Thank You

for your help in producing this edition of High Spirit:

Kathy Abernethy

Jeremy Campbell

Jim Cunningham

Rick Dickerson

Liz Ford

Kathy Frey

Lisa Fulginiti

Michelle McCann

David Nice

Dave Nicholas

Jane Owens

Stephanie Reese

Elaine Richard

Laurie Salzmann

John Sandy

Tom Smithgall

Robin Stauffer

Karen Tshudy

Laurie Watson

Chuck Weyland

Welcome to our 80th year in business! As many of you know, my father, Sanford High, started the business in January of 1931, during the Great Depression, with the purchase of King Welding Company. Ironically, we are celebrating our 80th anniversary after also experiencing some of the worst economic conditions that this country has faced since that time. Yet, while the business environment has been dismal and at times very challenging, we have persevered, just as my father did many years ago. In fact, in March of 1931, creditors locked the doors to the shop located at 27 West Lemon Street in Lancaster, due to undisclosed payables from the previous owner. Mr. High was not to be deterred, however. They took the welding and cutting lines out to the sidewalk and continued operations until the legal issues were resolved. This is just one of many stories that demonstrate the persistence, tenacity, and innovation that have been a part of the fabric of High® over these many years, and on behalf of the High Family, thank you for your continued dedication and hard work, even in the most difficult of circumstances.

Throughout the coming year, we will look for opportunities to recognize this important milestone in our history and to celebrate our achievements these past 80 years. The organization has enjoyed significant growth and expansion under the umbrella of High as we know it today, and now as the Company is transitioning to the third generation of ownership, we are assuring that we remain strong and true to our values.

Throughout the coming year, we will look for opportunities to recognize this important milestone in our history and to celebrate our achievements these past 80 years.

We are again at that time of the year when we review the things that happened during the previous year and we take a moment to highlight our achievements. While 2010 was very challenging in many respects, it is always fitting to recognize the accomplishments that occurred within the High companies and to lift up the successes that are worth celebrating. While in some of our companies financial results may not have been consistent with plan, and in some cases were downright disappointing, it was clear that our team of co-workers worked very hard in 2010. We also continued to make significant progress with our formalized commitment to triple-bottom-line sustainability, a key priority for us.

During 2010, High Steel Structures Inc. (HSSI) experienced tremendous financial success, and that success came at a very important time, in light

of the economic conditions that we were facing. The High Occupancy Toll (HOT) Lanes contract on the I-495 beltway south of Washington, D.C., represented a large portion of our work in 2010. This single contract, the largest ever for HSSI, included 46 different bridges that needed to be reconstructed or widened along that stretch of highway. The bridge over Lake Champlain between New York and Vermont, which replaced the one that was closed and demolished due to structural deficiencies, was another large contract for HSSI in 2010. Two significant projects were also booked by HSSI for work in 2011 – a new truss bridge between Indiana and Kentucky, and the reconstruction of the I-80 Inner Belt in Cleveland, Ohio. Both of these projects will be fabricated in 2011, with the Inner Belt project extending into 2012. HSSI also continued its commitment to modernization with the new CNC drilling gantry that was added. This machine, manufactured in Italy, is the first of its kind in the world. Combined with two CNC drilling/burning tables installed in 2009, this tremendous leap forward in drilling accuracy and productivity has helped to modernize HSSI and has resulted in significant cost savings for the Company. HSSI achieved a 25 percent improvement in OSHA Recordable Rate in 2010 as compared to 2009, and Plant Three in Williamsport received VPP recertification by OSHA.

High Transit LLC (HTL), in addition to hauling for HSSI, completed its second full year handling the shipping needs of High Steel Service Center LLC (HSSCL), and it began to manage the shipping operation of High Concrete Group LLC (HCGL), as well. Throughout the year, HTL handled 5,750 loads, including 2,610 for HSSI, 2,312 for HSSCL, and 270 for HCGL. In order to better service the special needs of HSSI’s increasingly larger girders, HTL added a 14-axle, double-drop steerable trailer late in the year.

High Concrete Group LLC (HCGL) worked jointly with HSSI in 2010 to sell the first two concrete bridge projects – the Tappan Zee and Kew Gardens, both located in New York – and the focus on safety continued with the Springboro Plant achieving a full year without an OSHA recordable injury. The Mid-West Field Crew completed three years without a safety incident, and the Denver Plant was presented with the 2009 High Industries Inc. President’s Safety Award in the Spring of 2010. As was mentioned previously, management of HCGL’s shipping operation was successfully transitioned to HTL, and we were successful in developing the first collapsible frame for shipping, which allows trailers to be double-stacked for return trips to the plant. A 50 percent

reduction in admixture costs was achieved in 2010, and thermally efficient, lightweight CarbonCast ® Insulated Cladding accounted for 50 percent of new product sales.

High Steel Service Center LLC (HSSCL) implemented Policy Deployment and Continuous Improvement processes, providing valuable insight, expertise, and innovative ideas to help reduce operating costs. The Sales Team was also strengthened and restructured, resulting in a 22 percent increase in tons shipped in 2010 and positioning HSSCL for an additional 33 percent growth in tons shipped in 2011. The Customer Quality, Vendor Quality, and the On-Time Delivery metrics, all important in the Service Center business, continued to position HSSCL as a top-performer in its industry.

High Associates Ltd. (HAL) added to its retail portfolio in 2010 with the opening of Phase I of Mill Creek Square in Lancaster, Pennsylvania. The Ramada Inn site at the entrance to Greenfield Corporate Center was also acquired during the year, with plans to clear the site for future development, and the former Trojan Yacht site on Greenfield Road was acquired in an effort to reposition the 142,000 square foot building located on 17 acres of land that is adjacent to other High-owned land in Greenfield Corporate Center West. The multi-family residential communities experienced an improvement in occupancy throughout the year, which we hope is an indication that the economy has hit bottom and is beginning to trend in a more positive direction.

For the third year in a row, High Construction Company (HCC) was named General Contractor of the Year by the American Subcontractors Association of Central Pennsylvania, and achieved 642 days without an OSHA Day Away Case incident. Construction was completed on the second service center project for the Pennsylvania Turnpike Commission, and two new replacement service center projects began. The “Energy Solutions” product line was introduced and the investigative phase of determining potential business opportunities in the Marcellus Shale region was completed. Construction projects are now aggressively being pursued in that region by a number of our business units. Greenfield Architects Ltd. (GAL) also completed the design of the new Calvin and Janet High Center for Worship and Performing Arts at Messiah College.

High Hotels Ltd. (HHL) continued on its path to grow the number of hotels in its portfolio with the opening of the new SpringHill Suites by

In the Fall of 2010, Mill Creek Square, located on Route 30 east of Lancaster, held its grand opening.

Marriott in Ewing, New Jersey – its 11th hotel. Marriott Hotels recognized two of our hotels with awards in 2010 – the Courtyard by Marriott in Lancaster, Pennsylvania, was recognized with the Platinum Award, and the Courtyard by Marriott in Middletown, New York, received the Gold Award – both for outstanding guest satisfaction and product inspections. Marriott’s “refreshing business” lobby reinvention was completed at the Courtyard by Marriott in Middletown, New York, and the Hampton Inn-Harrisburg West successfully completed its 20year re-licensing product improvement plan. The Hampton Inn-York was recognized with Hilton’s Circle of Excellence Award and overall, HHL achieved a 25 percent improvement in OSHA Recordable Rate as compared to 2009.

High Safety Consulting Services Ltd. (HSCSL) spent time gearing up to provide gas/oil specific training throughout the Marcellus Shale region. Several members of the staff continued with personal development by achieving specific industry qualifications and certifications to further enhance the abilities of the group, and respiratory fit testing equipment was purchased to also increase responsiveness. Customer satisfaction and loyalty remained high with many long-term customers and a satisfaction rating of 4.8 out of 5 for service provided.

Co-workers in the Shared Resource Units provided support for the many activities throughout 2010, as well. In our continuing effort to keep informational processes current and meet the needs of the business units, a three-year technology implementation plan involving HAL, Accounting Services, and Information Services was approved. The SAP application was also upgraded in 2010, providing many new features and capabilities that can be enabled as process improvements are identified within the business units.

Legal and Treasury worked with HAL to encourage tenants to utilize electronic funds transfer of monthly rent payments to eliminate check handling, and nearly 250 contracts and

subcontracts were negotiated during the year, the largest involving HSSI with the Innerbelt and Milton Madison projects, and for HCGL, the Tappan Zee bridge project. Treasury also participated in the restructuring of High’s credit card system – going from a single card to two cards – a purchasing card and a travel and entertainment card.

The Tax Department supported information technology enhancements with the conversion of HII fixed asset records to SAP, and significant advancements in estate planning and ownership succession occurred through enhanced utilization of the High Family Trust. High philanthropy was also solidified for the future with the restructuring of The High Foundation for the Calvin High and Dale High families.

During 2010, Wellness Programs continued to promote weight loss, increased physical activity, flu immunizations, and smoking cessation, with participation by hundreds of co-workers. The Co-worker Activities Committee (CAC) held a full year of creative and interesting events.

The Co-worker Satisfaction Survey (CSS) was again conducted in 2010, which was the first time that back-to-back annual surveys were carried out. Focus groups were facilitated and action plans established to respond to those areas where improvement is needed. We plan to continue to use this tool annually. We also will participate in the Best Places to Work in PA program this year, not only for the valuable recognition this exceptional honor brings, but also because it is one more effort that, like the CSS, challenges us to work together – to continue to grow, improve, communicate, and be the very best that we can be.

High co-workers not only work hard, they give back to their communities. In 2010, co-workers pledged $250,295 to the annual United Way Campaign, representing an increase in per capita giving from $261.59 in 2009 to $263.46 in 2010. Co-workers also participated in and supported many other important causes throughout the year, all of which contributed toward an enhanced quality of life in the communities in which we do business.

Space limits our ability to recognize more of the outstanding accomplishments achieved in 2010, as those listed here barely scratch the surface. On behalf of the High Family, thank you for all of your efforts! As we look forward to the year before us, we continue to face challenges in many of our operating units; however, there are also many new opportunities to make things happen. I know that I can count on all of you to persevere and come through this tumultuous time an even stronger, more viable, family of companies.

In July, the Co-worker Activities Committee held a Fun Fair in the Greenfield Coporate Center for co-workers and their family members.

1931 At the age of 23, Sanford High borrowed $7,500, with the help of his father, to purchase King Welding Company, 27 West Lemon Street, Lancaster, Pennsylvania. On January 1, High Welding Company was formed.

1933 Sanford High had met with State Highway Officials to promote welding, as opposed to riveting, of steel bridges. This resulted in the experimental welding of a bridge near Stewartstown, Pennsylvania.

1941 Having outgrown its Lemon Street location, High Welding Company moves to James and Water Streets.

1946 High Welding Company was contracted to re-floor the Belvedere Bridge over the Delaware River. It was High Welding Company’s first major project involving fabrication and erection of structural steel, and the catalyst for future growth.

1951 Calvin G. High joined the company full time.

1952 A 10.5 acre site along Old Philadelphia Pike in Lancaster was purchased and used for steel storage until 1954, when construction was started on Plant One.

1955 The Company moved to Old Philadelphia Pike, Lancaster.

1956 High Welding Company, previously a proprietorship, was incorporated in its 25th year.

High Steel Structures Inc. (HSSI) is currently fabricating and setting up the structural steel for its $17 million contract for the Lake Champlain Bridge in upstate New York. Connecting Crown Point, New York, and Chimney Point, Vermont, this is a fast-track high profile emergency replacement project. The new 4,234 ton modified network tied arch requires complex fabrication and the application of a metallized coating to protect the steel from the harsh weather common to the area.

Randy Roth, this project is especially challenging for his team, due to its size and the requirement for full set-up and reaming. Because the over 40-foot deep rigid frame delta-leg girder assemblies at the beginning of the arch span exceed the height at which complete vertical assembly and set-up can be done safely, the set-up and reaming teams are working on the bridge’s ten delta-legs in three stages:

Stage 1: The entire delta put together in the lay down position.

Stage 2: The top part of the delta with the roadway girder is set up to elevation vertically in an inverted fashion, as shown in the photo above.

Stage 3: In the photo below, the bottom part of the assembly, which will ultimately rest on the pier, is set up vertically in the field position. Even with this method, the height of the bottom delta-leg portions in this stage will require Manlifts of up to 30 feet high.

The new bridge, which is jointly owned by the New York State Department of Transportation and the Vermont Agency of Transportation, replaces a truss bridge built in 1929. The old bridge was closed suddenly due to severe deterioration, and was taken down by explosive demolition in late 2009. The new bridge is expected to be open to traffic in the Fall of 2011.

High Concrete Group LLC (HCGL) has been awarded a $20 million contract to produce architectural cladding enclosures for the new Dulles Corridor Metrorail Project. This 3,800-piece project is being produced at the Denver, Pennsylvania, plant and is one of HCGL’s largest nongarage projects to date. It was secured as a result of a selling process that began nearly three years ago during a day-long HCGL Concrete Innovations & Answers® seminar, where representatives from The Bechtel Company and Dulles Transit Partners, LLC inquired about the use of precast for the project. During the next two years, HCGL’s A.J. Sassaman, Regional Sales Manager, and Ken Baur, PE, LEED AP, Director of Research and Development, made regular visits to the Washington, D.C. area to provide assistance and design support.

1963 S. Dale High joined the Company full time upon graduation from Elizabethtown College.

1963 High Realty, predecessor of High Properties, was formed. The build-lease process began as the first building was constructed in Greenfield Corporate Center.

1967 HSSI’s Plant Two was built.

1971 High Welding Company changed its name to High Steel Structures Inc.

1976 High Realty Corporation, a residential real estate listing and sales office, was formed. It was sold to Gateway Realty in 1990.

1977 To maintain friendships formed during their years at High, a group of retirees formed the High Beamers.

1977 Kurtz Precast Corporation, predecessor of High Concrete Group LLC, was acquired.

1977 A new holding company, High Industries Inc., was formed. Dale High served as its Chairman, President, and Chief Executive Officer.

1978 Lantz Builders, predecessor of High Construction Company, was acquired.

1978 High Steel Service Center LLC opened its doors.

This 325,000 square-foot transit project includes thermally efficient precast enclosures for five new metro station buildings, six entrance pavilions, and two ventilation structures. Cladding will feature a two-color utility-size brick veneer finish. Approximately one-third of these panels will be thermally efficient CarbonCast® insulated sandwich designs with C-GRID ® shear trusses. Erection will begin in Spring 2011, with completion scheduled for 2013.

1980 The High Foundation, a philanthropic non-profit organization, was formed.

1980 High Associates Ltd. was formed for the purpose of selling, leasing, and managing commercial, industrial, and residential real estate.

1981 Greenfield Associates Ltd. was formed to provide consulting and organizational development services to High® and outside organizations. It was closed in the early 1990s.

1982 Formigli Corporation, later known as High Concrete Structures Inc. of New Jersey, was acquired. The plants in Williamstown Junction and Vineland were later closed.

1983 High Industries Inc. became involved in cable television systems, forming High Cablevision in 1987. Following the acquisition and divestiture of these small local companies, High Cablevision ceased operation.

1983 High Steel Structures Inc. was named a Star site in the OSHA Voluntary Protection Program.

1983 Sanford H. High passed away on December 25.

1985 High Investors Ltd., an investment firm offering private real estate and venture capital syndications, was formed.

1985 High Steel Structures Inc. acquired Williamsport Fabricators.

1987 High Food Services Ltd. was formed. The company was divested in 2006 , and operations remain at the Greenfield Corporate Center location.

1987 High Employee Services Ltd. was formed. In 2004, it was acquired by a larger organization.

1987 High Communications Partnership was formed, purchasing radio stations in North Carolina, Virginia, and Kentucky. As consolidations occurred, operations were terminated.

1988 American Helix Technology Corporation was formed, and provided a variety of compact disc products for the audio and computer industry. It was subsequently acquired by a Japanese company.

High Steel Service Center LLC (HSSCL) has started to brand its products to gain name recognition. This ecofriendly campaign consists of corner edge protectors and protective paper stenciled with the HSSCL logo and made from 100 percent recycled materials. Used to protect skids of steel produced in the plant, this packaging helps to ensure that customers receive quality products in perfect condition.

So what is in a name? By stamping the HSSCL logo on everything shipped, co-workers take ownership of the product. This level of pride is evident in customer satisfaction, both at their purchasing level and in their operations. This branding also keeps the HSSCL name at the forefront, enabling it to meet the needs of customers while building trustworthy relationships for the long haul.

High co-workers are preparing to replace approximately 28 percent of the total concrete deck area on the Tappan Zee Bridge in New York. This $14.5 million project is the first significant concrete bridge work for High Concrete Group LLC (HCGL), and is a major win for the High Bridge Team, a partnership between High Steel Structures Inc. (HSSI) and HCGL. The precast contract is part of a contract awarded by the New York State Thruway Authority to general contractor Tutor Perini Corporation of Peekskill, New York, and is the second phase of re-decking the three mile-long bridge.

Co-workers at HCGL’s Denver plant will fabricate 421,793 square feet of precast decking in 849 pieces, which Tutor will transport and install.

High co-workers Raymundo Torres and Bryan Shaver prepare a form for pouring slabs.

Installation of the precast slabs will begin in March 2011, with completion in the Fall. Overall project completion is slated for Winter 2012. Originally opened in 1955, the Tappan Zee Bridge spans the Hudson River between Rockland and Westchester

Counties in New York. One of the nation’s largest bridges, it is a lifeline for New York City, serving an average of 140,000 vehicles per day. Because minimizing impact of construction on travelers is a priority, the Thruway Authority decided in favor of precast slabs, stating, “Deck replacement materials will be manufactured off-site, reducing noise onsite, and shortening the duration of the project overall.”

The Tappan Zee project is an example of leveraging HSSI’s bridge market knowledge and HCGL’s manufacturing capabilities. This marks a new era of cooperation, and is an important step in developing new products and markets.

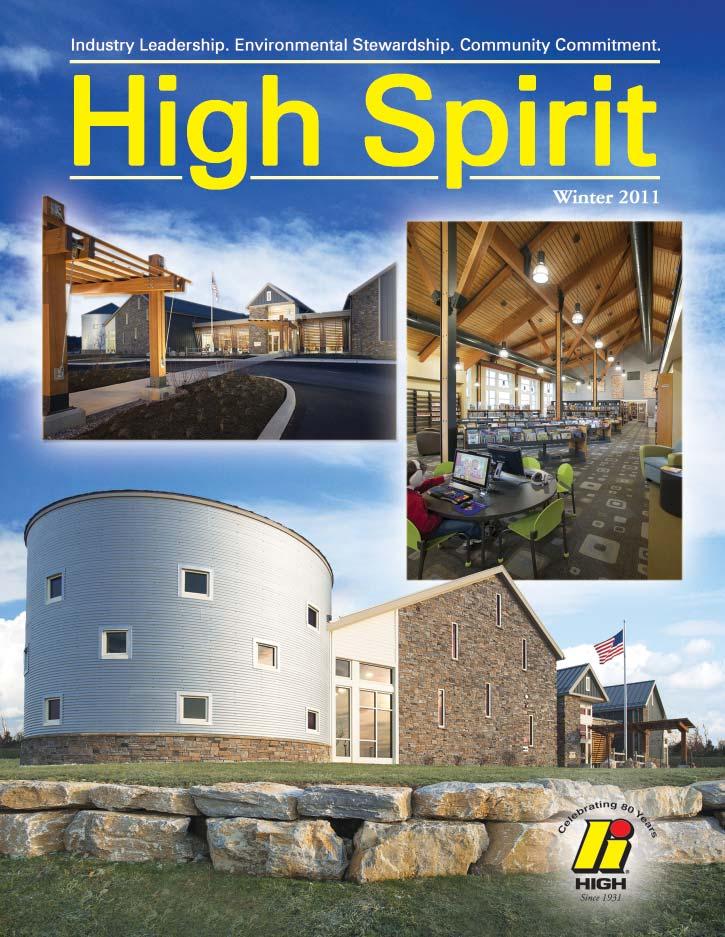

High Construction Company (HCC) completed the construction of the Manheim Township Public Library in Lancaster, Pennsylvania, which opened in September 2010. The new library reflects Lancaster County’s rich agricultural heritage with a modern flair, using forward-thinking materials.

The facility’s design is reminiscent of a traditional bank barn and farmstead, complete with a siloshaped children’s library. The exterior features stone, fibercement siding, and metal roofing. Gable-end windows are narrow and elongated, resembling the vertical ventilation slits of tobacco barns. The marrying of old with new continues inside, where uniquely designed exposed timbers blend with modern steel connectors, stamped concrete flooring, and dramatic colors. The building also includes environmentally-friendly materials and an underground geothermal system.

Kurt Yoder and Matt Doerr install reinforcing steel in preparation to a concrete wall pour.

HCC served as the general contractor for the 26,000 squarefoot facility, and self-performed all concrete work (such as footers, foundations, slab on deck, slab on grade, and basement slab) and miscellaneous carpentry for the project, comprising 17 percent of the cost of work.

HCC’s key project management team included Dan Pietropola as Project Manager, Jennifer Mader as Assistant Project Manager, and George Hammer as Senior Project Superintendent.

1988 High Hotels Ltd. was formed and began development and management of limited-service hotels. By mid-2010, the portfolio had grown to eleven hotels in Pennsylvania (7), Maryland (1), New York (2), and New Jersey (1).

1989 Steven D. High joined High Industries Inc. as Safety Specialist. Following a variety of safety-related positions, today Steve is President of High Safety Consulting Services Ltd.

1990 Greenfield Architects Ltd. was formed.

1991 Gregory A. High joined High Associates Ltd., and later moved to High Hotels Ltd. Currently, he holds the position of Vice President of Ownership Strategic Planning with High Company LLC.

1993 With the oversight of the Corporate Benefits Department, the Wellness Committee was formed by health-conscious co -workers.

1994 High Steel Structures was awarded the Pennsylvania Governor’s Safety Award, PENNSAFE, for its long history of workplace safety.

1995 The High Family Council, consisting of Dale, Sadie, Steve, Greg, and Suzanne High, was formed to chart the Company’s future and to ensure ownership would pass smoothly to future generations.

1997 Calvin High retired from active management of High Industries Inc.

1997 Led by Steve High, High Safety Consulting Services Ltd. was formed.

2000 High Steel Service Center LLC was the first High Company to achieve the ISO-9000 certification.

2000 High Industries Inc. was named one of the Best Places to Work in PA.

2001 The High Family was able to preserve a part of its heritage by purchasing the property at 27 West Lemon Street, which housed High Welding Company when it first began.

2002 High Industries Inc. was awarded Family Business of the Year by Wharton Enterprising Families Initiative of the Wharton School, University of Pennsylvania.

2003 Calvin G. High retired from the Board of Directors, but remains active in real estate activities.

2003 High Steel Structures Inc. became the first North American steel bridge company to achieve ISO 9001:2000 certification.

2003 High Concrete Structures Inc. earned the Governor’s Award for Safety Excellence.

2004 Sanford H. High was honored posthumously as one of America’s Top 100 Private Sector Transportation Design and Construction Professionals of the 20th Century, as presented by the American Road and Transportation Builders Association (ARTBA).

2004 High Concrete Structures Inc. operations were expanded to an idle bay at High Steel Structures Inc.’s Plant Three facility in Williamsport, Pennsylvania.

2004 High Concrete leased a facility in Lebanon, Pennsylvania, and began production of CarbonCast® . Shortly thereafter, a fire destroyed the facility.

2004 With locations in Springboro, Ohio, and Paxton, Illinois, Concrete Technology Inc. was acquired to form High Concrete Technology LLC (later, High Concrete Group LLC).

Four years ago, the High Wellness Challenge was introduced to address a concern over rising health care costs and the health of High® co-workers. According to the U.S. Department of Health and Human Services, more than 75 percent of all health care dollars are spent on chronic and preventable conditions. Through the Wellness Challenge, we encourage coworkers to improve their lifestyles through education, behavior change, and by taking personal responsibility for their health.

Participating is simple and can be done for little or no cost. Start by obtaining a 2011 Wellness Challenge form from your Human Resources representative, a Wellness Committee member, or the High Intranet, then follow these easy steps:

Step 1:Participate in a Biometric Screening

“Wellness is an intentional choice of a lifestyle characterized by personal responsibility, moderation, and maximum personal enhancement of physical, mental, emotional, and spiritual health.”

-Wellness Council of America

This is item #1 of the Wellness Challenge, and is a requirement for 2011. Offered free to participating High co-workers and administered during work hours, it is a quick and effective way to learn more about your health risks. The screening measures your cholesterol, blood pressure, body fat, and BMI. Information and a schedule will be available in the coming months. Results of your biometric screening will be helpful to you when completing the next step.

Step 2:Complete the Health Risk Assessment.

Item #2, the confidential HRA is meant to raise awareness about potential health problems. (You will use the results from Step #1 to obtain a more accurate picture of your health risks.) This required item must be completed by September 30, 2011.

Step 3:Complete five additional elements.

During the course of the 2011 Wellness Challenge, select and complete five remaining elements.

Step 4:Submit the form.

Return the completed Wellness Challenge form to the Benefits Department by the October 31, 2011, deadline. All requirements must be met in order to go to the next step.

Step 5:Enjoy your reward!

In November, you will receive a lump sum payment of $350.

High is committed to engaging co-workers and their families in making healthy choices and becoming better health care consumers. Gaining a better understanding of your health risks and addressing those issues keeps the focus on preventive care. A healthy workforce is a core part of our success. Join the 2011 High Wellness Challenge today!

Kenneth Glidden, High Steel Structures Inc.

. . .earned an Associates degree in Business Administration from Elizabethtown College in January 2011.

Kenneth A. Hornbeck, High Associates Ltd.

. . .earned the Certified Commercial Investment Member (CCIM) designation from the CCIM Institute, an affiliate of the National Associate of Realtors, in October 2010.

Eric M. Lehmayer, MAI, High Associates Ltd.

. . .earned Associate Instructor credentials with the Appraisal Institute in November 2010, and is qualified to instruct the Institute’s “Basic Appraisal Principles” and “Basic Appraisal Procedures” courses.

Aidalis Lopez, High Company LLC

. . .earned Professional of Human Resources (PHR) certification in December 2010 from the HR Certification Institute.

Barbara M. Rutt, High Safety Consulting Services Ltd.

. . .earned certification as a Certified Safety Professional (CSP) from the Board of Certified Safety Professionals in January 2011.

A.J. Sassaman, High Concrete Group LLC

. . .earned an Associates degree in Business Administration from Colorado Technical University in September 2010.

High Associates Ltd.

. . .was named to PPL Electric Utilities’ Energy-Smart Business Honor Roll. HAL’s efforts included completion of major lighting retrofits in multiple facilities and installing occupancy sensors that resulted in significant energy savings.

Hilton Garden Inn, Wilkes-Barre, Pennsylvania

. . .recently earned a 93.9 percent “Outstanding Inspection”, the top rating within the Hilton inspection process. These semi-annual quality assurance audits are unannounced and are performed by a Hilton brand representative to evaluate the adherence to cleanliness, condition, and brand standards.

Kurt A. Schenck, Realtor®, High Associates Ltd.

. . .was honored as the Commercial and Industrial Real Estate Council Member of the Year by the Lancaster County Association of Realtors at its 76th annual banquet.

2004 High Concrete Innovations LLC was formed.

2005 Suzanne M. High joins the company as she, Steve High, and Greg High, were elected to the High Hotels Ltd. Board of Directors.

2006 W. Thomas Kennedy III and Nevin D. Cooley were named President and Chief Executive Officer of High Industries Inc. and High Real Estate Group LLC, respectively.

2006 High was named Central Penn Business Journal’s Corporate Citizen of the Year.

2007 High Steel Structures Inc. Plant Three facility in Williamsport, Pennsylvania, was designated a Star site in OSHA’s Voluntary Protection Program.

2008 In order to better serve its customers, High Safety Consulting Services Ltd. opened a second office in Lebanon, Pennsylvania.

2009 High Real Estate Group and Penn Square Partners celebrated the opening of the Lancaster Marriott at Penn Square and Lancaster County Convention Center.

2009 Dale High was appointed by the U.S. Chamber of Commerce to serve as a member of its Board of Directors.

2010 Upon the retirement of W. Thomas Kennedy III, Jeffrey D. Smith was named President and Chief Executive Officer of High Industries Inc.

2011 High marks its 80th year.

Jason A. Erb, MultiCut Blanking

Nominated by Patrick J. Donley, Maintenance Supervisor

Jason is a co-worker with a ‘can-do’ attitude. Qualified to operate nine major pieces of machinery, he takes his job responsibilities a step further to ensure that small maintenance issues do not grow into big problems, sometimes repairing equipment himself.

Jason works diligently to ensure equipment is running smoothly so that product is delivered as scheduled. On Blanking Line 1, he spearheaded the shear knife change, was instrumental in the removal and replacement of a failed cylinder, and assisted with replacement of a hydraulic power unit and with the Flat Track installation (fabricating the required guarding and interlock). He was also instrumental in the removal of entry pinch rolls and the tension roll on Slitting Line 2.

Dedication to ‘building trustworthy relationships’ with coworkers, and ‘valuing our customers and meeting their needs’ through proper equipment maintenance and operation, makes Jason a great example of Good Measure.

David L. Brodhag, Senior Estimator

A.J. Sassaman, Regional Sales Manager

Nominated by Thomas M. McEvoy

Nearly three years ago during a Concrete Innovations & Answers Seminar, Dulles Tranist Partners’ (DTP) design team members asked if HCGL could help them understand how they might use precast as an alternative to cast-in-place concrete for the Dulles Corridor Metrorail Project. For the next two years, Ken and A.J. made monthly visits to Washington D.C. to work with the DTP design team.

By including CarbonCast® panels, the HCGL team was able to save the customer design expense and expedite schedules. The tenacity and professionalism exhibited by Ken, Dave, and A.J., as well as their intimate knowledge of this large and complex project, enabled HCGL to edge out the competition on bid day.

This is a great example of a team-based approach to ‘building trustworthy relationships’. By ‘valuing our customers and meeting their needs’, A.J., Dave, and Ken are truly ‘innovative leaders’ worthy of the Good Measure Award.

The former Ramada Inn on Greenfield Road in Greenfield Corporate Center is now history. It was taken apart meticulously, piece by piece, and where material could be reused or recycled, it was. High Associates Ltd.’s (HAL) green approach to “disassemble” or “deconstruct”, rather than demolish, saved money while being sensitive to the environment. In all, 8,968.8 of the 9,313.4 tons – more than 96 percent of the material –was recycled or reused, and include the following:

Approximately 3 tons of non-ferrous metals;

178 tons of ferrous metals; approximately 4 tons of ceiling tile; and

8,784 tons of clean fill (some of which was used at Lancaster Airport).

In addition, some content was donated to Habitat for Humanity and more than $100,000 was generated as a result of a successful liquidation process that sold all the contents of the former hotel including furniture, fixtures, operating supplies, and equipment.

Tom Smithgall, HAL’s Senior Vice President of Development, oversaw the project and shares that, “As part of our sustainability initiative, it is gratifying to see our team collaborate so effectively with our vendor to successfully complete this project.”

HAL is currently working to determine the future use for the property.

As previously reported in High Spirit, the High® Green Initiative Committee undertook a project to evaluate the organization’s carbon footprint and associated Greenhouse Gas (GHG) emissions. A baseline for GHG emissions was established, based on the 2007 emission data. The GHG emissions emanate from the burning of fossil fuels, such as natural gas, electricity, and vehicle use. A commitment was made to look at ways to reduce fossil fuel use, which in turn would increase process efficiency and lower costs, as well as reduce GHG emissions.

Through the third quarter of 2010, overall GHG emissions have been reduced by approximately 15 percent from the 2007 baseline. When production levels were taken into account (as measured in GHG intensity per unit of production), the reduction was approximately 8.8 percent company wide. The production factors vary, depending upon the type of facility; for example, the High Steel Structures’ factor uses thousand tons of steel produced, while the High Hotels’ factor is based on the number of room nights booked. Looking at GHG emissions from a production intensity standpoint provides a truer indication of actual emission changes.

Many completed projects are contributing to the lower GHG emissions. These include the lighting retrofit that was conducted at all High facilities generating savings of more than $500,000 annually, and the installation of a more efficient heating system at the High Steel Service Center estimated to reduce gas usage by 40 percent, or $18,000 annually.

Business units that have exceeded the emission reduction goal using the production intensity factors include the High Corporate Office, High Hotels Ltd., and High Construction Company. High Steel Structures Inc., High Concrete Group LLC, and High Associates Ltd., while not quite meeting the reduction goal, all had lower GHG emissions than the 2007 baseline.

We will continue to look at ways to further reduce our carbon footprint as part of our green initiative and sustainability efforts and look forward to continuing to share the results of our progress to date.

When we think of High®, we typically think of red and yellow; but High companies are doing their part to also be identified as green.

The Hampton Inn hotel brand has stopped using polystyrene utensils and Styrofoam cups, and now uses Taterware. Made from potatoes, these products are 100 percent compostable, and will not contaminate soil or runoff water. Taterware is also approved by the FDA for direct contact with food, and can withstand hot foods and liquids.

All five of High Hotels Ltd. Hampton Inns – Harrisburg, Lancaster, and York, Pennsylvania; Middletown, New York; and Annapolis, Maryland – have made the switch, as did all Hampton Inns across the country.

In addition to recycling its scrap steel and shot fines, and complying with local requirements by recycling cardboard, office paper, and aluminum cans, High Steel Structures Inc.’s Williamsport, Pennsylvania, facility recently enhanced its efforts to include plastic water bottles.

During the hot summer months, bottled water is supplied to coworkers to keep them hydrated. Seeing the amount of plastic bottles generated and put into the trash stream prompted coworkers to suggest that a plastic recycling program be put into place. Containers for this purpose are strategically located in the plant, and co-workers have embraced the program.

Partnering with Verizon Wireless and E-Cycle, a global leader in wireless buyback and recycling, the Technical Assistance Center

(TAC) at High Company LLC has taken steps to reduce the number of wireless phones that end up in landfills. Through a responsible recycling program, TAC collects retired electronic equipment, wipes it clean of data, and reformats the device to factory settings. For its efforts, High receives a cash rebate for any device deemed marketable.

Phones and accessories that have outlived their market value are destroyed. Every battery removed is sent to an EPA-registered facility. Core technology, including the motherboard and all wiring, is shredded and melted down so that precious metals can be reused.

These are just a few examples of how a little effort by companies and co-workers can make a world of difference in our environment. By identifying and implementing environmentally friendly practices, we can all contribute to making High red, yellow, and green!

A commitment to the three R’s - Reduce, Reuse, Recycle - may seem to be a new concept at High®; however, looking through past issues of High Spirit, there is evidence that High co-workers were conscious of the need to reduce waste 15 years ago. Following is a partial reprint of an article from the Summer 1996 edition:

In past years, as High Steel Structures Inc. (HSSI) was preparing for summer, its heaviest shipping season, co-workers would comb local carpet stores to collect carpet remnants that could be used on the bottom of HSSI’s trailers to protect painted girders during shipping. However, HSSI recently found a better carpet source; other High companies.

Frank McCabe, President of High Hotels Ltd. (HHL), sent messages to the General Managers of the Lancaster, York, Harrisburg, and Reading Hampton Inns, asking them to notify HSSI when they are replacing carpet.

Another ongoing source has been High Associates Ltd. (HAL), which often renovates offices at Greenfield Corporate Center. By turning to its sister companies, HSSI has turned “one man’s trash” into “another man’s treasure”.

This practice continues today, creating a win-win situation for HHL, HAL, and HSSI. By reducing the bottom line on costs, as well as on the amount of waste going to landfills, these companies “contribute to a world of beauty and prosperity and peace.”

Following the United Way Day of Caring, which was held in early September, High® United Way Committees began the task of organizing meetings and events to rally co-workers in support of this worthy cause. Some committees planned events that were a bit unusual.

The High Steel Structures Inc. (HSSI) Committee held team challenges with a goal of reaching 80 percent participation. Winners hailed from Williamsport, Pennsylvania, and included the ‘Captain America’ and ‘Spiderman’ teams, who were treated to a pancake breakfast.

In Lancaster, HSSI held a ‘Kiss a Cow’ event. Co-workers purchased tickets to vote for co-workers they most wanted to see kiss the cow - or in this case, a calf named Bonnie, whose services were donated by Beth Tippett from Corporate Human Resources. The winning co-workers were: Steve Gerber, Vice President of Manufacturing; John Peiffer, Plant Manager, and; Sean Pitzer, Engineering Administration. As co-workers cheered them on, these good sports mooed and wooed Bonnie before planting a kiss on this bovine beauty’s nose.

At the end of its campaign, the High Company LLC (HCL) United Way Committee held a special Co-worker Karaoke event for its supporters. Darryl Gordon, Human Resource Director, performed Cool and the Gang’s “Celebration”, before introducing the main event. Larry Brown, Senior Vice President of Human Resources, Nevin Cooley, President and CEO of High Real Estate Group LLC, Steve High, President of High Safety Consulting Services LLC, and Jeff Smith, President and CEO of High Industries Inc., took the stage as lead singer Greg High, Vice President of Ownership Strategic Planning, who arrived riding a Harley Davidson motorcycle, joined them to perform Twisted Sister’s hard-driving anthem, “I Wanna Rock”. It was quite an exciting performance!

Left: Deneen Coplin shows her joy at winning the Harley Davidson motorcycle.

Right: She had him at “moo”! Sean Pitzer plants a big kiss on Bonnie’s nose.

With the final tally in, 2010 campaign pledges came to $250,295, with 60 co-workers contributing at the Leadership level.

To top it all off, a High coworker was randomly selected from all eligible entrants as one of the York County United Way grand prize winners. Deneen Coplin, Guest Services Representative for the Hampton Inn-York, Pennsylvania, was the winner of the York County agency’s random drawing for a 2011 Harley Davidson Touring Road Glide Custom motorcycle. Deneen was also treated to a VIP tour of Harley Davidson’s York plant where her bike was manufactured. This marks the second consecutive year that a High coworker won a United Way drawing.

Thank you, High co-workers, for opening your hearts and wallets in these difficult economic times, and for making our United Way Campaign a success. Through your selflessness and generosity, United Way and the agencies it supports are able to make a very positive impact in the communities in which we live and work.

Below, the band rocks a cover shot. Left to right are Jeff Smith, Larry Brown, Greg High, Steve High, and Nevin Cooley.