C .R . A . F .T Lab

MISSION

Under the direction of Andrew Kudless, the Bill Kendall Memorial Endowed Professor of Design Technologies, the Construction Robotics and Fabrication Technologies Lab (C.R.A.F.T. Lab) supports the Gerald D. Hines College of Architecture and Design in exploring innovative new ways of designing, building, and living in the world through the use of emerging technologies, materials, and processes.

Our research topics pursue the critical engagement of emerging technologies, including machine learning, robotics, augmented reality, and additive manufacturing. At the same time, we have a deep respect for traditional ways of making and look to build upon these by introducing computational design logic, new materials, and the critical application of new technologies.

How objects, spaces, and buildings are designed and made is rapidly transforming. It is imperative the Hines College finds ways of making the built environment less carbon-intensive while simultaneously developing the landscape to be more resilient to change. In addition, new technologies, including artificial intelligence and automation, create opportunities and challenges to how we currently operate.

Like the wave of innovation occuring during the mid-20 th century, our world is currently experiencing the beginning of the next industrial revolution. The roles of architects and designers and the related industries of manufacturing and construction are rapidly changing and being challenged to be more sustainable and productive.

The C.R.A.F.T. Lab serves our community in important ways:

• We serve students by preparing them to become leaders in their fields through critically engaging emerging technologies.

• We serve faculty by enabling them to pursue their research through the most advanced technologies.

• We serve the wider University of Houston academic community and our industry partners in collaborating on innovative research projects.

VISION

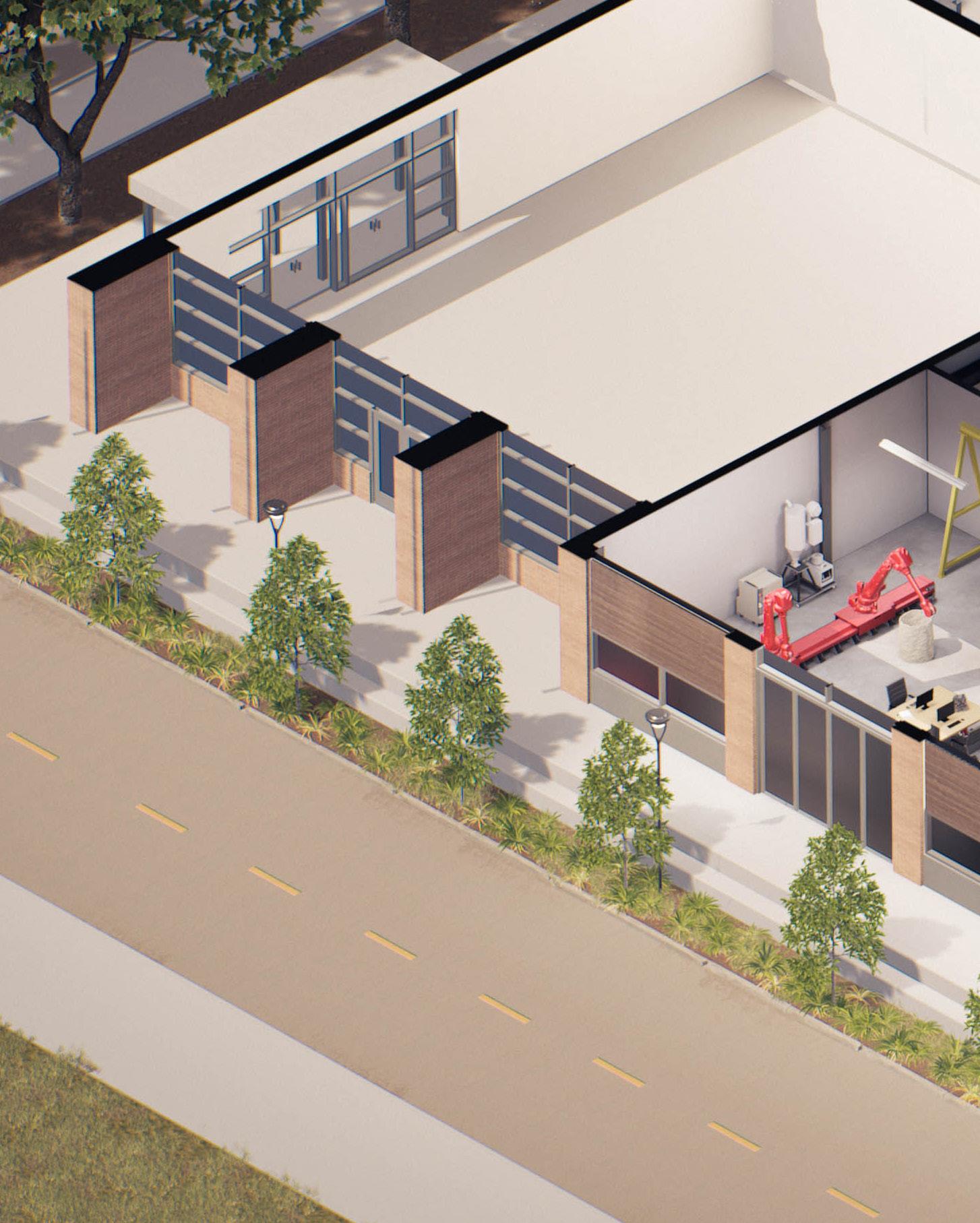

We envision the C.R.A.F.T. Lab as a world-class research facility drawing the most talented students and faculty to the University of Houston in pursuit of cutting-edge research on how we can collectively create more sustainable and innovative architecture and design. Located in one of the country’s fastest-growing cities, the Lab aims to contribute to a more resilient built environment through partnerships with leading design, architecture, and construction practices.

GOALS

• Create the most advanced center for emerging technologies used within design, architecture, and construction in Texas and one of the top facilities in the world. The equipment, processes, and knowledge available at the Lab will be a beacon of innovation for the University, the city of Houston, and the state of Texas.

• Develop robust interdisciplinary connections with faculty and students throughout the Hines College’s industrial design, interior architecture, and architecture programs to unleash the creative potential for world-class research.

• Partner with regional, national, and international industry, academic, and public partners in collaborative research projects expanding the capacity and network of the Hines College.

• Establish a well-funded and active post-professional program for students pursuing world-class research and make the Hines College a recruitment hub for future professional and academic leaders.

• Empower our communities through an intense focus on the sustainability and accessibility embodied in the materials, technologies, and processes used to make the world. We strive to create a more just environment supporting access to advanced technologies regardless of background. As part of a public institution, the Lab pursues research benefiting the public good by making high-quality architecture and design more accessible, safer, and in solidarity with the natural world.

• Attract, retain, and collaborate with the most innovative faculty, students, and researchers and collectively produce research projects at the forefront of design technologies.

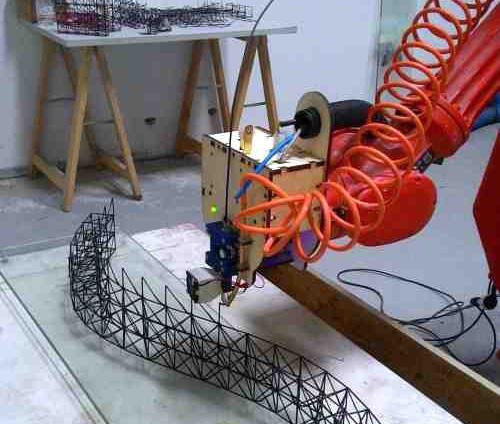

CONSTRUCTION ROBOTICS LAB

The Construction Robotics Lab is a state-of-the-art facility for research on automation in construction and manufacturing. The space is available to Hines College students and faculty and also serves as a hub for interdisciplinary research across the University of Houston and our industry partners.

This space consists of multiple industrial robots, capable of cutting various materials such as foam and wood, assembling aggregate structures like brick walls, and 3D printing with concrete, plastics, and other materials. The Construction Robotics Lab focuses on ways of making construction safer and faster while fabricating higher-quality structures reducing labor costs.

RESEARCH AREAS

• Large-Scale Additive

Manufacturing with Concrete, Adobe, and Recycled Plastics

• Circular Economy of Plastics

• Improved Productivity of Autonomous Construction

• Mass Timber Construction

ADVANCED WOOD FABRICATION LAB

The Advanced Wood Fabrication Lab empowers students and faculty to research new ways of building with wood. As one of the most sustainable materials on earth, wood combines strength and flexibility with a low carbon footprint. Timber is quickly becoming a major material in mid to high-rise architectural projects through the use of mass timber, and cities are rapidly changing their building codes allowing for this new sustainable building system.

The space’s primary equipment consists of a five-axis wood machining center and a large nine-axis robotic machining cell. Combining these two machines greatly increases the scale and complexity of projects our students and faculty create from wood. From furniture to building components, the Advanced Wood Fabrication Lab supports various designs and provides cutting processes, greatly augmenting those already available in the Hines College’s existing Burdette Keeland, Jr. Design Exploration Laboratory.

RESEARCH AREAS

• Mass Timber for Sustainable Construction

• Sustainable and Advanced Furniture Design

• Complex Joinery for Simplified Assemblies

EARTH PRINTING LAB

The most abundant and sustainable material on earth is the earth beneath our feet. It is found everywhere and has been used by cultures around the world for creating objects and structures for millennia.

The Earth Printing Lab explores new ways designers and architects build with earthen materials. From ceramic 3 D printing to slip-casting from digitally-fabricated molds, the space provides the expertise, materials, and equipment to explore this age-old material and give it new life.

This area is equipped with several cutting-edge 3D printers used to print with clay, biomaterial pastes, adobe, and concrete. It is also equipped with a kiln, work tables, and pugmills for mixing and extruding. Beyond earthen materials, the space explores the potential of printing with composite biomaterials integrating materials such as kelp, mycelium, and others.

RESEARCH AREAS

• Ceramic 3D printing

• Biomaterial (mycelium, kelp, etc.) 3D printing

• Digital Ceramics (slipcasting or die-extruding from digitally fabricated parts)

ADDITIVE MANUFACTURING LAB

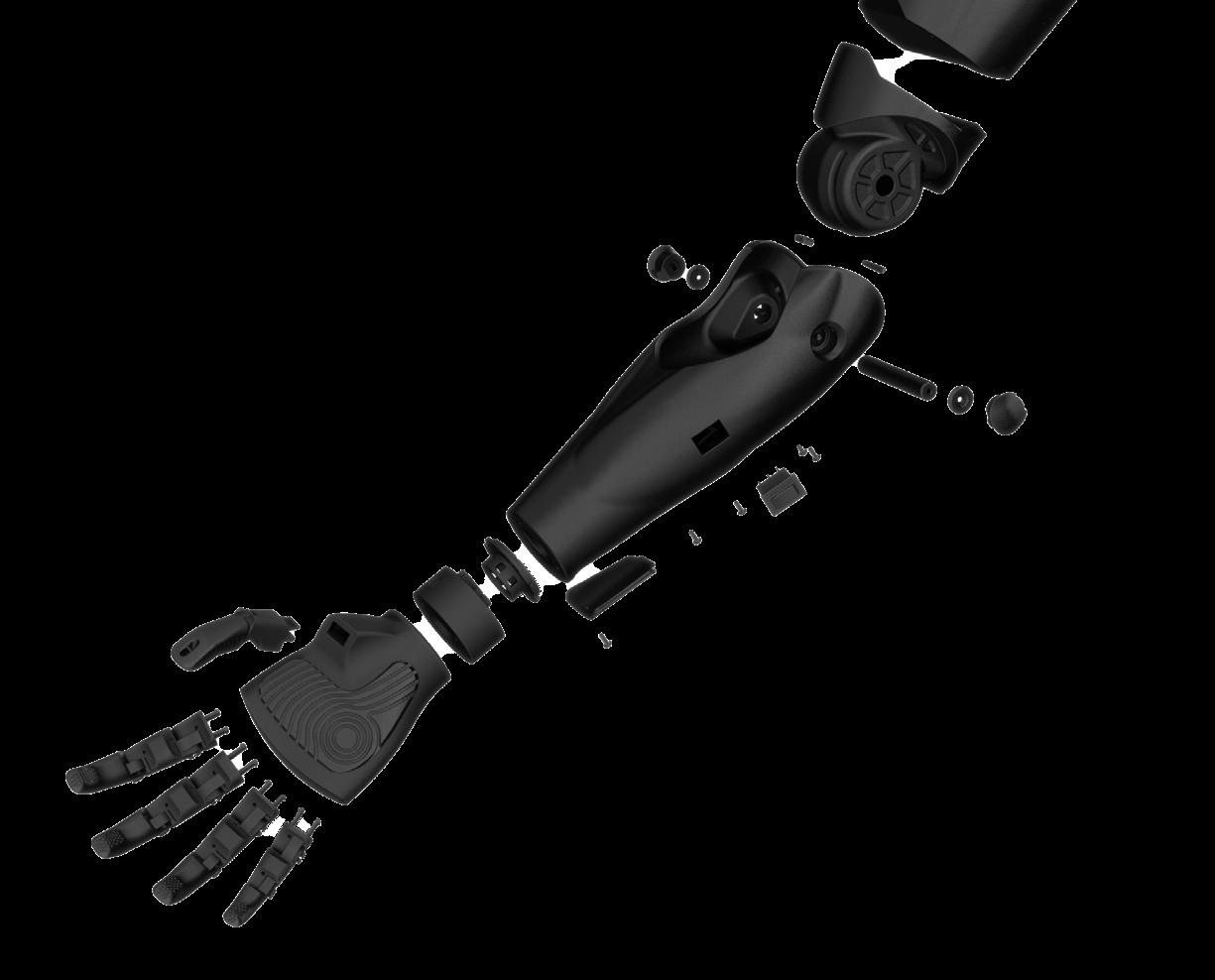

Additive Manufacturing, also known as 3 D printing, has changed how designers design and prototype their ideas. Rather than simply modeling-making, 3 D printing facilitates the production of fullscale parts that can be tested in real-world conditions. Since these technologies were first developed, the cost and precision have greatly decreased. Many students now have their own personal consumergrade 3 D printers. The goal of the Additive Manufacturing Lab is to provide students with a great range, accuracy, and material selection. This area is equipped with a wide range of printers able to print in many different materials. From relatively simple plastics to highperformance resins, fiber-reinforced plastics, and even various metals, the space gives students and faculty the tools to create professional prototypes.

RESEARCH AREAS

• Prototyping

• Biomedical Design

• Robotic End Effectors

• Architectural Models

INTERACTION AND COLLABORATION STUDIO

The Interaction and Collaboration Studio provides the Hines College with needed studio space exploring the future of design education. Designed to be adaptable to the needs of one or more design studios, the space serves as the home for interdisciplinary studios investigating computational design and fabrication, interaction design, and environmental analysis. With everything on wheels and power drops from the ceiling, the space is designed to be reconfigured as needed for different activities, including lectures, critiques, and studio work.

The space is equipped with a large touch-screen display students and faculty use for collaborative design sessions and interactive teaching. Cabinets hold a range of equipment students and faculty may check out, including drones for site surveys, Augmented Reality / Virtual Reality goggles, and environmental testing devices. In addition, the area serves as the makerspace for the design and fabrication of interactive devices using microcontrollers, actuators, and sensors.

Finally, this area also houses several collaborative robots serving as the entry point for teaching robotics and automation to future designers. These robots are designed for safe human interaction and can be easily programmed to perform tasks.

RESEARCH AREAS

• Collaborative Design

• Interaction Design

• Collaborative Robotics

• Artificial Intelligence

• Augmented Reality / Virtual Reality

• Environmental Analysis

ARMATURE COURTYARD

The Armature Courtyard is a public exterior gallery for the Hines College. Students and faculty use the armature to hang prototype wall structures so they both exhibit their innovative work to the larger community but also test to see how their work reacts to the weather. The armature also serves as a space where students demonstrate and test interactive installations with the public.

RESEARCH AREAS

• Design-Build

• Prototyping

• Public Exhibition

• Interaction Design

WORK YARD

The Work Yard is an unglamorous yet critical space for the C.R.A.F.T. Lab.. Not only is the space designed as the primary delivery and shipping area for the Lab, but it also acts as a large work and assembly area. The security gate gives students allhour access to a secure work area. Dust-collection equipment, casting large pieces, and other dirty activities are located here. The work yard is serviced by an industrial loading dock which greatly facilitates the delivery of equipment and materials. With the work yard adjacent to the interior materials storage area and the open build area, the space is a critical element in the flow of materials and projects for the Lab.

CASTING ROOM

The Casting Room is a purposebuilt space for the casting of various materials, including concrete, plaster, and resin. Currently, students cast outside of the Keeland Lab. This space gives students a well-lit area with secure storage, access to casting equipment and tools, and a sink. Students will have all-hour keycard access to the room.

SANDING ROOM

The Sanding Room provides Hines College students with an all-hour access space for the sanding of wood, plastic, and foam models. Designed with downdraft tables to pull harmful dust particles away from users, the room provides students with much better space for sanding. By giving students a great space, we hope to discourage sanding in the architecture building, which leads to poor air quality.

CIRCULAR MATERIALS LAB

The Houston region is home to one of the largest plastics industries in the world. While plastics have many advantages, we have grown accustomed to a “take-make-waste” culture of use (or misuse). Just as the region is transitioning energy to more renewable resources, the plastics industry is also moving towards a circular economy of plastic reuse and recycling.

The Circular Materials Lab serves as the Hines College’s innovation hub for recycling the plastic waste of various campus waste streams and making new materials for student use. In addition, the space explores other materials traditionally considered waste and finds ways of giving them new life through innovative design and fabrication processes.

The space serves as the material research and supply hub for large-scale robotic 3 D printing of recycled plastics for furniture and architectural products taking place downstairs in the Construction Robotics Lab. It is also home to the Precious Plastics student group, the UH chapter of the international Precious Plastics movement. The space is equipped with shredders, granulators, sheet presses, injection molding machines, and extruders.

RESEARCH AREAS

• Circular Economy of Plastics

• Biomaterials

• Additive Manufacturing

Students Served