1 minute read

Switch (green) – front or rear additional control circuit (option

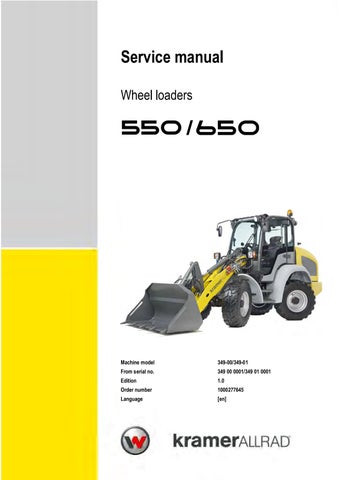

3.24 Lubrication work on the loader unit

• Park the wheel loader on level ground • Apply the parking brake and secure the machine with wheel chocks • Raise the loader unit so you can lubricate it comfortably from the ground • Stop the engine and remove the ignition key

Caution!

In order to avoid damage to the lubrication points, use only lithium-saponified brand-name grease!

Lubricating the loader unit, lift, tilt and lock rams

C

D

Lubricate the following lubrication points on the loader unit of the machine: •Lubricate grease nipple C of the tilt ram bearing on the frame every 10 service hours.

Lubricate more frequently when in heavy-duty operation •Lubricate grease nipple D of the loader unit bearing every 10 service hours. Lubricate more frequently when in heavy-duty operation •Lubricate grease nipple E on the lift ram bearing on the frame every 20 service hours

•Lubricate grease nipple F of the tilt rod bearing every 10 service hours. Lubricate more frequently when in heavy-duty operation •Lubricate grease nipple G of the tilt ram bearing every 20 service hours •Lubricate grease nipple H of the lift ram bearing every 20 service hours. Lubricate more frequently when in heavy-duty operation •Lubricate grease nipple I of the tilt lever bearing every 10 service hours. Lubricate more frequently when in heavy-duty operation •Lubricate grease nipples K of the quickhitch bearing every 10 service hours.

Lubricate more frequently when in heavy-duty operation •Lubricate grease nipples L of the tilt lever bearing every 10 service hours. Lubricate more frequently when in heavy-duty operation

E

Fig. 57: Lubrication points on frame

L F

G

K I H

Fig. 58: Lubrication points for lift and tilt ram bearings