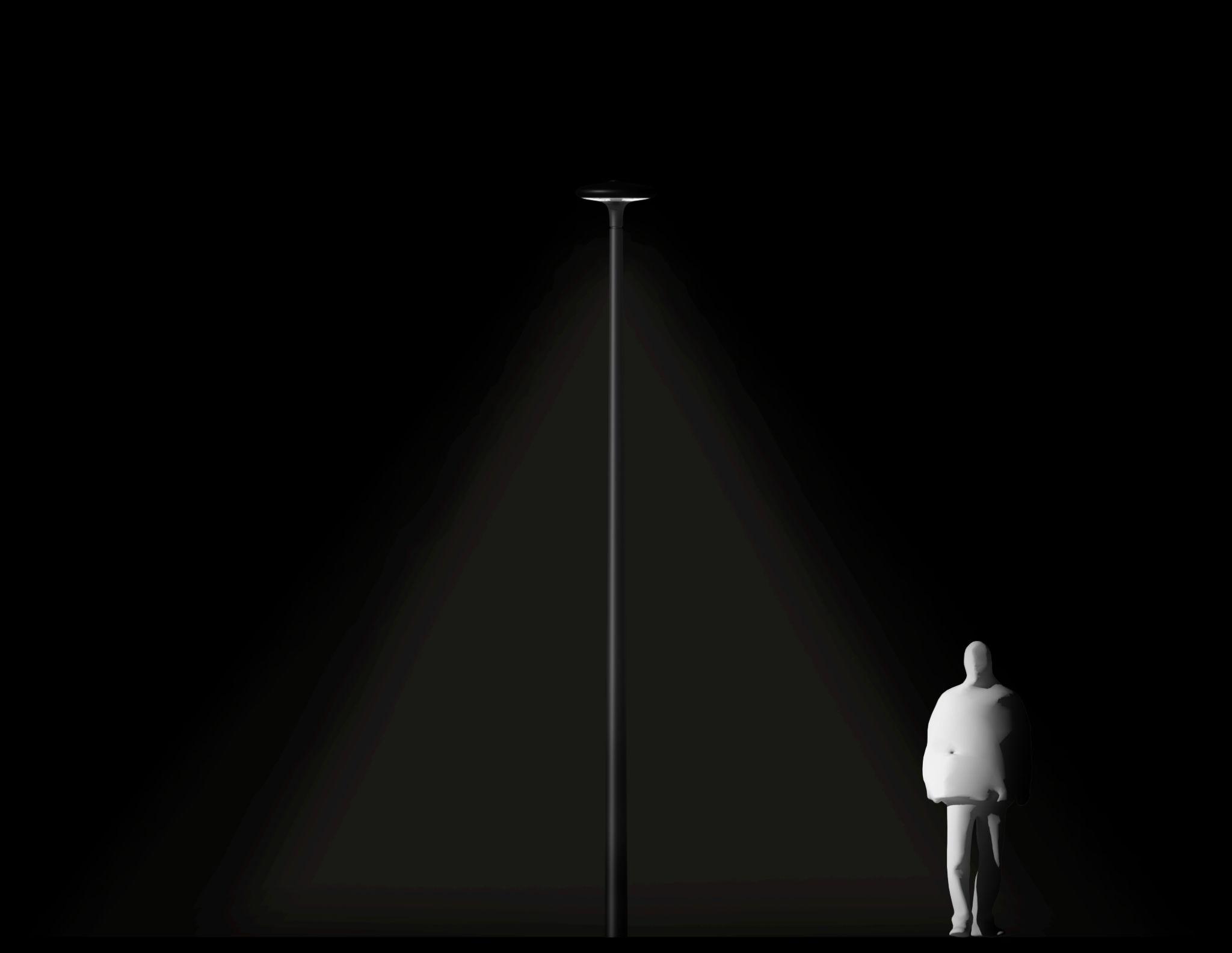

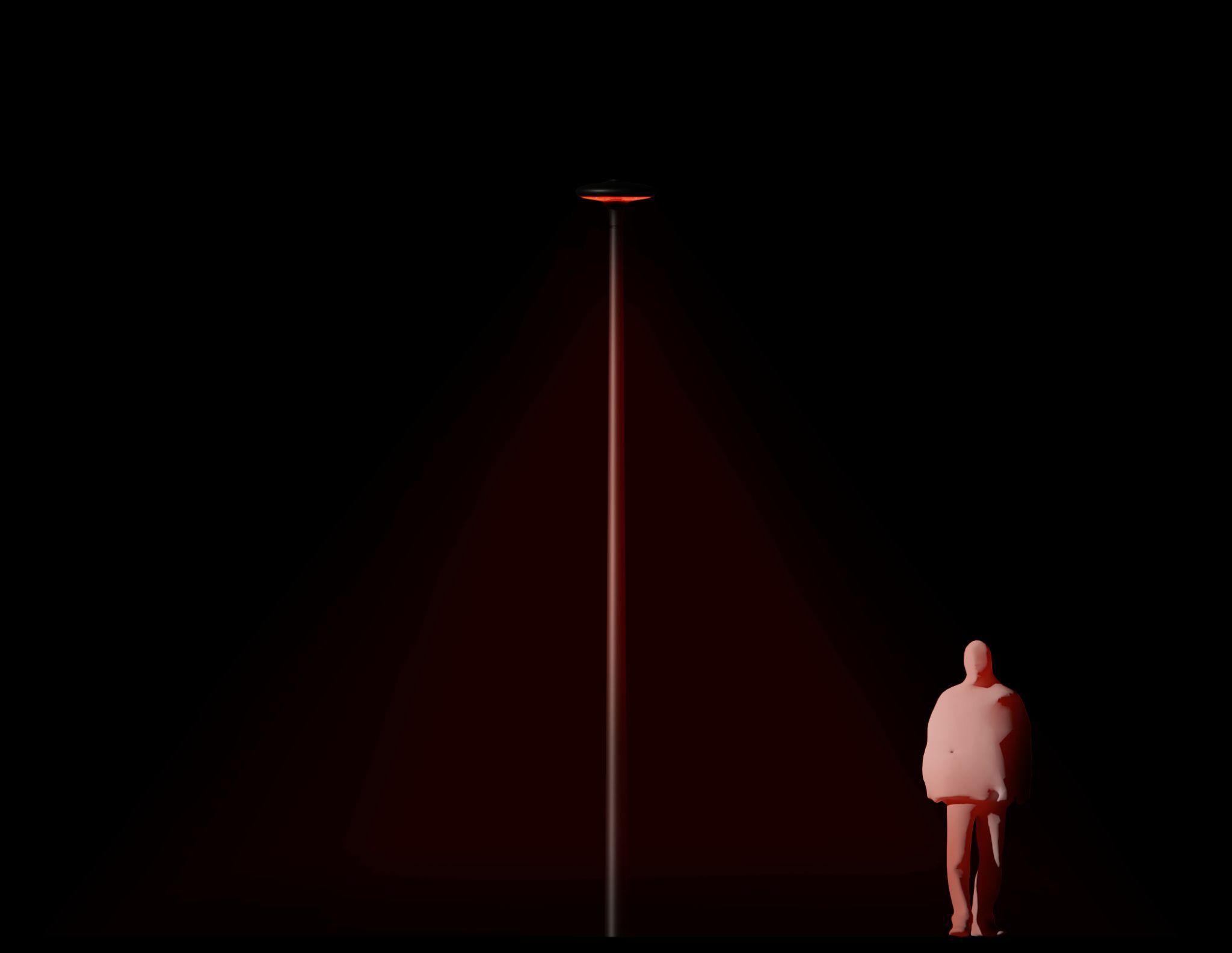

AYA Luminaire

SELUX / WEST 8 COLLABORATION

This project was a collaboration between WEST 8 and the german urban lighting company Selux. The two companies had previously collaborated together on the very successful Olivio system luminaire.

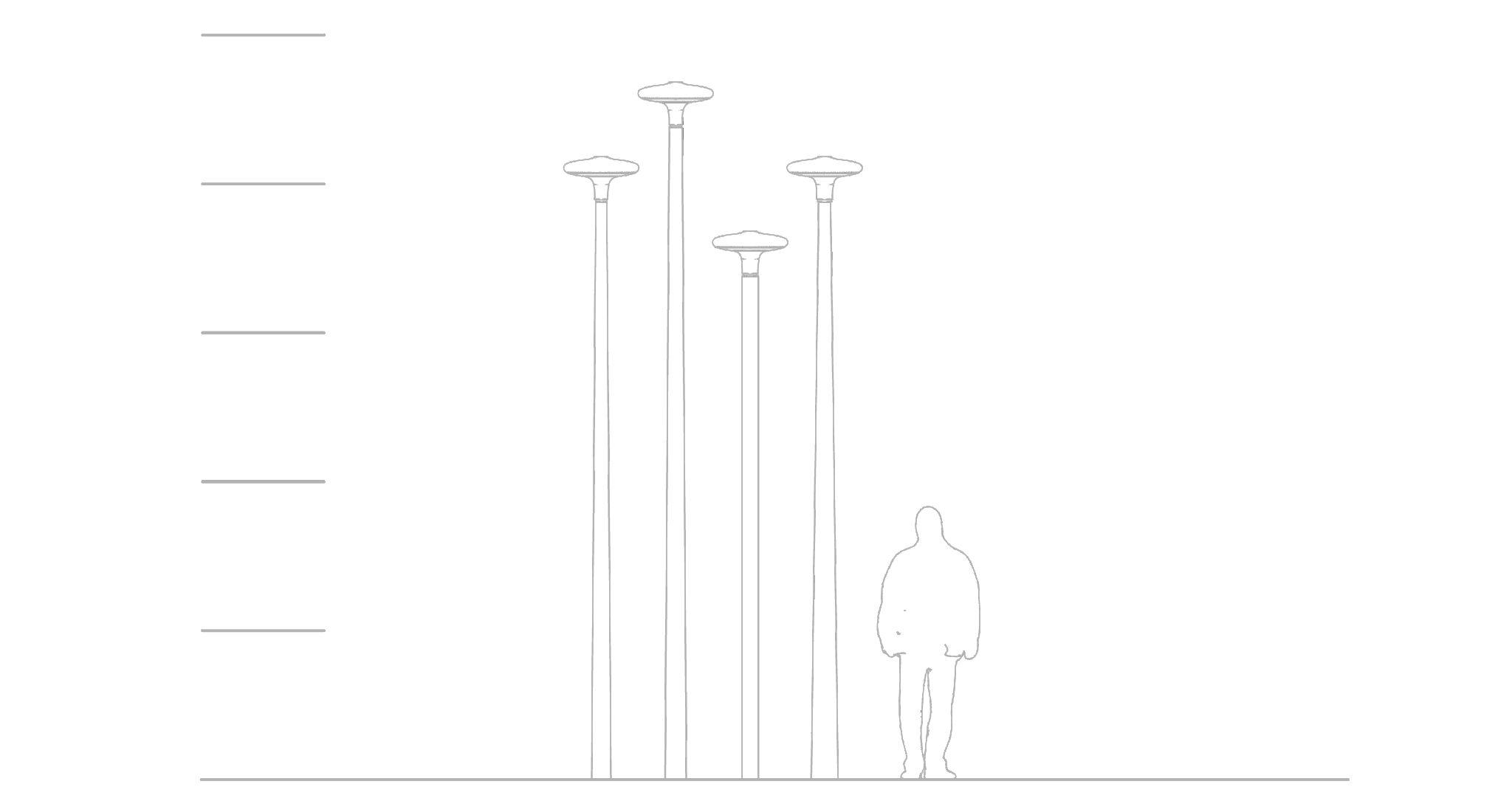

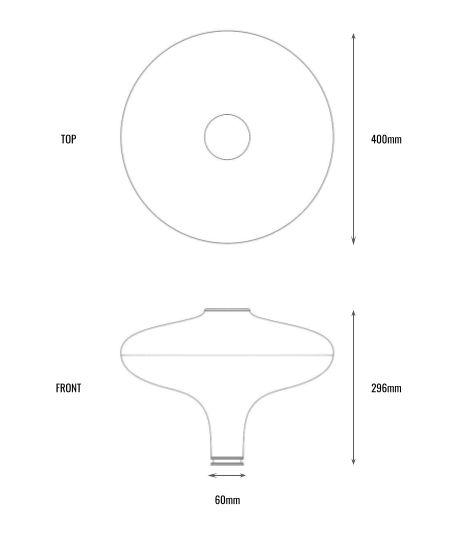

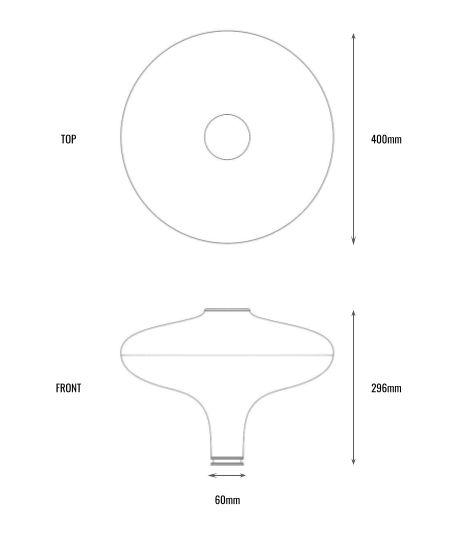

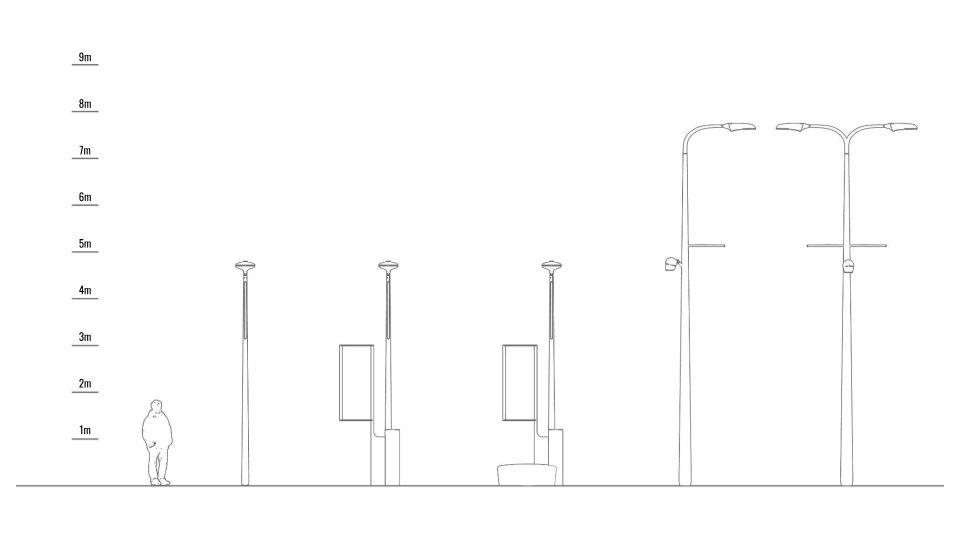

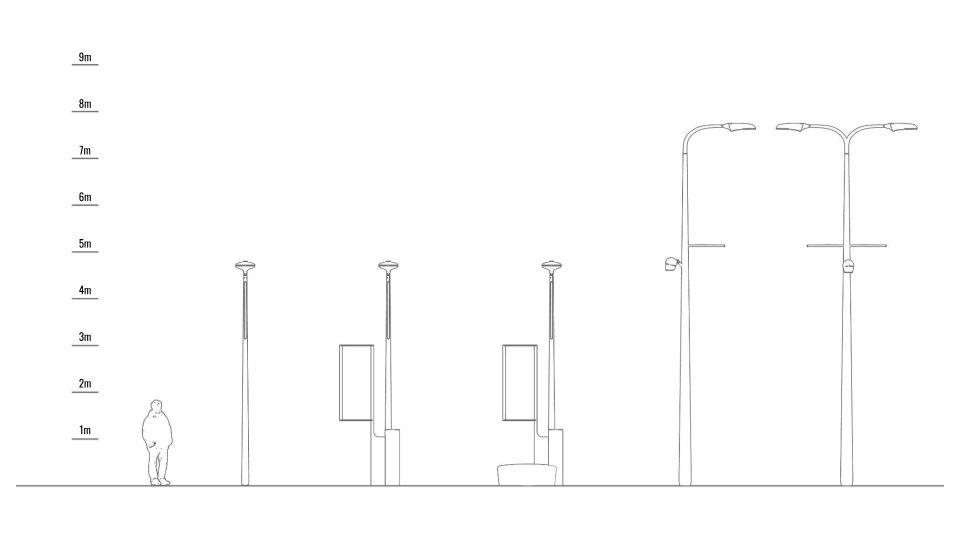

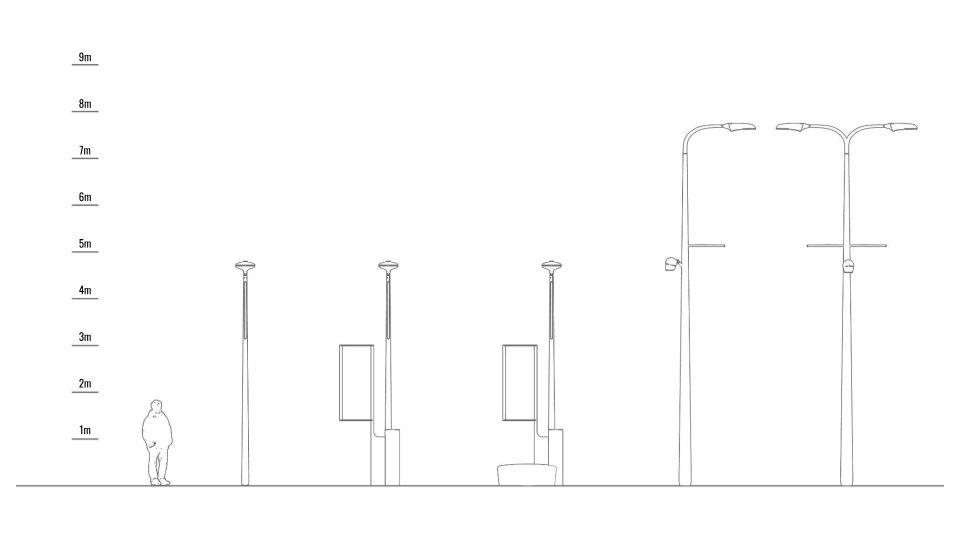

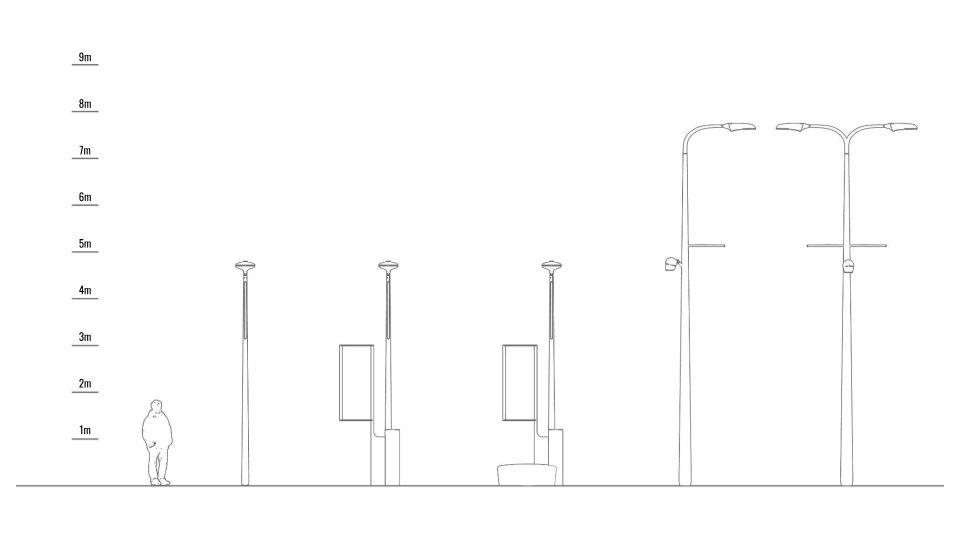

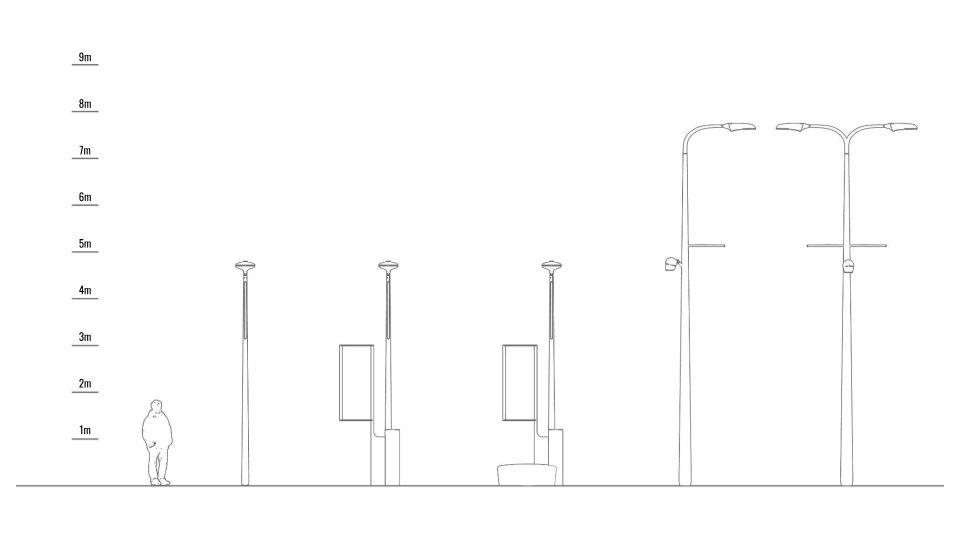

The goal of this project was to design a new poletop luminaire for public spaces where only pedestrians can come that could be fully bluetooth compatible and be able to adjust the light color and intensity depending on the time of day.

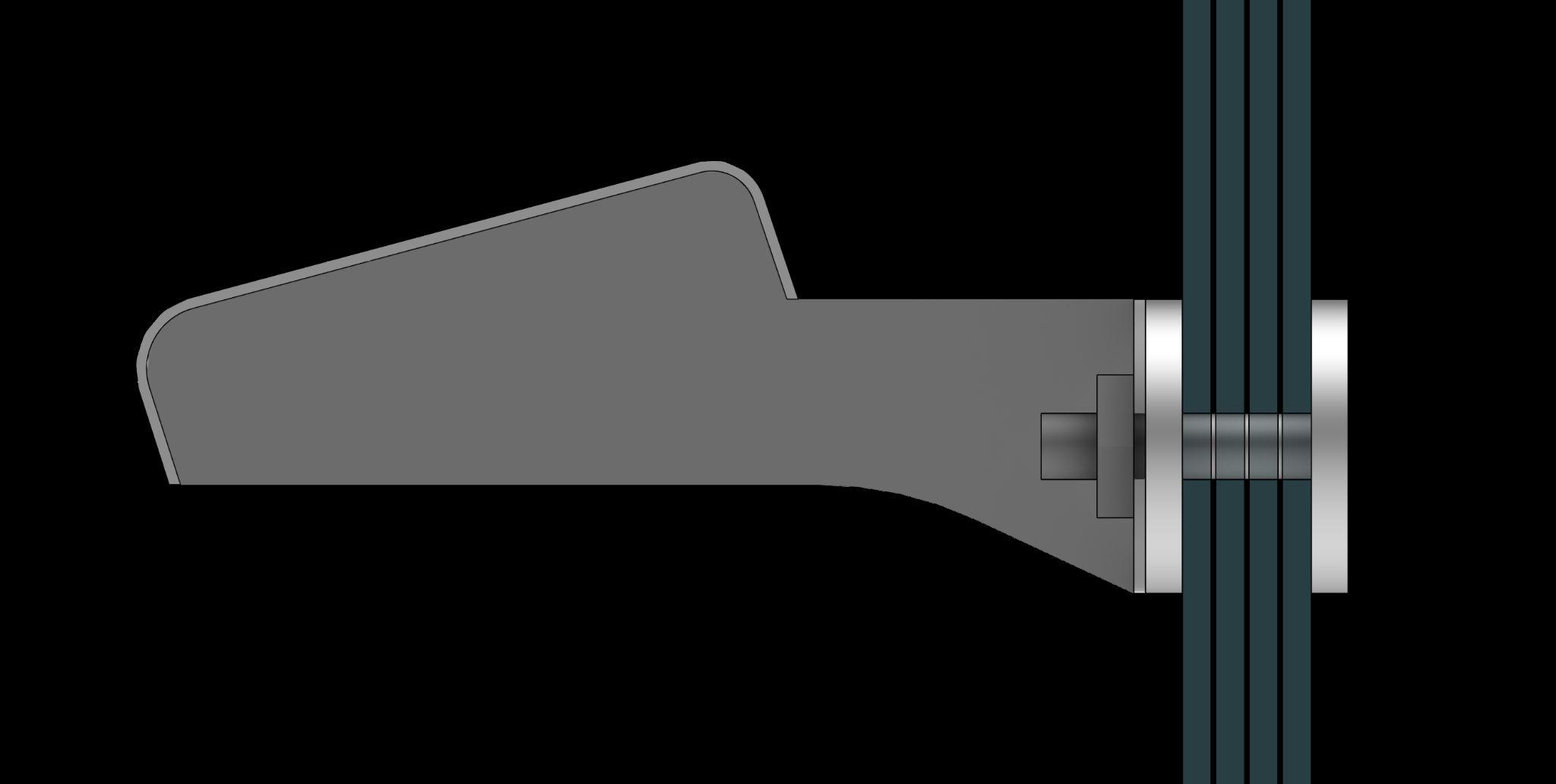

During the project WEST 8 would take care of the design aspects like shape and dimensions of the different housing parts and the connection bracket.

Selux would later take the design and work out the technical details before taking the design into production. The luminaire is expected to hit the market in the first quarter of 2024.

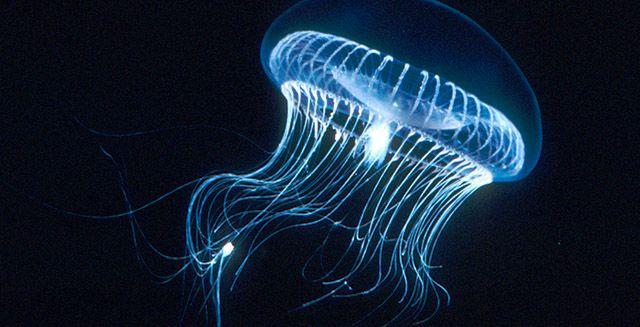

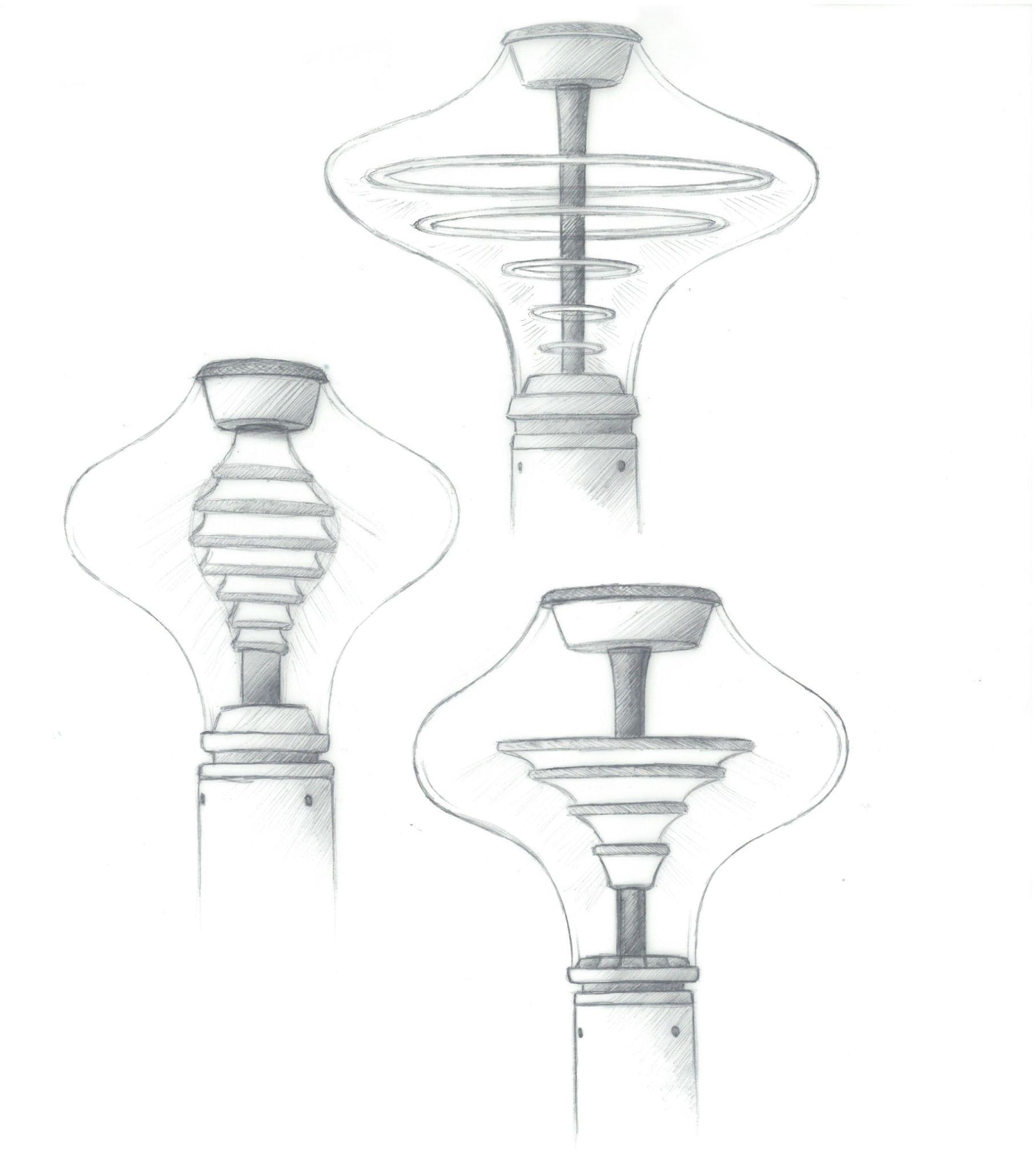

DRAWING INSPIRATION FROM NATURE

During the different brainstorming sessions at the beginning of the project we took inspiration for the design of the luminaire by looking at nature and bioluminescent organism such as mushrooms and jellyfishes.

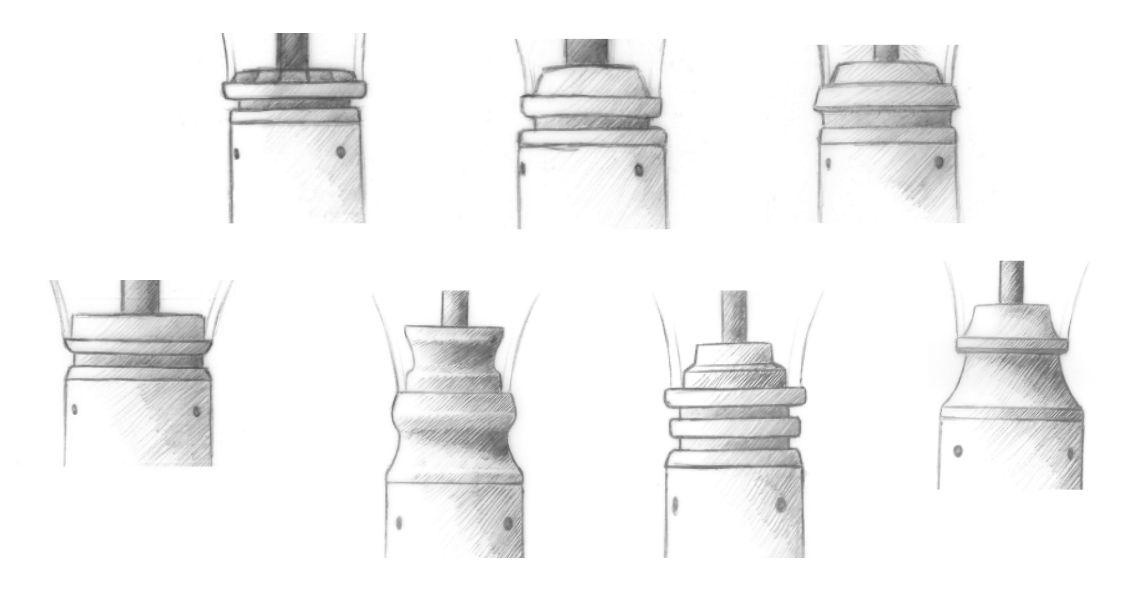

REFINING SHAPE & DESIGN

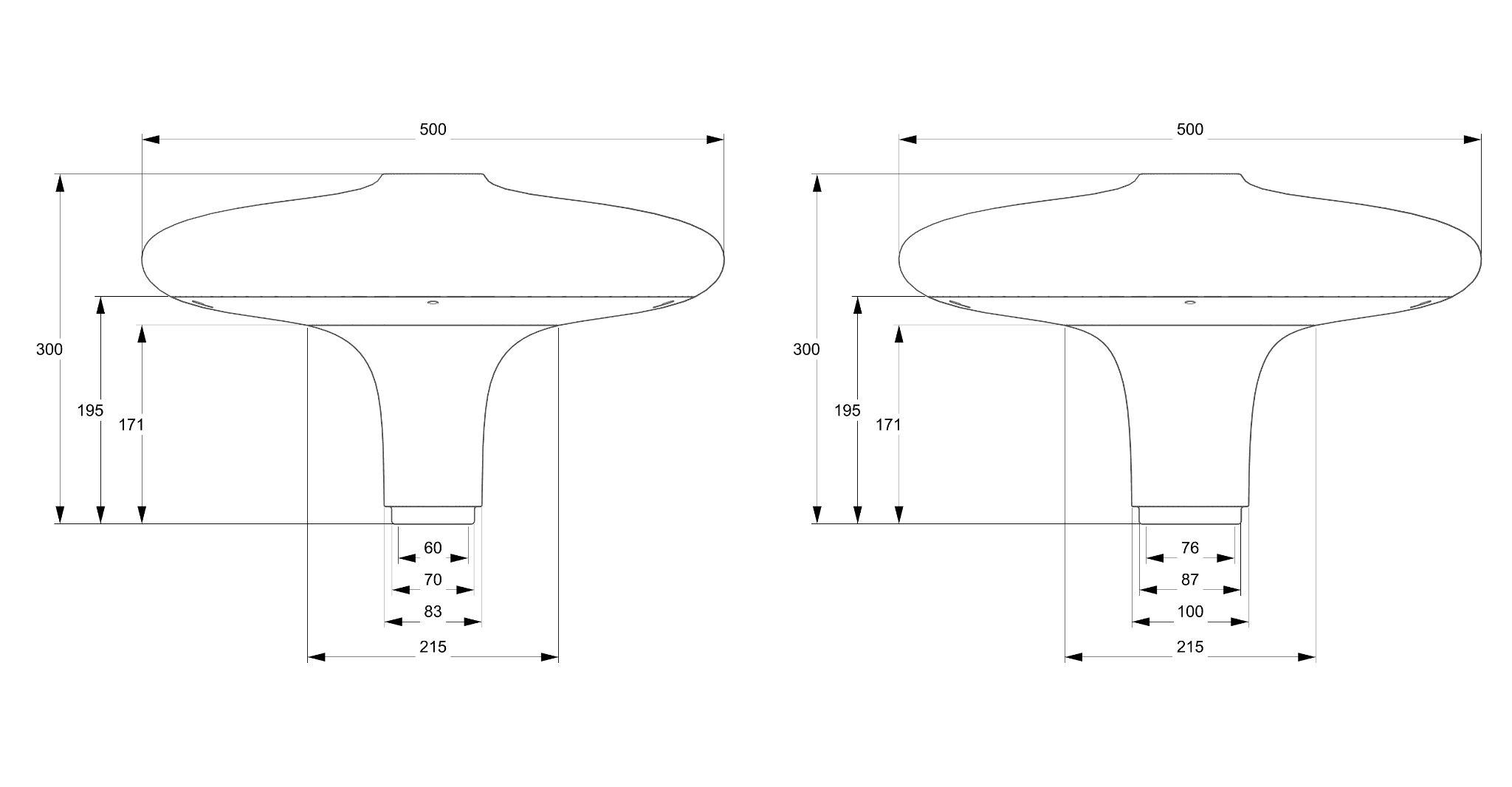

One of the challenges designing the luminaire was to find one shape and size that would look aesthetically pleasing on two sizes of light poles.

This was achieved by designing a luminaire housing that could be fitted with two sizes of pole connection brackets: 60mm and 76mm.

This would limit the amount of special parts which would benefit development and production costs.

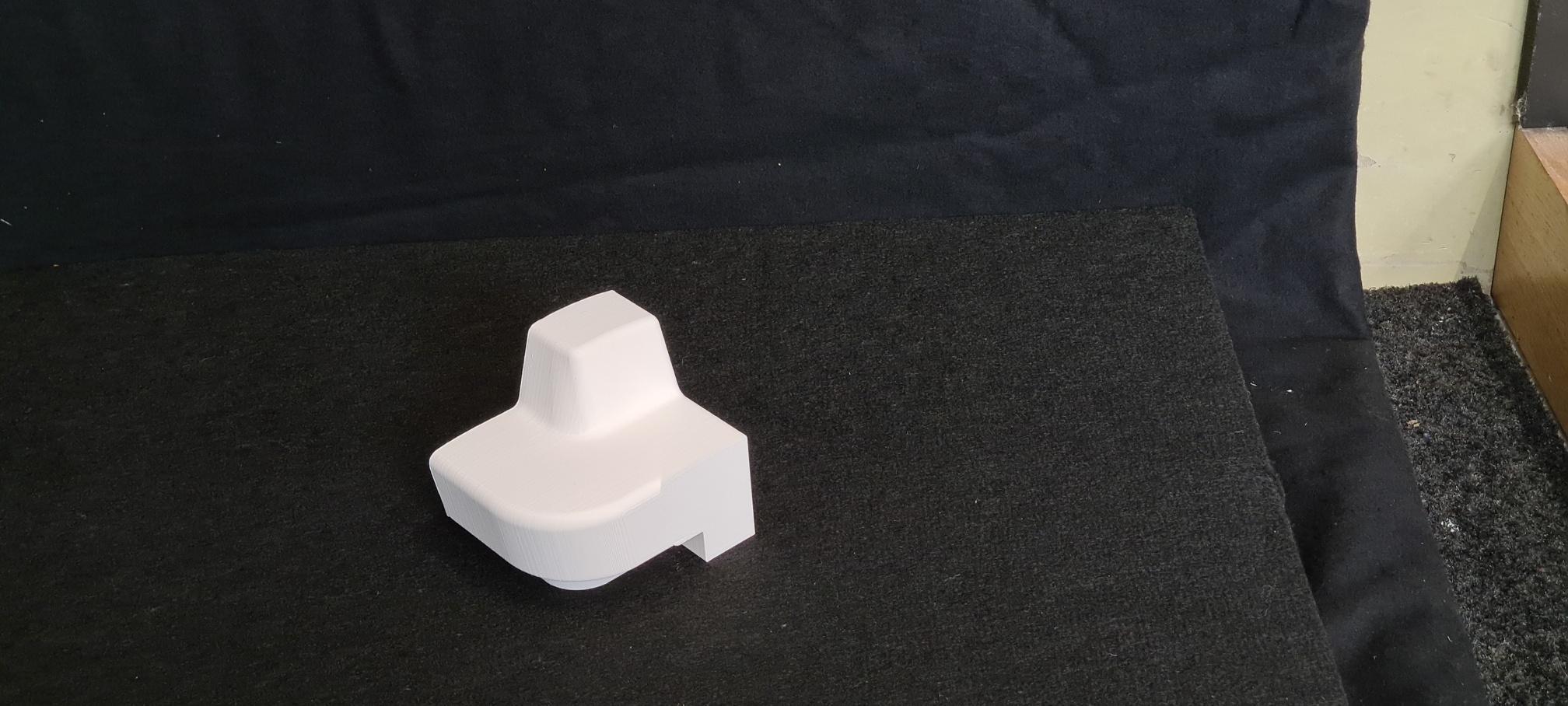

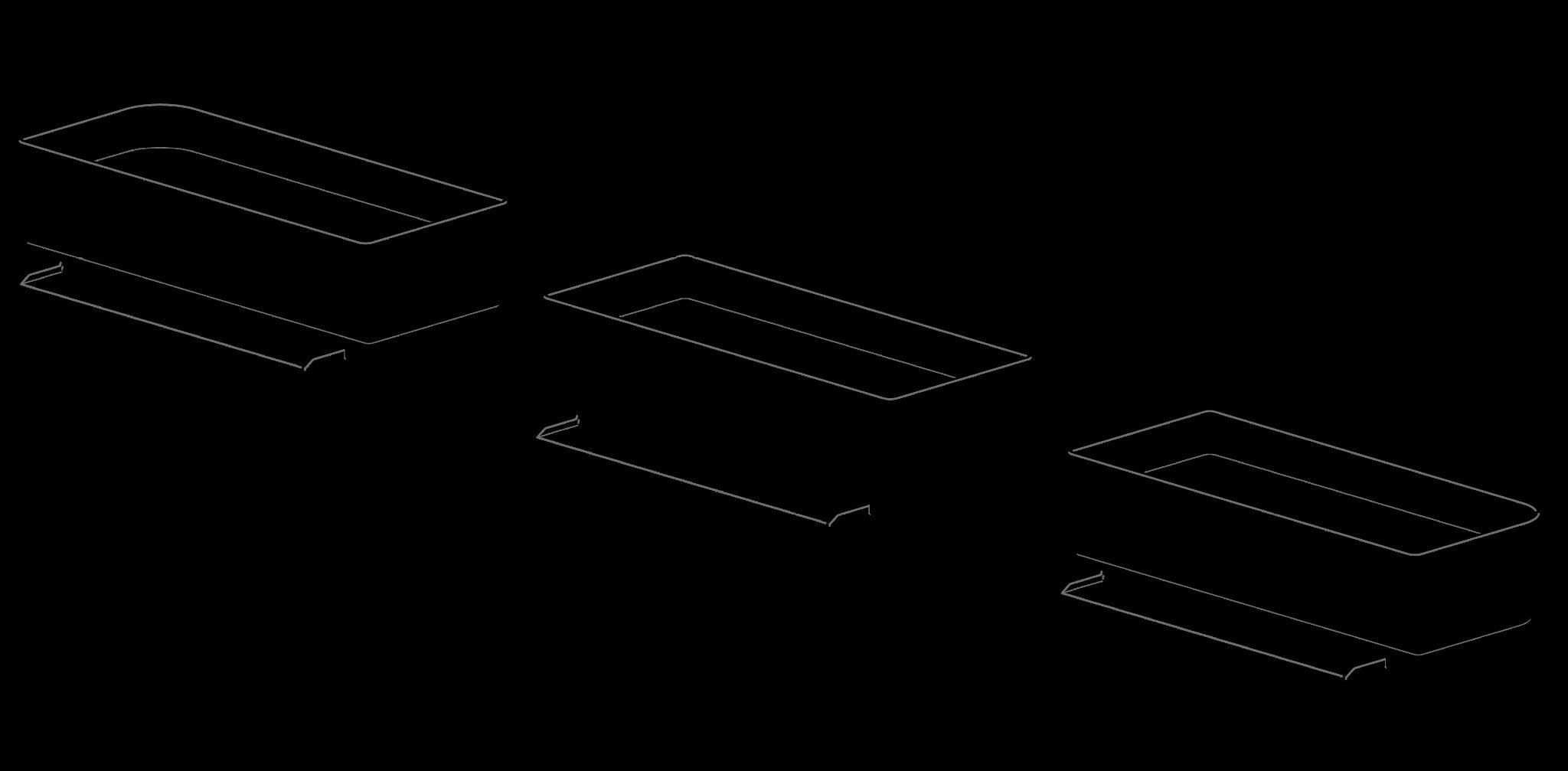

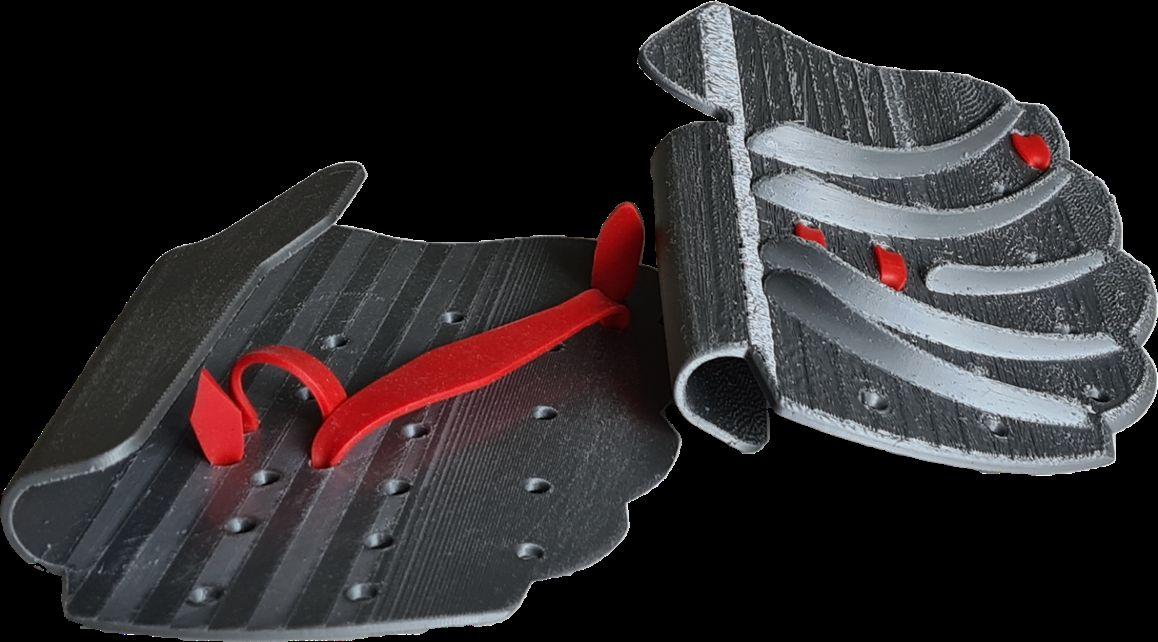

3D PRINTED 1 TO 3 SCALE MODEL

Once the final design was achieved I made a scaled down version of the luminaire that was suitable for printing with an Ultimaker S5.

A couple of materials were used to fabricate the different parts of the model.

● ABS for the housing cap, the pole bracket and footing

● PLA for the two reflectors

● Tough PLA for the inner fixing piece

● Transparent PLA for the glass part

Assembled scale model without transparent part

Assembled scale model with transparent part

Assembled scale model with 1 to 3 scale wooden pole

From left to right: Luminaire housing cap, reflectors with inner fixing piece, pole bracket and transparent partPRODUCT RENDERS

IN CONTEXT RENDERS

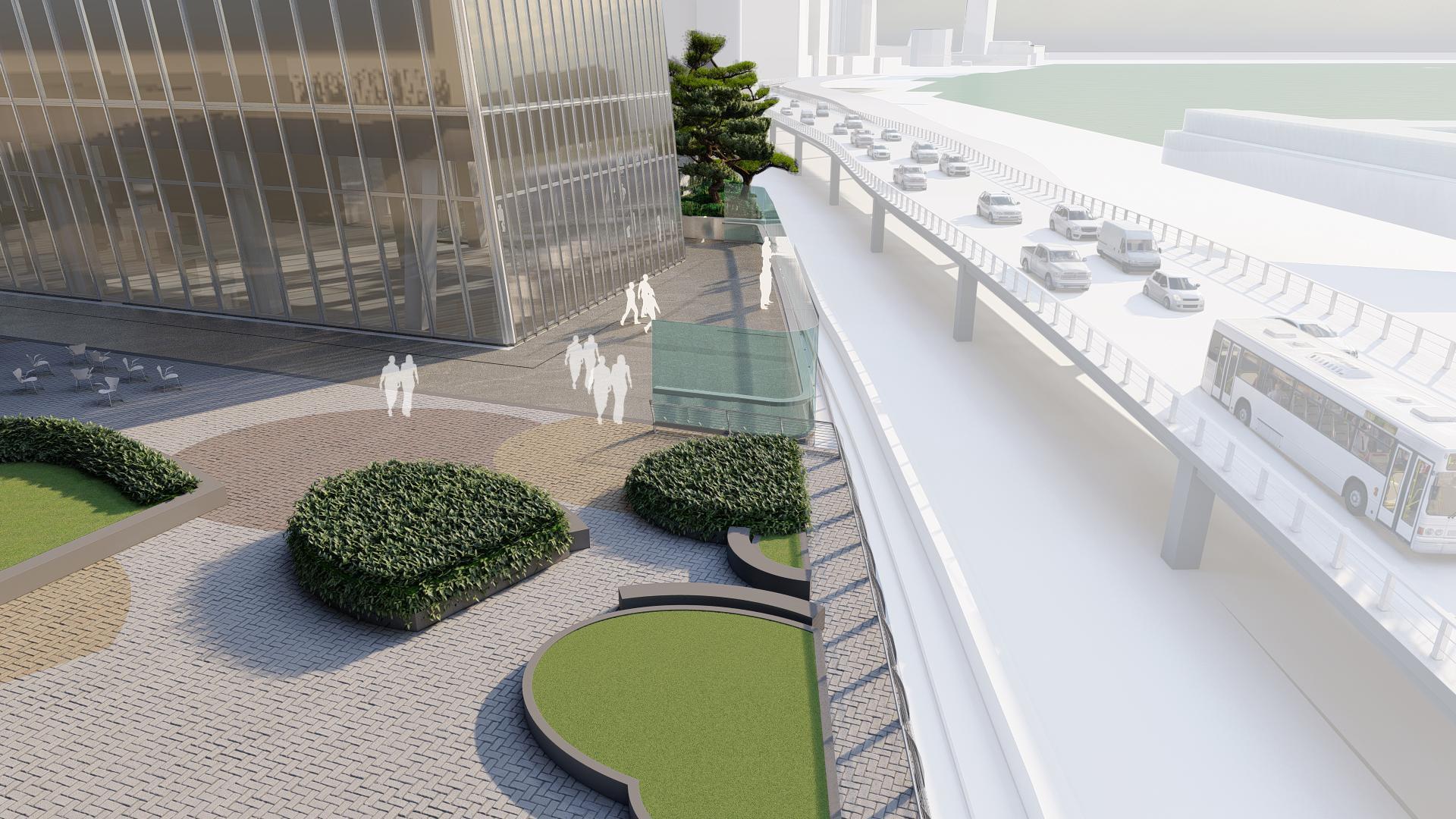

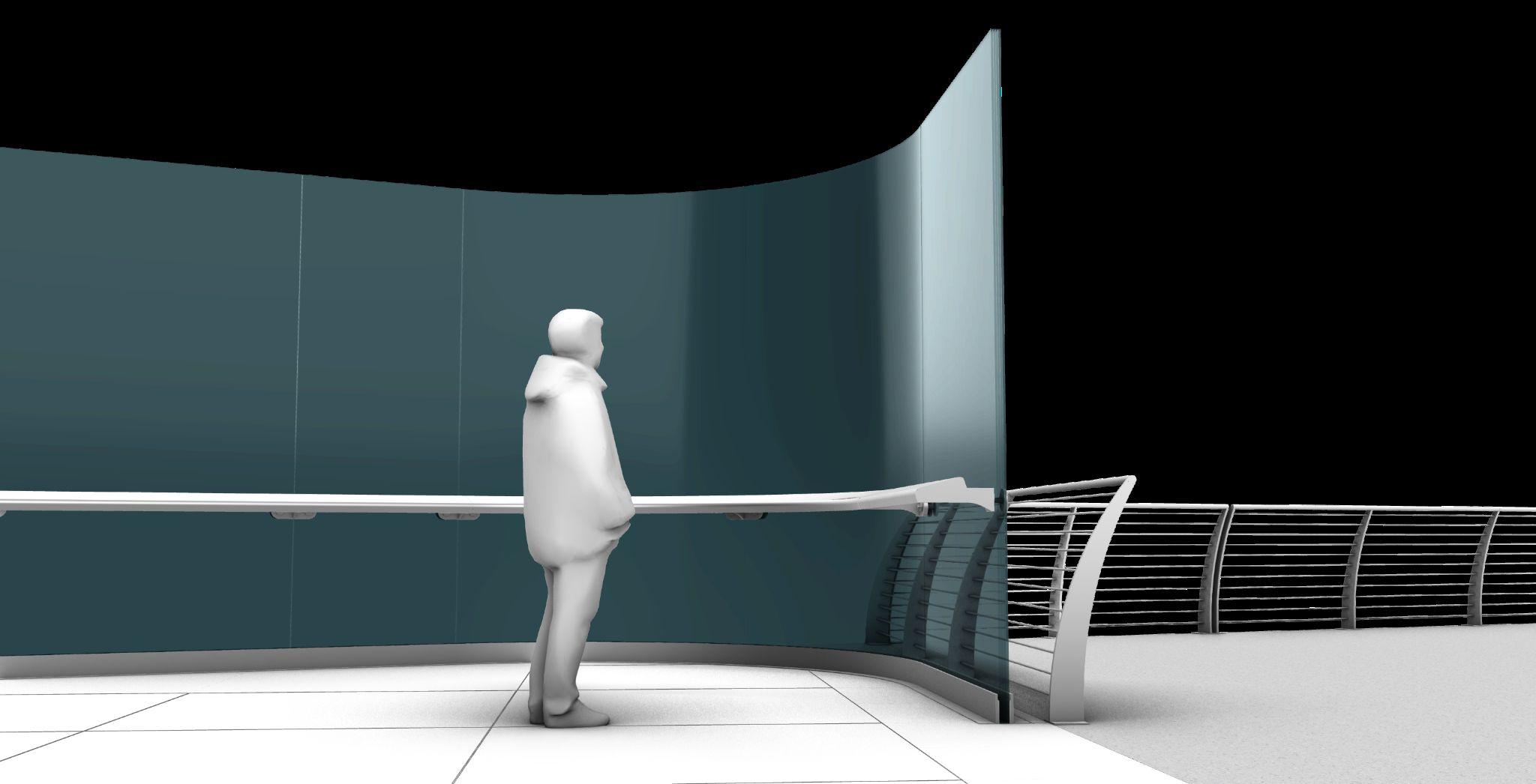

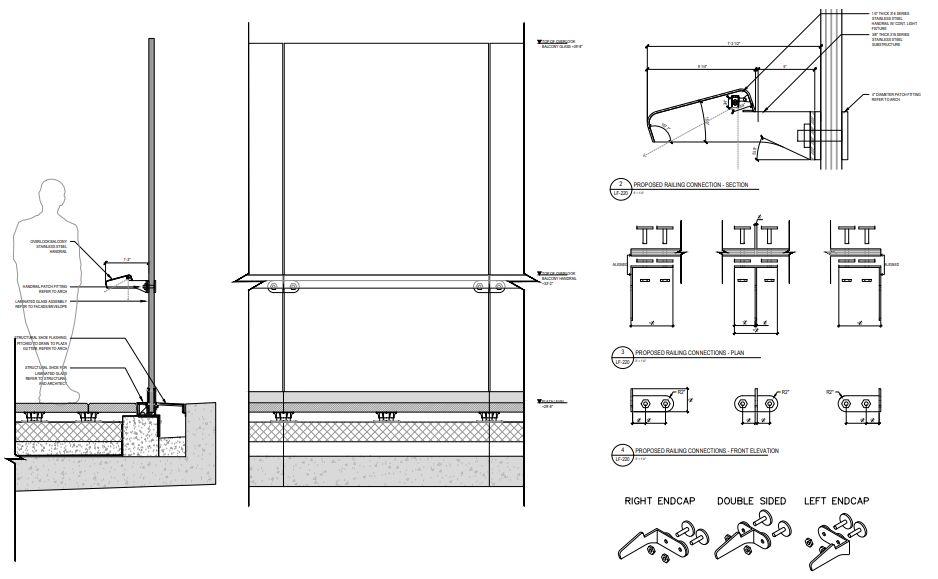

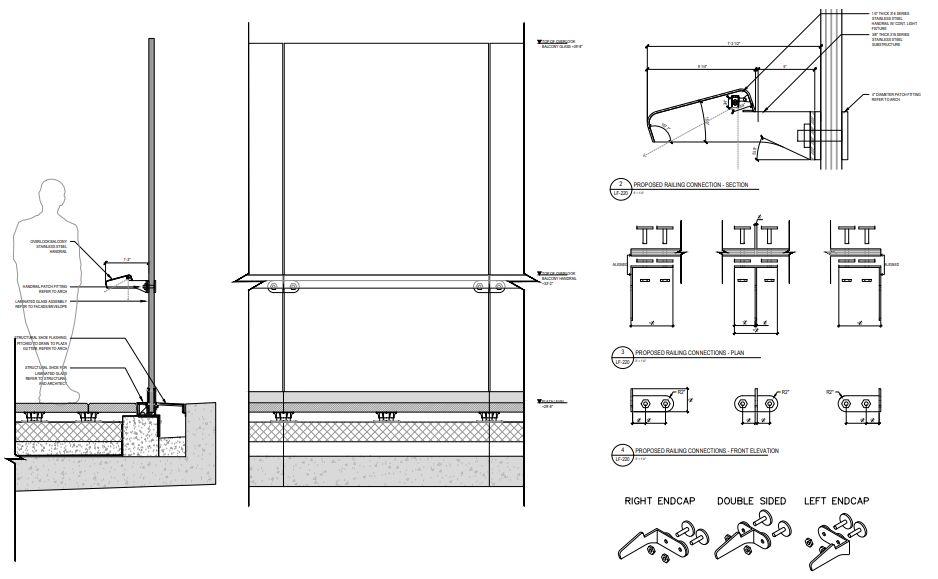

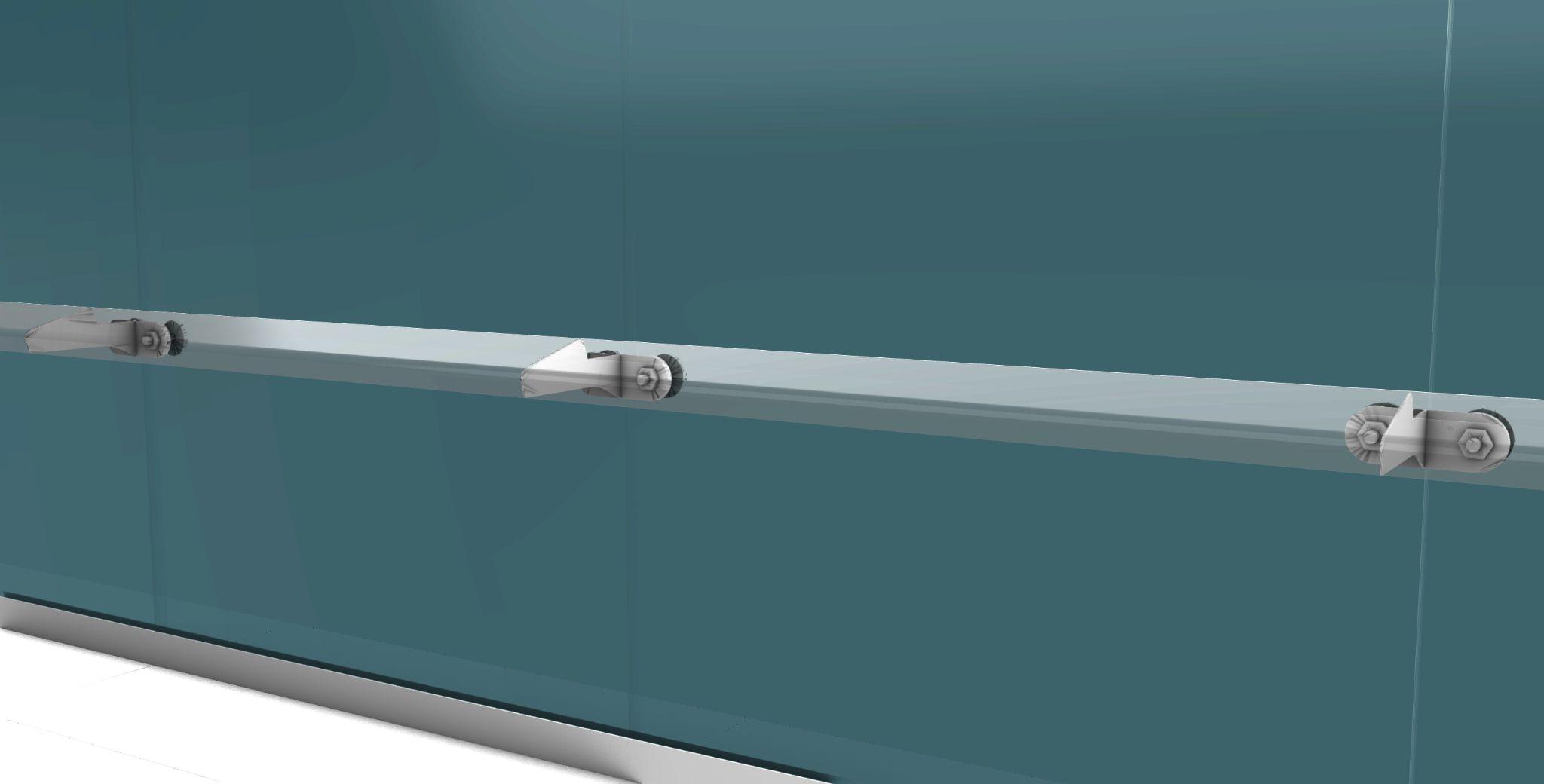

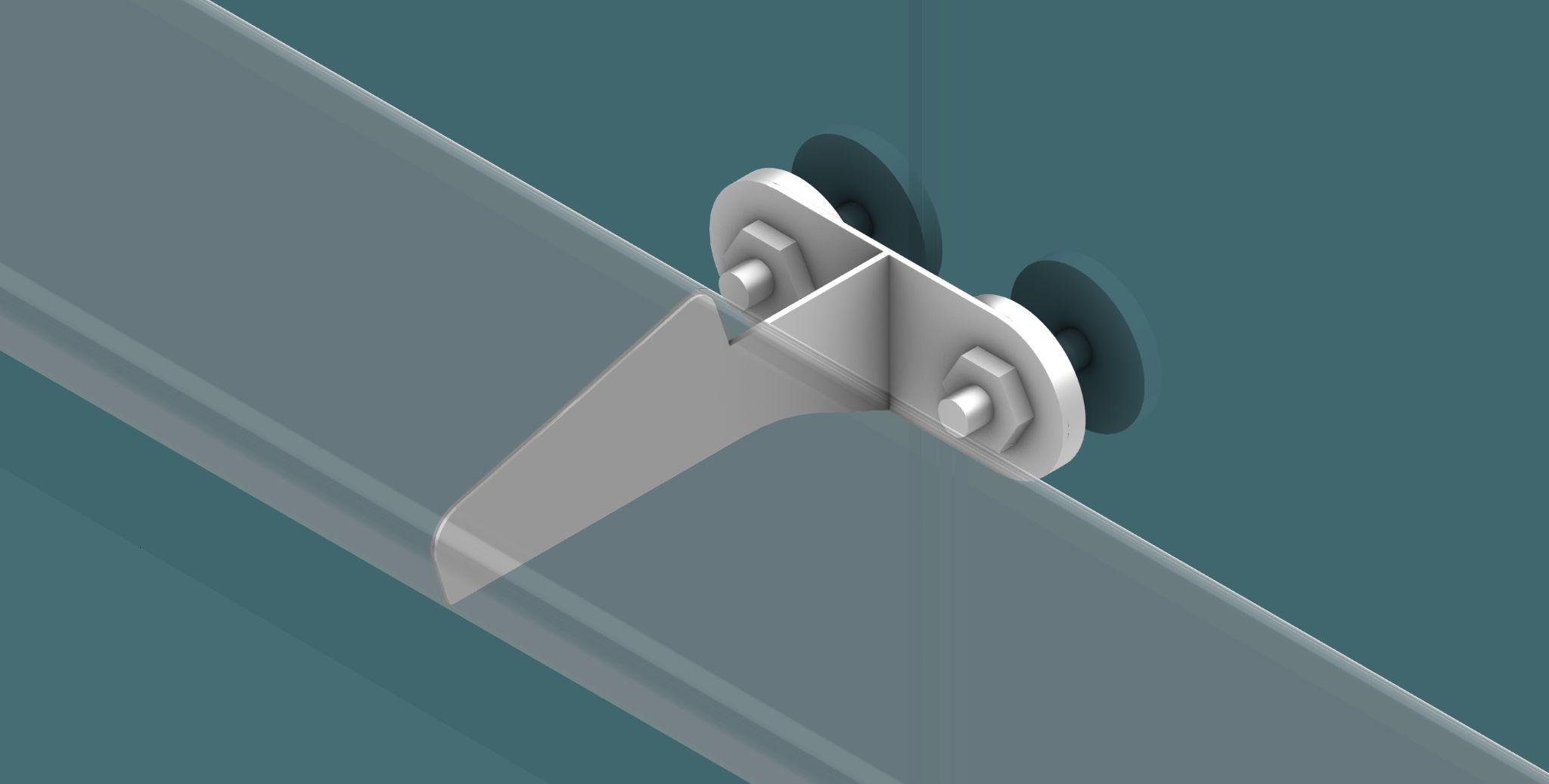

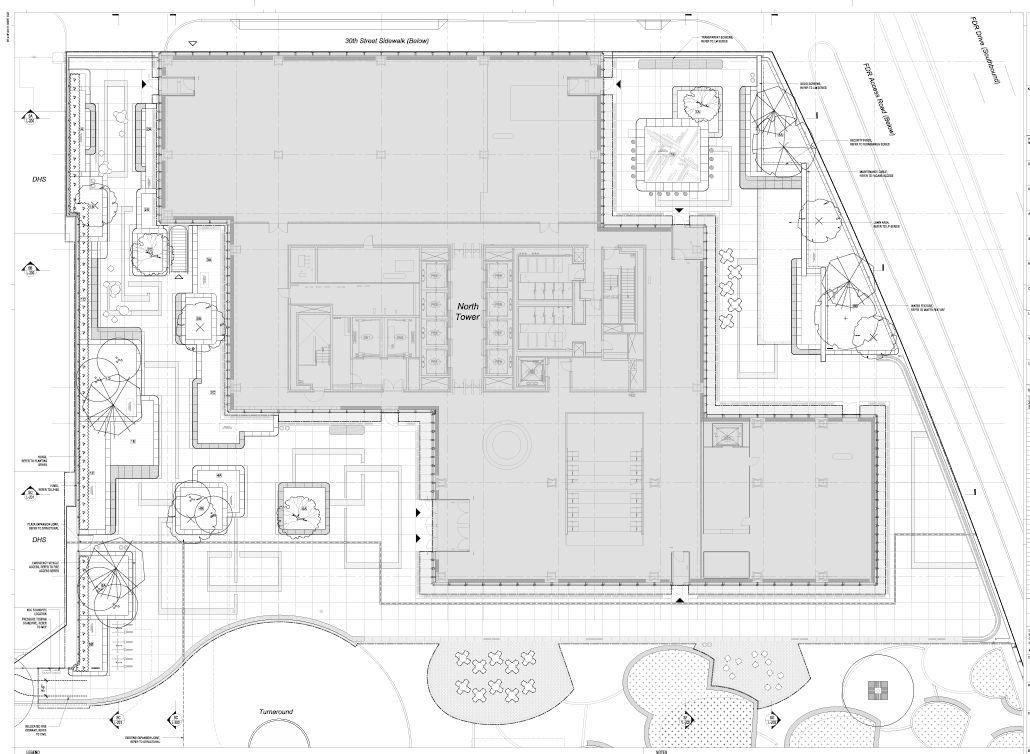

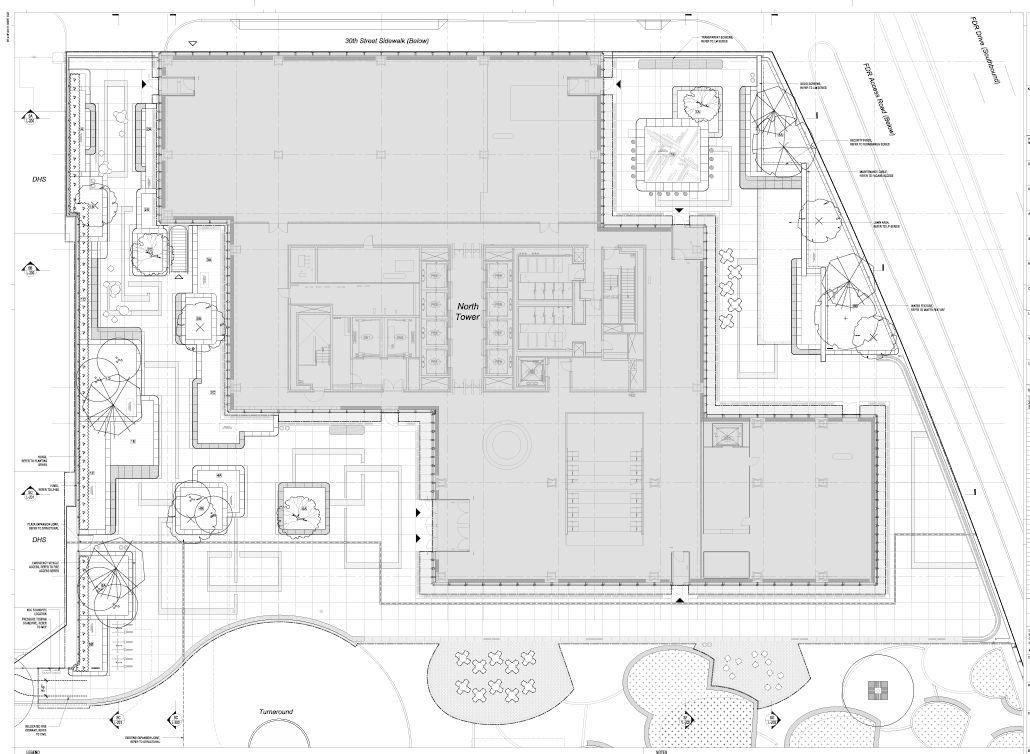

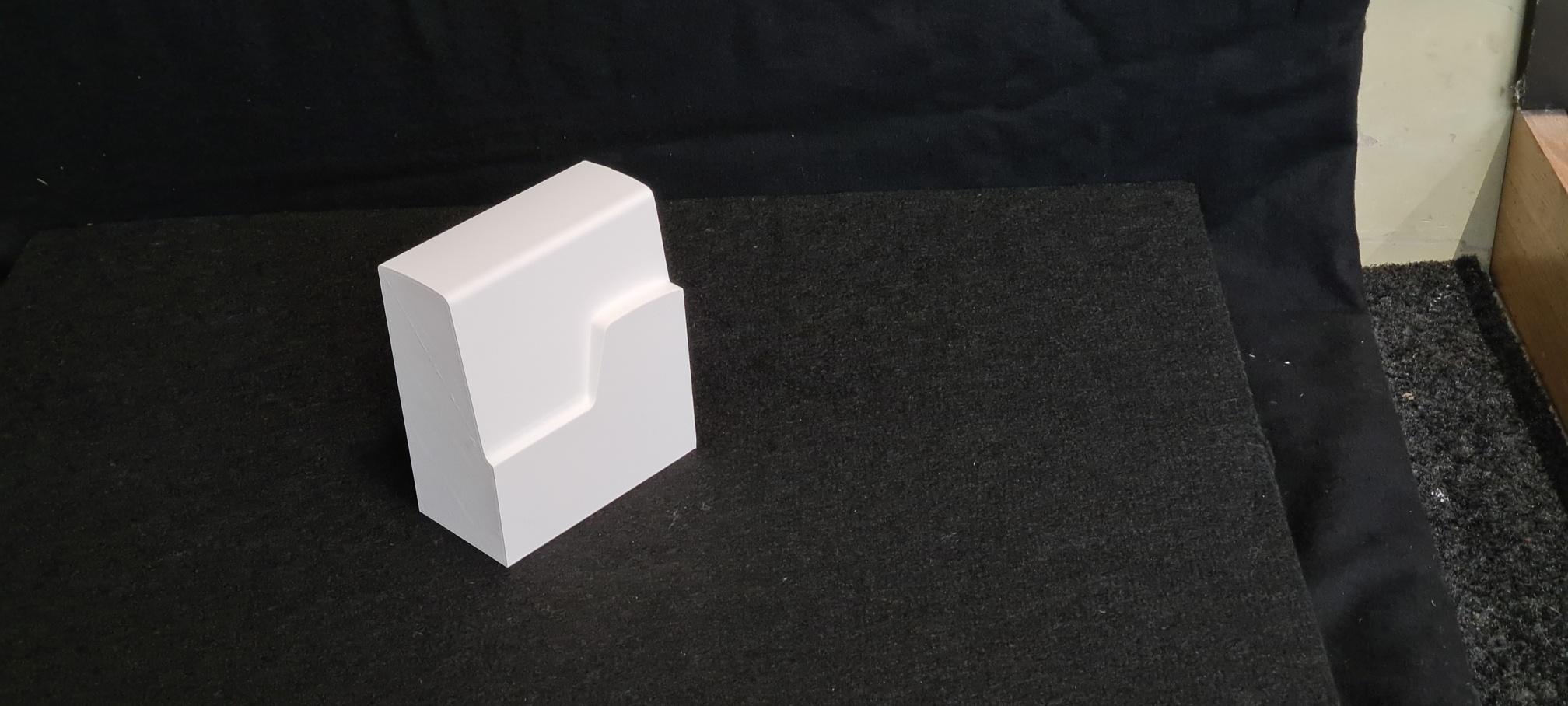

Life Science Center

OMA / WEST 8 COLLABORATION

This project was a collaboration between OMA and WEST 8.

The two companies had previously collaborated during the competition phase to acquire the project.

In this project WEST 8 was in charge of the open space surrounding a new Center for Life Science that will be built in New York.

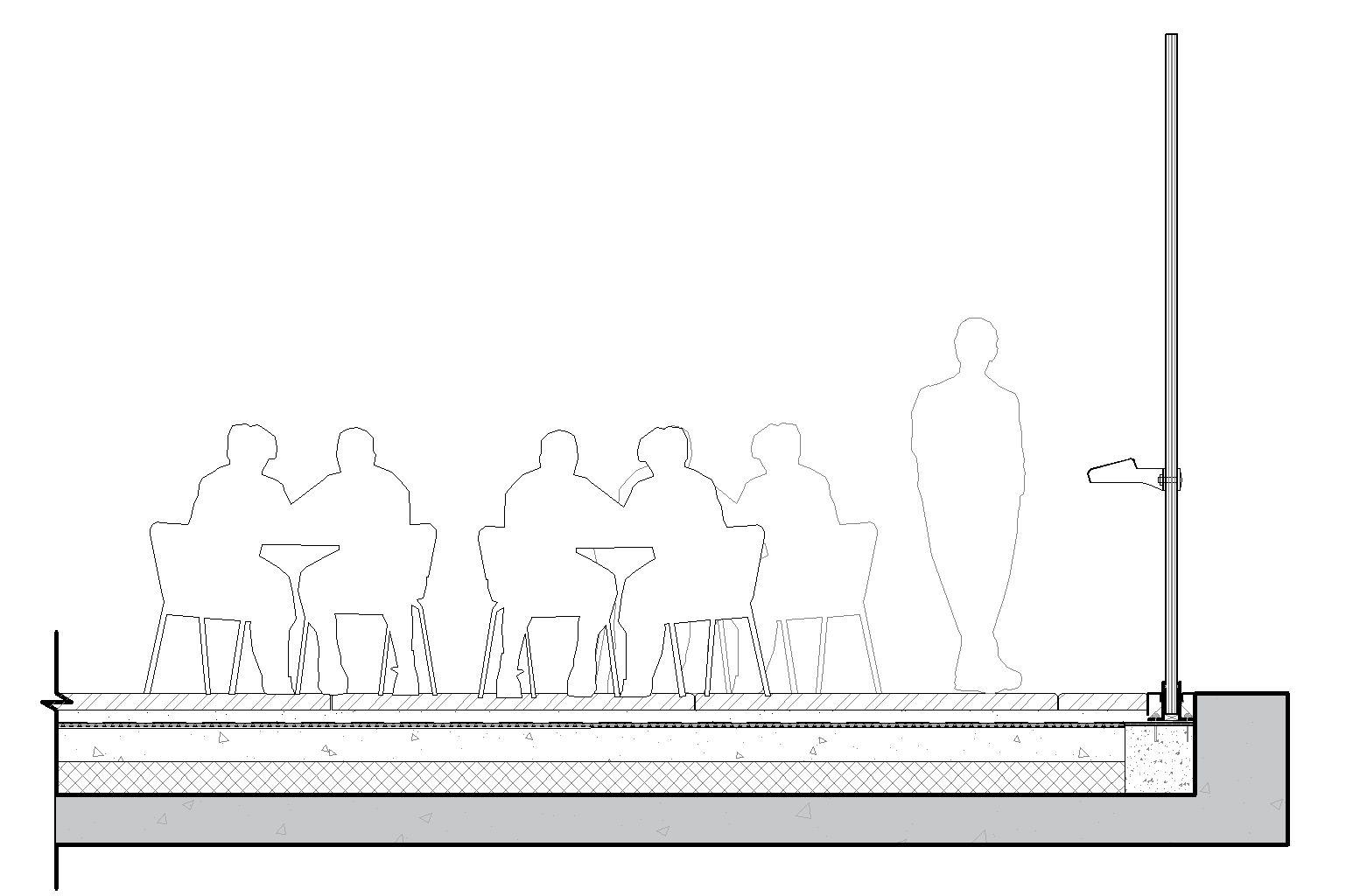

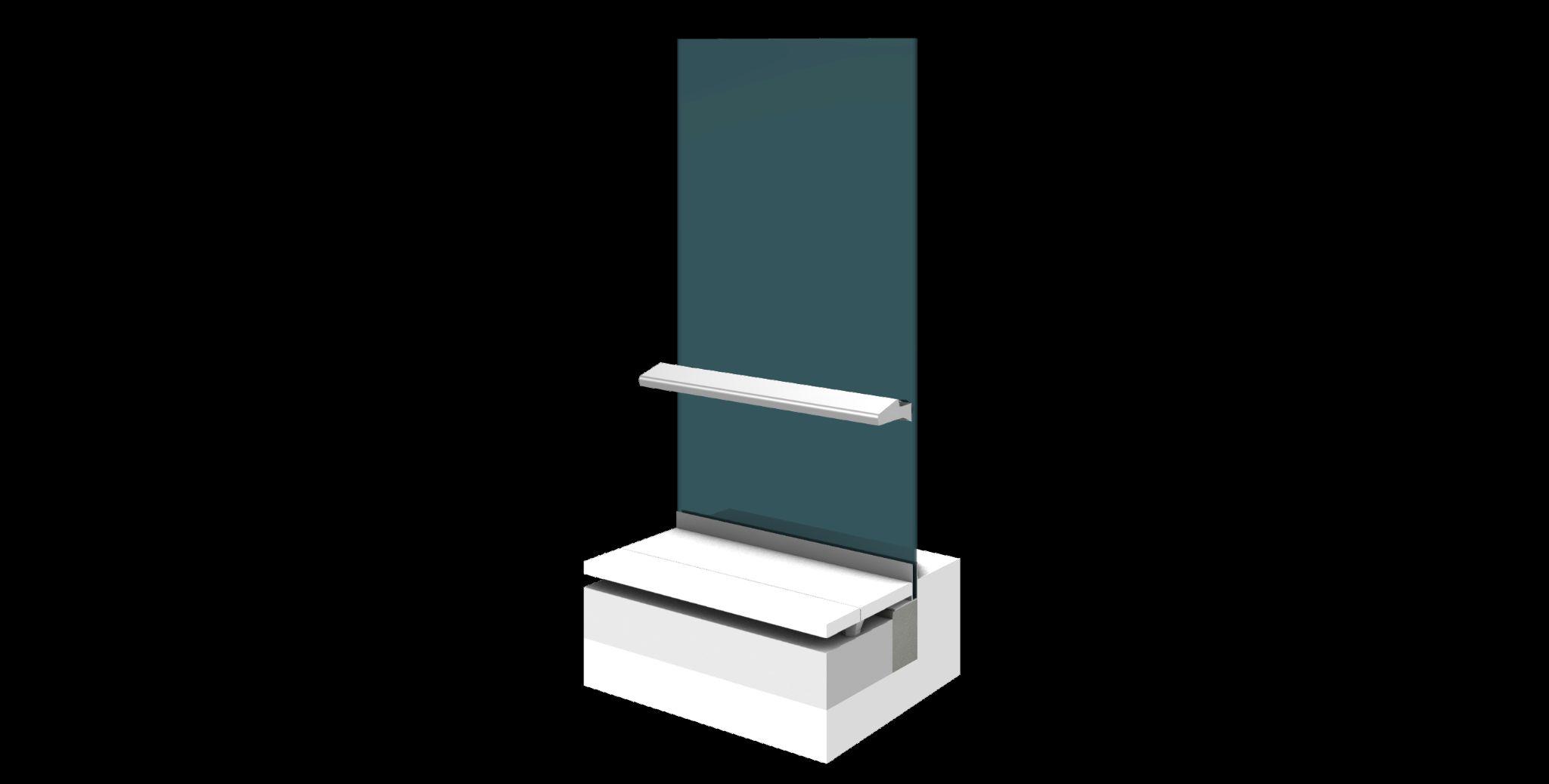

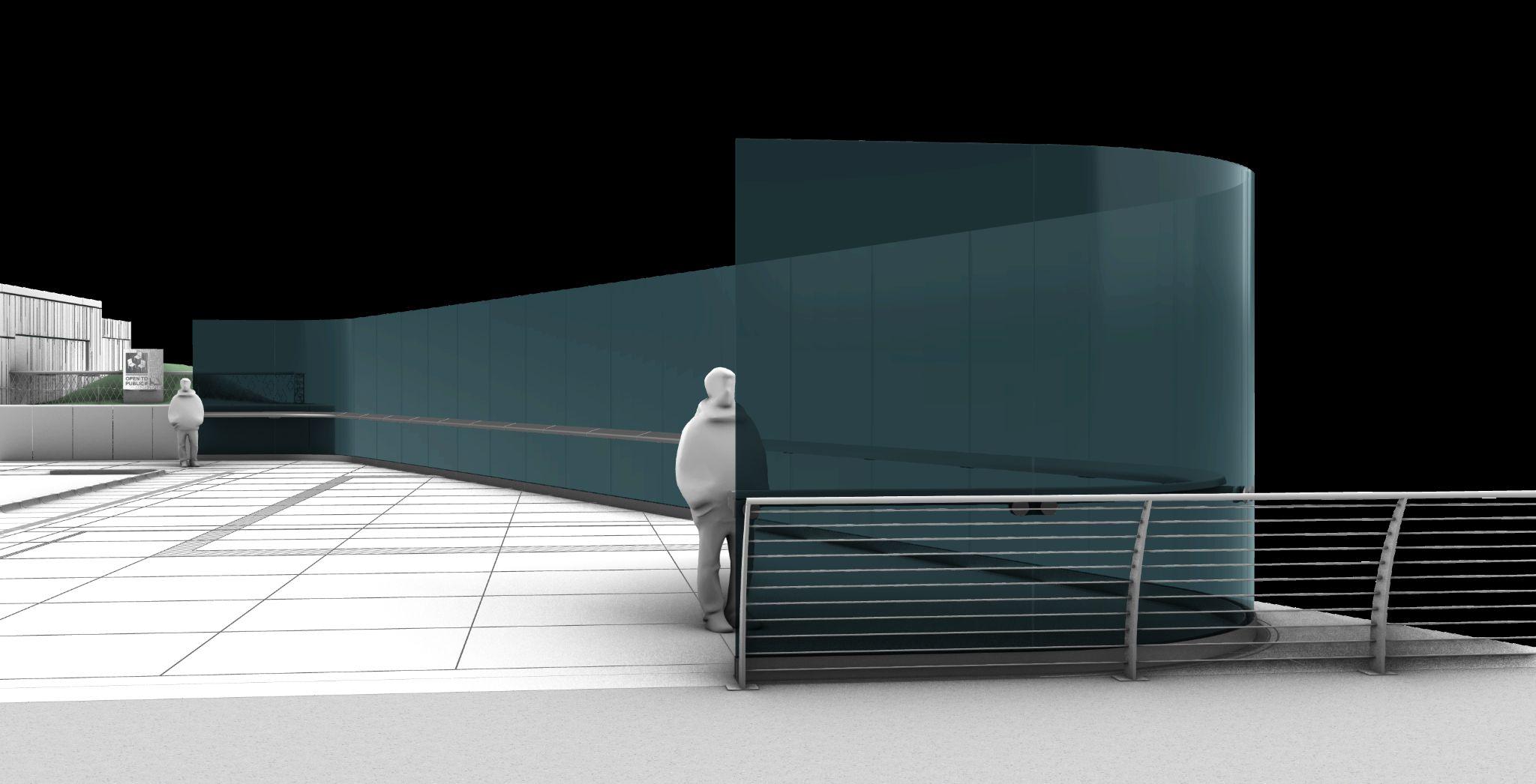

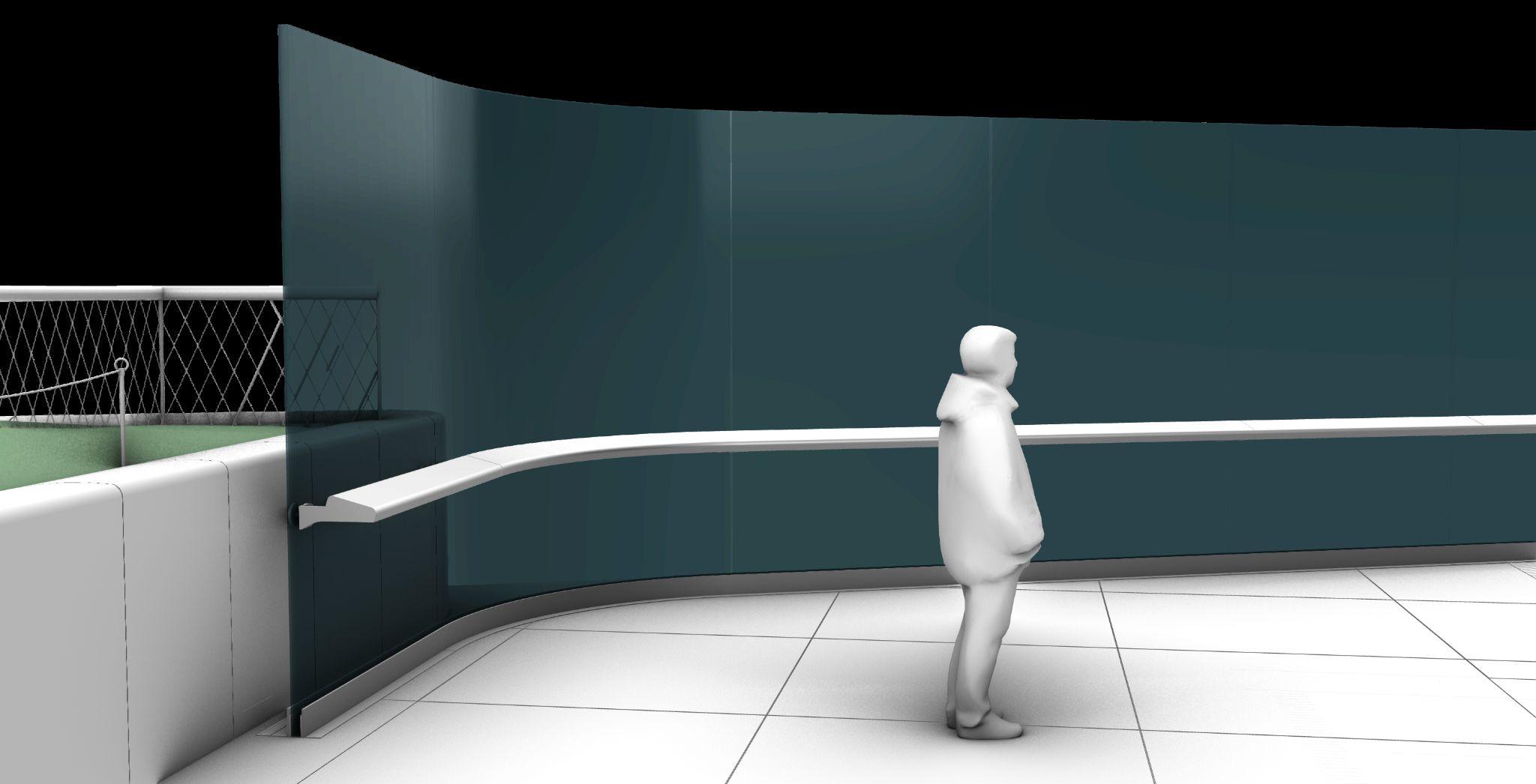

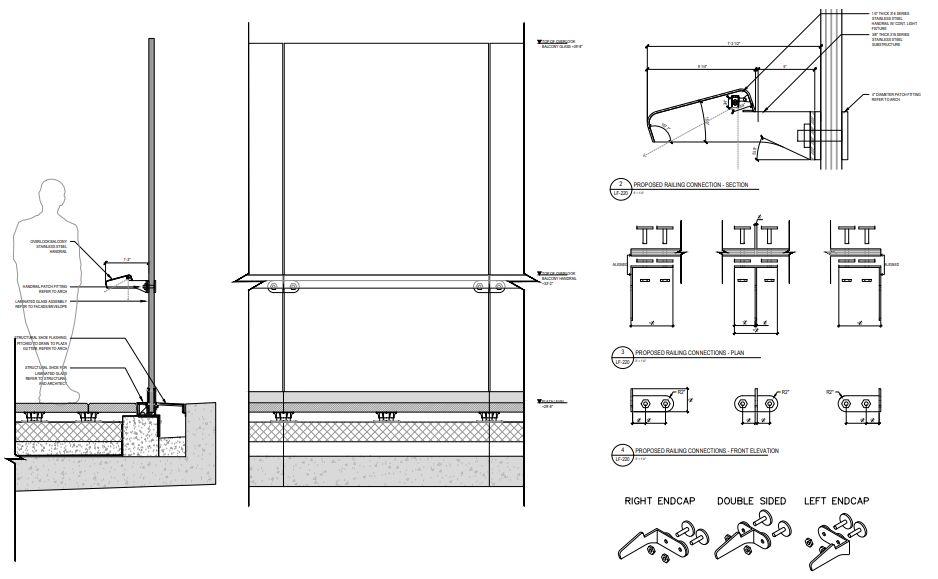

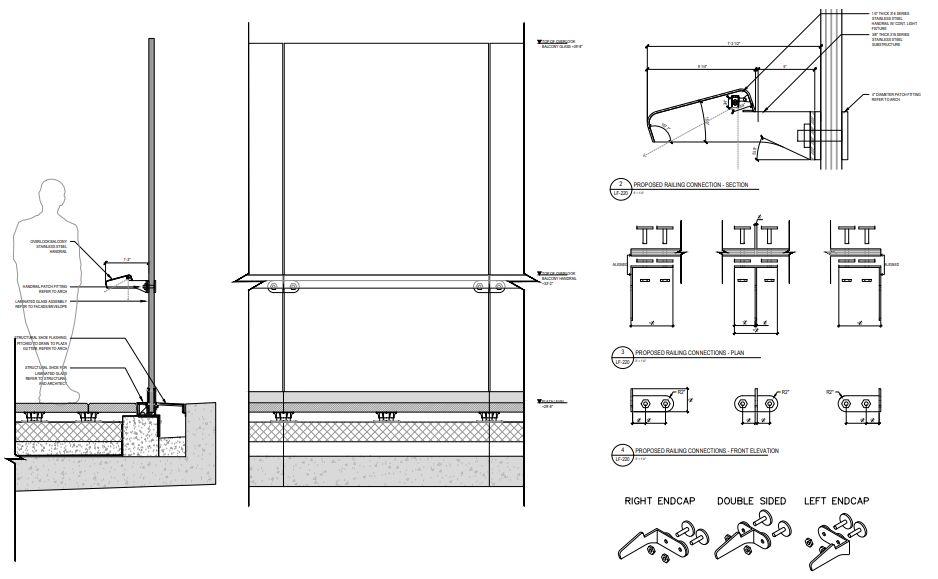

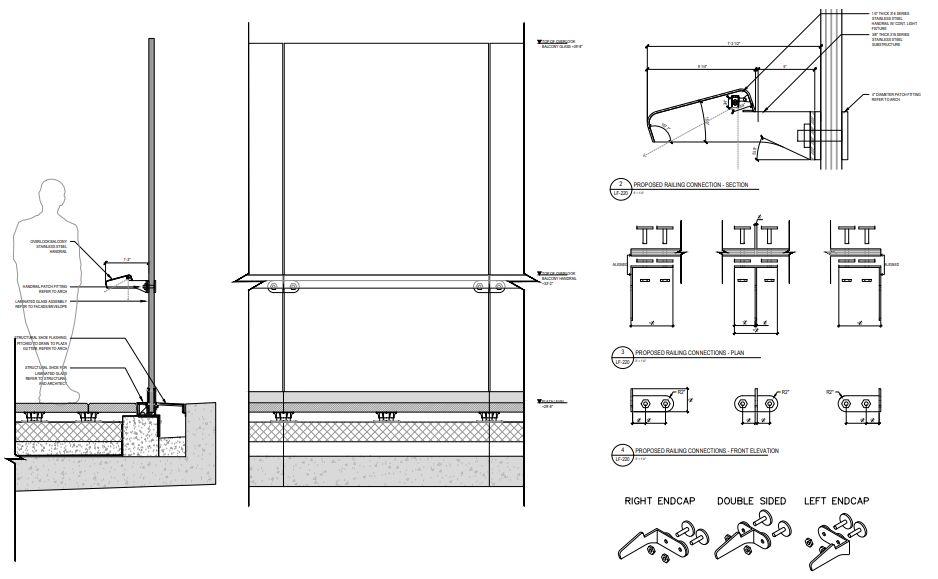

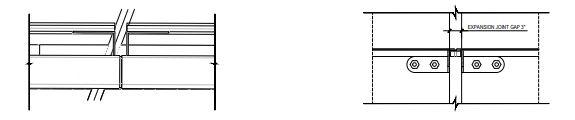

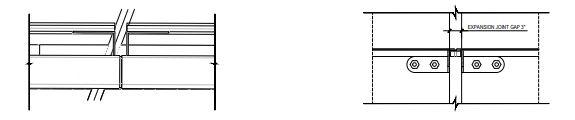

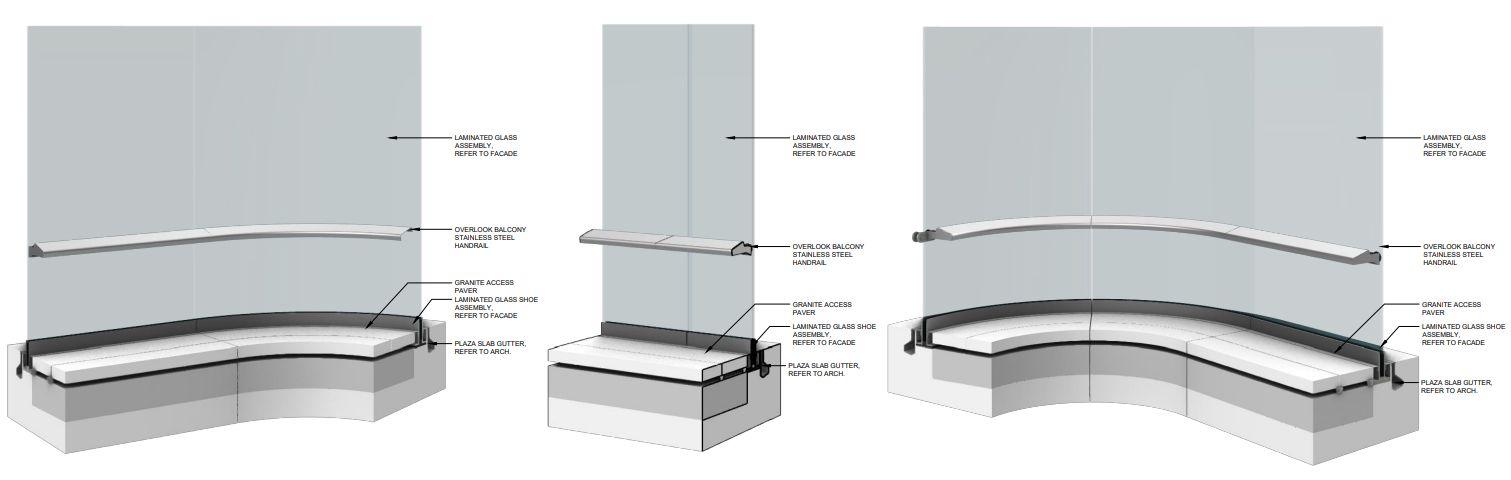

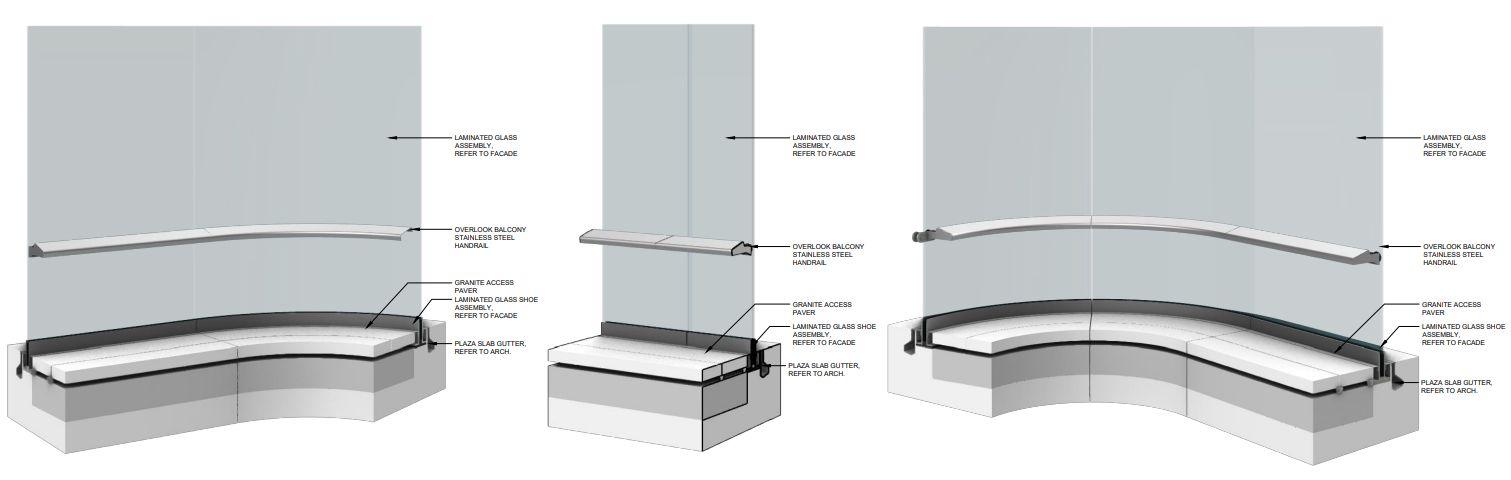

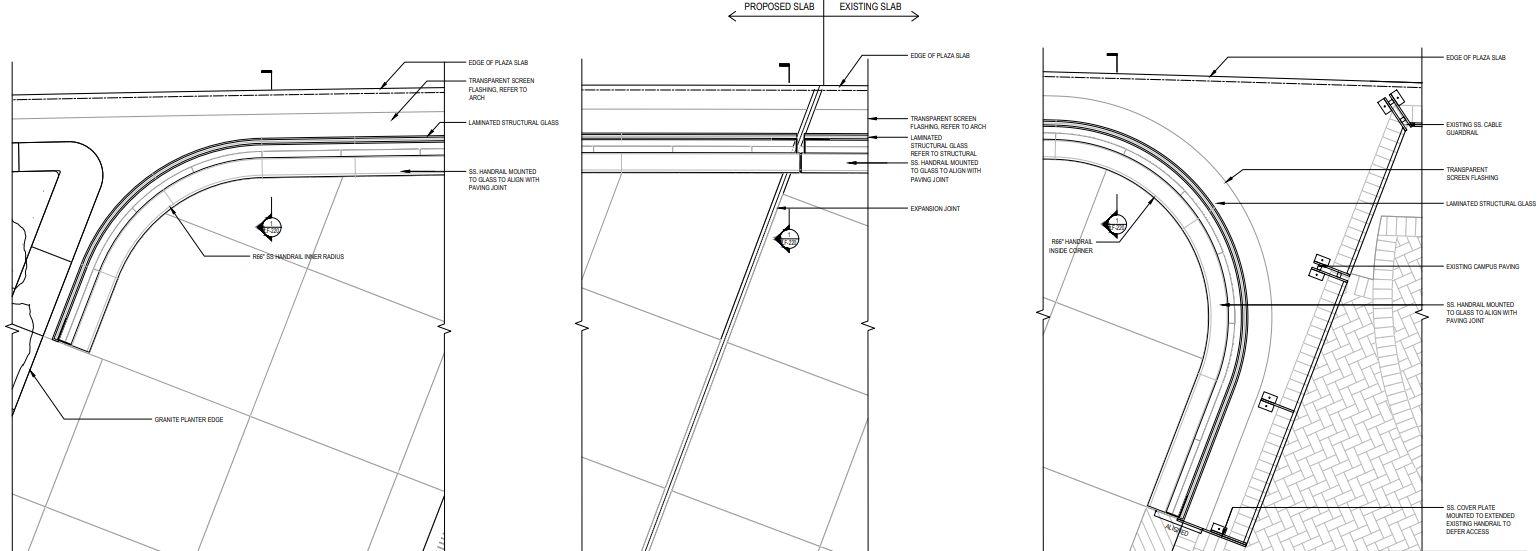

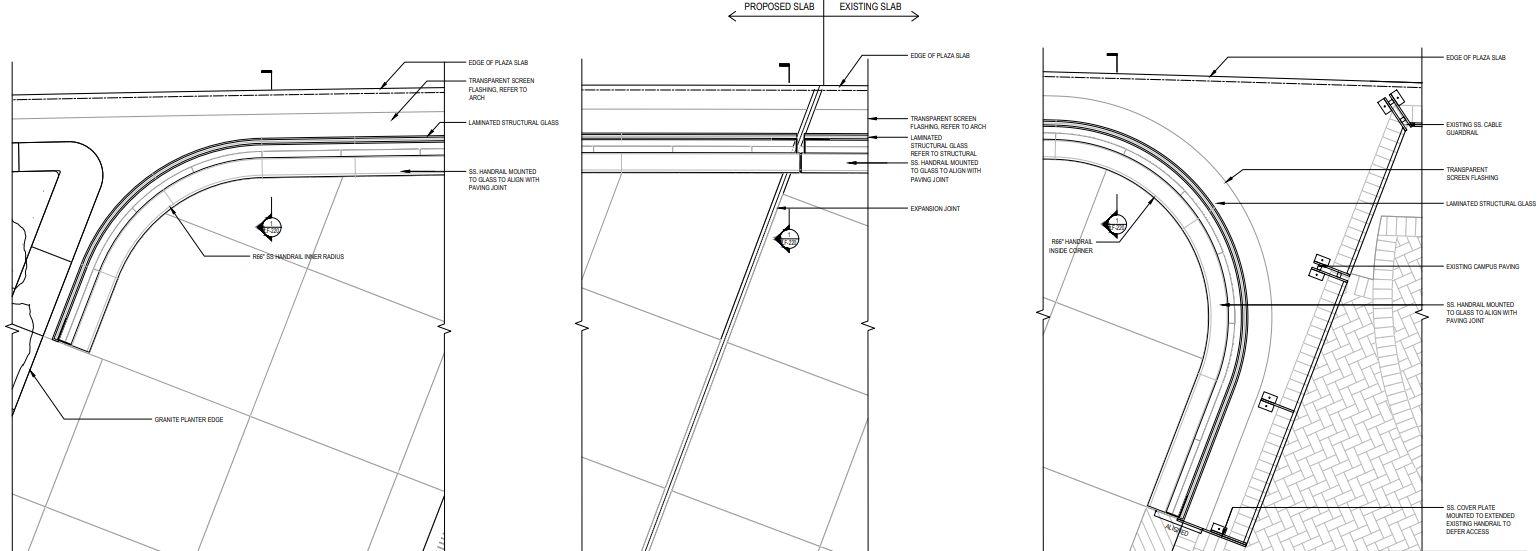

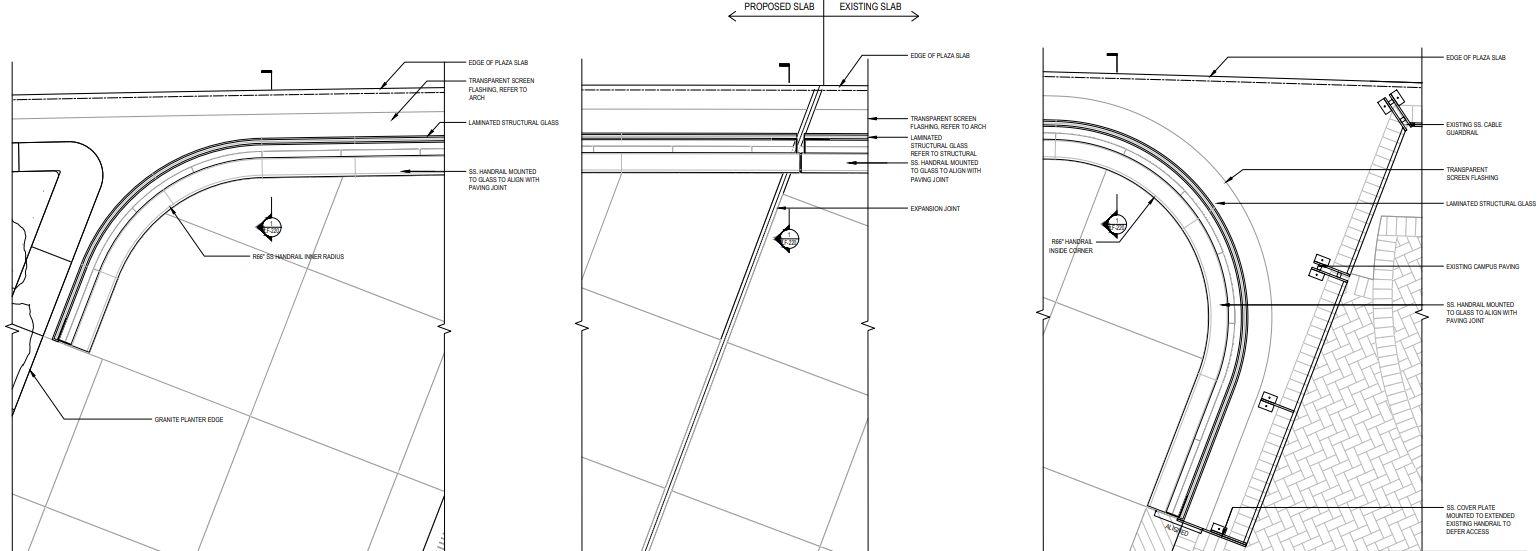

During the project I designed and modelled the new railing consisting of an aluminium profile attached to 3,5m tall laminated glass panels.

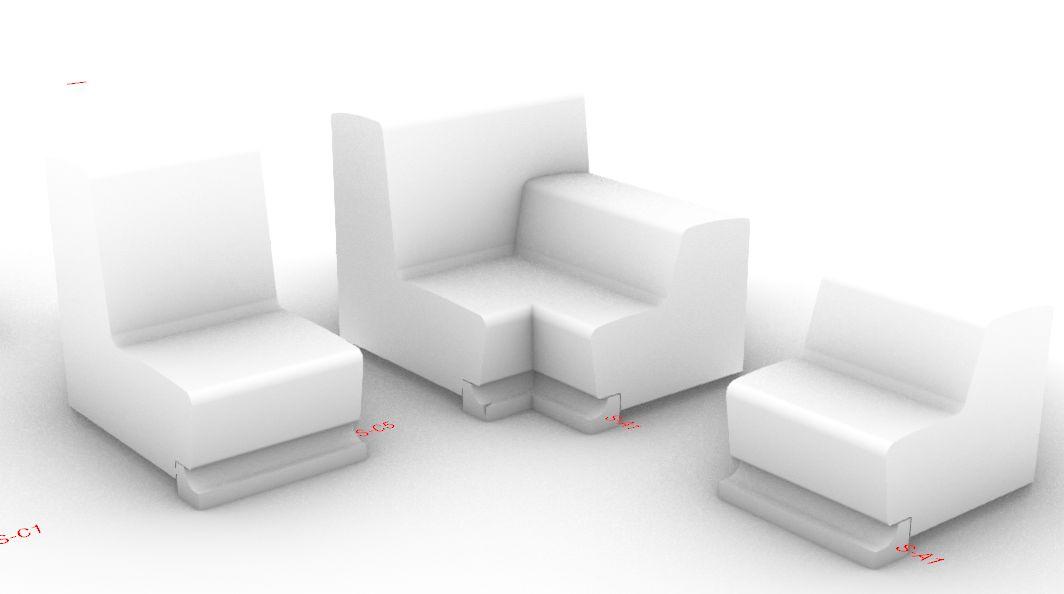

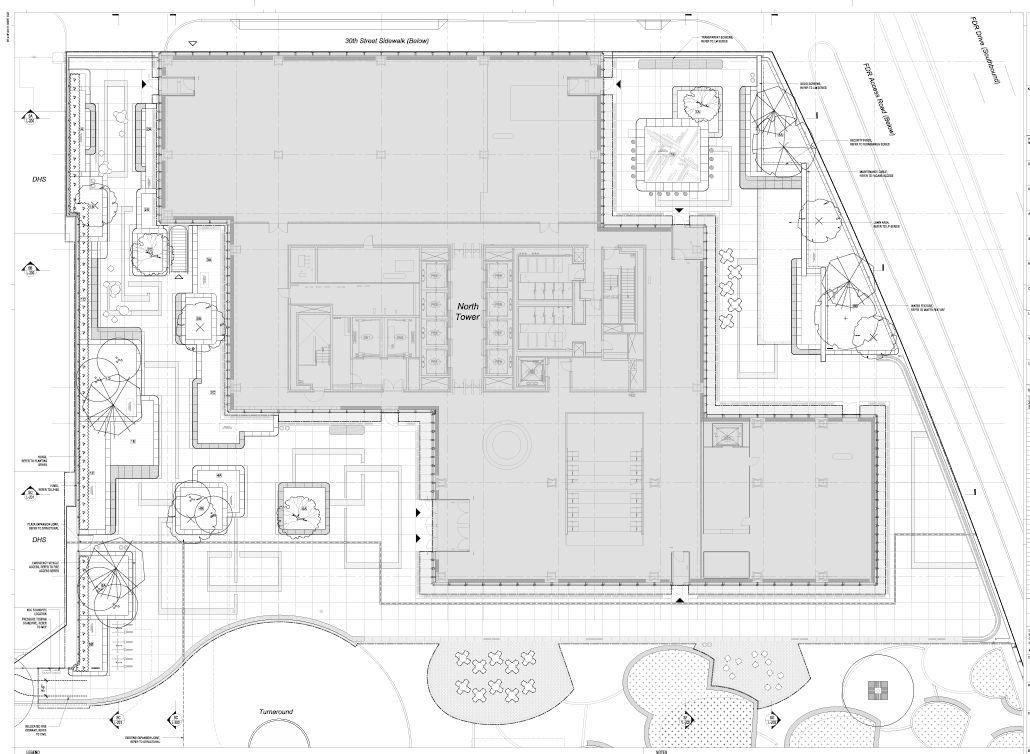

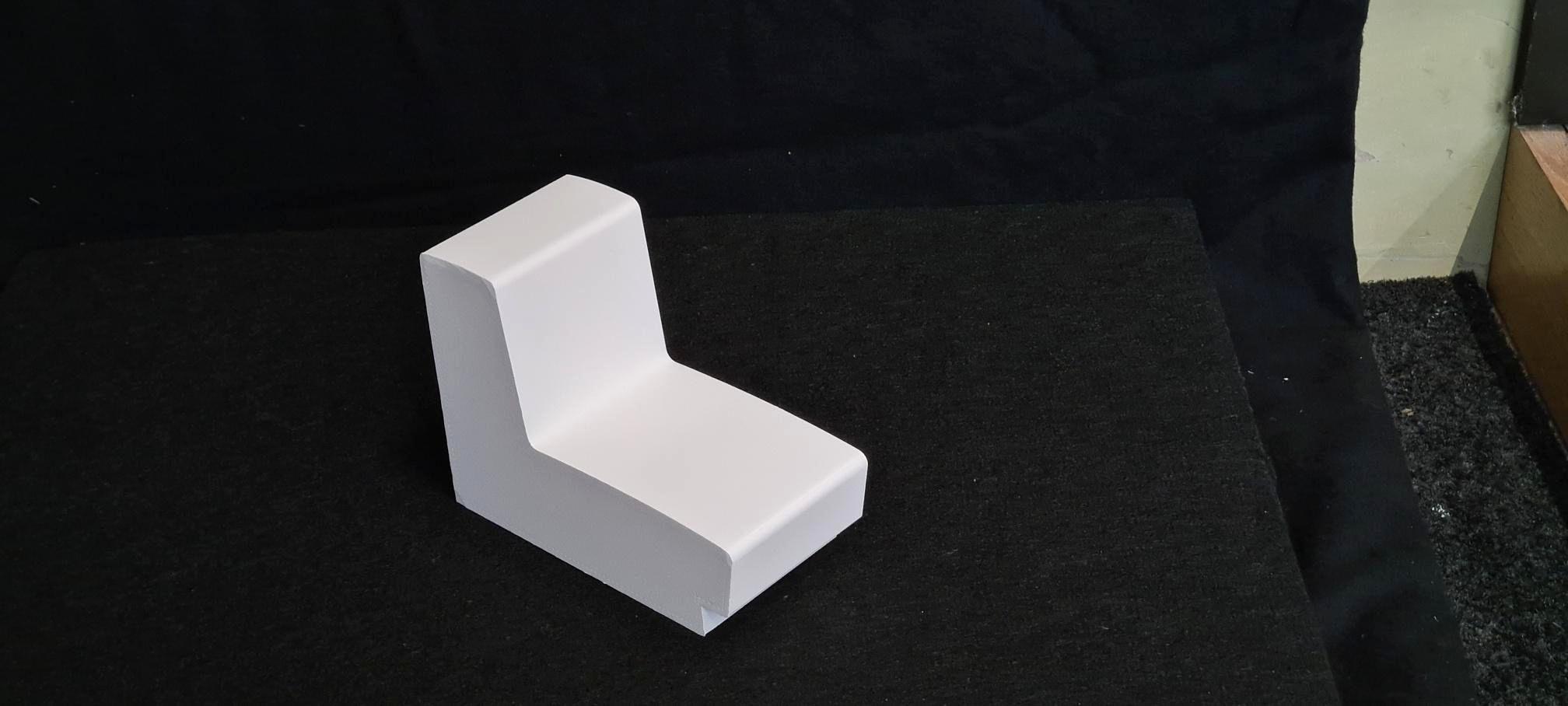

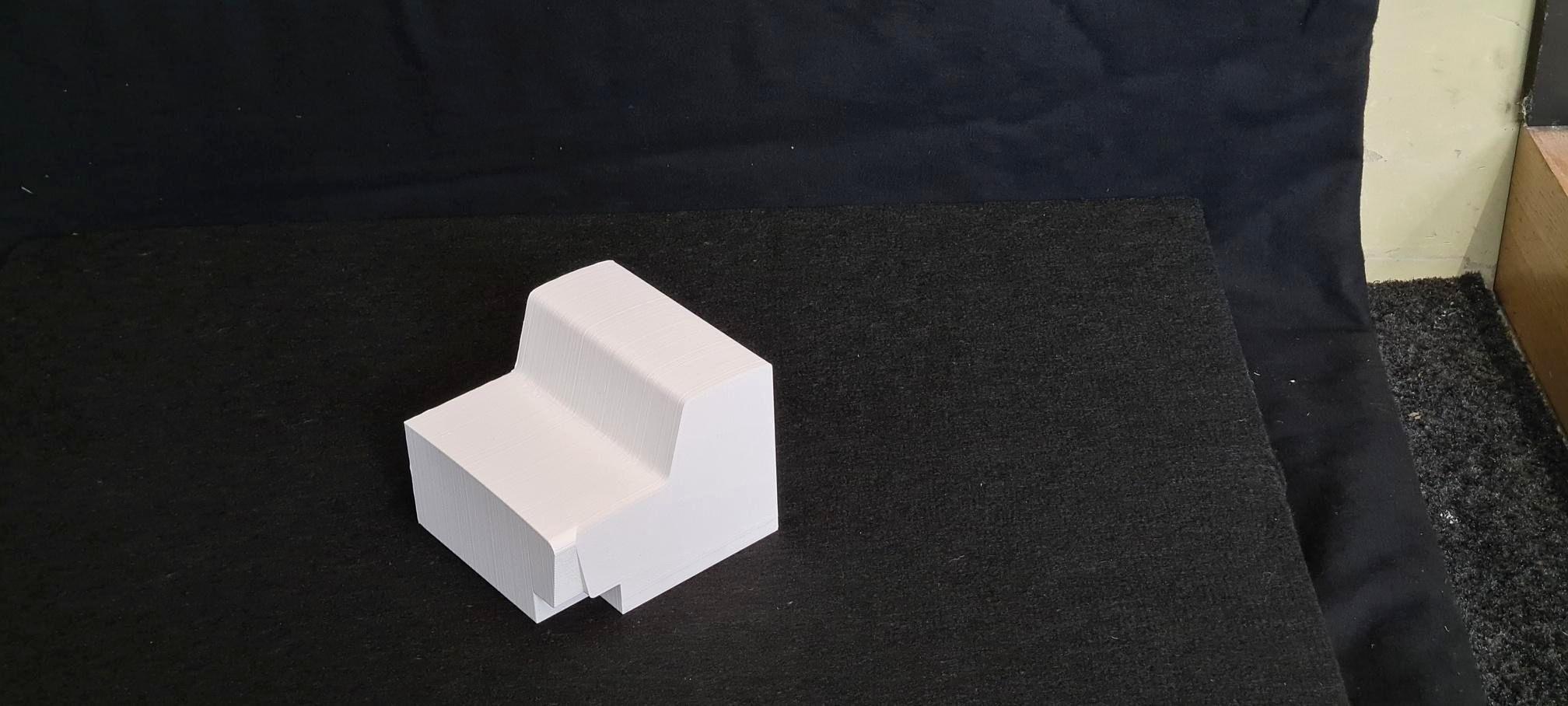

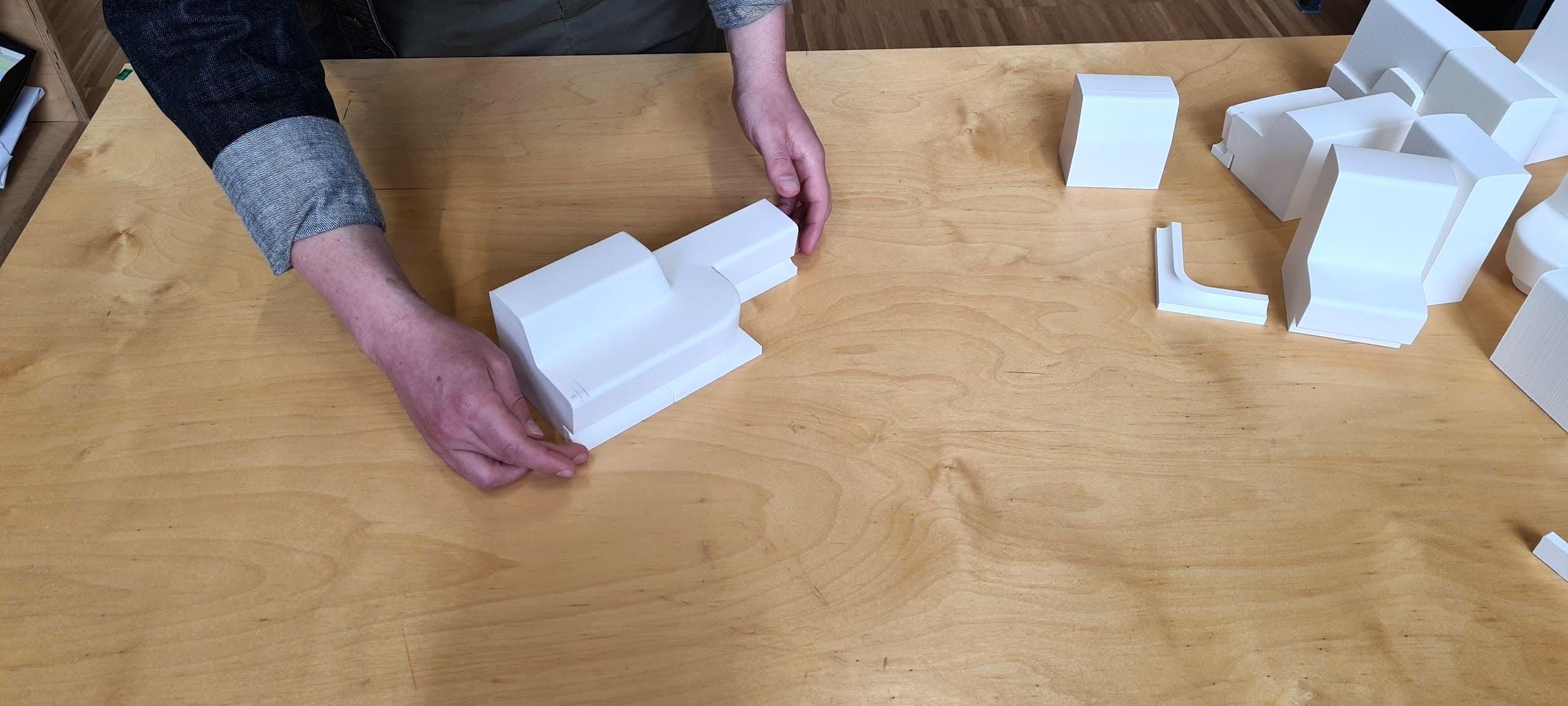

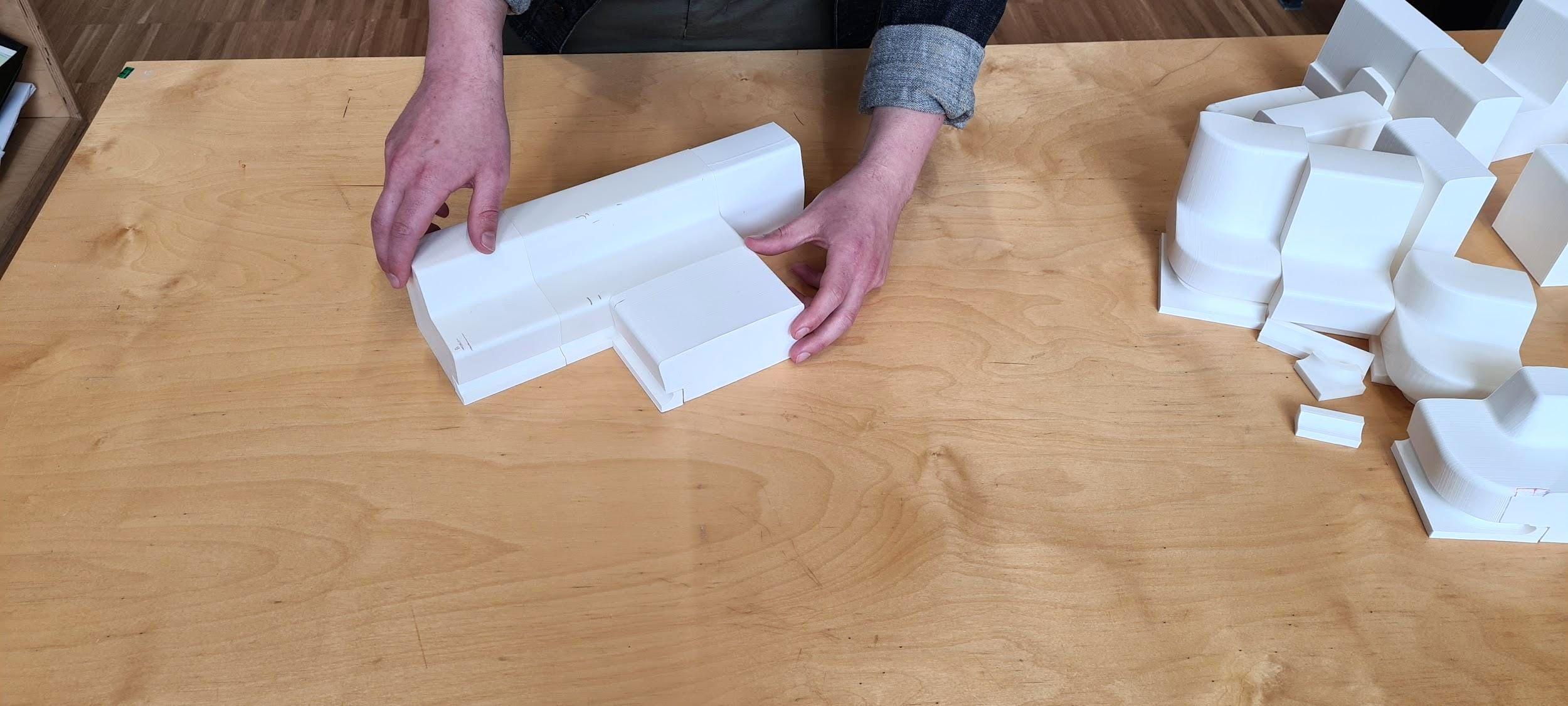

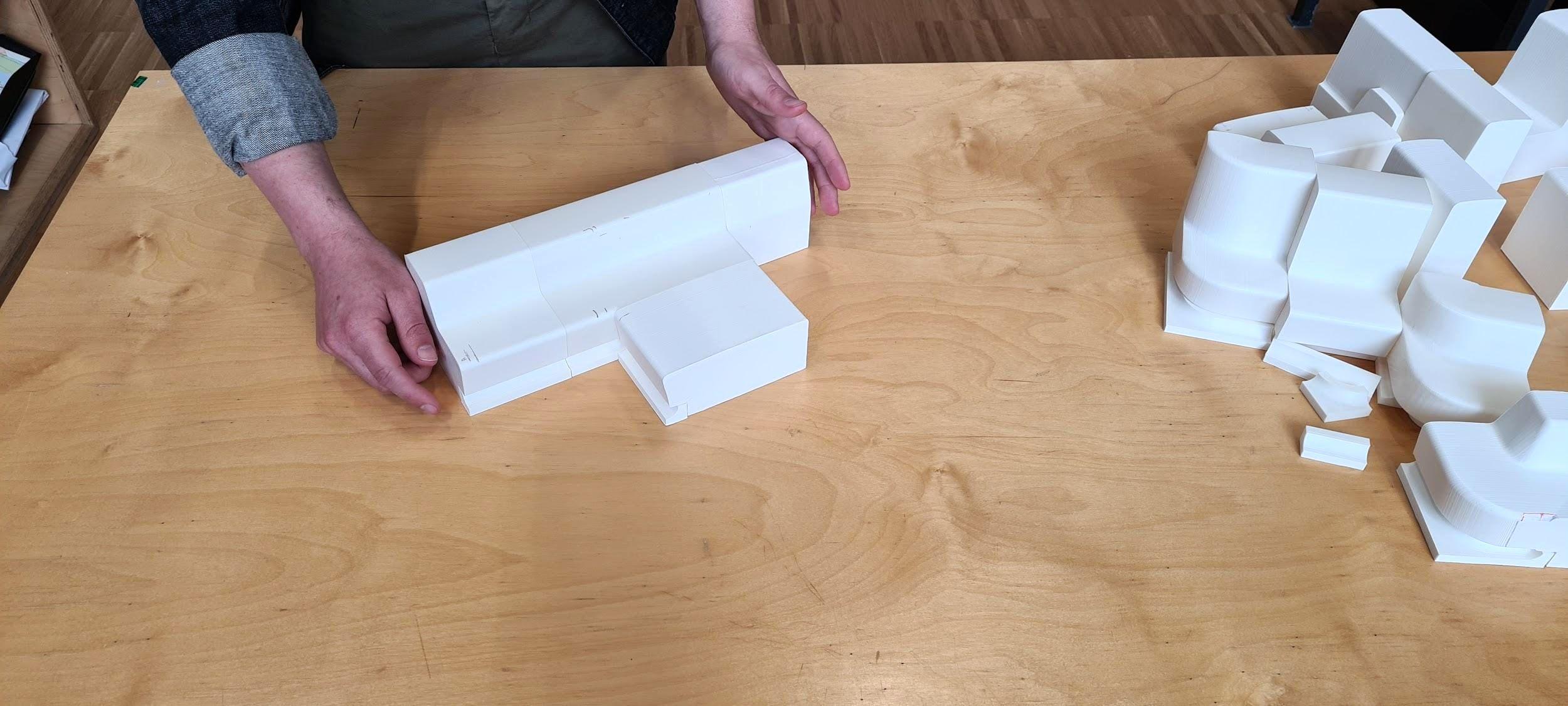

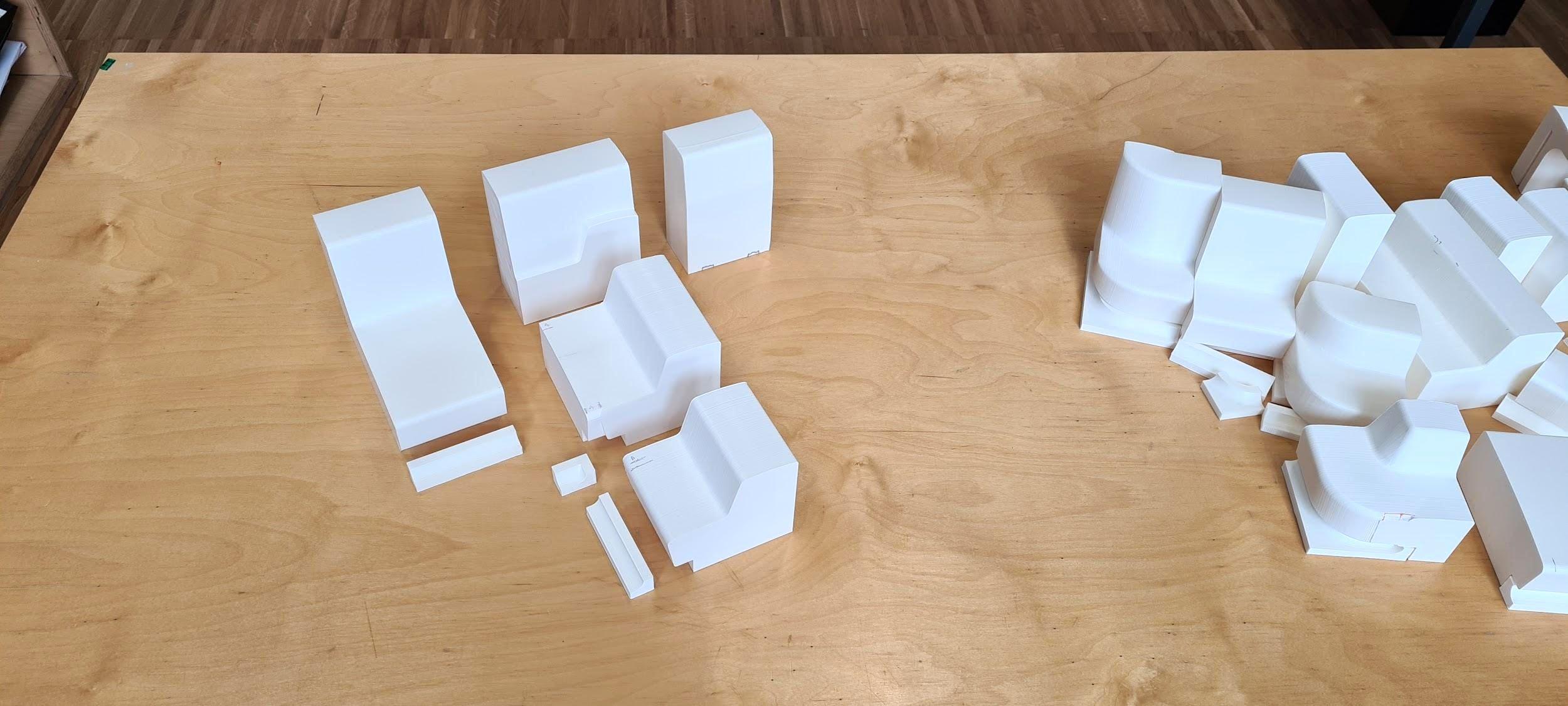

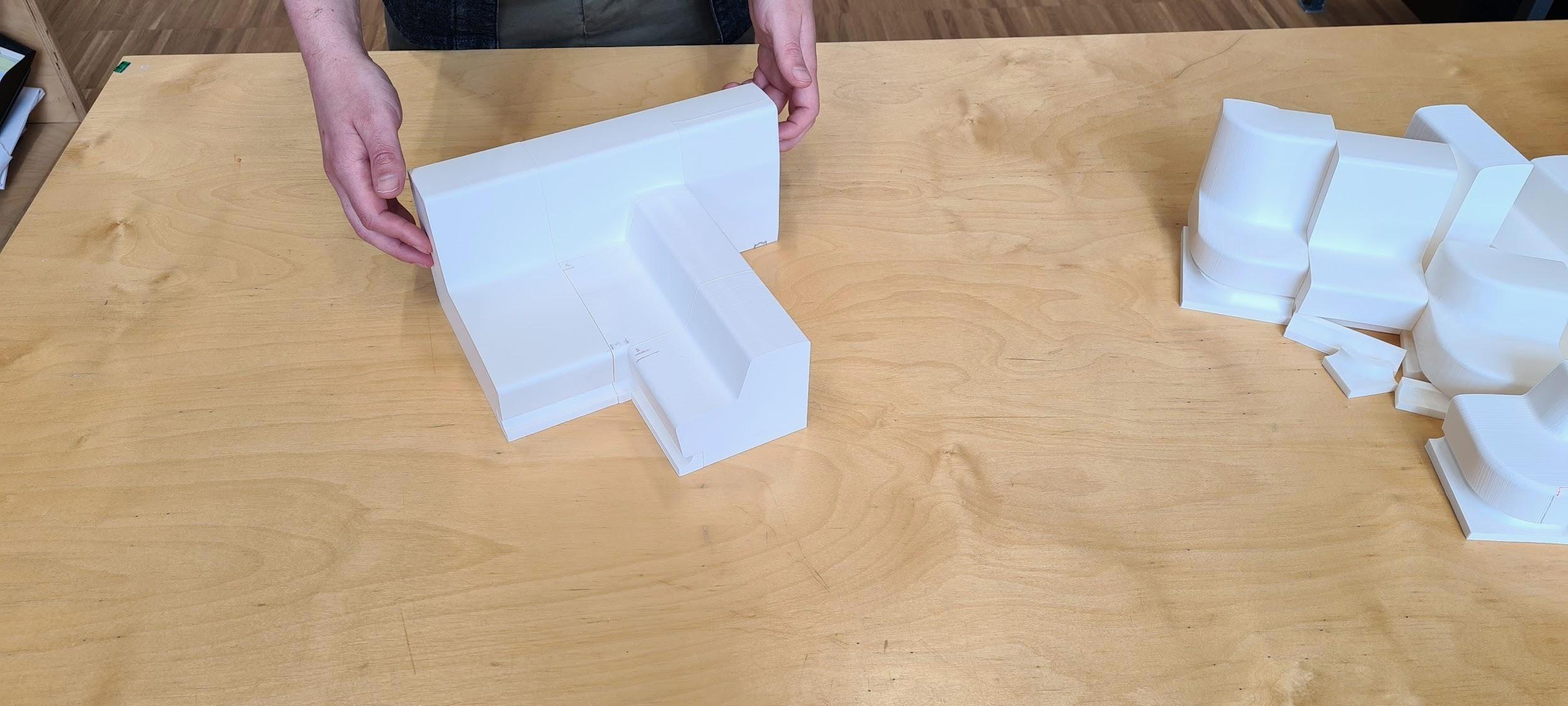

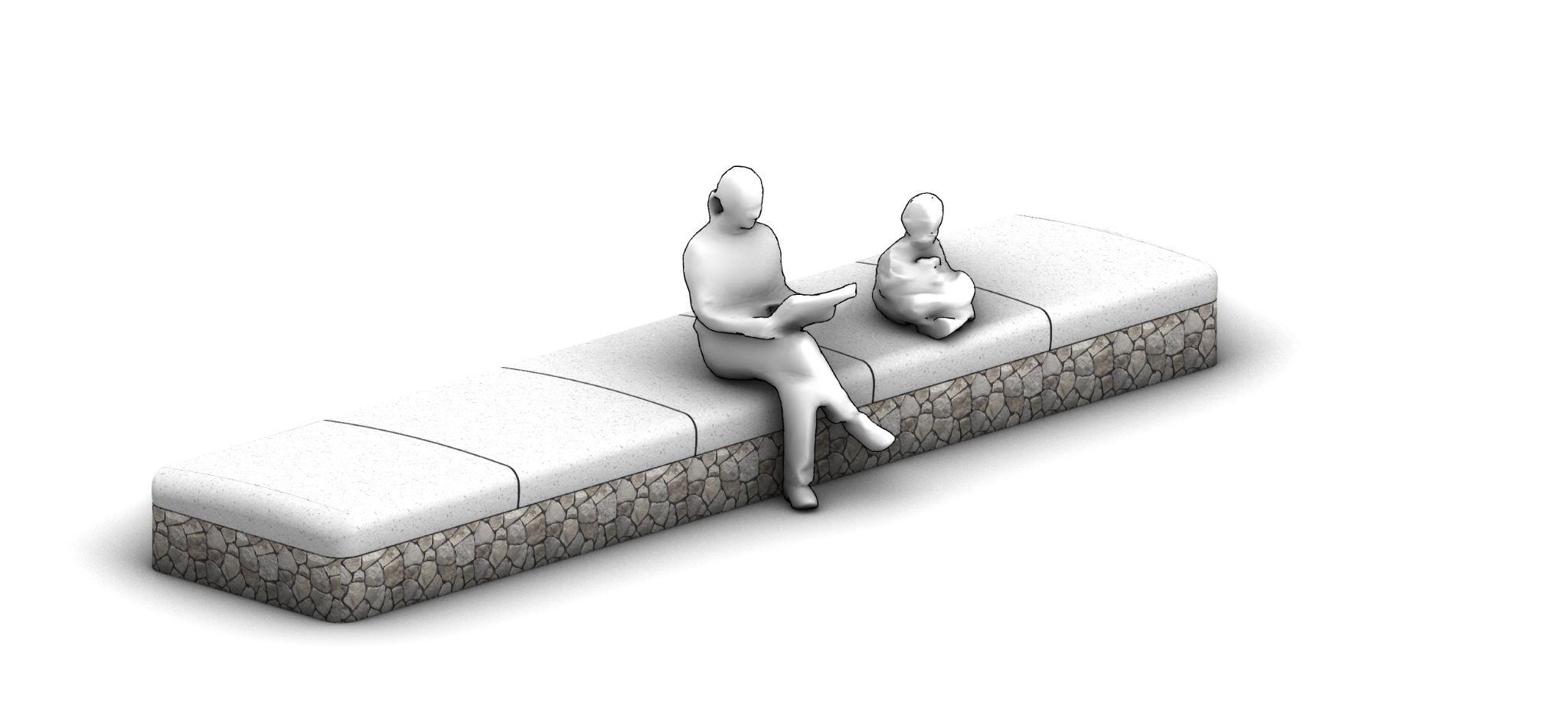

Another task was to optimise the design of modular seating and planter edges by 3D printing 1 to 10 scale models and testing the different compositions.

GLASS HAND RAILING

ZOOM INS & CONSTRUCTION DRAWINGS

SPECIAL MODULES

SEATING & PLANTER EDGES

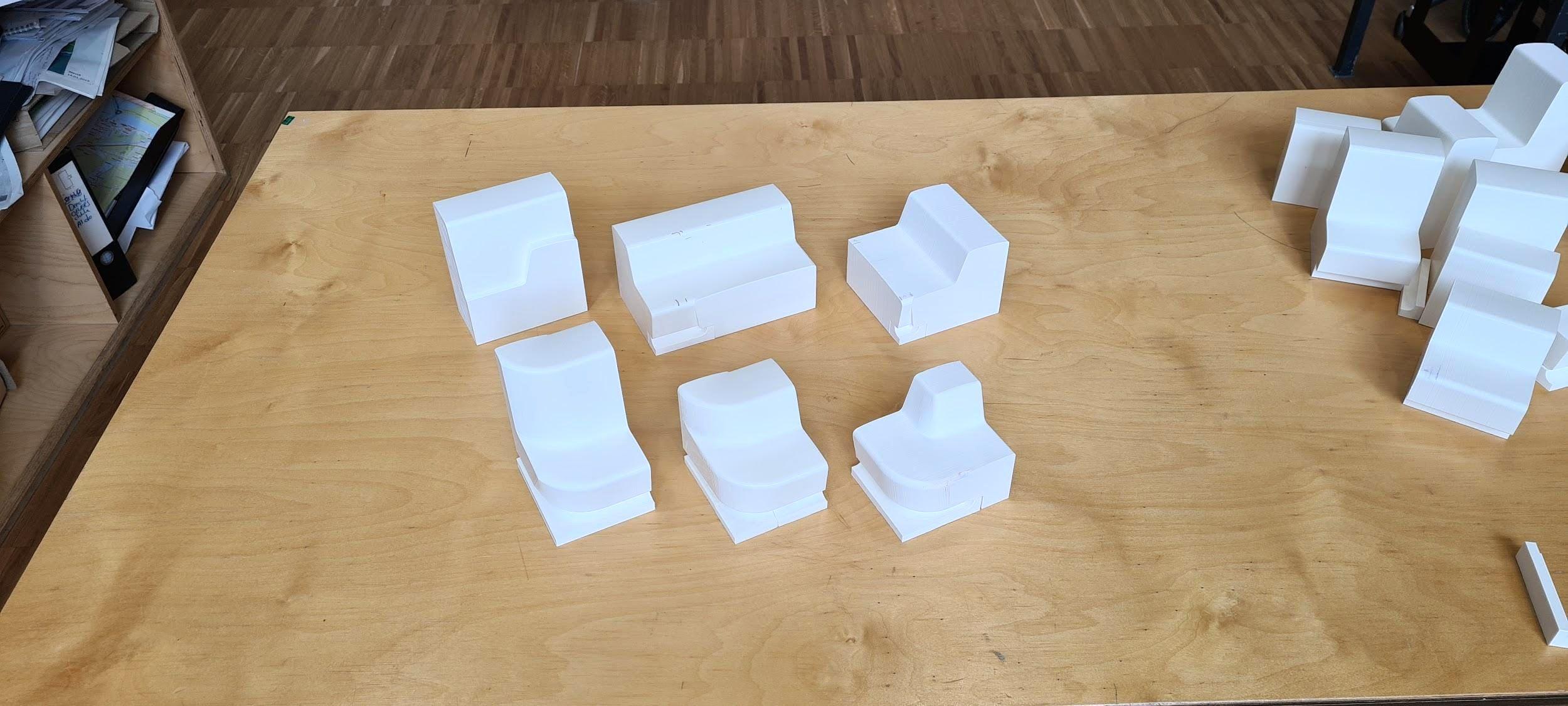

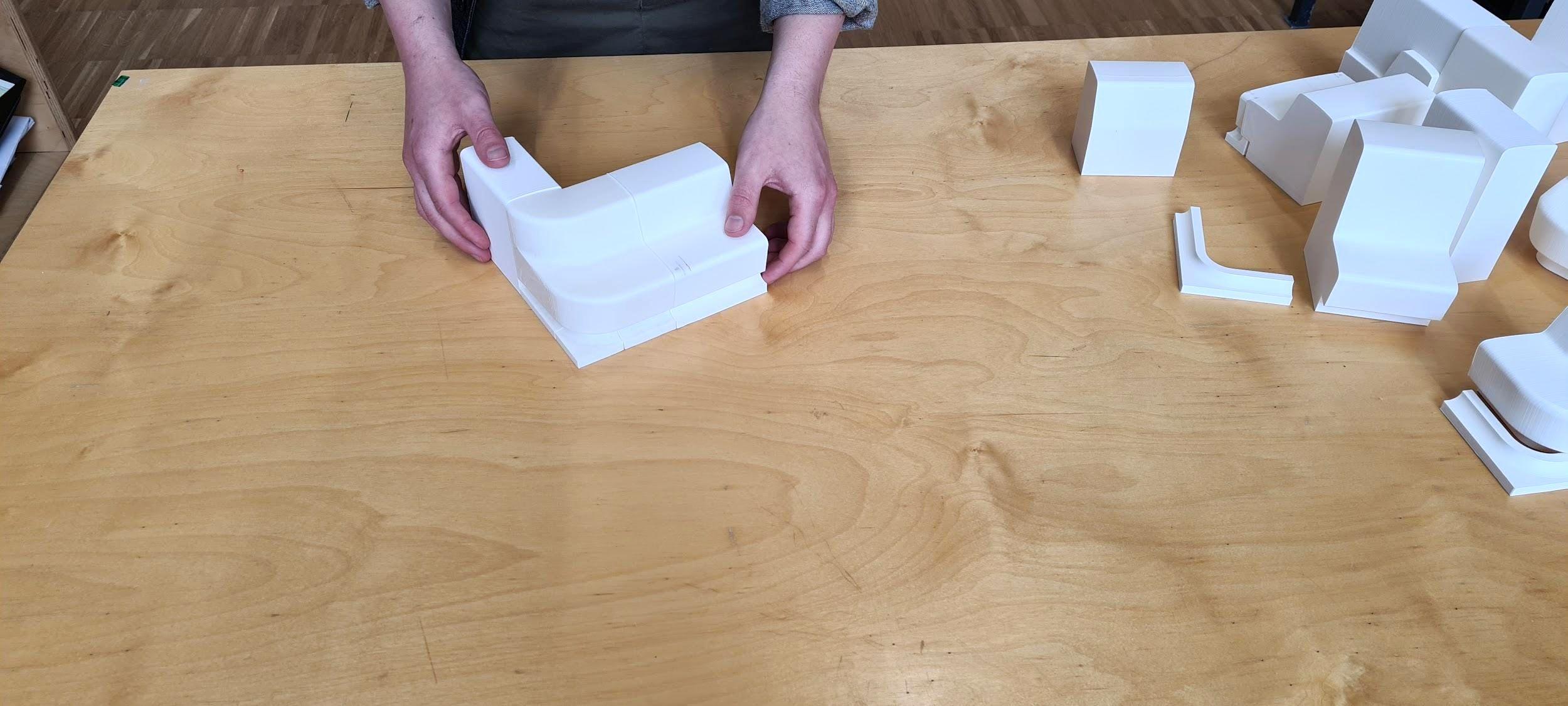

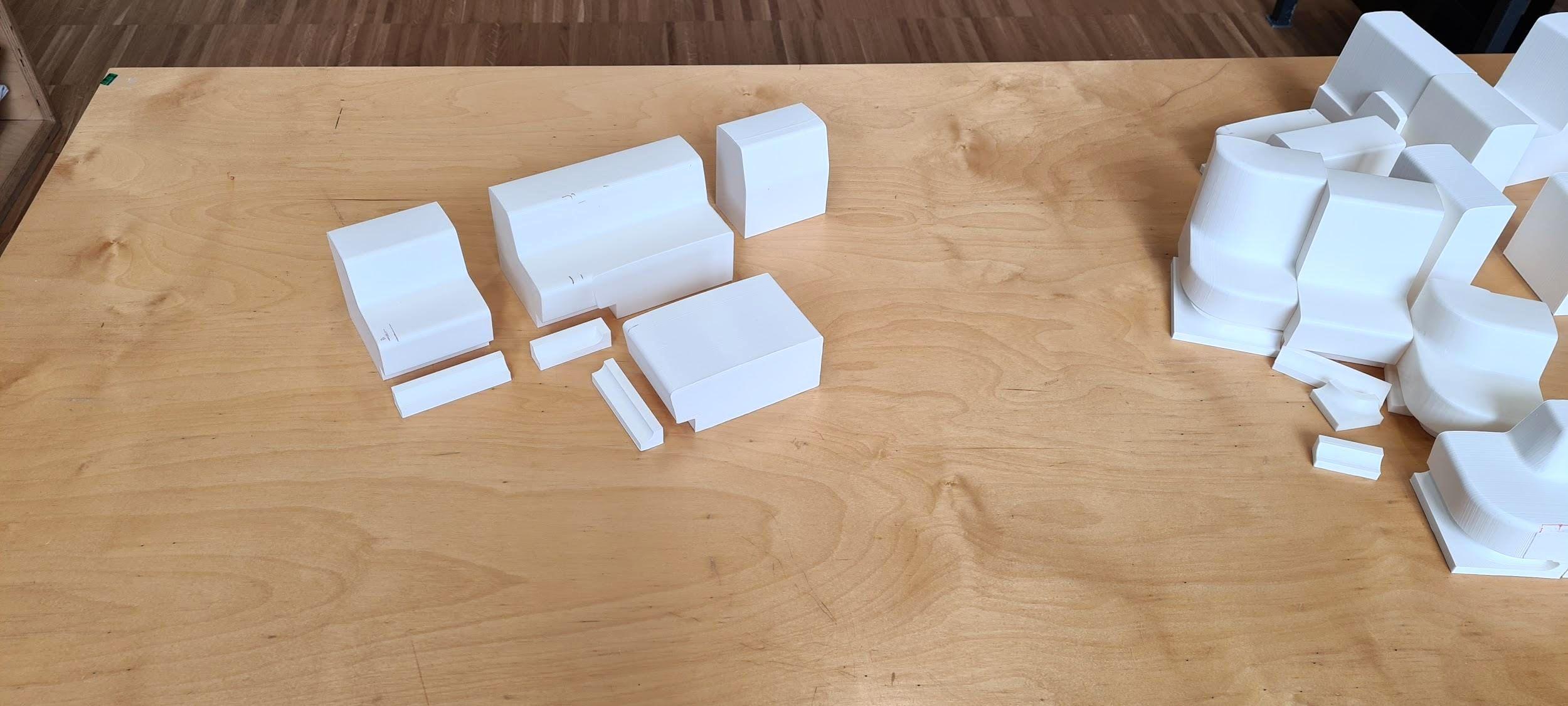

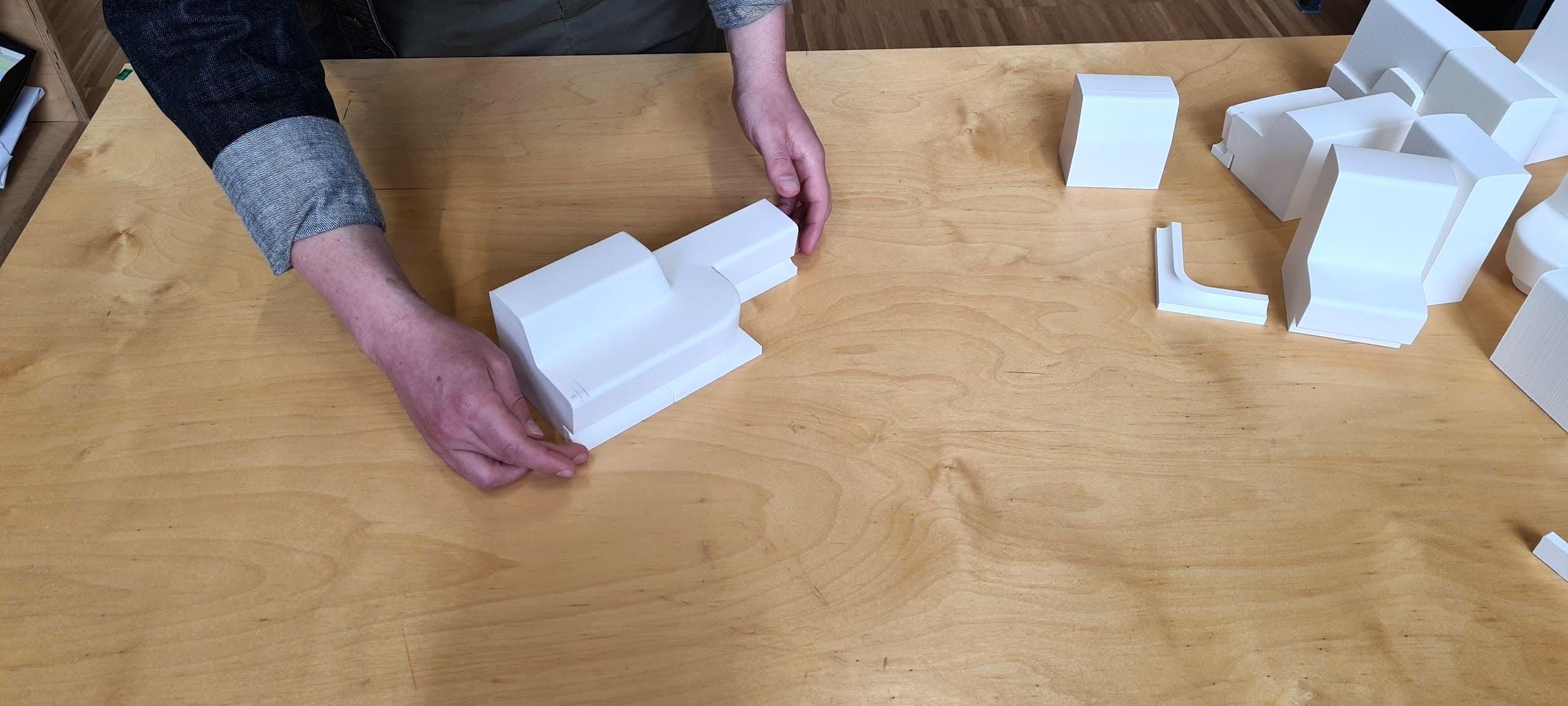

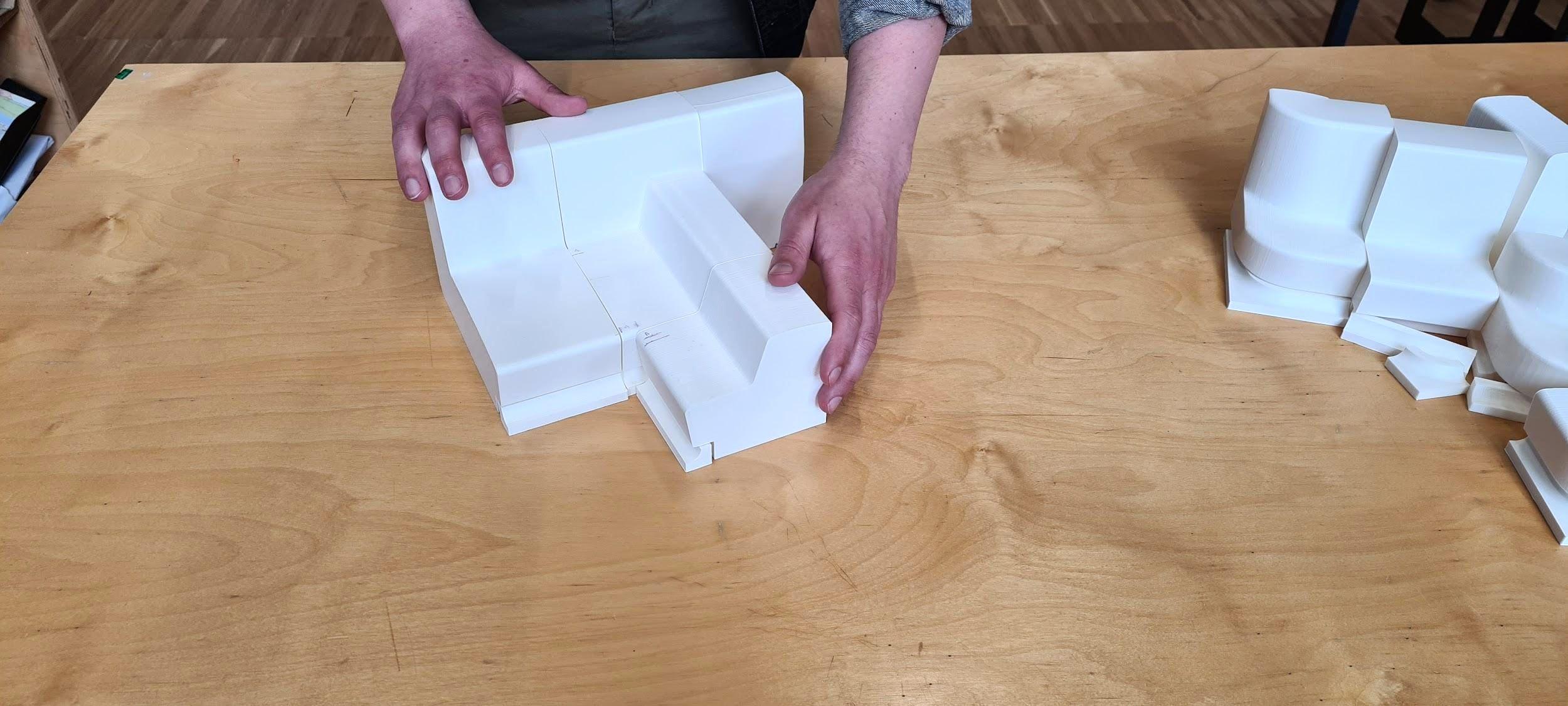

The design optimisation process for the seating and planter edges system consisted of different 3D modeling and scale mock-up studies.

For the scale mock-ups I started by identifying and isolating the unique corners and transition points where different types of modules met.

For printing I selected a scale size that would deliver good print quality and details and still allowed multiple pieces to be printed at the same time, thus making optimal use the printing surface area.

One of the challenges during the process was making sure all the pieces would read as closed solid polysurfaces after being scaled down and converted to the different file formats.

Identifying the unique pieces that required further study

3D PRINTED 1 TO 10 SCALE MODELS

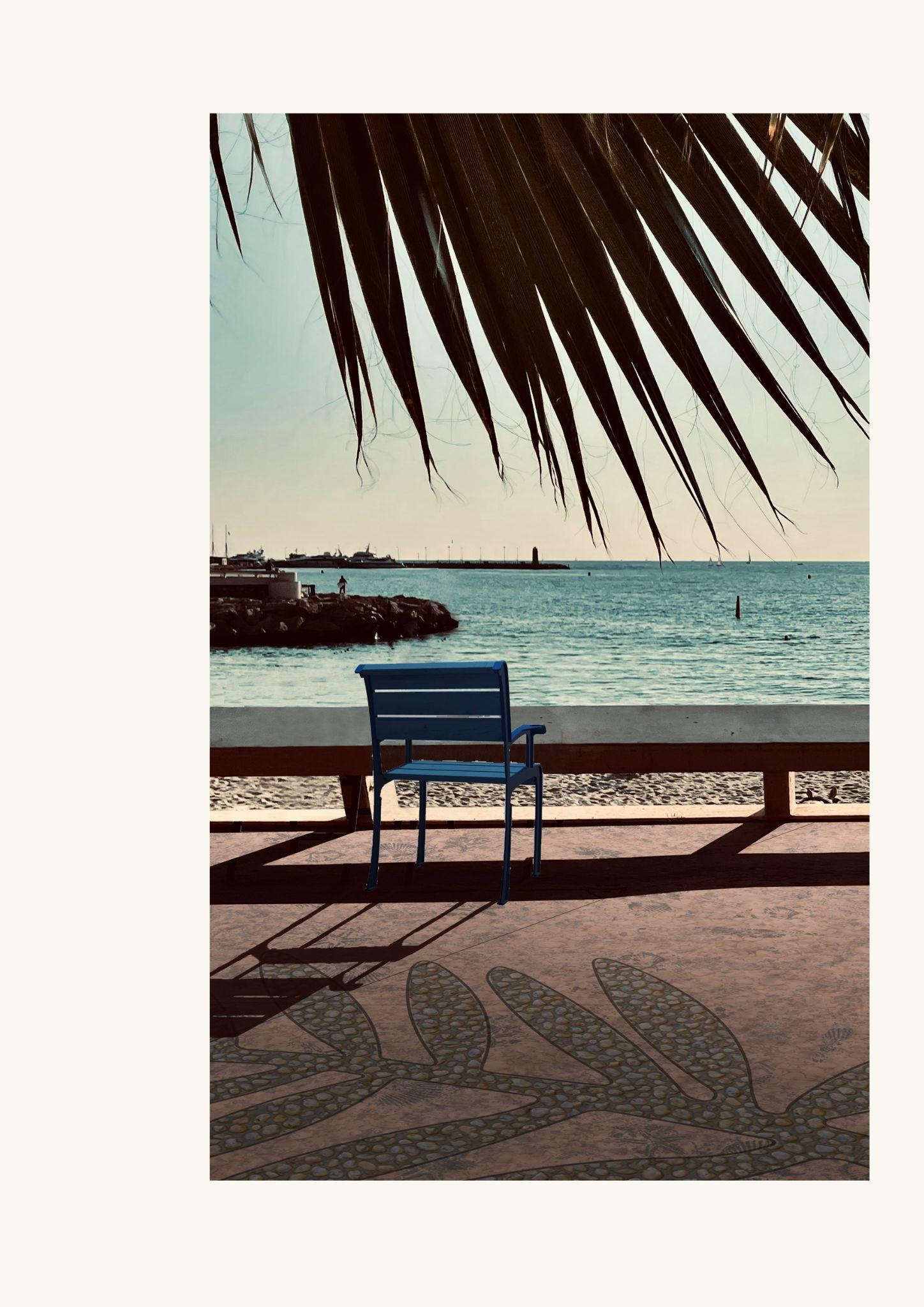

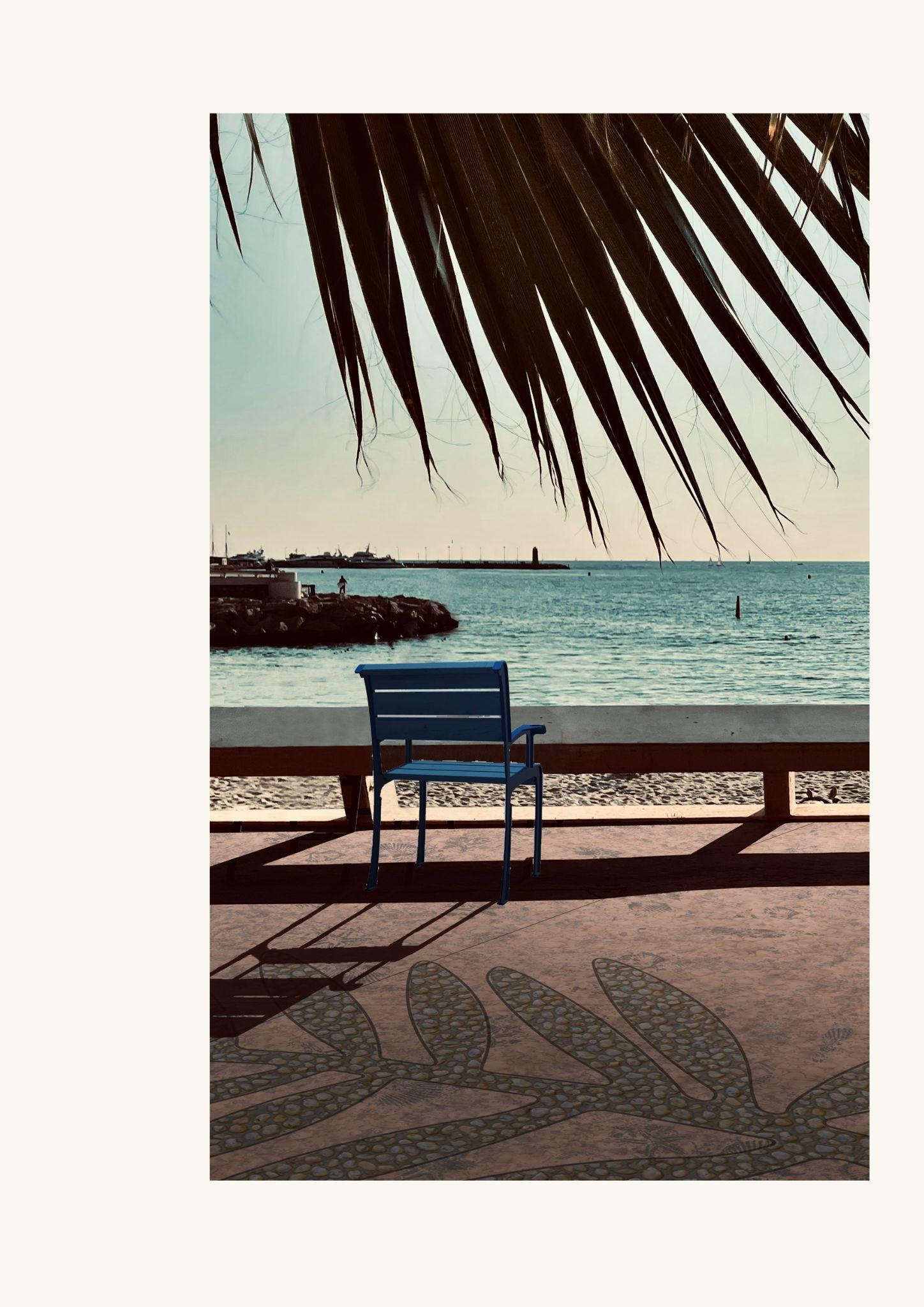

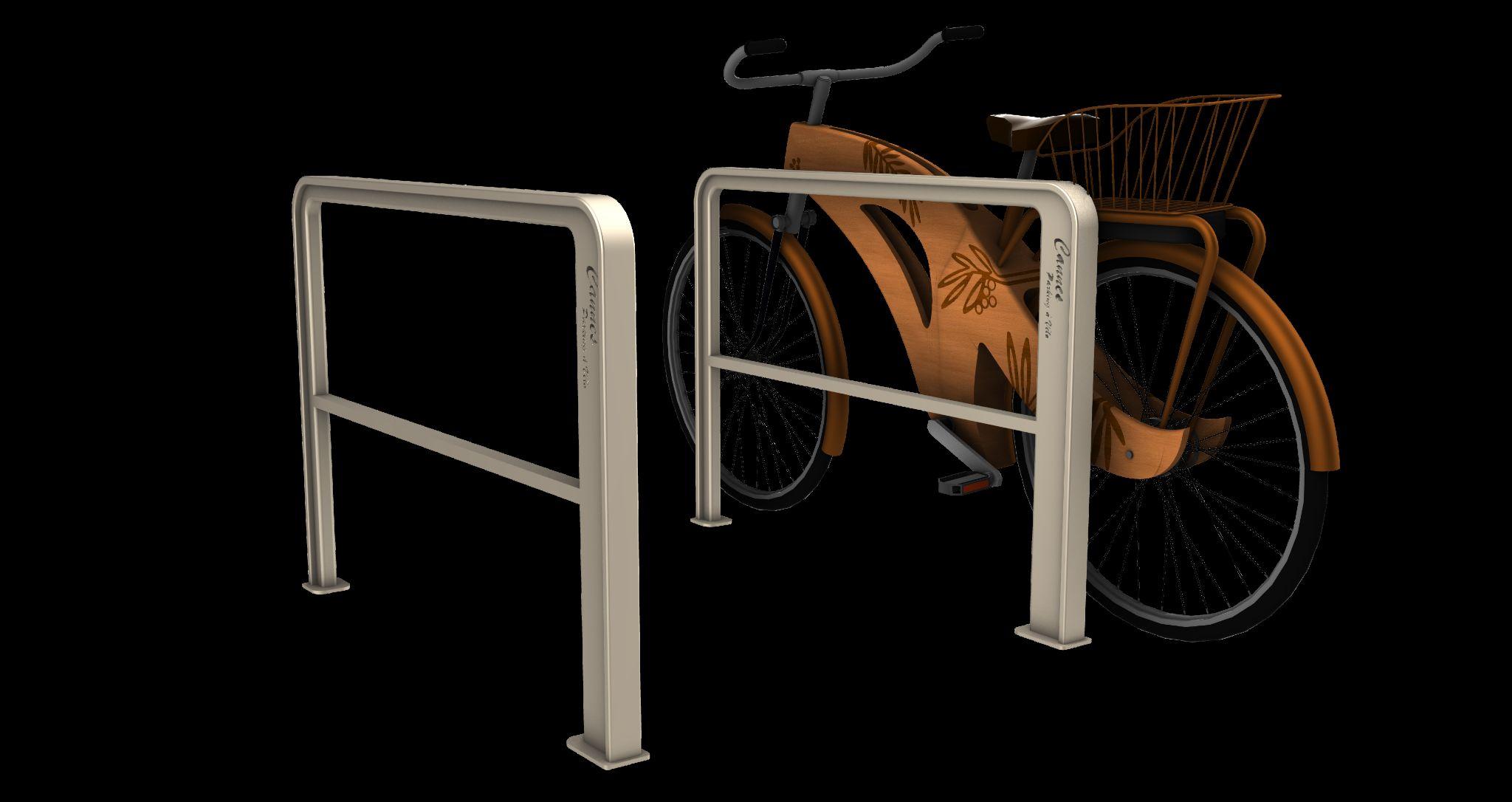

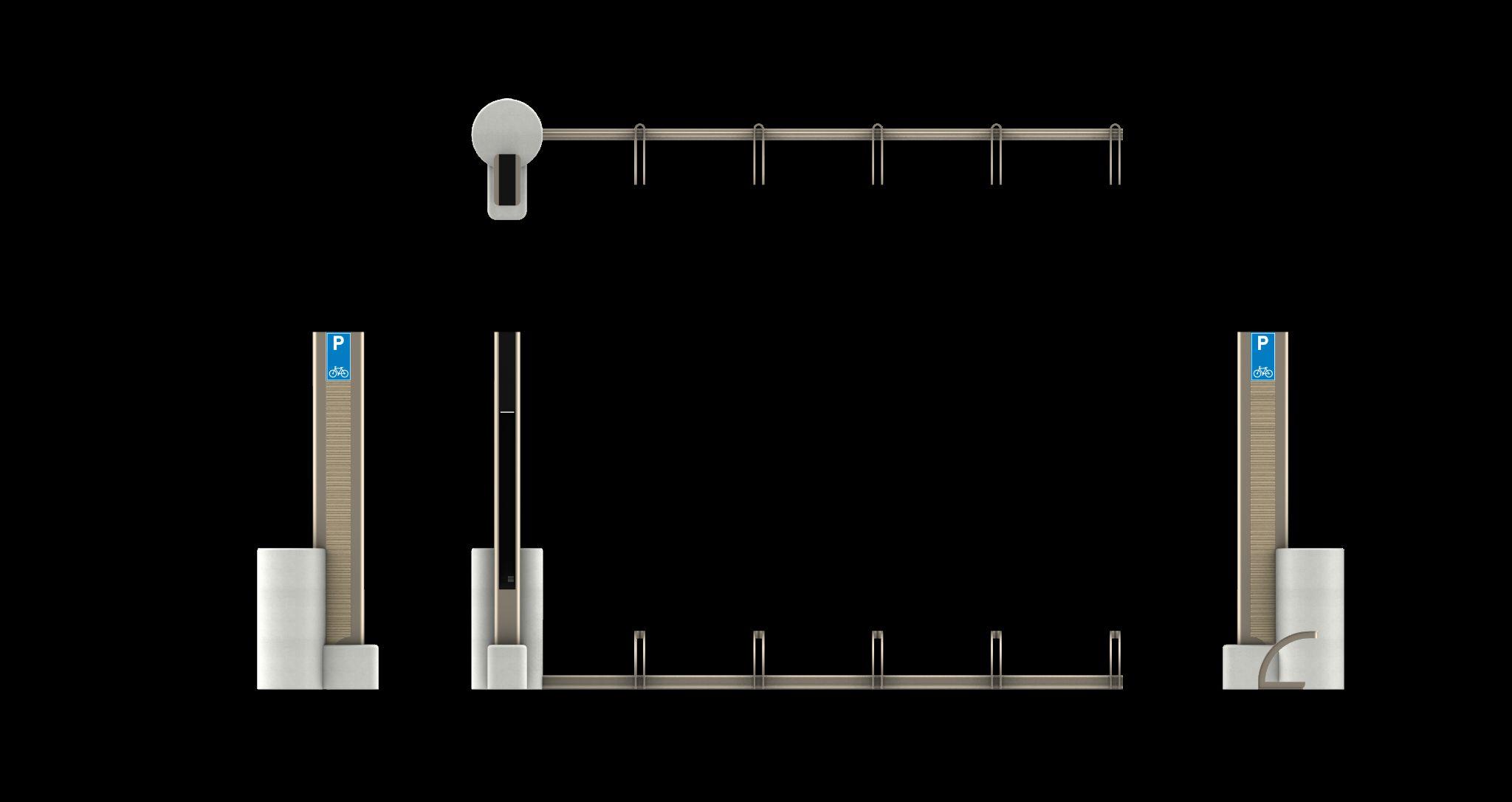

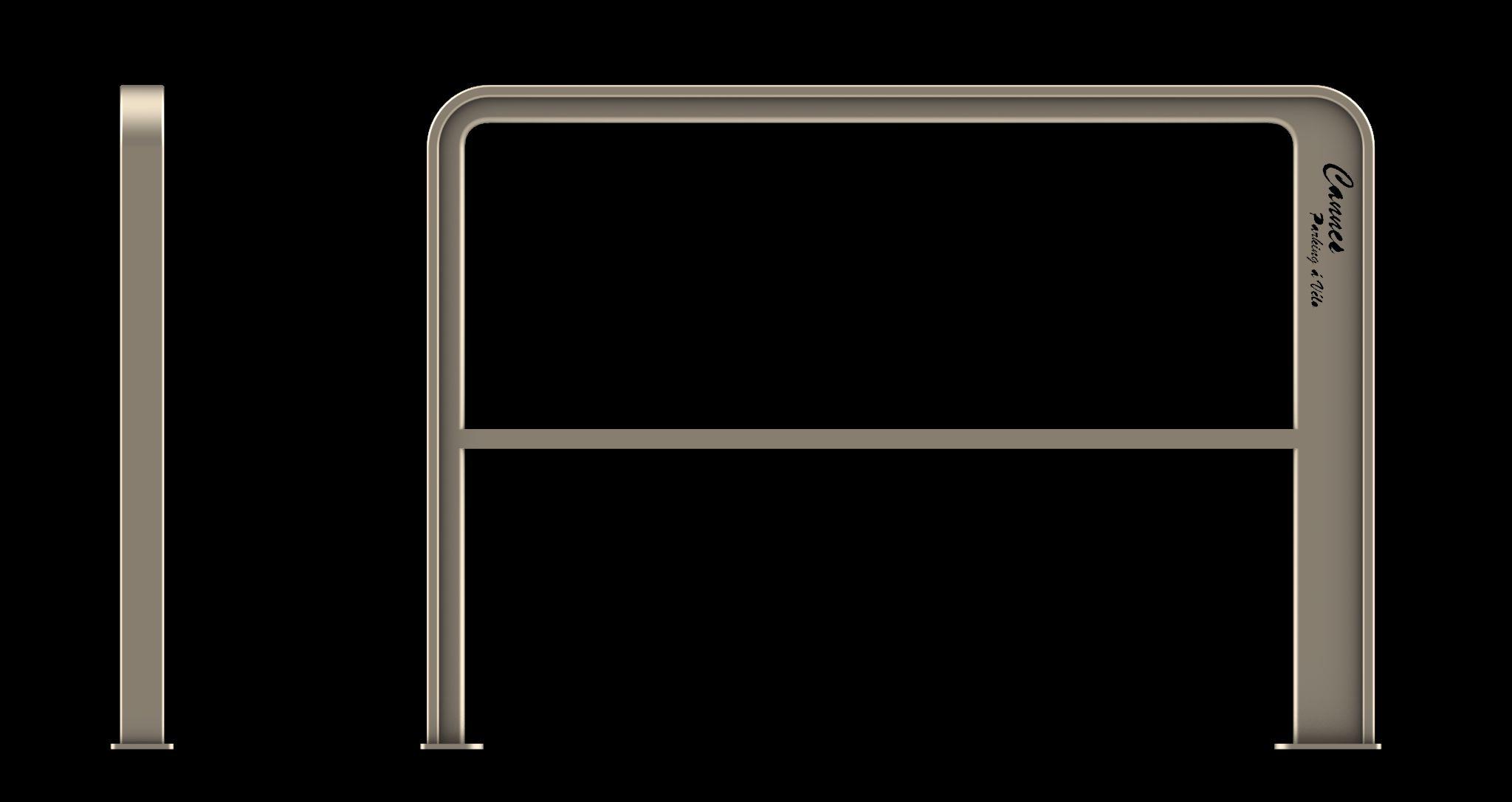

Cannes Competition

BOULEVARD DE LA CROISETTE

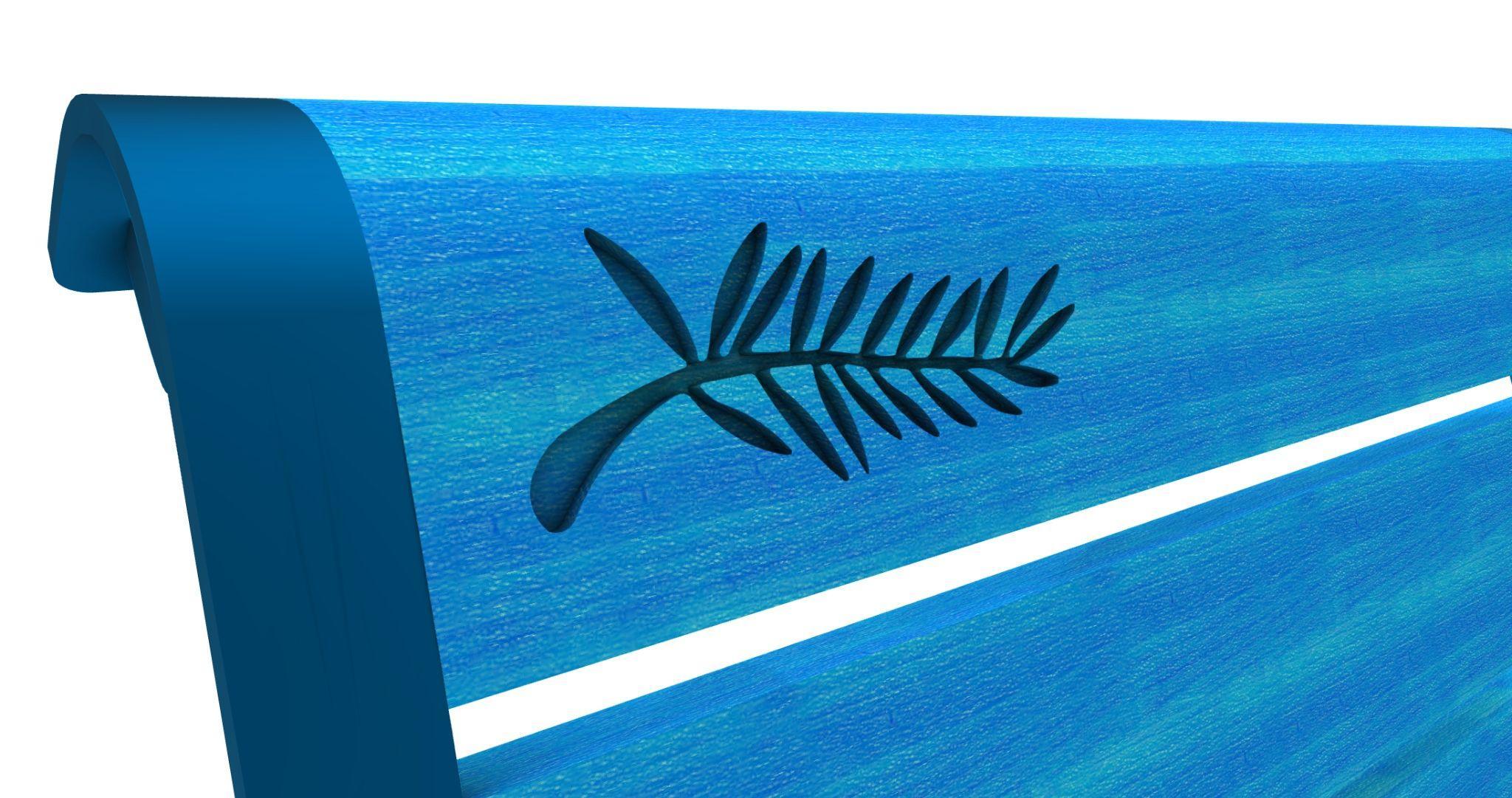

During my time at WEST 8 I have been able to work on various competition projects, one of which was the tender for the redesign and redevelopment of the famous boulevard de la Croisette in Cannes, which starts at the theater where every year they hold the film festival.

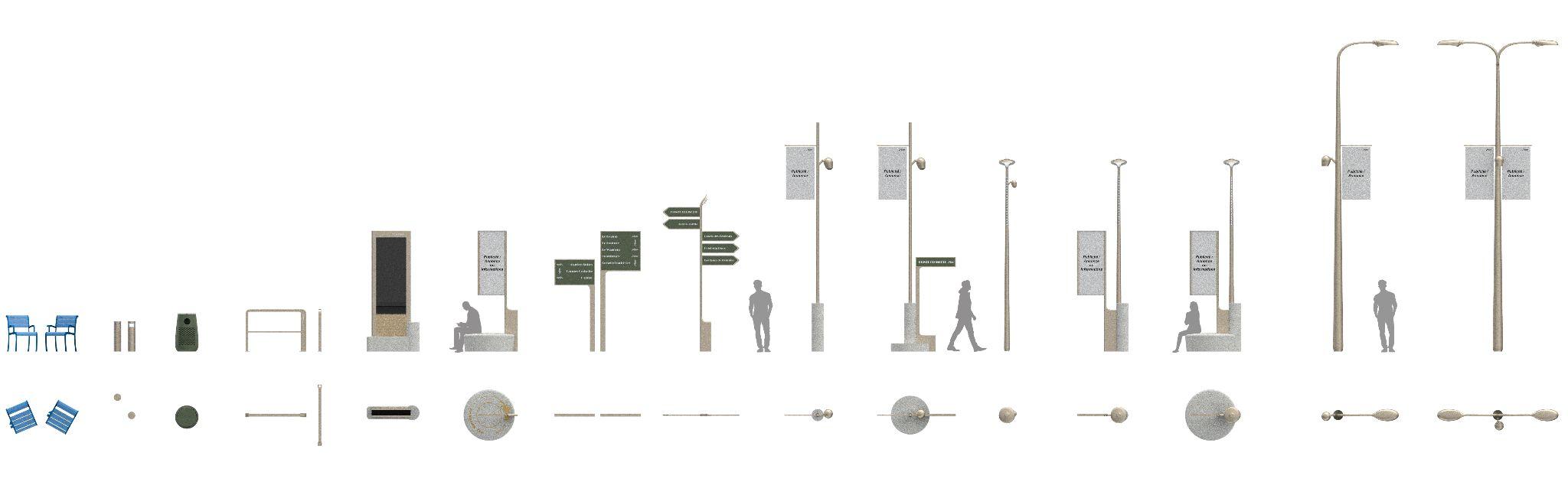

During the project I designed and modeled a vast number of urban furniture products of different sizes, from sitting, mobility, security and wayfinding elements, to lighting and decorational planting elements.

THE NEW BLUE CHAIR

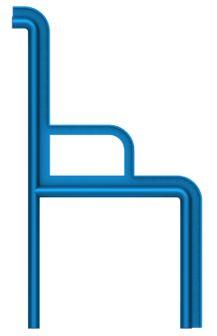

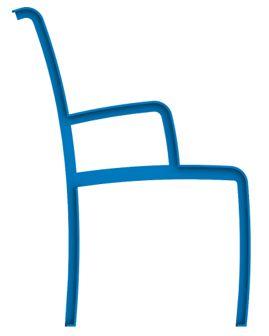

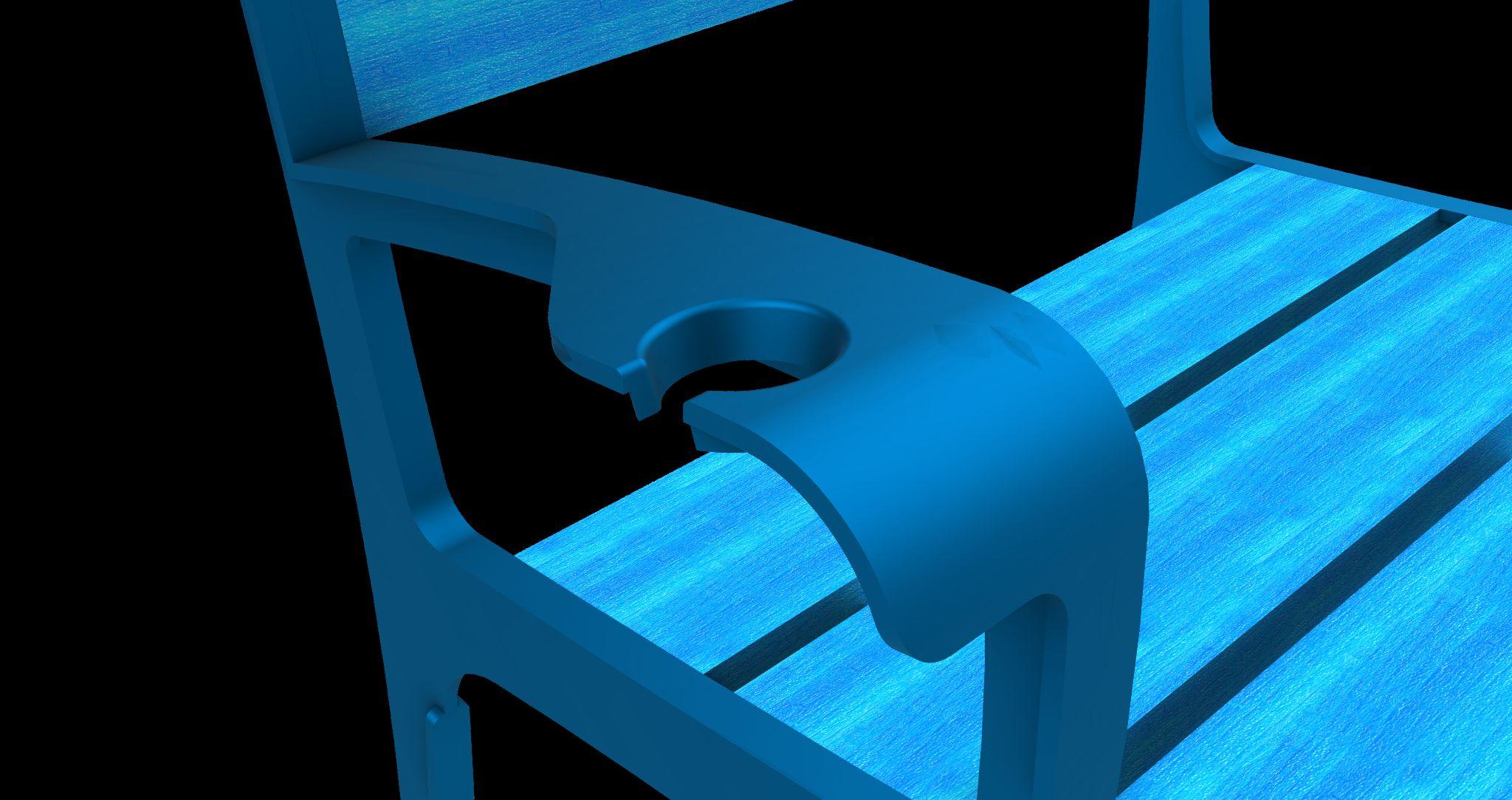

One of the main tasks that I worked on during this project was to redesign the famous blue chair which design hadn’t change since the early 1990.

THE NEW BLUE CHAIR

Champagne glass holder

Champagne glass holder

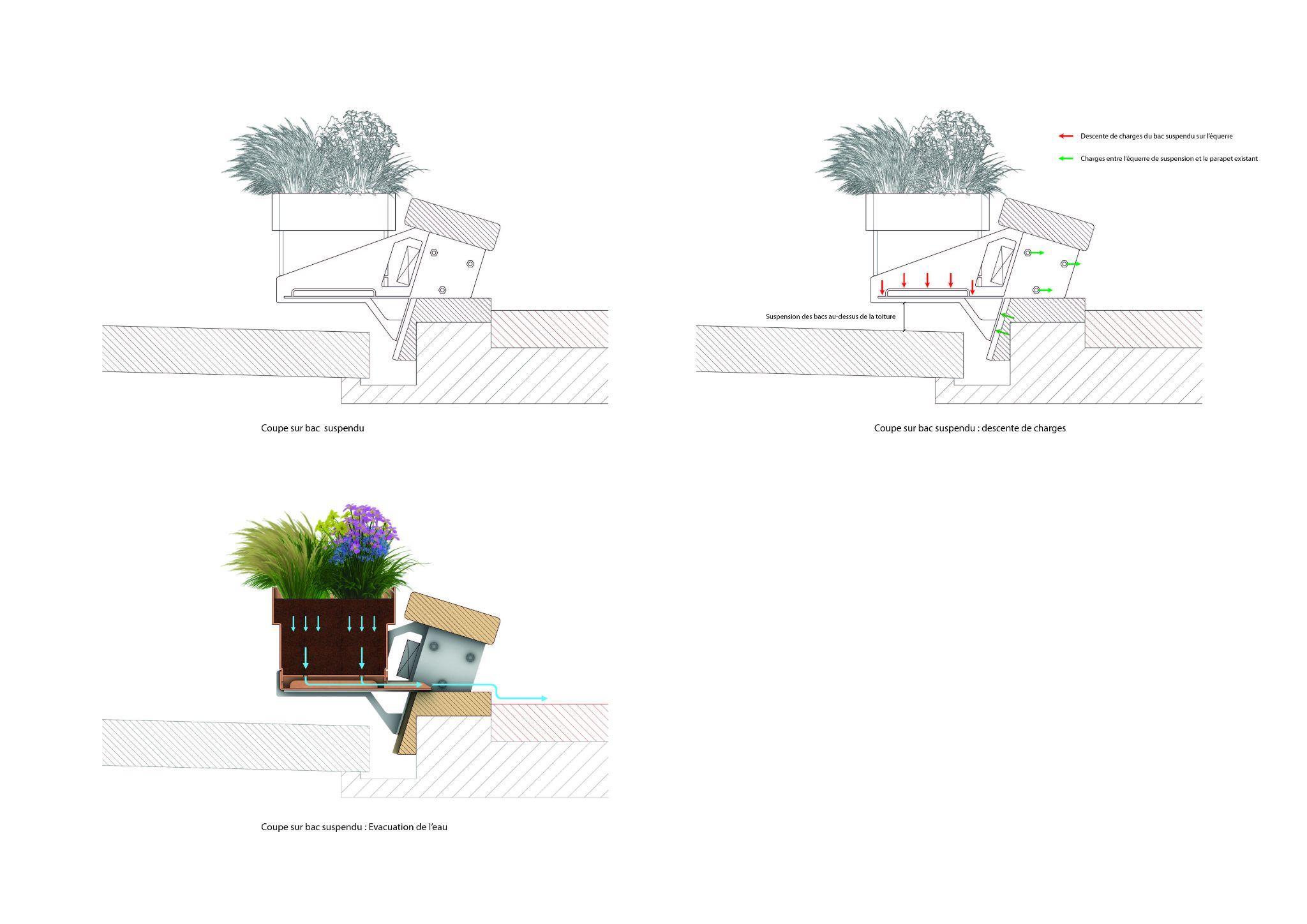

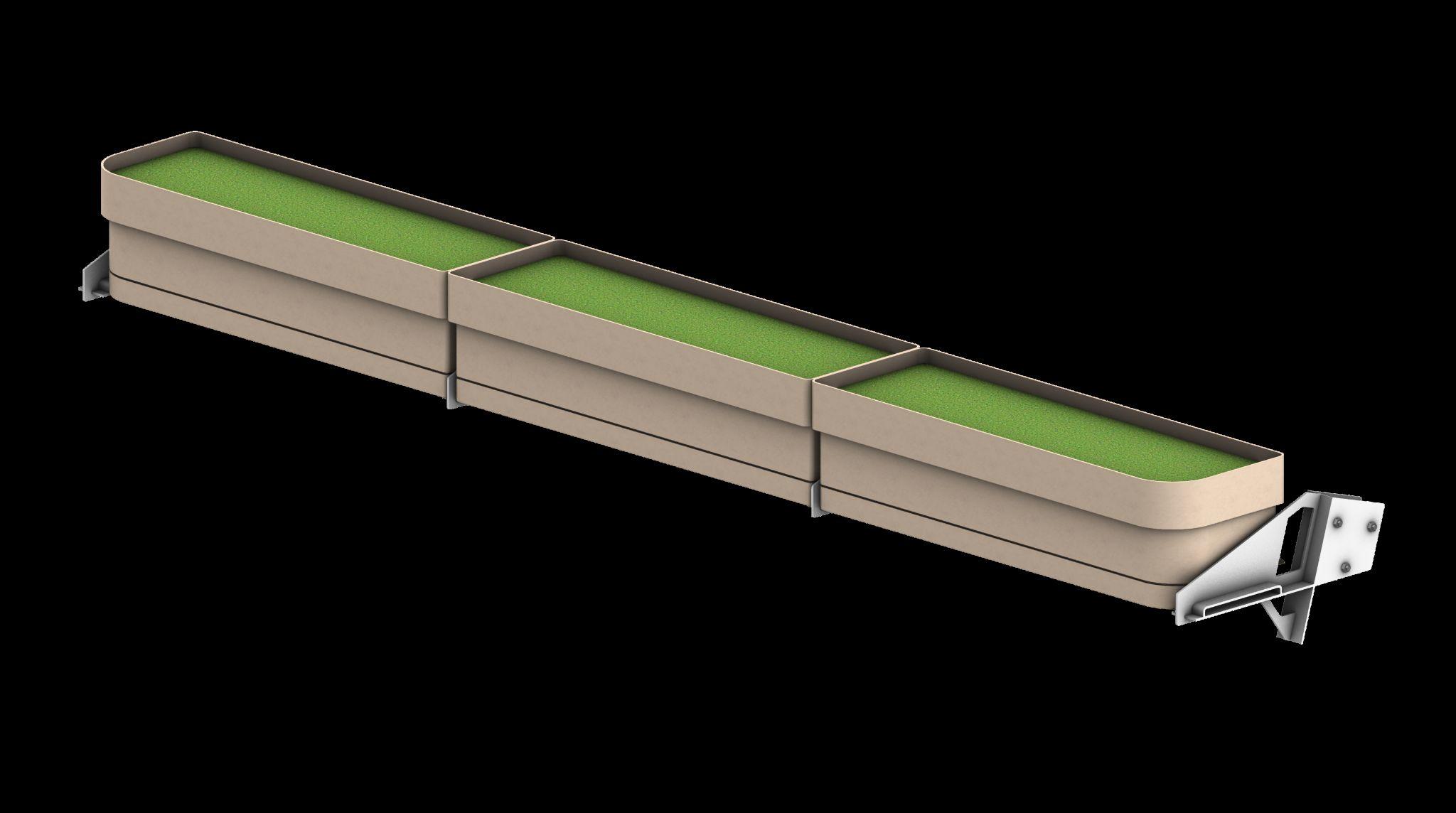

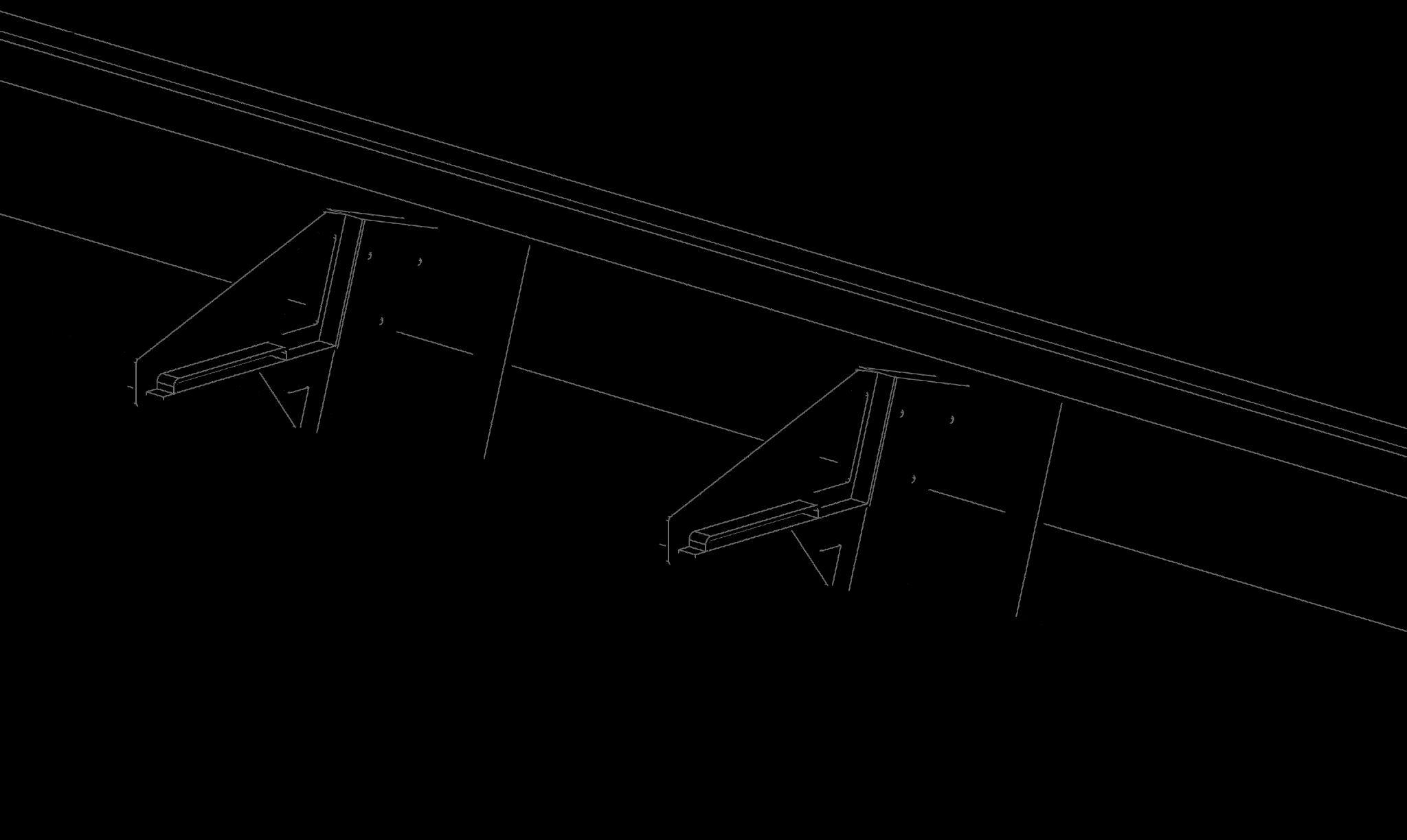

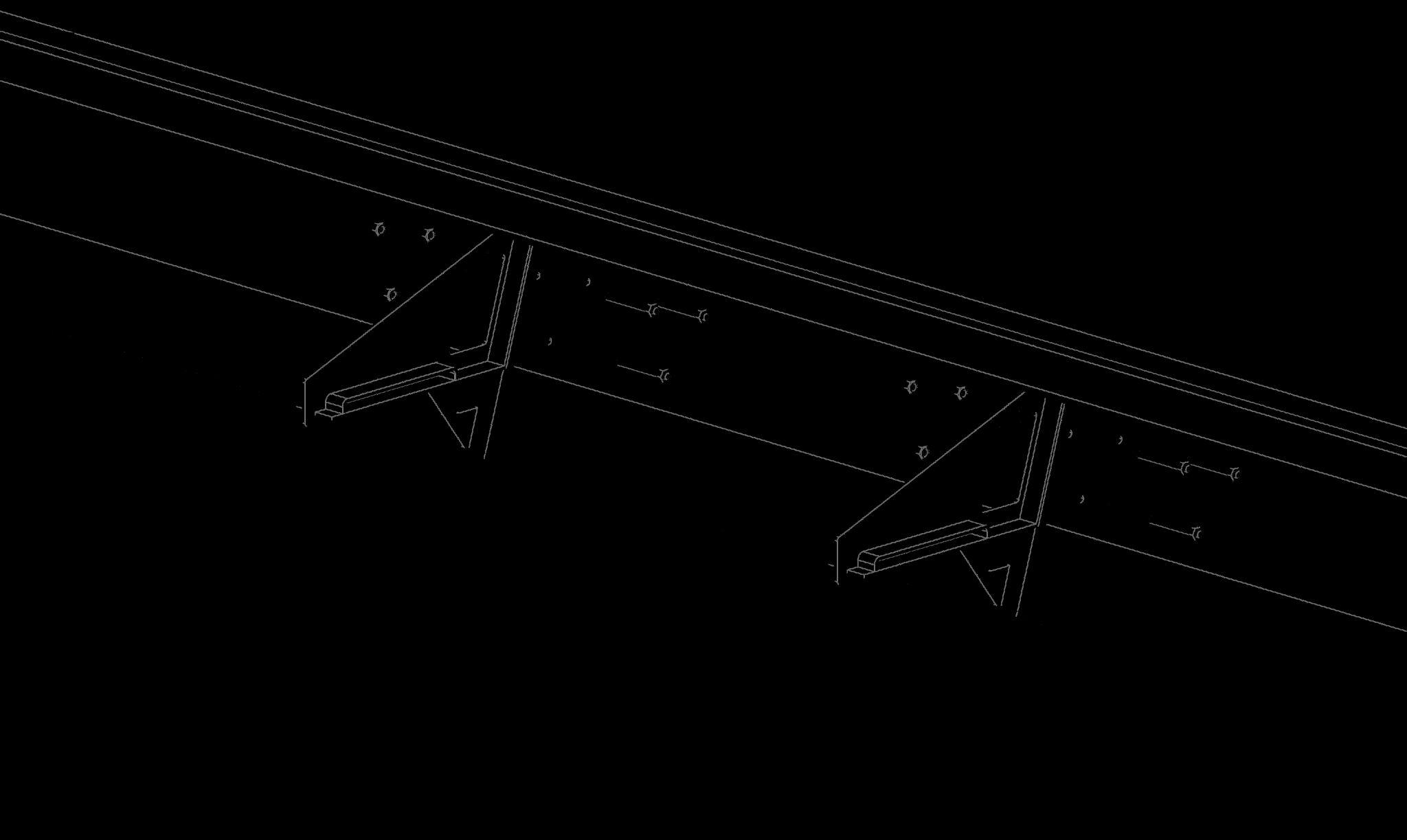

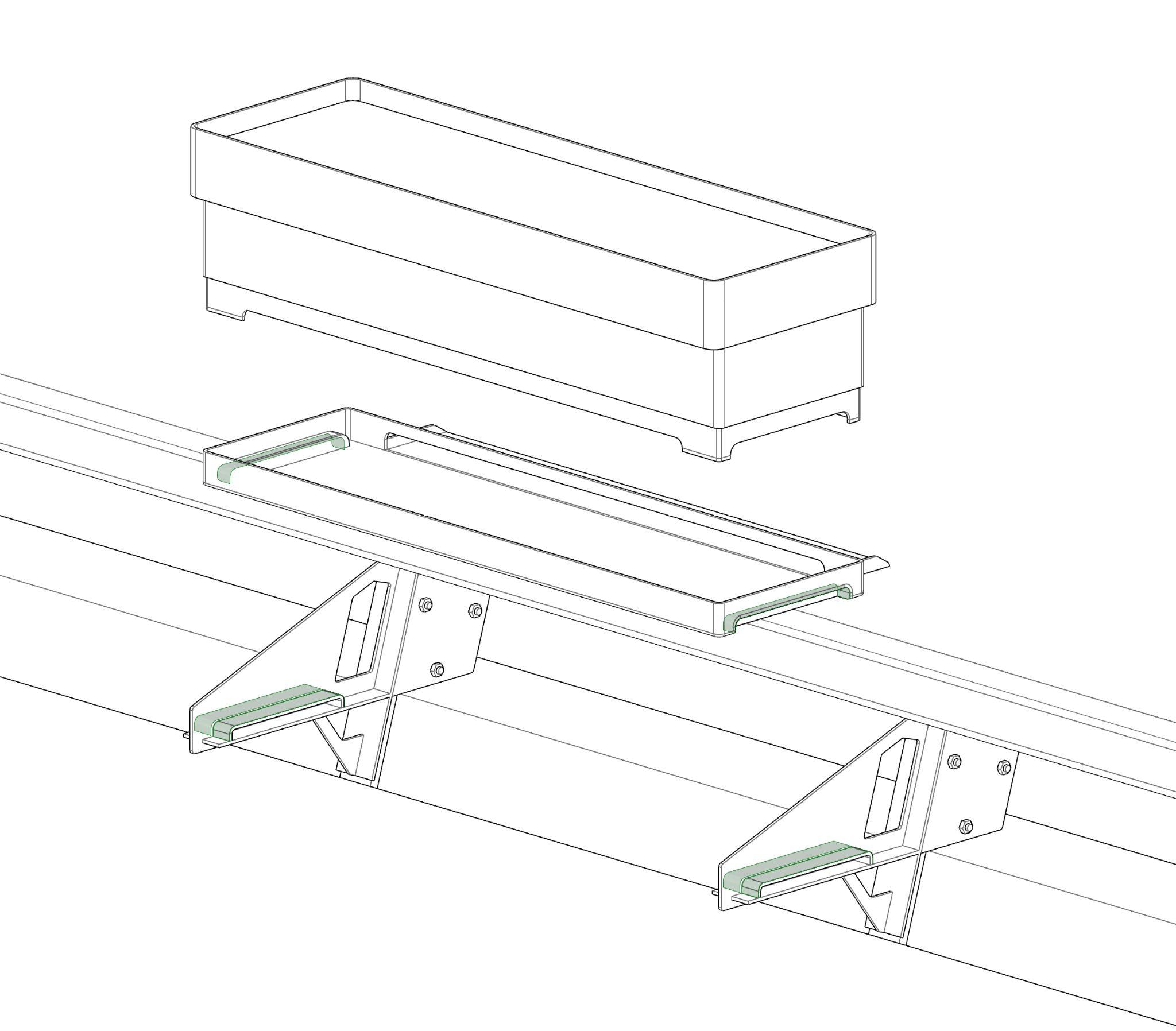

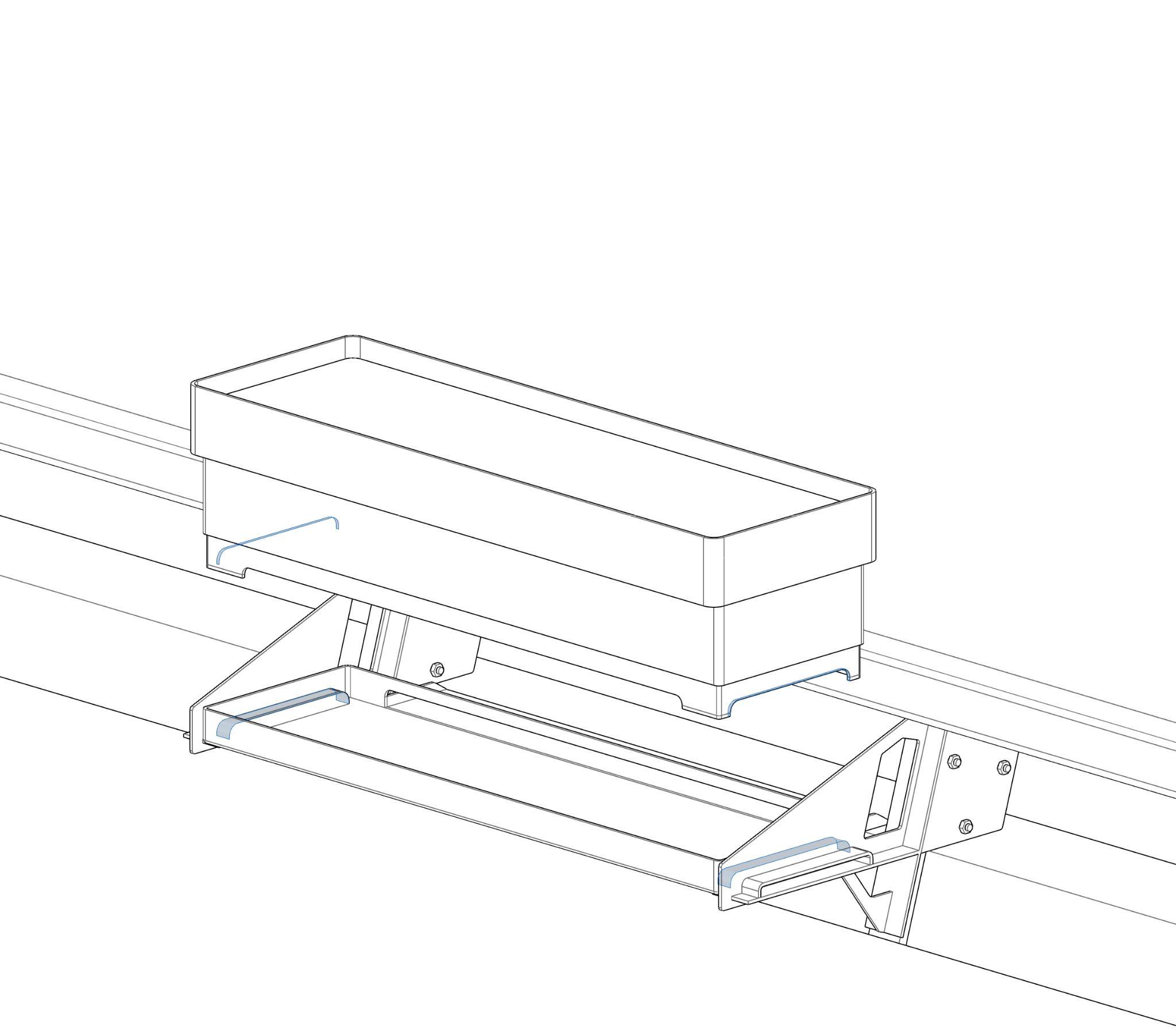

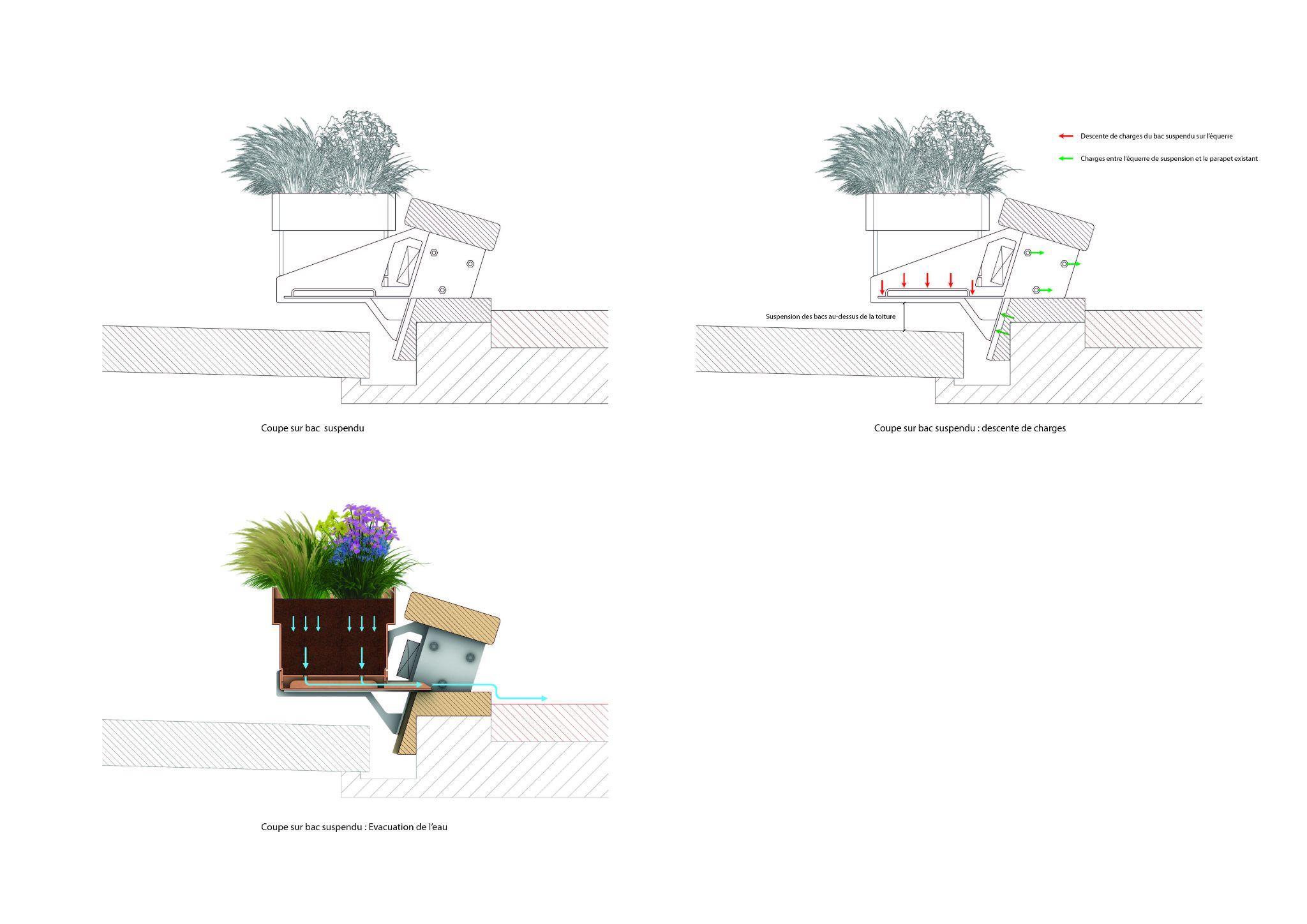

SUSPENDED PLANTERS CONCEPT

Another task was developing a concept of a system of suspended planters that could be mounted on the retaining wall along the promenade.

The planters would serve as an extra decorative element and to partially hide the view of the roofs of the beach bars and restaurants

COMPONENTS & INSTALLATION

NEW URBAN FURNITURE CONCEPTS

MULTIPURPOSE ELEMENTS

PEDESTRIAN LIGHTING

WAYFINDING & MOBILITY

3D PRINTED 1 TO 10 SCALE MODELS

One of the parts of this competition would be a live presentation on location with the representatives of the city of Cannes. For this presentation I produced 1 to 10 scale models of the new blue chair and some of the urban furniture elements.

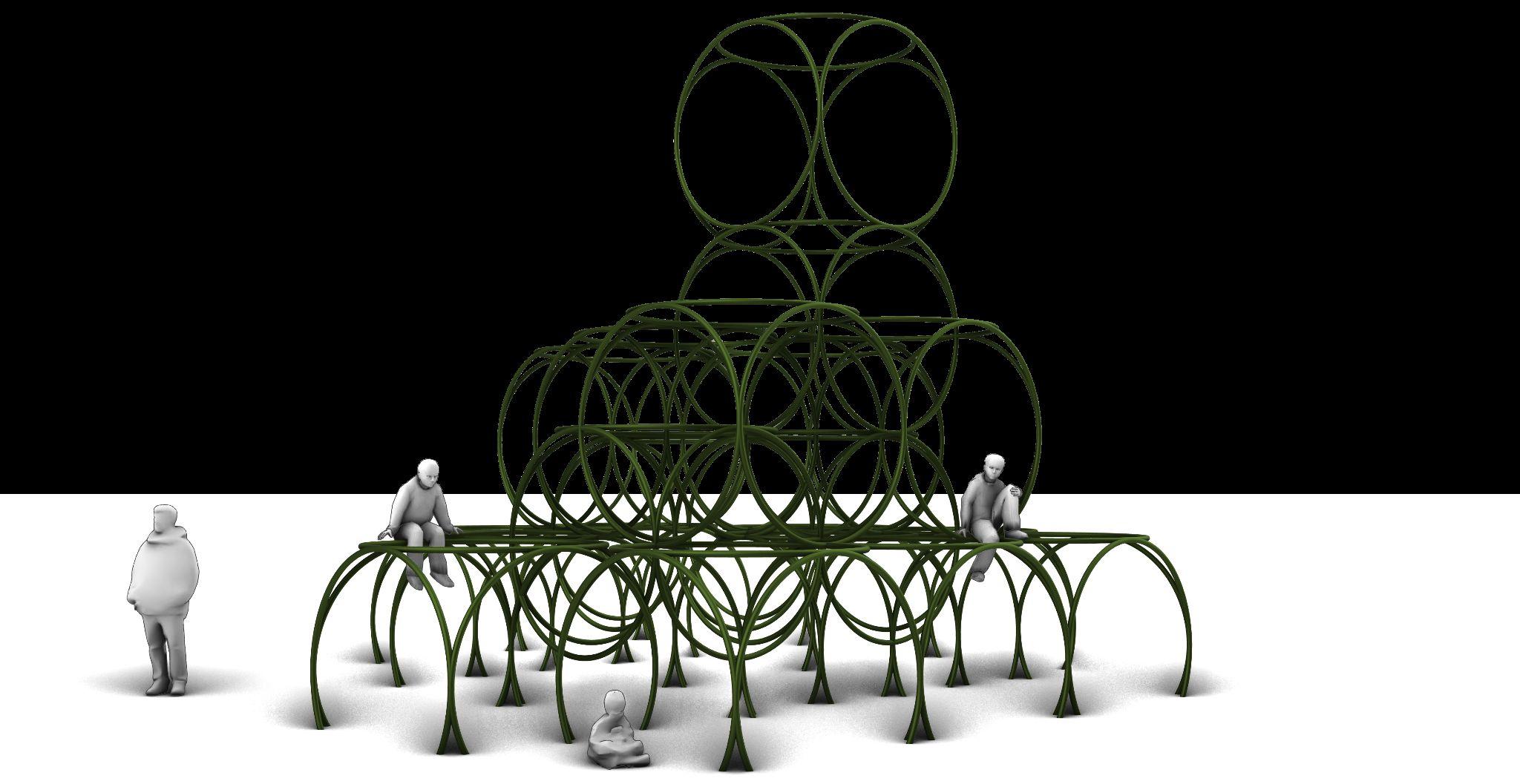

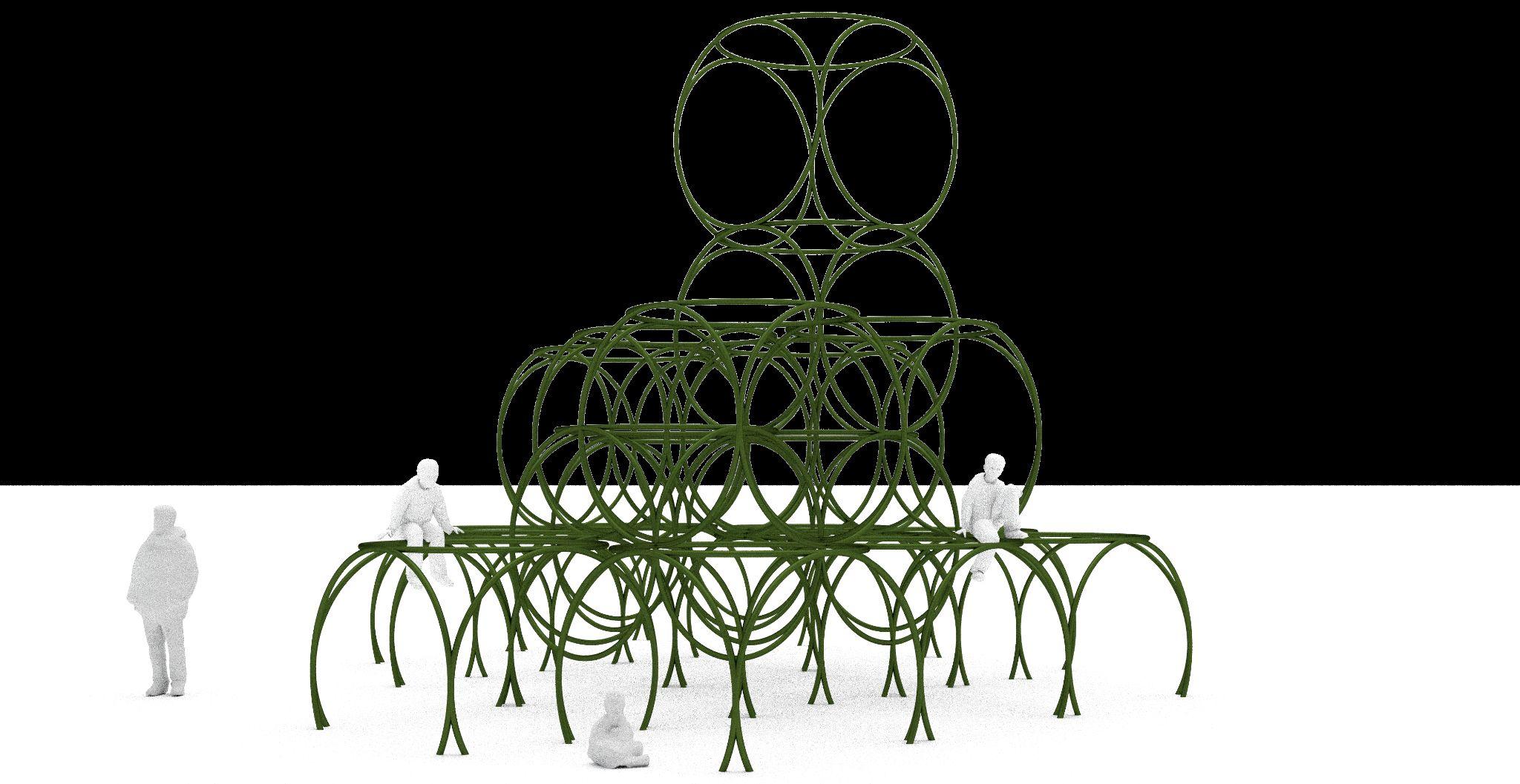

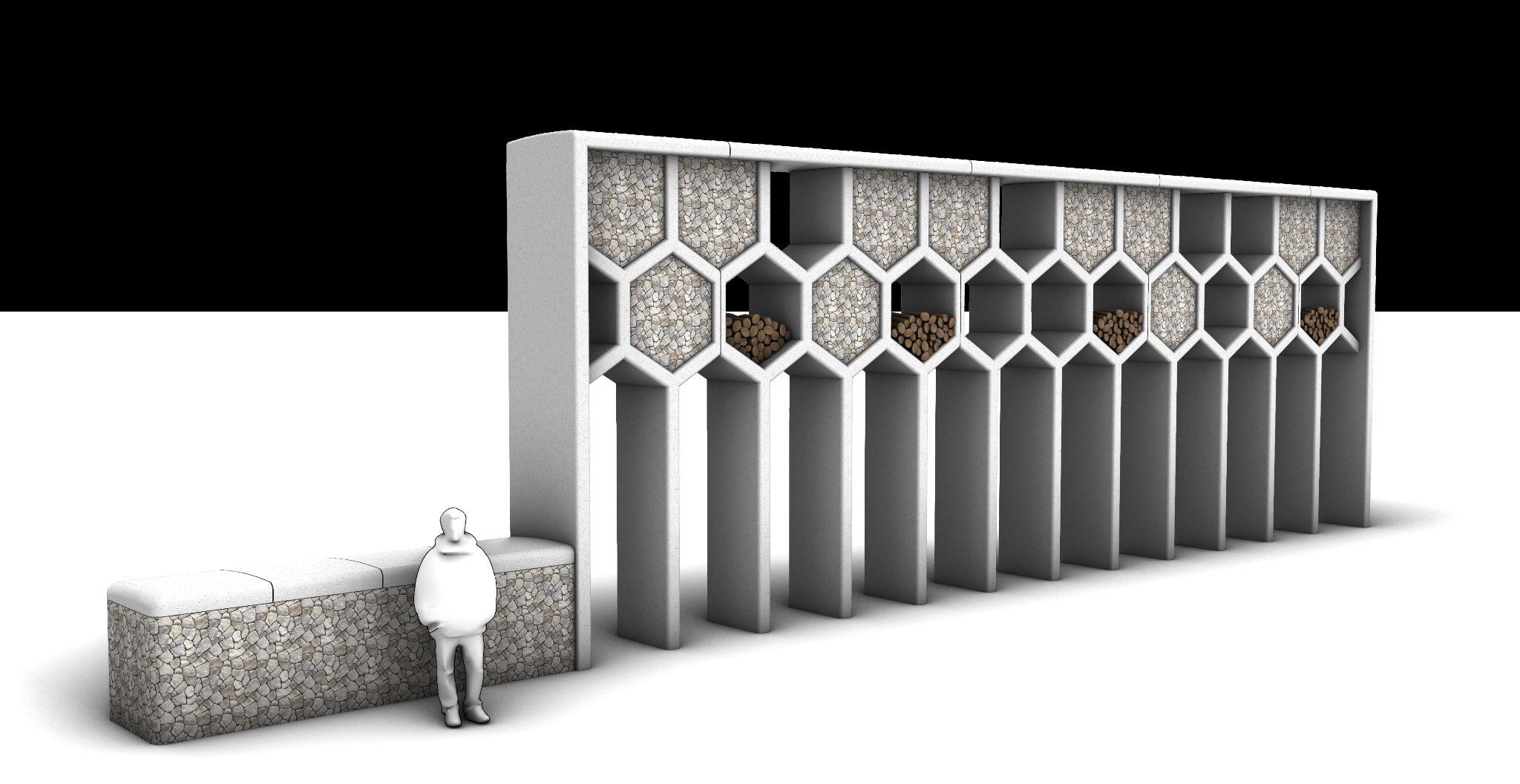

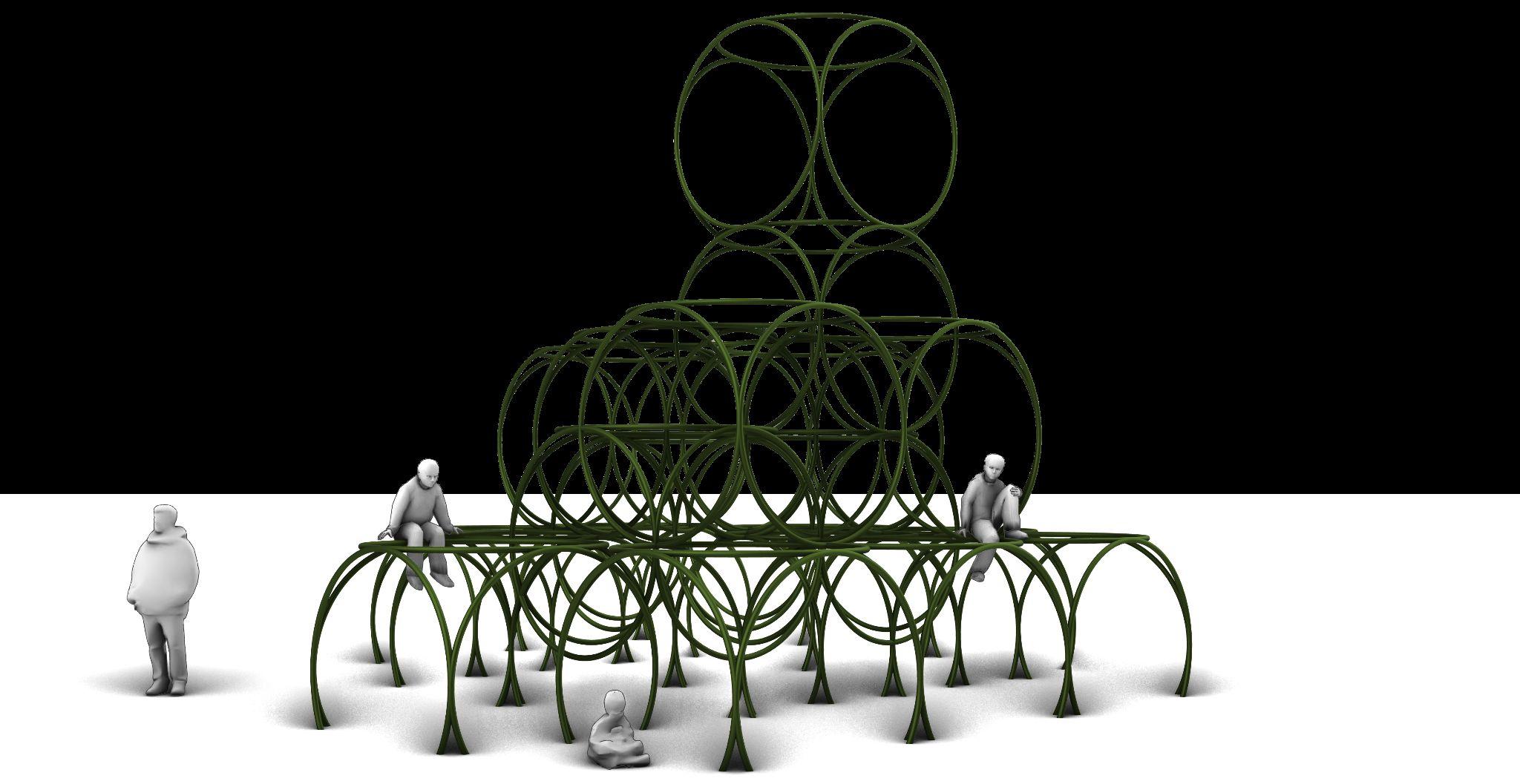

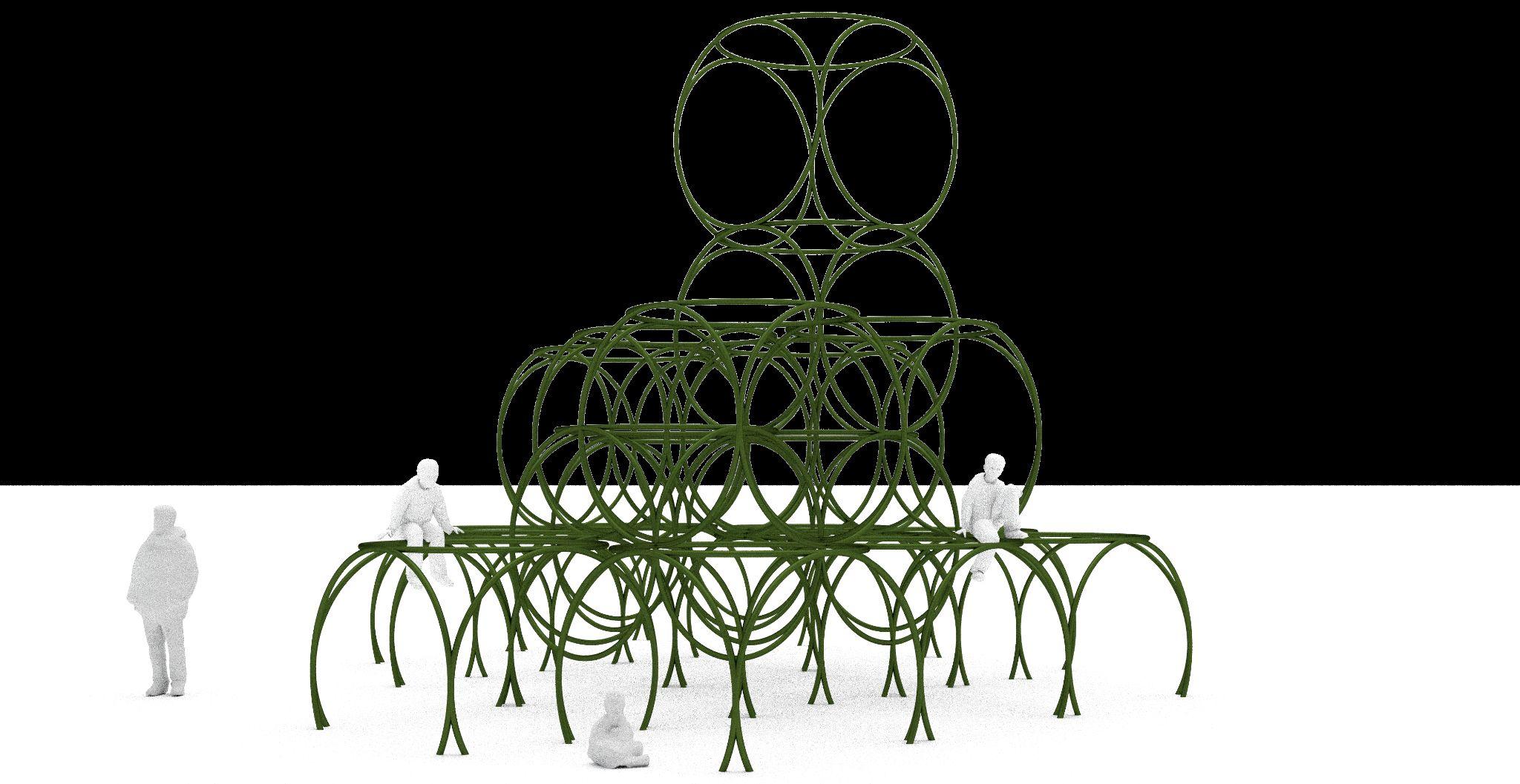

Paysandú Waterfront

OMA / WEST 8 COLLABORATION

This was another collaboration project between WEST 8 and the architecture firm OMA. In this project WEST 8 was in charge of the landscape architecture and design of the new waterfront in Paysandú, Uruguay.

With an area stretching 10km along the Rio Uruguay, the masterplan coexists with the flooding conditions, unlocks and evisions the future development while protecting and enhancing the natural environment.

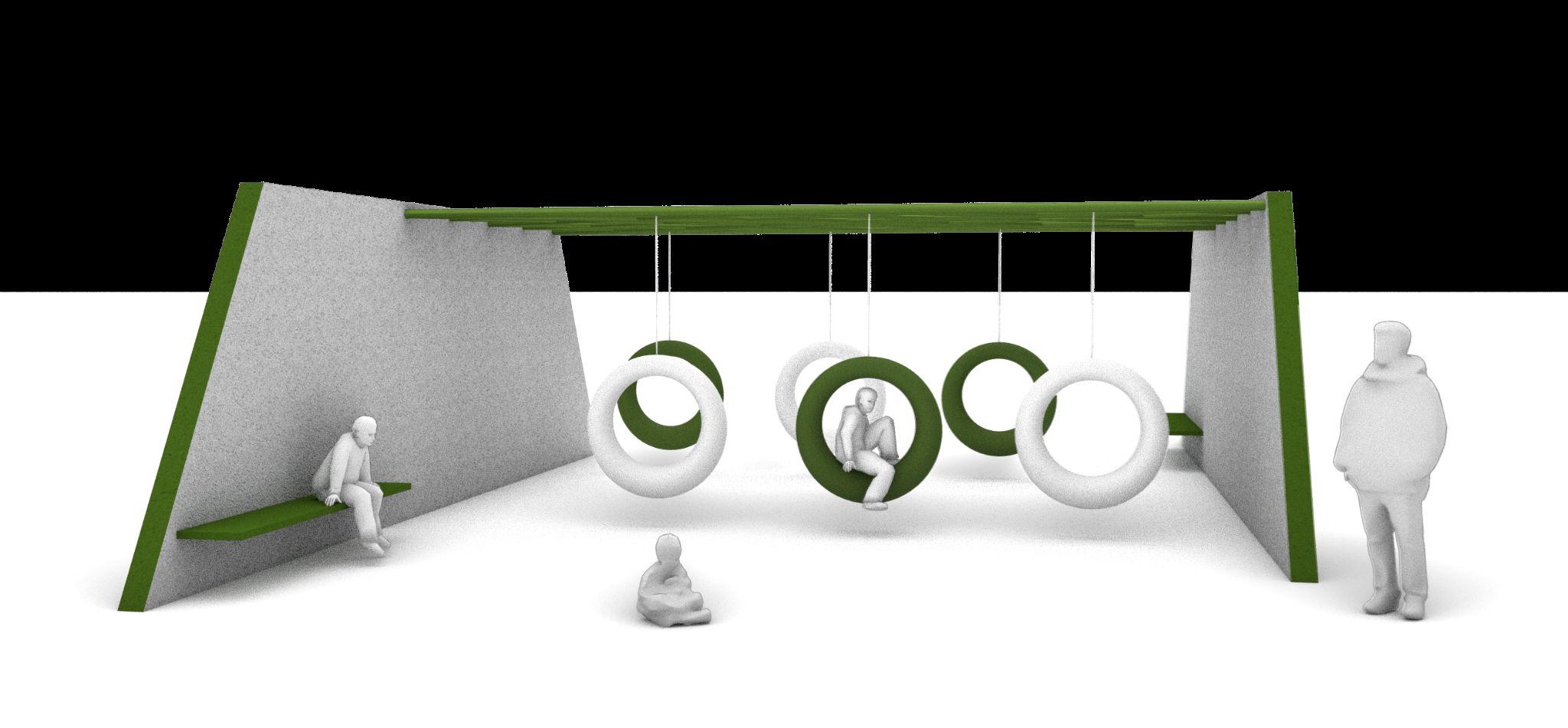

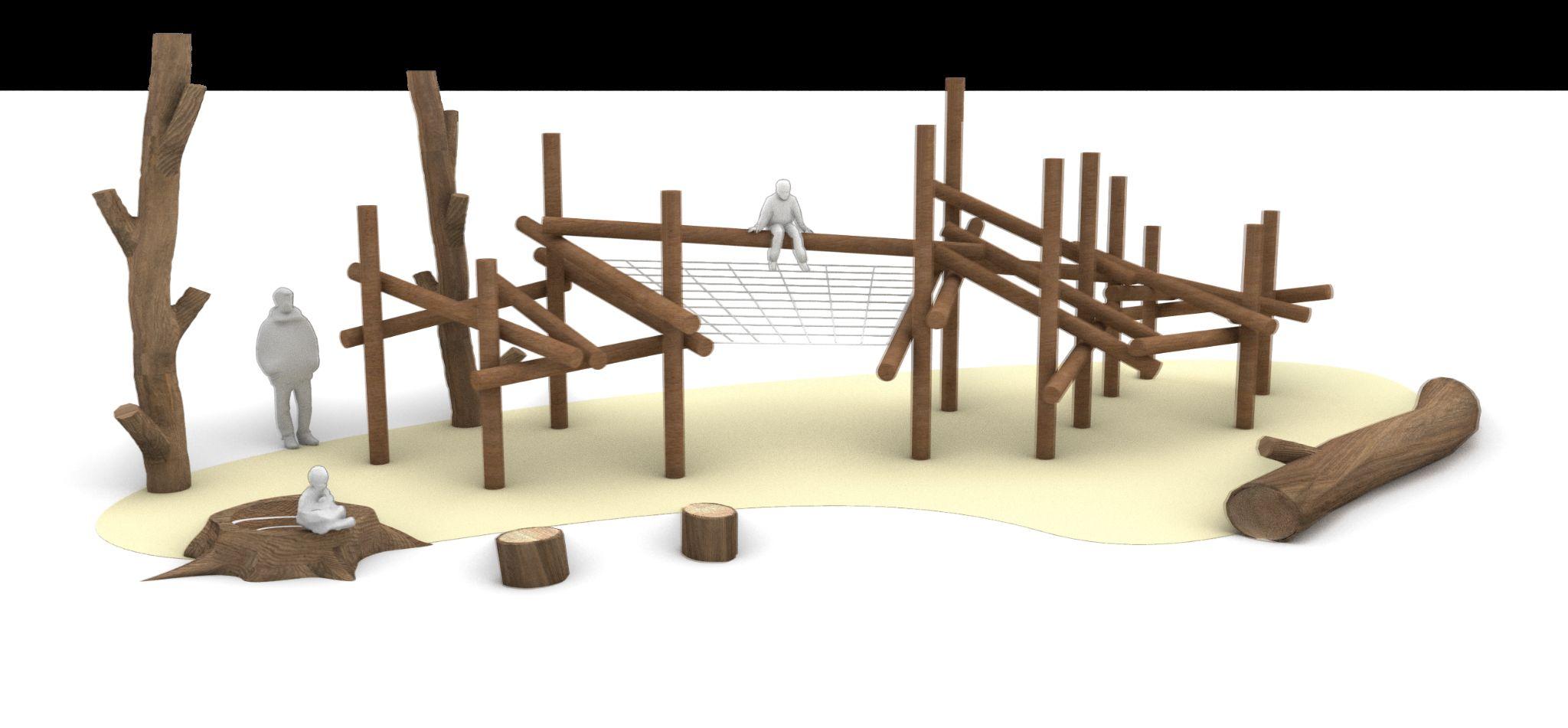

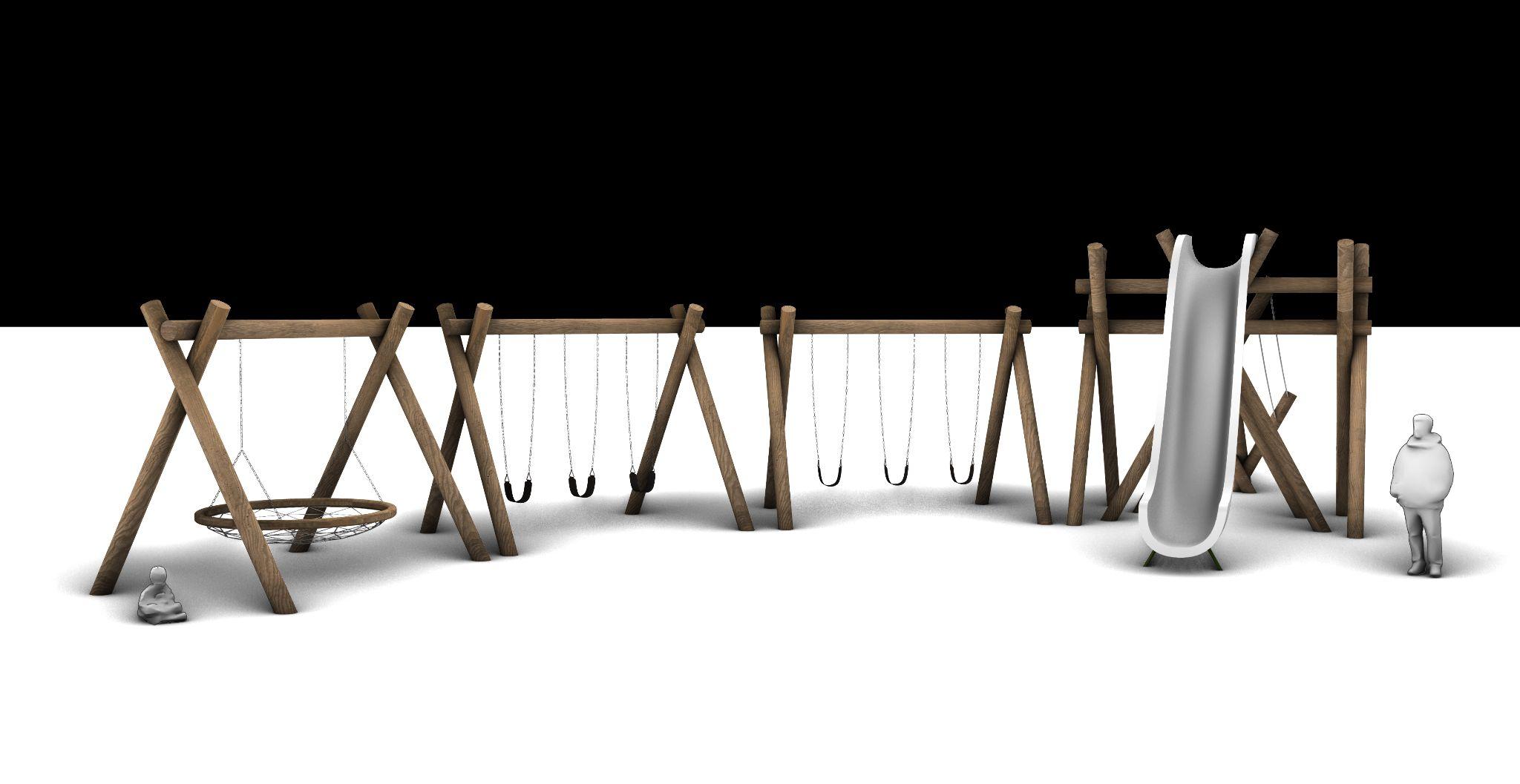

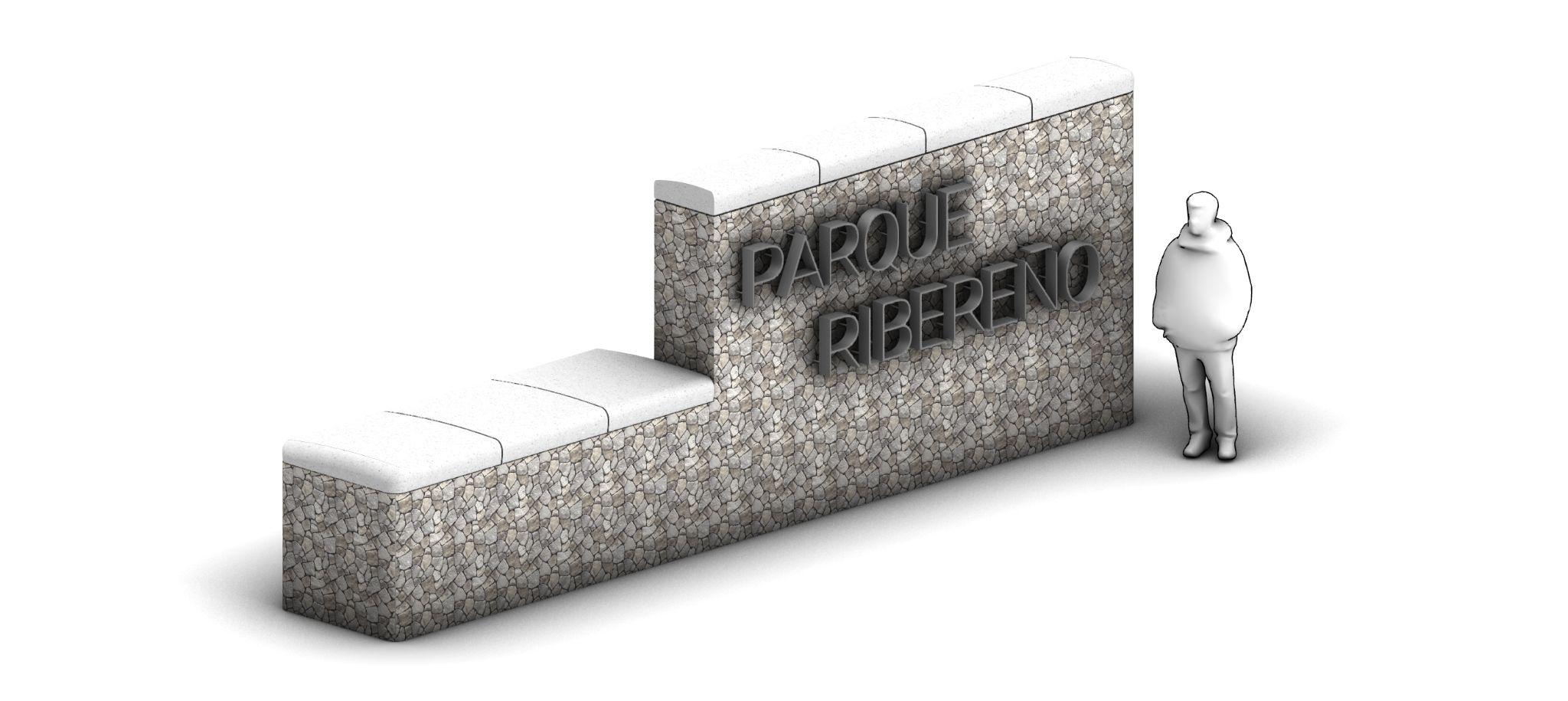

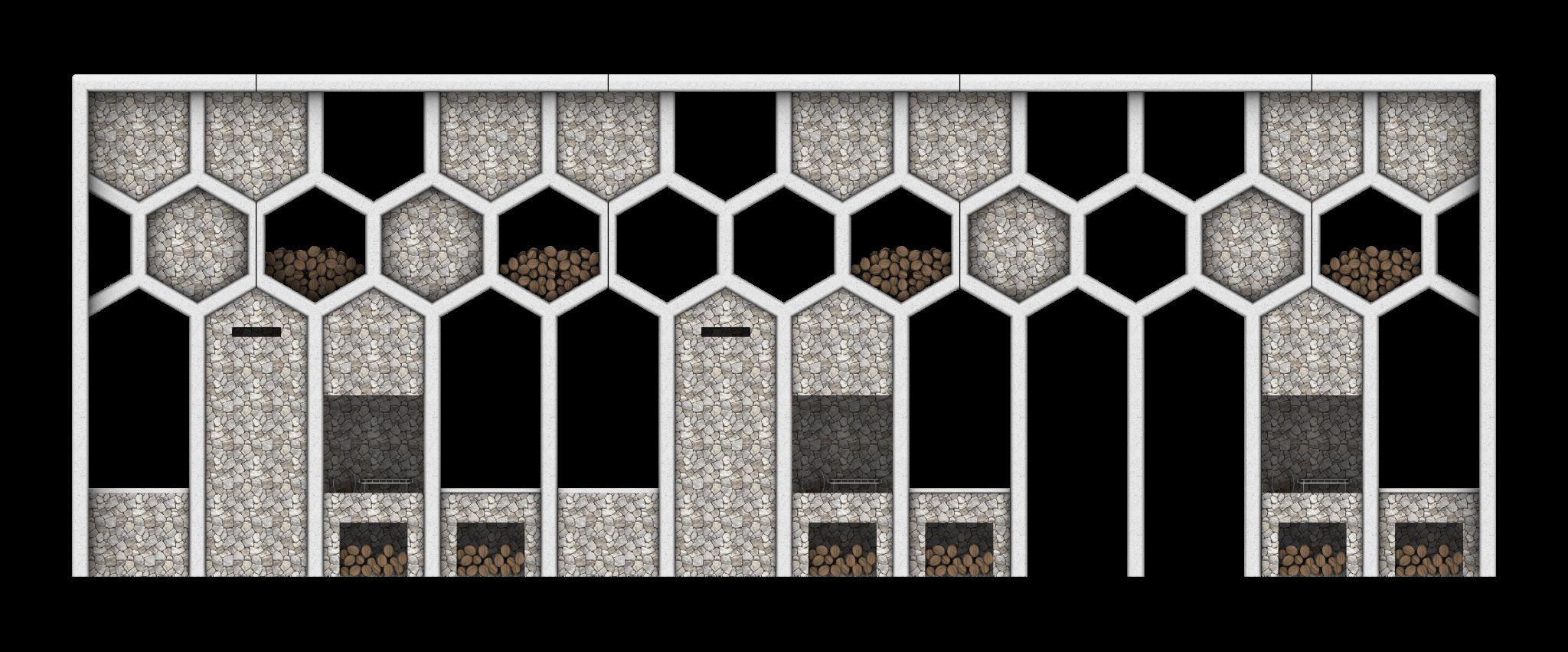

For this project I developed concept designs of recreational equipment for the revised park and playground area.

In addition I designed a family of perimeter walls, sitting edges, public barbeque installations and a pergola

PLAYGROUND ELEMENTS

SITTING EDGES & URBAN ELEMENTS

STUDIES PROJECTS

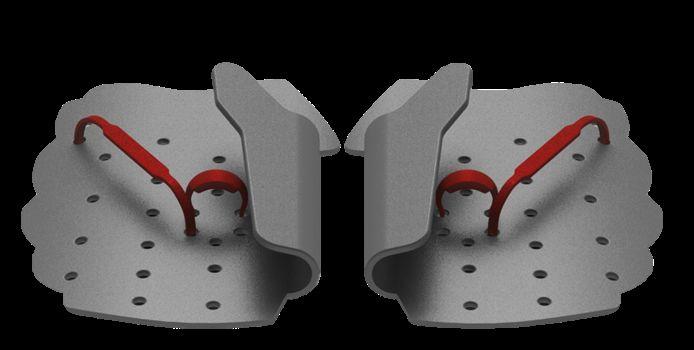

Design Intelligence

THIRD YEAR MINOR

For the Minor Design Intelligence we could choose and set up our own assignment.

Being a swimming nerd and a competitive swimmer myself, I took this opportunity to do something related to the sport.

I designed hand paddles specific for the breaststroke and, through 3D printing, I created a working prototype made from ABS filament.

During the concept developing fase I was able to test my models and eventual prototype at my swimming club with other breaststroke specialists.

Integration Design

SECOND YEAR TEAM PROJECT

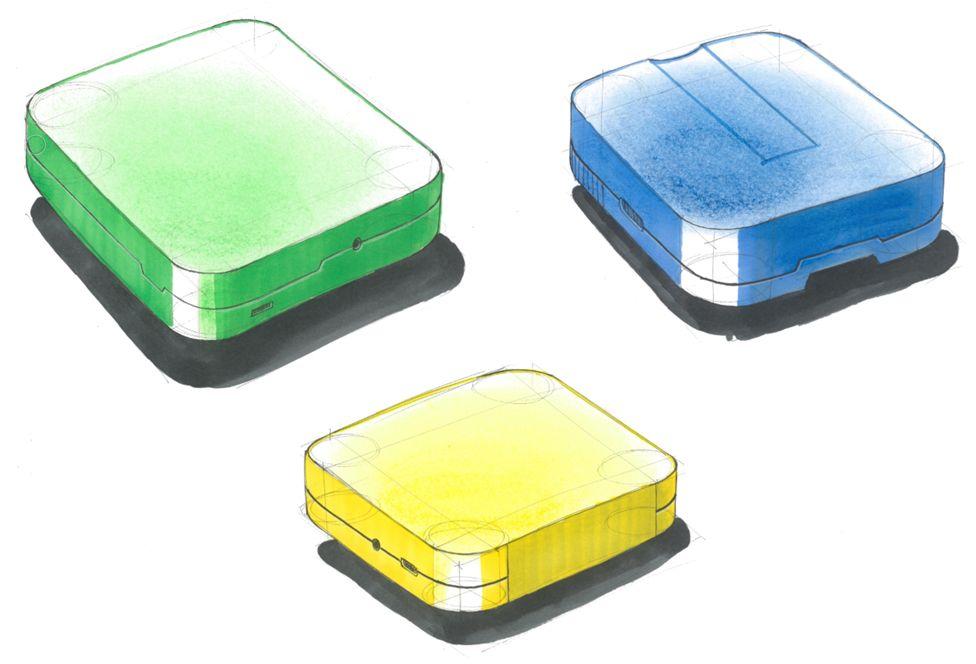

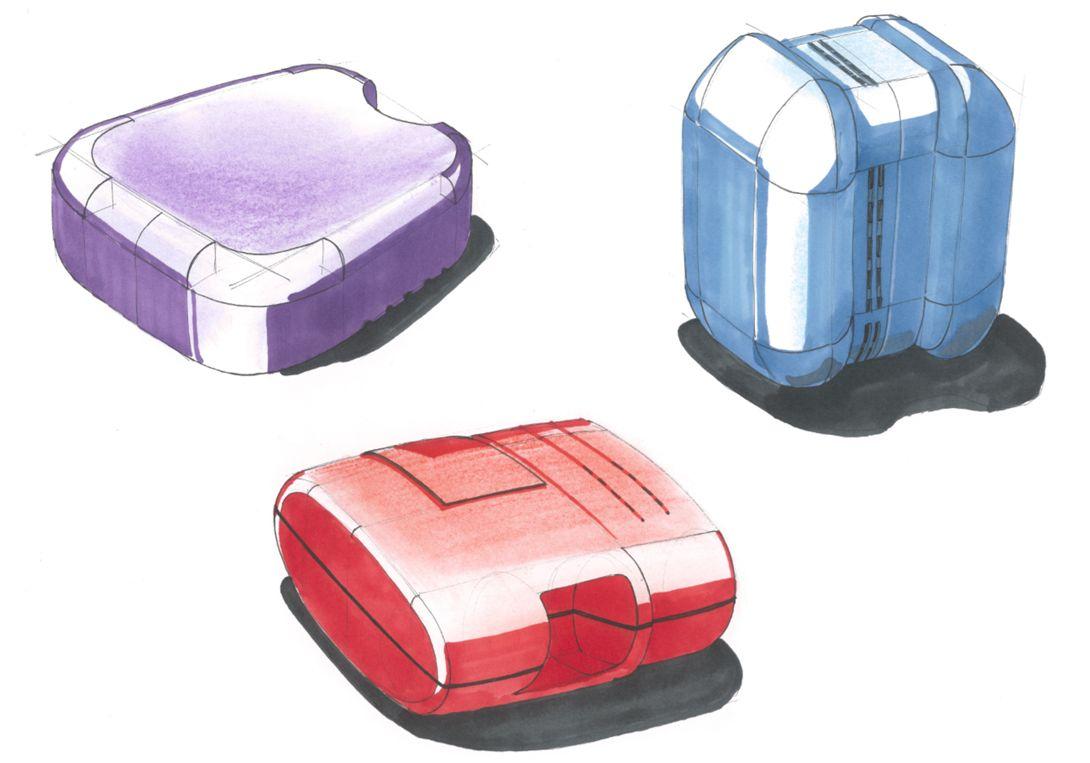

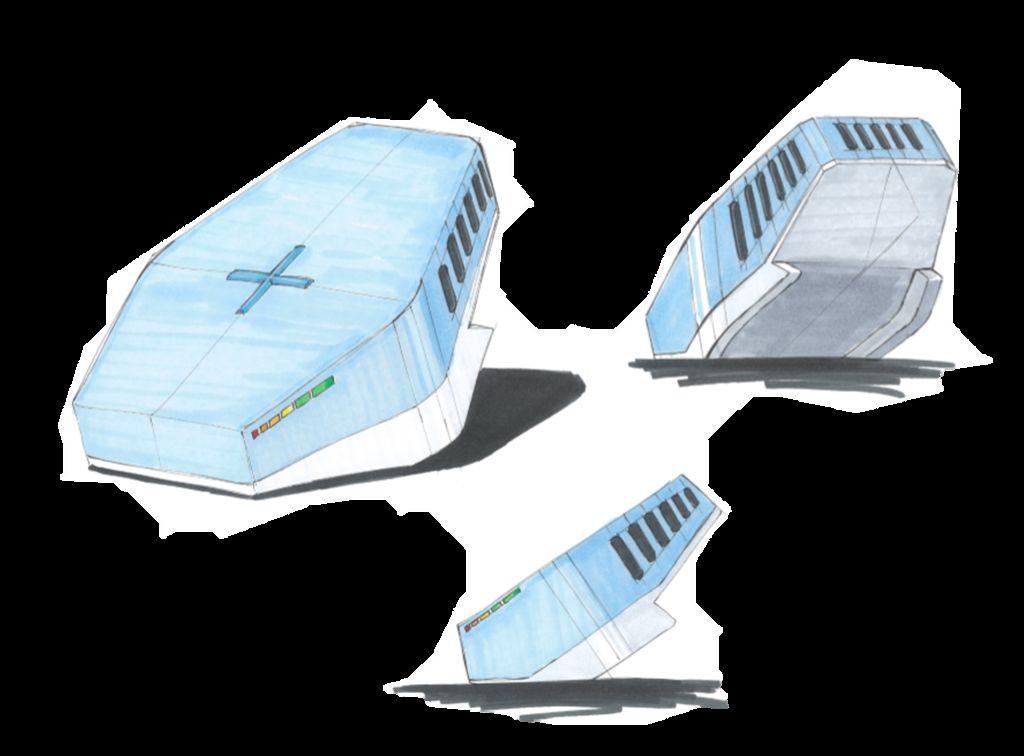

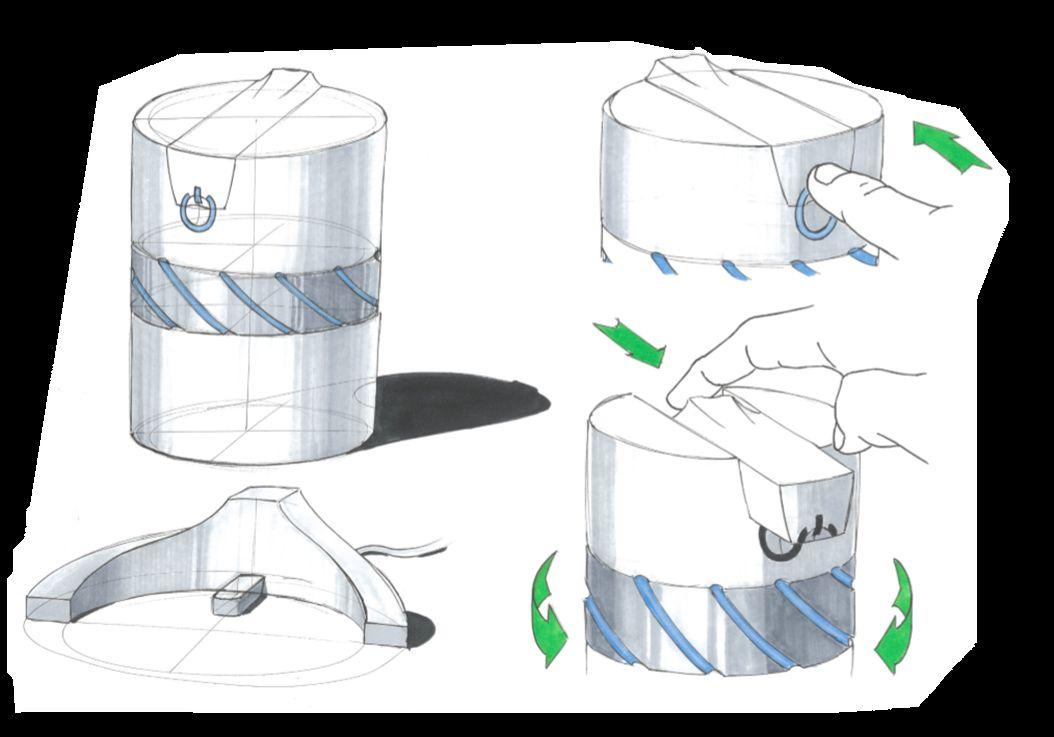

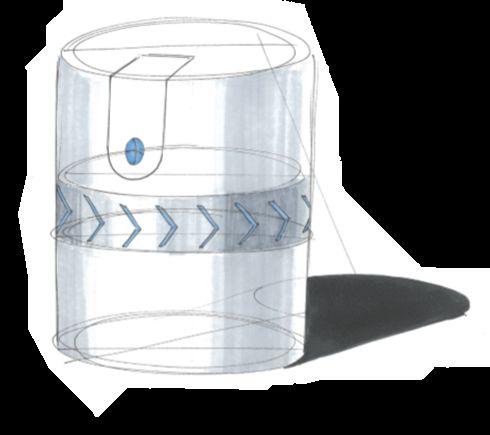

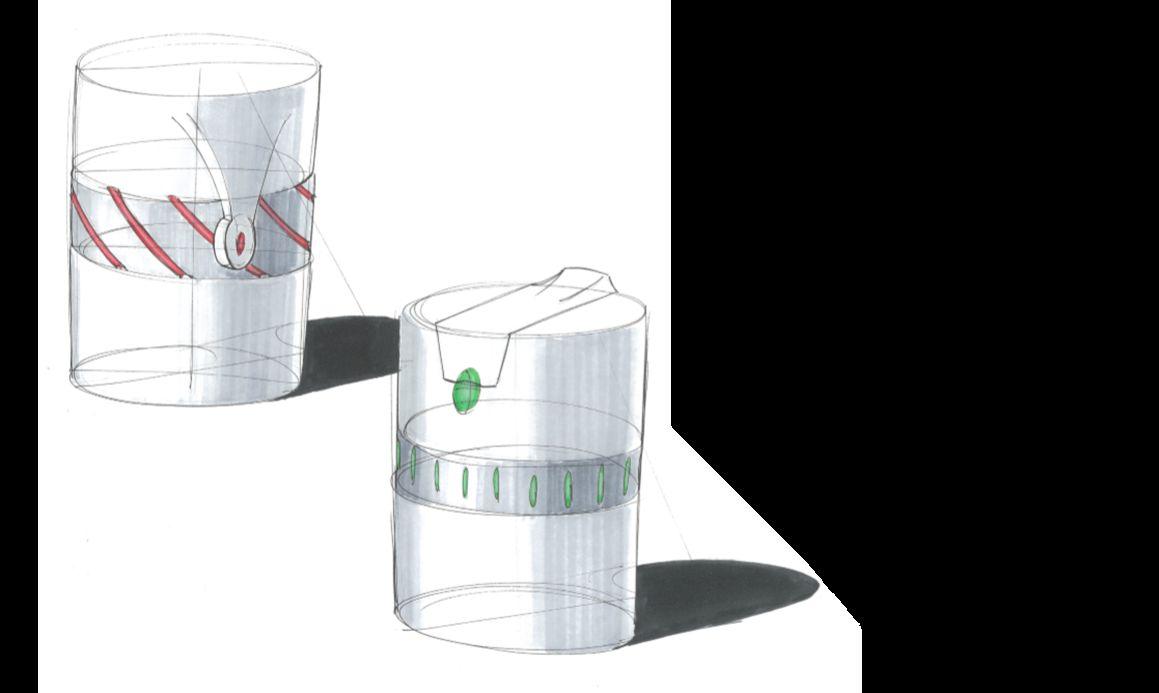

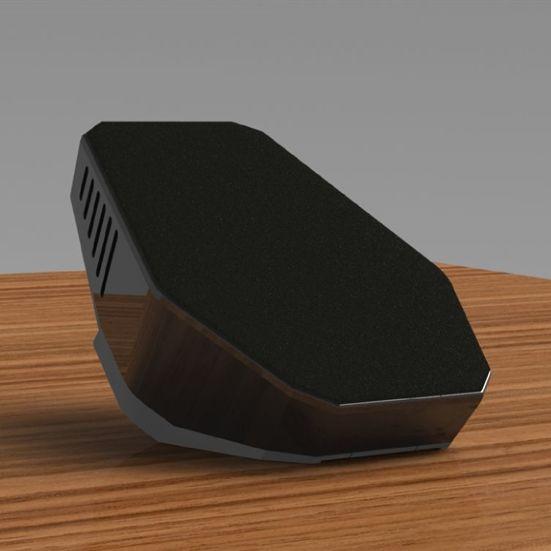

During the Integration Design project, we worked in groups to design a housing for the wireless charger issued by Zens

In collaboration with Ahrend, we designed a housing that meets our starting goals.

During the design process, we took into account the client’s various requirements and wishes.

After the design process, a prototype was 3D printed using two colors of PLA filament.

Product Dimension

FIRST YEAR PROJECT

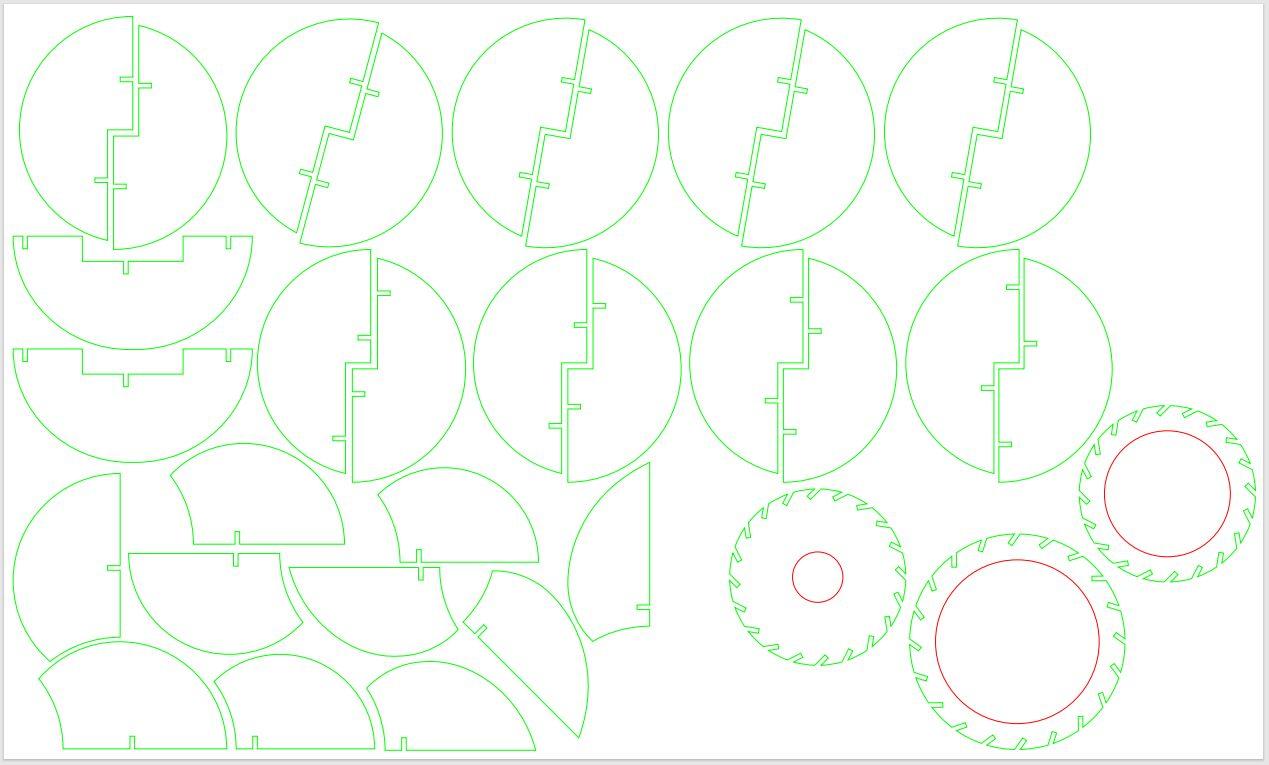

For the Product Dimension project, I got to design a lamp without additional connecting elements such as glue and screws.

One of the major requirements of this project was that all the components had to be fashioned from a single sheet of material of maximum 1000 x 600 mm. We were able to choose between materials like paper, plastic, wood or metal.

The lamp is inspired by seashells and is shaped like a spiral with three central rings of different diameters. The three rings are also the connecting and support elements of the lamp.

This project was made for the company Cre8

Personal Project

One of my personal projects. A lamp made of 3.6mm thick plywood hardwood with laser cutting.

The different shapes are projected into the environment through a play of light and shadows.

One of my personal projects. A lamp made of 3.6mm thick plywood hardwood with laser cutting.

The different shapes are projected into the environment through a play of light and shadows.

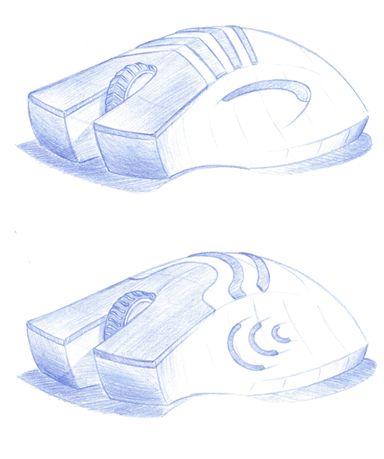

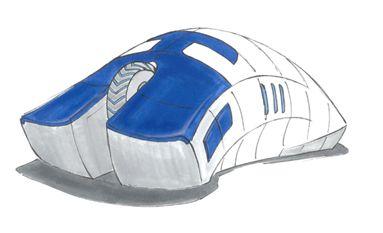

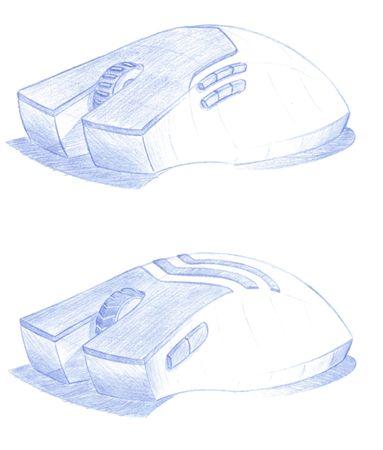

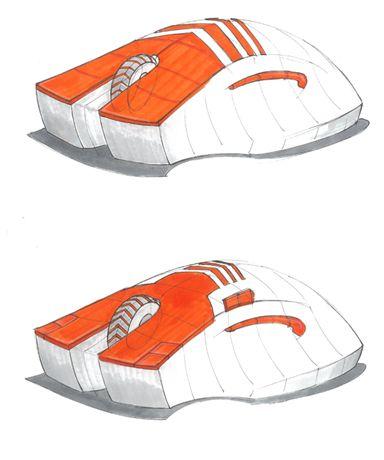

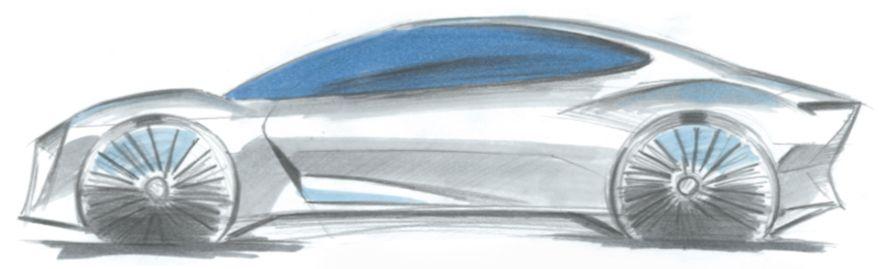

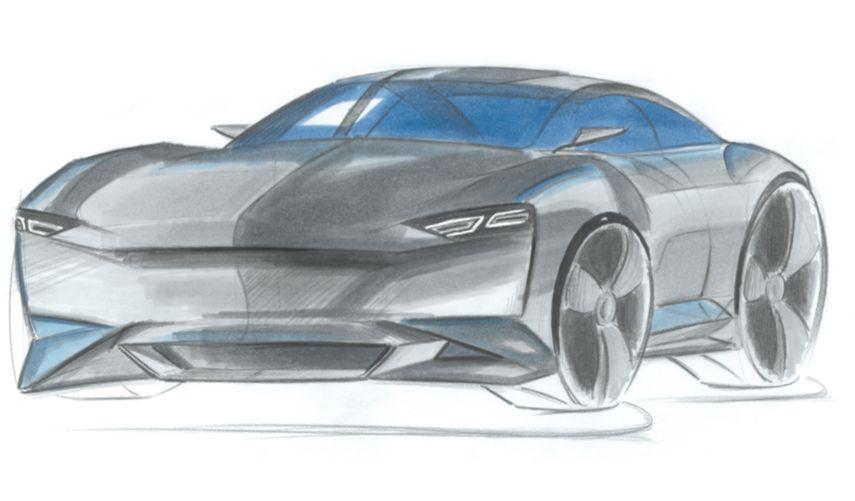

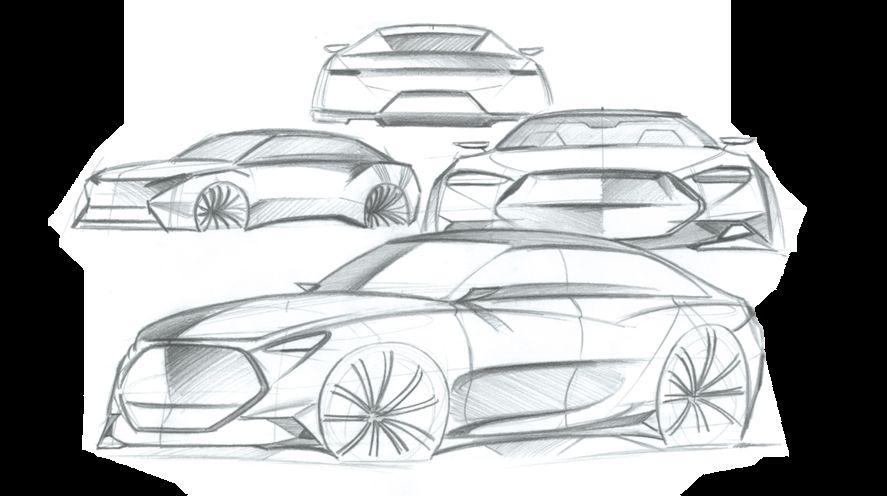

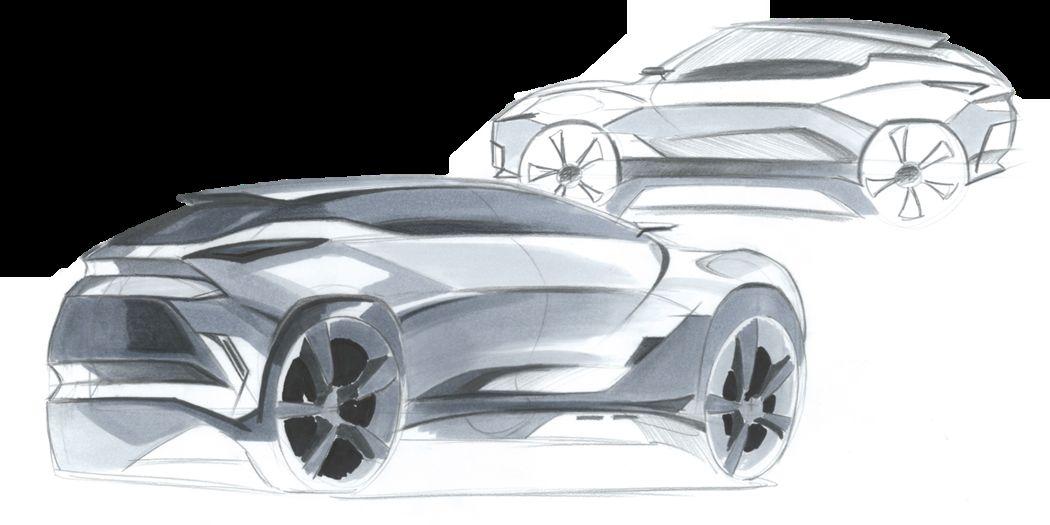

HAND SKETCHING