1 minute read

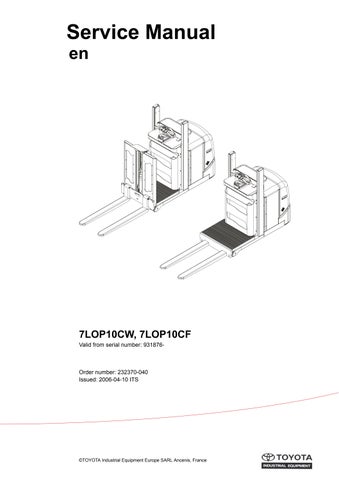

Electromagnetic brake – 3370

7.1 Included components

13

7.2 Disassembly

•Loosen the screws (10).

•Lift out the brake assembly from the motor axle.

•Place the brake assembly on a clean surface.

•Gradually unscrew the adjusting screws (2) in order to release the spring tension evenly and little by little.

7.2.1 Inspection

Inspect all parts for damage and/or wear.

•Be sure to especially examine the brake disc (6) and the wear surface on the pressure plate (3).

•Inspect the springs (11) and spacers (4,5) for damage.

•Inspect the hub splines (8) and the friction plate splines (6) for damage.

•Inspect the magnet plate (1) and pressure plate (3) for swelling/deformations and other damage.

7.3 Assembly

•Carefully clean all parts.

•Assembly of the brake assembly is done in reverse of disassembly.

•Pay attention to the following:

-The holes in the pressure plate (3) must be centred with the corresponding holes in the magnet housing.

-The correct number of springs is installed.

-The play is correctly set. Adjustment may be required.

NOTE!

The friction surfaces must not come into contact with oil or grease since this will seriously impair braking performance.

7.4 Manual release of the brake

The brake can be manually released, e.g. if the brake is broken and the truck needs to be moved to the service area or to facilitate easier centring of the brake disc during assembly. To release the brake, gradually screw in the two screws (13) evenly.

WARNING!

Lost braking function.

Braking does not work when the brake has been manually release. Drive the truck at reduced speed and be very careful. Do NOT forget to remove the screws after completed work.

7.5 Adjustment 7.5.1 Adjusting the play

•Measure the play in three different positions.

•Adjust the play by removing the shims (5).