YINUO ZOU

Telephone: 1(778)-927-7783 Email: yinuo.zou@mail.utoronto.ca

Portfolio Link: https://issuu.com/heyhailie/docs/portfolio-_yinuo_zou_2023-issue

EDUCATION

THE UNIVERSITY OF TORONTO | John H. Daniels Faculty of Architecture, Landscape, and Design | Toronto, ON

Master of Architecture GPA 3.86/4 Sep. 2020 – May 2023

• Teaching Assistant for Structures, Building Systems, and Environments I

• Teaching Assistant for Building Science, Material, and Construction II

THE UNIVERSITY OF BRITISH COLUMBIA | Faculty of Forestry | Vancouver, BC

Bachelor of Science, Wood Products Processing (Co-op) GPA 89%/100% Sep. 2017 – May 2020

• UBC Sauder School of Business: Minor in Commerce

• 2020 Honors Standing Students (WPP)

BEIJING FORESTRY UNIVERSITY | Faculty of Material Science and Engineering | Beijing, China

Bachelor of Science GPA 93%/100% Sep. 2014 – May 2017

PROFESSIONAL EXPERIENCE

NICK MILKOVICH ARCHITECTS INC. | Intern Architect | Vancouver, BC May 2022 – Aug. 2022

1512 WESTERN CRESCENT | Vancouver, BC | Residential project | Schematic Design phase

• Prepared legal documents, such as contracts and drawings for applying building permit under the BC Building Code and UBC Development and Building Regulations

• Assist generating creative solutions to architectural design according to client’s need during SD and DD phases

MUSEUM of ANTHROPOLOGY | Vancouver, BC | Envelope + Seismic Upgrades | Construction phase

• Developed proficiency in creating both two- and three-dimensional constructional shop drawings to smooth communication with contractors

• Assisted with specifications and material selections document preparation, such as glazing type, in the CD phase

DAIZEN JOINERY LTD. | Technical Designer | Kamloops, BC May 2019 – Dec. 2019

KUKUI’ULA HAWAIIAN RESIDENCE SET | Koloa, HI, US | Timber Frame Structure and Joinery Design

SACRET WATER RESIDENCE SET | Tetons Country, WY, US | Timber Frame Structure and Joinery Design

• Successfully managed and coordinated three graphic design projects from architectural concepts through fabrication completion, which were worth up to $700,000

• Provided proposal layouts and shop drawings for the construction contract bidding under tightly scheduled deadlines

• Built an interface between modeling design software (Cadworks for 3D modeling) and manufacturing programmatic system (Cambium for Hundegger CNC Machine), which bridges the gap between design and fabrication

Other Coordinating Works

• Developed a new timber frame connection index including wood to wood joinery and wood to steel joinery that reduced the overall design phase span to 80% and enhanced customer satisfaction

• Helped tackle design and machine operating issues back and force between the office and the fabrication shop

• Established trustworthy relationships with designers, architects, and key clients

HONORS AND CERTIFICATIONS

Certification: LEED AP Building Design + Construction

Scholarships: University of Toronto Fellowship - Architecture, Landscape and Design

University of BC Wood Products Processing Award

Trek Excellence Scholarship (International Students)

Faculty of Forestry International Student Scholarship

SKILLS

Architectural: Rhino, Revit, AutoCAD and Solid Work, V-Ray, Enscape, Grasshopper

Adobe Creative Suite: Photoshop, Illustrator, InDesign

Feb. 2023

Aug. 2020

Nov. 2018

Nov. 2018

Feb. 2018

Others: Microsoft Office Suite, 3D Printing, Laser Cutting Digital, Python, GIS, Climate Studio, Midjourney, Handcrafting

Other Language: Chinese (Mandarin)

The Climatorium

Comprehensive Studio Project in the University of Toronto Instructor: Brigitte Shim Winter

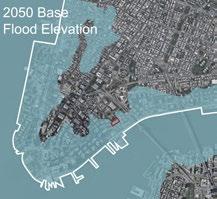

2022Located in a concrete jungle, Lower Manhattan lacks adequate green infrastructure. There is minimal green space in the surrounding neighborhood, and nearby schools lack adequate playground areas. More importantly, the climate is changing in the city. We are seeing flooding, heat waves, and severe thunderstorms. Thus the project must increase green space and address environmental concerns. Aware that foliage-covered facades don’t automatically equate to sustainable architecture, it has to be a living and built system that slows down, soaks up, and filters the changing climate.

This project’s goal is to provide adequate green infrastructure for Lower Manhattan and address the climate. We propose a continuous sloped structure where public space, landscape, and program intertwine in one entity. With the combination of “living shorelines” landscape to protect infrastructure from extreme storms and flooding on the ground and elevated landscape to provide public activities on the roof, the building becomes the park and the park becomes the building in a seamless whole.

Dry Scenario

Medium Rainfall Scenario

15mm of rain

Water volume 433 m^3

Water level - 1.65 m

Tidal Flood Scenario

1-2times a year flood

Water volume 1914 m^3

Water level - 3.65 m

Massing Model

Extended roof top playground to the adjacent primary school Elevated landscape architecture to provide public activities on the roof

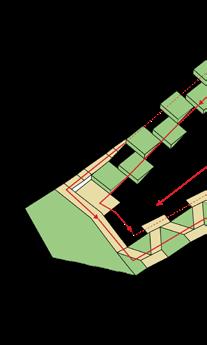

Circulation & Program

“Living shorelines” landscape to protect infrastructure from extreme storms and flooding

Welcoming Water to The Site Strategy

Circulation

Ground Route Vertical Route

In this program study, the ground circulation view, with entry points on the site coming the ISO view, we can see how the required each block. Observing the green roof loop creates a multi-functional "HUB"

Green

Green Roof

Pedestrian Route

Continuous Green Loop

Massing Diagram

Program List

Civic Functions

Food Court & Retails

Workshop & Education

Office & Commercial

Semi-open Space

Building set along the perimeter area of the site

Create a noise insulated courtyard for public realm

circulation is shown from worm's eye coming from four directions. Using required program is arranged in from a bird's eye view, the green "HUB" accessible to the public.

Office Area integrated along the eastern edge Sloping roof to create natural transition

Building Becomes the Park & Park Becomes the Building

Stepped Botanical Garden

Outdoor Learning Space

Building Becomes the Park & Park Becomes the Building

Stepped Botanical Garden

Outdoor Learning Space

Relaxing Space

Extended Children Playground

Semi-open Grassland

Detailed Programs

An interior courtyard view from the main entrance, showing the semi-open wetland and the central sunken water square.

An interior courtyard view from the main entrance, showing the semi-open wetland and the central sunken water square.

Passive Heating and Cooling System

1. Solar Chimney

2. Glazing Inlet

3. Glazing Outlet

4. Ceiling Fans

5. Acoustic Transfer Vent

6. Hopper Window

7. Casement Windows

8. Vented Corridor

9. Wood Pallet Facade Shading Device

Solar chimneys heat up air by absorbing sunlight. Solar chimney air enters the corridors from the classrooms through open windows. As the warm air rises from the solar chimney, it exhausts out the top. The vertical ventilation is complete.

As opposed to summer cooling mode, the intake windows on the exterior of the solar chimney at level 2 open to let air cool down the interior. In addition to passive ventilation, a radiation cooling panel is also attached to the ceiling. A second source of cooling air is provided by underfloor air-conditioning.

During winter heating, the exterior solar chimney intake windows are closed, allowing the air to warm up and insulate the building. Heat can also be provided by radiant heating panels and underfloor air distribution systems.

“Hydrological Battery” That Intercepts Storm-water And Collects Rainwater

Rainwater Supply

Potable Water Supply

Non-Potable Water Supply

Gray Water Discharge

Black Water Discharge

Structure Study

Eglinton Transferia

Integrated Urbanism Studio Project in the University of Toronto Instructor: Christo Marcopoulos Fall 2021

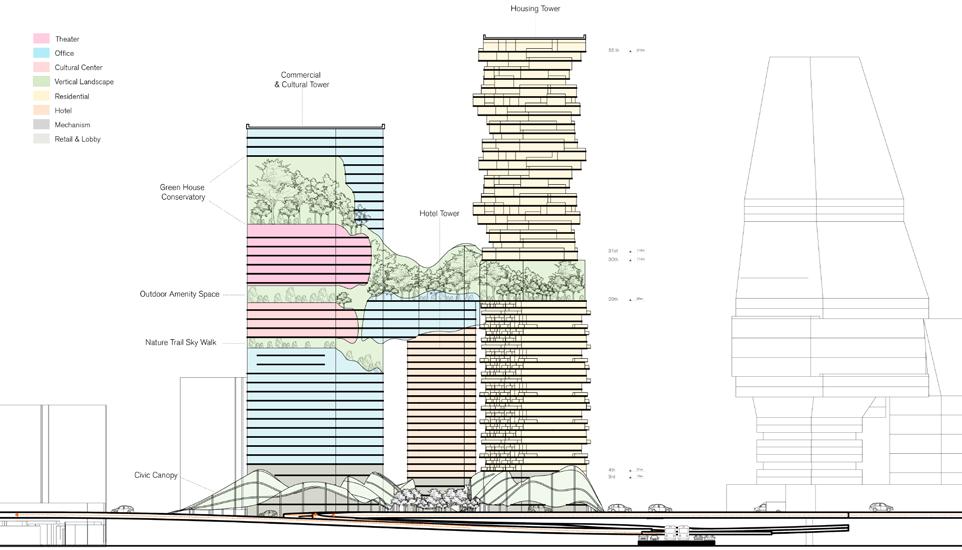

Most of the political discussion in Toronto has focused on how to bring more density while addressing spatial and environmental inequality. It is only in the last few years, with the city climbing the international ranking as one of the least affordable metropolitan cities, that affordability, climate change, and social resilience have become objects of political debate. In the wake of the completion of the upcoming Light Rail line along the Eglinton corridor, this project intends to establish a spatially just, socially resilient and environmentally friendly model of urbanism.

By envisioning networks of buildings, infrastructure, and landscapes in response to politics. This design project negotiates issues of climate resilience, spatial and social equity, postcarbon economies, and housing affordability all the while recognizing the limits of our disciplinary tools.

Population Density Study in The City of Toronto

The population of the Toronto area will hit 8 million in the next 10 years. In development, can we find other ways to reduce colonization and not take land for granted? In an extreme highway loop, population can be condensed on unused urban space, resulting in high density on a small plot of land, and people can give back land to nature.

Site Analysis

A high level of traffic volume is present at the exit of Don Valley Parkway, which dominates the site, resulting in the high demand for parking spaces due to the high traffic volume. Aside from this, there are a lot of green spaces and ravines surrounding the site.

A high level of traffic volume is present at the exit of Don Valley Parkway, which dominates the site, resulting in the high demand for parking spaces due to the high traffic volume. Aside from this, there are a lot of green spaces and ravines surrounding the site.

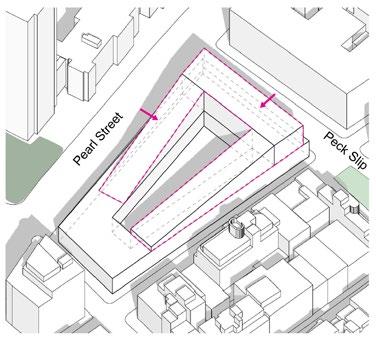

Massing Diagram

Three towers 60 degree facing away each other

Wider view wider internal space between towers

Adjusting floor plate according to program

View direction adjustment Broader view for residence

Office Tower Residence Tower

Office Area

Extrusion to various height according to the programs

A green belt connecting all towers with surrounding green area

Center

Planted Terrace

Theater Culture Center

Green House Conservatory

Nature Trial Sky Walk

Section with Generative AI Visualization

Prompt: An office tower featuring a glass facade and a landscaped chasm that cuts through the building’s exterior over eight floors, interior view, details,16K, uhd, ultra realistic and fantasy photography --q 2 --s 250 --uplight

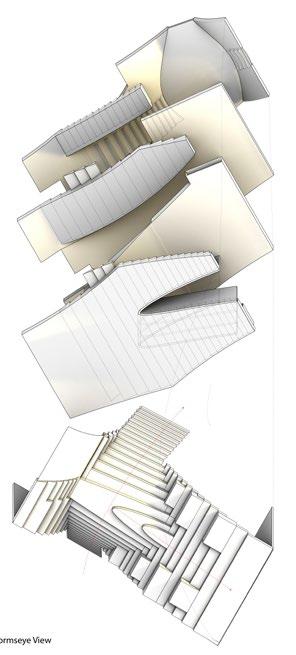

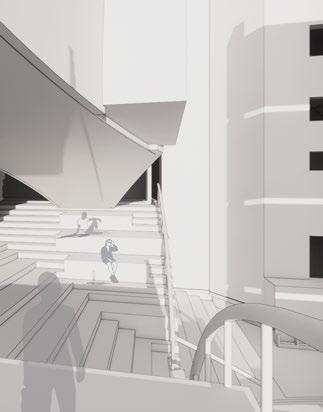

Everytown Urban Academic Campus

Studio Individual Project in the University of Toronto

Instructor: Carol Moukheiber Fall 2020

The site is located in an urban academic campus in Everytown, on the East Coast of North America. Two linked landmarked buildings houses the Art and Architecture school. This project has intention to build cohesion between the two schools by demolishing the middle connecting structure and re-designing a central unified Lobby from which to enter the two schools.

The new Lobby will serve as a collective meeting point for all of the students from both schools. It will also have to address the different floor heights from the two existing flanking buildings. Staircases, ramps, and other circulational means will act as the main organizing principle between public and private programs, collective and discrete spaces, the partition of light and dark zones, and the transitional threshold between the exterior and interior of the building.

Shared Inhabitation:

A circulation system is integrated with the functional areas of each level in the project. Instead of separating two roles, sharing space can be achieved by combining the private area with the public area. As if juxtaposing solid and void elements, public and private elements exist together. By forming a consistent single trajectory in the center building, tilted floors and planes connect adjacent buildings of different level height.

Solid void diagram

Circulation Diagram

Solid void diagram

Circulation Diagram

Unfolded Scenographic Sequence - Stairs Unravellings

Fiber Guard

Thesis Studio Project in the University of Toronto Instructor: Zachary Mollica Spring 2023

Paper is one of the most commonly used materials in our daily lives. The common characteristic of all paper products is that they are flat, a planer and throwaway material, after use we simply throw them away in the blue bin, believe we did a great job. However, paper products cannot be recycled and remade as many times as we would like. For example, egg cartons or food clam shells are made from paper that’s already been recycled many times and so the fibers have become too short to be recycled into anything else. These cartons often get thrown away or land filled as a result.

Since the paper products cannot be recycled 100% or remade as many times as we expected. Paper discarded every day and paper fibers that have reached their worst grades at the end of their recyclable life will be used in this thesis project, to form 3D molded pulp products that can be used in building shearing layers with longer timescales of change, also serving as carbon sequestration to increase the durability, resilience, and longevity of buildings.

Problem Discovery

Architecture students use a big amount of paper. Especially during final week, the paper recycling bins are all like this. Totally, there are 12 of them need to be emptied and refilled every week.

Paper Production Procedure

Newspaper Paper Tube Magazine Paper

Printer Paper (A4, 17x11, letter)

Wax paper Kraft paper/vellum Plot Paper

Newspaper Paper Tube Magazine Paper

Printer Paper (A4, 17x11, letter)

Wax paper Kraft paper/vellum Plot Paper

Thesis Methodology

The development of my thesis can be divided into two directions. One is about analyzing material properties and applying variable control methods to scientific experiments, testing different additives and brick thickness, density, and oven dry temperature. In order to determine the best variable combinations, each of them has been subjected to mechanical testing. Testing results will be applied to the 3D Form Design Direction, as the material will tell me what form it wants. In preparation for the larger prototypes and applications to both furniture and walls, various milling endurance checks and finish types were applied to small samples.

Applications

Furniture Wall Tile

Acoustic Barrier

Finishing Method Experiments

Finishing Products

- Oil-based Stain Finishing 1

- Oil-based Stain Finishing 2

- Double layer clear coating

- Natural Beeswax Finishing

- Torch - Flammability

Milling Tests

Computational Milling

3D Form Design

Aesthetic Appeal

Computational Mold Design

Best Variable Combinations

DIY

Wastepaper

Collecting retired low value paper products

Tracing Volume of carbon stock

Natural Pigments

- Beet Juice

- Purple Cabbage Juice

- Berries Juice

- Spinach Juice

- Carrot Juice

Sanding, Drilling, Laser cutter, Band saw, CNC profilling

Mechanical Experiments

Pulp Brick Compression Test Results

3/4"

In the compression crushing test, white glue mixed with the piece had the greatest stress and the smallest deformation before crushing, whereas without glue, it experienced about 4.7% deformation over length. Under high vertical loads, it may result in the product size being unstable and unrecoverable, even though it can be used as energy absorbing material during deformation.

with Different Bonding Material Bending Test Results

Following that, I put all three pieces through a horizontal bending test. There was no significant difference in performance between three recopies. Chemical glue is more difficult to recycle than the one mixed with rice glue.

Pulp

with Different Thickness Bending Test Results

As the depth was increased, the bending capacity shifted dramatically. Since pressure penetrates from top and bottom, it is difficult to maintain an even vertical density and moisture content when the thickness is increased.

No Glue Pulp Brick Compression Test

Rice Glue Pulp Brick Compression Test

White Glue Pulp Brick Compression Test

No Glue Pulp Brick Compression Test

Rice Glue Pulp Brick Compression Test

White Glue Pulp Brick Compression Test

The evolution process consists of four steps. The first version connected four walls with glue joints at each corner, but water penetration and vertical pressure easily weakened the glue. After that, I formed a grove wall system using steel rods tightened in one direction. Laminated veneer layers collapse with internal force, pushing surrounding walls outward. Steel rods were added to tighten another direction in the third version, but this complicates assembly and disassembly. I decided to make the final version of the mold from one piece and layer it vertically. In addition to allowing water to drain from the inside, it also allows me to cast bricks of varying heights.

Casting Mold Evolution

Four walls with glue Joints

Grove

Explode at the glue surface

Plywood layers failed to hold in another direction

With support in the middle can be used to cast hollow bricks

Perform the best under pressing, can adjust height

walls with rods tighten in X direction

One more rod added to support in Y direction

One piece walls stack to heights in need

walls with rods tighten in X direction

One more rod added to support in Y direction

One piece walls stack to heights in need

Form

Applications in Building Skins

Discussion – Failure Scenarios

CNC Double Curved Brick

-313.94g Carbon Sequestration

Corrugated Concave Brick

-119.32g Carbon Sequestration

CNC Egg Carton Tile

-213.87g Carbon Sequestration

Corrugated Acoustic Wall Panel

-12.3095g Carbon Sequestration

Graphic 3D Pulp Tile

-2258.30g Carbon Sequestration

1.

1.

2.

3.

5.

4.

4.

5.

3.

4.

1.

2.

1.

1.

2.

3.

5.

4.

4.

5.

3.

4.

1.

2.

Applications in Furnitures

Bar Stool Seat Top

-3412.50g Carbon Sequestration

Plywood

SPF(Solid Wood Lumber)

Hardwood

MDF

Paper Pulp

Brick

Cork

Compression (Crushing) Strength, Mpa

Elastic (Young's Tensile) Modulus, Gpa

SACRED WATER RESIDENCE SET

Technician Design Work at Daizen Joinery Manager: Juergen Poepsel, Summer 2019

Size: 9, 991.81 sq.ft

Location: 2950 West B-Hive Road, Tetons Country, WY, US

Project in Charge: Timber frame structure and joinery design

Status: Design phase is done, pieces are under fabrication

Invisible Wood to Steel Timber Frame Connections

GIRDER TRUSS DETAILS

KING POST TRUSS DETAILS

WOOD COVERED STEEL I-BEAM DETAILS

Without worrying about heat preservation in the garage, roof area could be used to the maximum by combining pitch changes

KUKUI’ULA HAWAIIAN RESIDENCE SET

Technician Design Work at Daizen Joinery Manager: Juergen Poepsel, Fall 2019

Size: 4,915.73 sq.ft Location: Koloa, Kaua’i, HI, US

Project in Charge: Timber frame structure and joinery design Status: Design phase is done, pieces are under fabrication

Exploded Axonmetric Diagram

Roof Structure - Rafter Tails attached to Tusses with Insulation underneath Cladding Beam and Post with Concrete Base, Plywood Shelving, and Windows Doors

Cross Section Views

West Elevation

Exposed heavy timber rafters add great value to the look of the house. These rafter tails have slot on top and bird mouth underneath that slide up to extend to truss rafter end.

Entry

South Elevation

To prevent termite damage, post beams material all get change to Western Red Cedar. When large size clear WRC cannot be found with enough source material, our answer is getting some treated Glulam core and add WRC as a veneer around it.

Garage

Jack rafter roofing ensures the tight fit that contains step housing to hip/valley rafter. Timber frame shade structures at the entry porch with full length rafters bearing on the hips Visible Western Red Cedar T&G DeckingInvisible Wood to Wood Timber Frame Connections

KING POST TO RIDGE

PLATE TO POST

SCISSOR TRUSS HALF LAP

PEGGED PLATE SCARF

LOG RAFTER TO SQUARE PLATE

KING POST TO LOG RAFTER AND RIDGE

KING POST TO RIDGE

PLATE TO POST

SCISSOR TRUSS HALF LAP

PEGGED PLATE SCARF

LOG RAFTER TO SQUARE PLATE

KING POST TO LOG RAFTER AND RIDGE

Invisible Wood to Steel Timber Frame Connections

WESTERN VANCOUVER CRESCENT

Group Work at Nick Milkovich Architects

Project Manager: Gail Wang Summer 2022

Size: 9429.54 Sq. ft

Location: Vancouver, BC, Canada

Project in Charge: Prepared approval drawings, study models, 3D models and reviewed docs

Status: Schematic Design, Design Development

UBC MUSEUM OF ANTHROPOLOGY

Group Work at Nick Milkovich Architects

Project Manager: Anne Gingras, Wai Lui Summer 2022

Envelope + Seismic Upgrades

Location: 6393 NW Marine Drive, Vancouver, BC, Canada

Project in Charge: Prepared shop drawings revisions and review docs

Status: Construction phase, on going

Skylight Visual Mock-up Review

NMA attended the Museum of Anthropology to conduct a review of the Skylight Visual Mock-up (VMU). The Skylight VMU consists of three full-size curved insulated glass units (IGUs).

After numerous reviews of various IGU samples [different frit colors (grey and black), patterns (dots and holes), coverage densities, body tinted glass (grey and bronze)], and the final full scale visual mock-up; NMA would like to recommend the Sample ‘A’ IGU, which is the ultra clear glass assembly with the fine black dot frit pattern for the skylight replacement at MOA.

From our observations of the VMU, it was evident that the use of clear glass with the fine smaller dot fritted pattern reinforces the original design intent. This allows the artifacts and the building to be accurately represented under natural light. In addition, it allows users a better representation of the natural color of the sky when looking out through the skylights.

Shop Drawings Revision And Details

This project involves the rehabilitation of multiple areas of the Museum’s envelope, as well as seismic structural upgrades to the Great Hall. In order to protect against a potential earthquake, the Great Hall will be fully rebuilt using base isolation. The movement joint panels within the Great Hall provide great movement tolerance to the large glass windows, which allows visitors and artifacts to be protected from potential damage during large earthquakes.

EPOXY RESIN RIVER SIDE-TABLE

Directed Studio at UBC Advisor: Philip Evans, Vincent Leung Winter 2019

The live wood edges used on the tabletop add an interesting edge to the chunky fractured design. They are visible and solid thanks to a repair through epoxy resin. The results not only salvage items though to be beyond repair, but also provide custom nostalgic feelings with ancient time-worn wood. Free standing foundation which has a plateau with a cutout in its center that governs the geometry of assemblage. Five identical elements with up-sidedown ‘U’ shaped interlocking fit into each other.

CAMERA-SHAPED WINE CABINET

This project is presenting a wine cabinet in a camera shaped feature, which is made from interlocking layers of birch plywood. The body’s space is separated by several layers of shelf for storing plenty wine bottles and wine glasses. The lens part also remain the ability to rotate and display. I designed this using Solid Work then MasterCam and using laser cutter to make a 1:10 scaled down model to check all the connection, then operating CNC machine to fabricate out an ideal size cabinet.

Wood Products Design and Development Project at UBC Advisor: Vincent Leung Fall 2018

Wood Products Design and Development Project at UBC Advisor: Vincent Leung Fall 2018

STOOL CRACKLE STAINING AND FINISHING

The crackle lacquers with laser cut air route represents my valuable studying trip from China to Canada. Crackled feature adds a level of sophistication and dimension to the design also salute Chinese crackle glaze ceramic. Interchangeable tint on legs also pay my respect to rolling glaciers in Canada.

Spray the natural color base coat (Nitrocellulose lacquer) and let it dry. The base coat will show through the crackled coat

Applied tinted ocean blue crackled medium.

More crackled medium turned to bigger cracks

Small cracks with limited crackled medium amount Map layout and flight liner laser cutTABLETOP VENEER COLOR-MATCHING

This customized tabletop design is playing with different species of wood veneer, turning small pieces of waste veneer to beautiful geometric patterns. The elephant feature is partially symmetric, using natural wood veneer color to 3D effect in shades.

Beech Fine Wood

Tobacco Oak Wood

Plum Fine Wood

Cheery Fine wood

Wood Veneer

Afodia Wood Veneer

Bubinga Wood Veneer

Beech Fine Wood

Tobacco Oak Wood

Plum Fine Wood

Cheery Fine wood

Wood Veneer

Afodia Wood Veneer

Bubinga Wood Veneer

Reference List

Nick Milkovich

Nick Milkovich Architects Inc.

Architrect AIBC, FRAIC, Principal

Contact: nick@milkovicharchitects.com, 604-737-6061

Brigitte

Shim

Shim-Sutcliffe Architects, Principal

Professor at the UofT

Contact: brigitte.shim@daniels.utoronto.ca, 416-368-3892

Dai

Ona

DAIZEN JOINERY LTD.

Founder, Business Development

Contact: dai@daizen.com, 250-573-1112

Zachary

Mollica

Assistant Professor at the UofT

Emerging Architect Fellow

Contact: zachary.mollica@daniels.utoronto.ca, 416-368-3892