12 minute read

Functions of and How to Use User Mode (TT-300XL-1)

How to Use the Working Range Limit Function

[NOTICE]

If the working range limit is registered very close to an obstacle, there is a risk of the crane colliding with the obstacle, depending on the operational status and the manner in which the load is handled. When registering a range limit, allow a sufficient clearance to avoid collision.

The working range limit function gives warning only, and does not automatically stop crane motions. When the alarm buzzer sounds, immediately halt the crane motion.

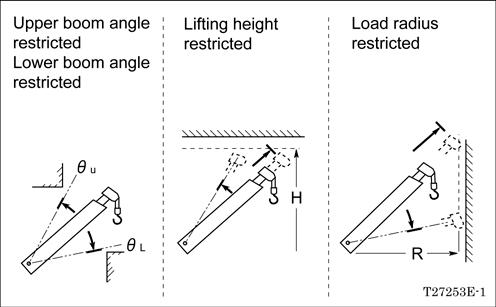

The working range limit function gives warning when the crane reaches the previously registered boom angles (upper and lower), lifting height or load radius.

The function is useful for handling a load in a confined place because it defines the area in which the boom can operate.

[NOTICE]

Turning the power off (PTO switch: OFF) automatically erases all the previous settings stored in memory after approximately 2 hours. To resume the operation more than 2 hours after the power has been last turned off, enter the settings all over again.

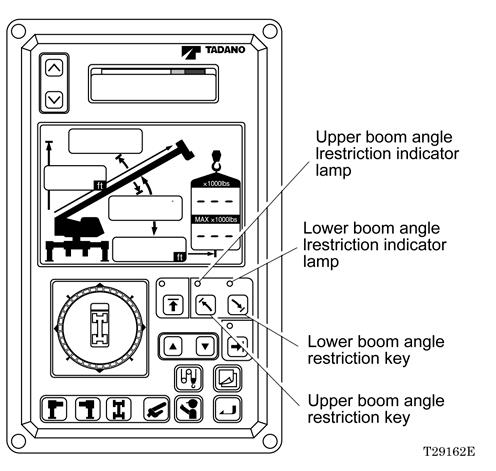

Boom Angle Limit

Raise or lower the boom to the desired angle, and press the upper or lower boom angle restriction key. The corresponding restriction indicator lamp will flash and the buzzer will sound continuously, indicating that the boom angle limit has been registered in the memory. When the boom is moved back to an angle within the set limit, the restriction indicator lamp stops flashing and stays lit and the buzzer stops.

Thereafter, the upper or lower boom angle restriction indicator lamp flashes and the buzzer sounds continuously whenever the upper or lower limit previously registered is reached.

To cancel the boom angle limit function, press the boom angle restriction key again.

The corresponding boom angle restriction indicator lamp will go off.

Functions of and How to Use User Mode (TT-300XL-1)

Lifting Height Limit

Move the boom to the desired height, and press the lifting height restriction key. The lifting height restriction indicator lamp will flash and the buzzer will sound continuously, indicating that the height limit has been registered in the memory. When the boom is moved back to a height within the set limit, the lifting height restriction indicator lamp stops flashing and stays lit and the buzzer stops. Thereafter, the lifting height restriction indicator lamp flashes and the buzzer sounds continuously whenever the height limit previously registered is reached.

To cancel the height limit function, press the lifting height restriction key again. The lifting height restriction indicator lamp will go off.

Load Radius Limit

Move the boom to the desired load radius, and press the load radius restriction key. The load radius restriction indicator lamp will flash and the buzzer will sound continuously, indicating that the load radius limit has been registered in the memory. When the boom is moved back toward the non-critical side, the load radius restriction indicator lamp stops flashing, and stays lit and the buzzer stops.

The load radius restriction indicator lamp flashes and the buzzer sounds continuously whenever the limit previously registered is reached.

To cancel the load radius limit function, press the load radius restriction key again. The corresponding load radius restriction indicator lamp will go off.

Functions of and How to Use User Mode (TT-300XL-1)

Display of Working Range Limit Values

Press the register key while working range limits have been registered. While the key is being pressed, the registered working range limit values are displayed. On the moment display will be displayed a message "Working range".

[NOTICE]

This display is not made during a preoperational check of the AML and when a working state is being registered.

When working range limits are not registered, the message " " will be displayed.

Functions of and How to Use User Mode (TT-300XL-1)

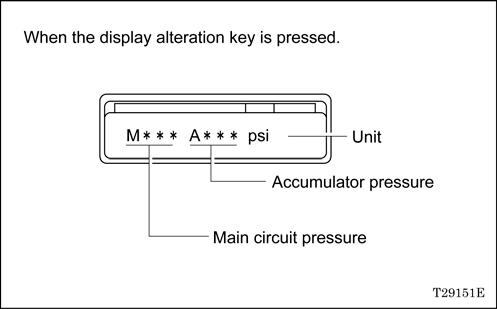

Display Alteration

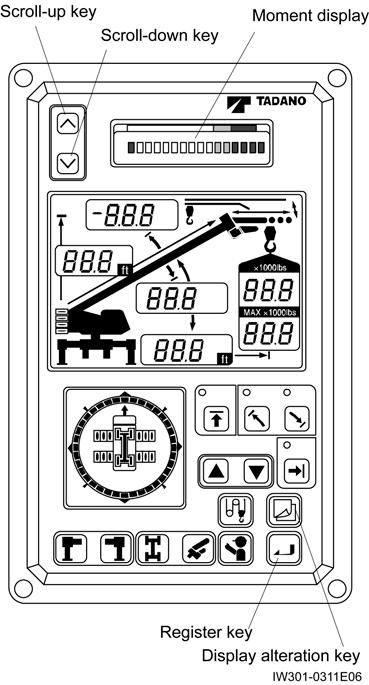

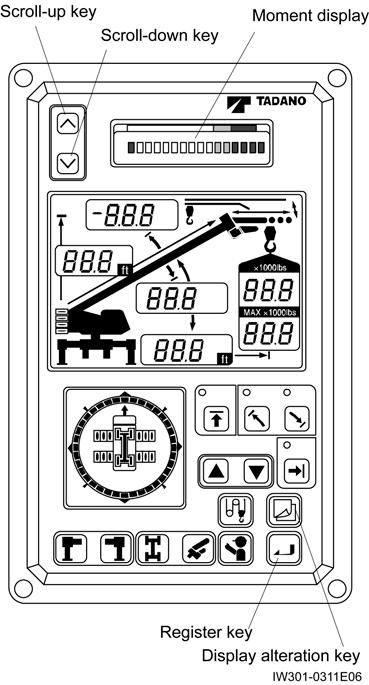

Displays on the moment display and the display panel 1 can be altered, as shown below in the figures, by pressing the display alteration key. The indicative symbols are displayed, too.

Displays on the actual load display and the rated load display do not alter even when the display alteration key is pressed.

General: Adjustment Mode and Maintenance Mode

[ADJUSTMENT AND MAINTENANCE]

General: Adjustment Mode and Maintenance Mode

1. Keys and Switches for Adjustment and Maintenance

8. Moment input short-circuit switch

9. Protect switch

10. Moment zero adjuster

11. Abnormality display LED

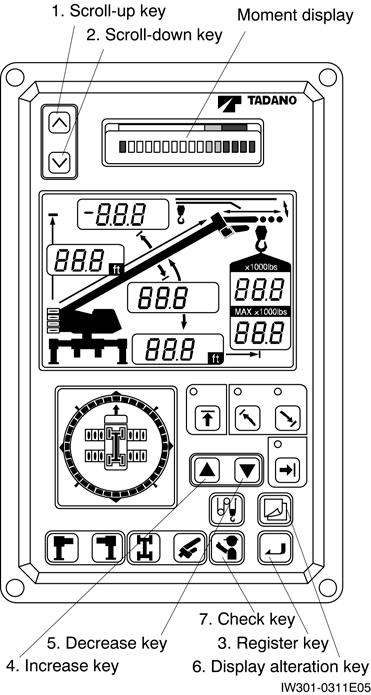

1. Scroll-up key

Used to see the previous lines of message displayed on the moment display.

2. Scroll-down key

Used to see the next lines of messages displayed on the moment display.

3. Register key

Used to register the selected state and write the adjustment value in EEPROM.

4. Increase key

Used to increase the adjustment value.

5. Decrease key

Used to decrease the adjustment value.

6. Display alteration key

Used to change the display to the upper menu.

Top view

7. Check key

IW301-0131E02

Used for îDo Checkî and îAo Checkî functions in the maintenance mode.

8. Moment input short-circuit switch

Not used for this machine.

9. Protect switch

Set this switch to OFF when changing the mode from user mode to adjustment mode. With this switch OFF, data in the EEPROM becomes rewritable.

10.Moment zero adjuster

This adjuster is for adjustment by the AML manufacturerís service personnel. Do not tamper.

11.Abnormality display LED

Lights when the AML is in abnormal conditions or when the AML adjustment is initialized.

General: Adjustment Mode and Maintenance Mode

2. Mode Structure and Menu

The AML device has three modes and AML functions are allotted for these models.

2. Maintenance Mode:

Used to make functional checks of AML. This mode has the following menus:

[ï Maintenance]

[ï Adjust clock]

[: Prog. version]

[: Data ID. number]

[: Di check]

[: Ai check]

[: Disp ELEV PRES]

[: Do check]

[: MDT Monitor]

[: Key SW check]

[: Display check]

[: Disp. err data]

[: Erase err data]

1. User Mode:

Used to indicate moment ratio or to perform AML pre-opetational inspection (Normally used).

In normal use, turn ON the protect switch mounted on the adjustment window on the top of AML. AML will go to the user mode when the power turns on.

[: Disp. O/L data]

[: Erase O/L data]

[: OP board check]

[: Ao check]

[: Sio check]

[: Adjust Monitor]

General: Adjustment Mode and Maintenance Mode

3. Adjustment Mode:

Used to make detector adjustment. This mode has the following menus:

[ï Adjust] [: Adjust L & A]

*Boom length zero-point adjustment

*Boom length span-point adjustment

*Boom angle zero-point adjustment

*Boom angle span-point adjustment

*Swing angle zero-point adjustment

*Swing angle span-point adjustment

*Outrigger length zero-point adjustment

*Outrigger length span-point adjustment

[: Adj. work rad] *Load radius span adjustment

[: Adjust MMT]

[ï Adjust CNT dat] [: Adj. ELV speed] (*2)

*Moment zero-point adjustment

*Moment span-point adjustment

[: Reset ELV data] (*2)

[ï Adjust AO] [: Adjust AO Ofs.] (*2)

[: Reset AO Ofs.] (*2)

[ï Initialize L & A] [: Reset DEF. FCT]

[ï Initialize MMT] [: Reset zero. span]

[ï Disp. O/L data] [: Reset PCSN] (*1)

[ï Erase O/L data]

[ï Adjust PCSN] (*1)

[ï Reg. Capac.]

[: Head-OFF Capac] (*2)

[ï Language] [: Jib Select]] (*2)

[: S/T Select]

[: Winch drum PSN]

(*1) : This menu is prohibited to be used.

(*2) :In case of TT-300XL, This menu is not applied.

General: Adjustment Mode and Maintenance Mode

3. Method of Shifting Modes

1. ìUser modeî → ìMaintenance modeî

Press the scroll-up key, scroll-down key, and register key at the same time. Then, the moment display changes from the bargraph to [ï Maintenance]. This display denotes the ìMaintenance modeî.

2. ìMaintenance modeî → ìUser modeî

Press the display alteration key. When the bargraph shows up on the moment display, AML goes back to the ìUser modeî.

3. ìUser modeî → ìAdjustment modeî

Turn OFF the protect switch at the adjustment window on the top of AML. Then, the moment display will change to [ïAdjust], and will denote ìAdjustment modeî.

4. ìAdjustment modeî → ìUser modeî

While the main menu of the adjustment mode is displayed, turn ON the protect switch. Then AML will go back to ìUser modeî and bargraph will be displayed on the moment display.

5. ìMaintenance modeî → ìAdjustment modeî

While the main menu of the maintenance mode is displayed, turn OFF the protect switch. The moment display will change to [ïAdjust], and will denote ìAdjustment modeî.

General: Adjustment Mode and Maintenance Mode

4. Method of Menu Selection

1. When AML is in ìMaintenance modeî or ìAdjustment modeî, the main menu is displayed on the moment display of bargraph display portion. Displayed menu changes by means of the scroll-up or scroll-down key. Press the register key to select the displayed item.

2. If the selected item in the main menu has any sub-menus, the sub-menus are displayed on the moment display of bargraph display portion. You can select the sub-menu in the same way sa main menu selection.

3. By pressing the display alteration key, the display changes to the upper menu.

4. The following marks displayed in the menu: ìïî, ì:î and ì î.

When a main menu is displayed, the mark ìïî stands before the menu name. (Ex. ìïAdjust î)

When a sub-menu is displayed, the mark ì:î stands before the menu name.

(Ex. ì:Adjust MMTî)

The ì î mark after the menu name indicates that the depression of the scroll-down key calls for another menu.

Required Adjustment After AML System Parts Replacement

Required Adjustment After AML System Parts Replacement NOTICE]

EEPROM stores the adjustment values for each specification number. When replacing the CPU board, remove the EEPROM after removing it from the broken CPU board to dispense with adjustment work other than clock adjustment. Visually check that the value displays such as boom length and boom angle and symbol display on the display panels 1 and 2 on the AML conform the actual crane condition.

Boom length detector

Boom angle detector

Swing angle detector

Replaced part

Outrigger extension width detector

Pressure sensor for moment detection

Display board

CPU board only (When reusing EEPROM removed from the broken CPU board)

CPU board (When EEPROM is not to be reused) EEPROM

Required adjustment

Boom length adjustment

Boom angle adjustment

Swing angle adjustment

Outrigger extension width adjustment

Moment adjustment

None

Clock adjustment

Perform adjustment initialization and take every step of adjustment. For adjustment items and procedure, see ìAdjustment Proceduresî on the subsequent page in the ìFunction of and How to Use Adjustment Modeî section.

Functions of and How to Use Adjustment Mode

Functions of and How to Use Adjustment Mode

Adjustment Procedures

WARNING

Before making an adjustment, extend the outriggers fully and set the crane on firm ground for safety.

[NOTICE]

You can adjust boom length, boom angle, swing angle, and outrigger extension width in random order.

You can adjust swing output and elevation output in random order.

After all adjustment is completed, erase-protect the overload history, referring to ìErasing the Overload Historyî in the ìFunctions of How to Use Adjustment Modeî section.

The adjustment items and procedures are as follows:

1.

Functions of and How to Use Adjustment Mode

1. Adjustment Initialization [NOTICE]

Adjustment initialization should be performed only when EEPROM is replaced. If the EEPROM removed from the faulty CPU board is reused when the CPU board is replaced, adjustment initialization is not required. By the adjustment initialization, the conversion factors (standard values specified for each specification) stored within the AML program that convert detected voltage input from the detectors into physical volumes is read out from the P-ROM and written onto the EEPROM.

Perform the initialization only once before the first adjustment takes place. If this initialization is done while adjustments are being made, you must restart the adjustment from the very beginning.

For adjustment initialization, you have to execute the following two menus.

[ï Initialize L&A] : Initialize the conversion factors for boom length, angle, and deflection.

[ï Initialize MMT] : Initialize the conversion factors for moment.

1.1 Procedure of Conversion Factors Resetting

1. Select the main menu [ ï Initialize L&A ] in the adjustment mode, and press the register key to select the menu.

2. When [: Reset DEF. FCT ] appears, reset the deflection factor by pressing the register key.

3. When the message [Done] appears, the deflection factor resetting is completed. Press the display alteration key to return to the main menu.

4. Press the register key again to select the main menu [ïInitialize L&A ] in the adjustment mode.

5. When [: Reset DEF. FCT ] appears, press the scroll-down key to display [: Reset zero. span], and then press the register key to reset the zero span factor.

6. When the message [Done] appears, the zero span factor resetting is completed. Press the display alteration key to return to the main menu.

1.2 Procedures of Moment Adjustment Resetting

1. Select the main menu [ï Initialize MMT ] in the adjustment mode, and press the register key to select the menu.

2. When [Reset MMT] appears, reset the moment factor by pressing the register key.

3. When the message [Done] appears, the moment adjustment resetting is completed. Press the display alteration key to return to the main menu.

Functions of and How to Use Adjustment Mode

2. Capacity Setting

[NOTICE]

Check the specification number of ìAdjustment Value Tableî in the INFORMATION AND DATA section whether your crane needs to perform this setting.

The crane capacity data is stored in the ROM. This setting is performed to partially change the crane capacity data in the ROM.

The crane capacity data normally does not need this setting.

For the capacity setting, select one of the four sub-menus indicated below.

[: Head-Off Capac] :

Used to set the maximum rated lifting capacity to the specified value.

[: Jib Select] :

Used to change the capacity for jib-mounted condition to the capacity for jib-unmounted condition.

[: S/T Select] :

Used to change the capacity for single-top-mounted condition to the capacity for single-top unmounted condition.

[: Winch drum PSN] : Used to specify the mounting position of winch drum for capacity adjustment.

2.1 Procedure of Head-off Capacity Setting

[NOTICE]

A head-off capacity value defined with this function is compared with the capacity (rated lifting capacity) data stored in the ROM, and the value whichever smaller is set as the capacity. Note that if the head-off capacity value is zero, the capacity data stored in the ROM is used.

1. Select the main menu [ï Reg. Capac. ] in the adjustment mode, and press the register key to select the menu.

2. Press the scroll-up or scroll-down key to display [: Head-Off Capac ], and then press the register key to select the menu.

3. The currently registered head-off capacity value is indicated on the moment display. Display example: [Capacity 99.2 kp] (TR-450XL-4)

4. Press the increase or decrease key to adjust the head-off capacity value as desired. Every time you press the increase or decreace key, the head-off capacity value increases or decreases in steps of 0.1 klbs. If the key is held down, the value increases or decreases in steps of 10klbs.

5. When the desired head-off capacity value is reached, press the register key to save it.

6. Press the display alteration key to exit the menu.

Functions of and How to Use Adjustment Mode

2.2 Procedure of Jib Selection [NOTICE]

When the jib-unmounted (detached) condition is selected, the jib capacity data stored in the ROM becomes unusable and also the jib mass is excluded from capacity calculation.

1. Select the main menu [ï Reg. Capac. ] in the adjustment mode, and press the register key to select the menu.

2. Press the scroll-up or scroll-down key to display [: Jib Select ], and then press the register key to select the menu.

3. The currently registered jib capacity condition is indicated on the moment display. Using the scroll-up or scroll-down key, adjust it to the desired condition .

Display example:

[Jib = Mounted ]

Press the scroll-up key.

[Jib : Not Mounted]

When ì = î is indicated, it means that the displayed condition is registered currently.

4. When the desired condition is displayed, press the register key for confirmation. When the setting is completed, ì:î in the Jib condition display changes to ì = î.

Display example: [Jib: Not Mounted]

Press the register key. [Jib = Not Mounted]

5. Press the display alteration key to exit the menu.

2.3 Procedure of Single Top Selection [NOTICE]

When the single-top-unmounted (detached) condition is selected, the single top capacity data stored in the ROM becomes unusable and also the single top mass is excluded from capacity calculation.

1. Select the main menu [ï Reg. Capac. ] in the adjustment mode, and press the register key to select the menu.

2. Press the scroll-up or scroll-down key to display [: S/T Select ], and then press the register key to select the menu.

3. The currently registered single top capacity condition is indicated on the moment display. Using the scroll-up or scroll-down key, adjust it to the desired condition.

Display example:

[S/T=Mounted ]

Press the scroll-up key.

[S/T : Not Mounted]

When ì = î is indicated, it means that the displayed condition is registered currently.

4. When the desired condition is displayed, press the register key for confirmation. When the setting is completed, ì:î in the single top condition display changes to ì = î.

Display example:

[S/T : Not Mounted]

Press the register key.

[S/T = Not Mounted]

5. Press the display alteration key to exit the menu.