7 minute read

Procedures for Assembly and Disassembly of Regulator

from Sumitomo SH250-5 SH250-5LR Hydraulic Excavator Service Repair Manual WLSM2105-00W - PDF DOWNLOAD

1.Tools

The table below shows the tools required for the assembly and disassembly of KR3G-9*04-HV.

Tool name and dimensions Required tools are indicated with ○ Part name

Name B

2 Hexagon socket head bolt (shouldered bolt) Rc mounted valve (Rc screw) ROH plug (G screw)

Hexagon socket head locking screw - - - M4

2.5 - - - M5

Hexagon wrench 3 - - - M6

4 M5 BP-1/16 - M8 5 M6 BP-1/8 - M10 6 M8 BP-1/4 RHO-1/4 M12 M14 8 M10 BP-3/8 RHO-3/8 M16 M18 10 M12 BP-1/2 RHO-1/2 M20 12 M14 - - - 14 M16 M18 BP-3/4 RHO-3/4 - 17 M20 M22 BP-1 RHO-1 - 19 M24 M27 - - -

Closed wrench Socket wrench Double-head (single-head) wrench 22 - - VP-3/8 - 24 M16 M16 - 27 M18 M18 VP-1/2 - 30 ○ 36 M20 M20 - - - VP-3/4 -

41

- - VP-1 - 46 M30 M30 - - 50 - - VP-11/4 - 55 - - VP-11/2 - Monkey wrench - ○ Medium-sized x 1 Screwdriver - ○ Medium-sized flathead screwdriver x 1 - ○ For stop ring, TSR-160 Pliers - ○ For locking ring, TRR-150 Torque wrench - ○ With adjustable specified torque tightening Steel rod - ○ Diameter φ4 or less L=100 Hexagon socket head bolt - ○ M4 for pulling out adjusting ring, L=about 50

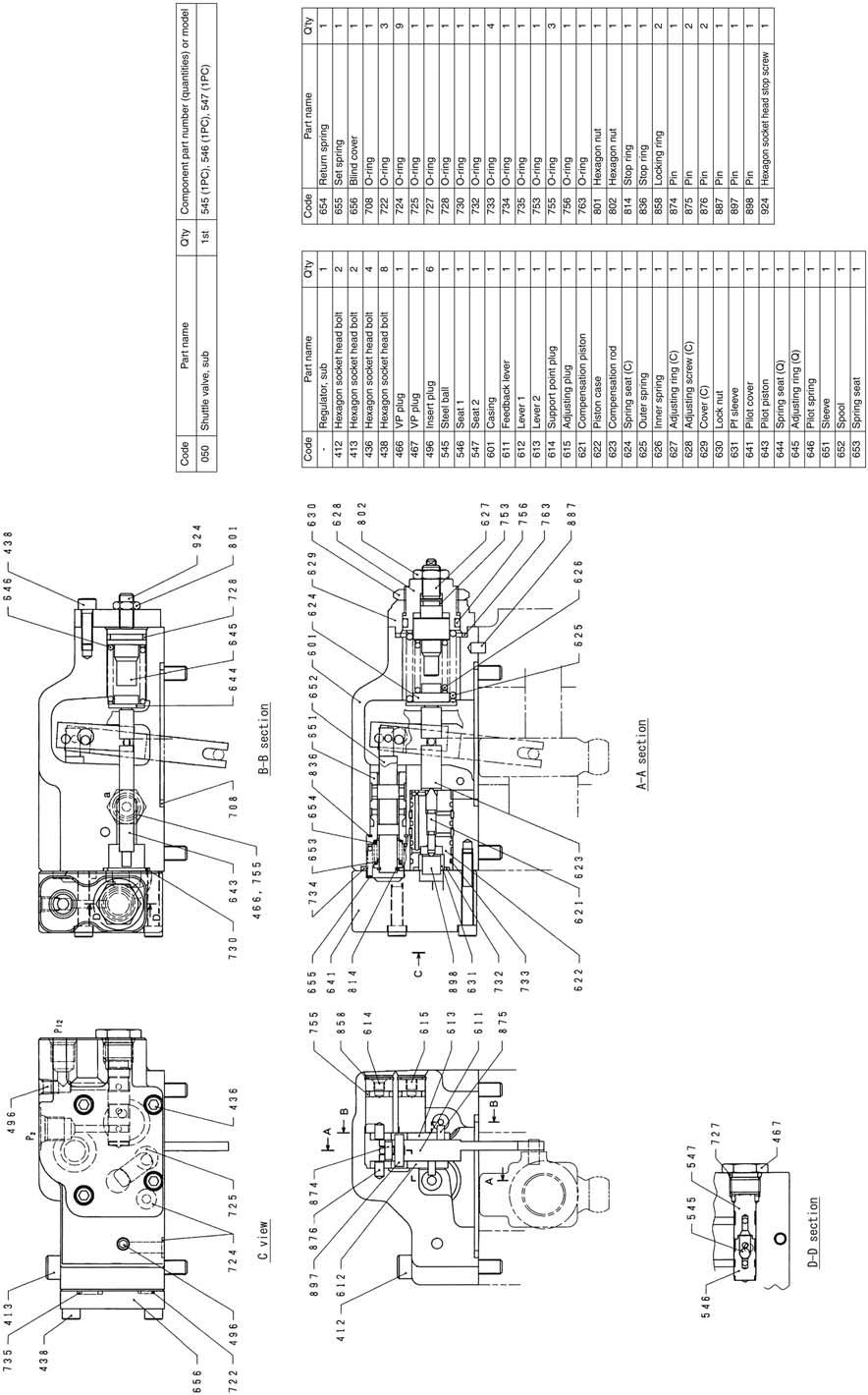

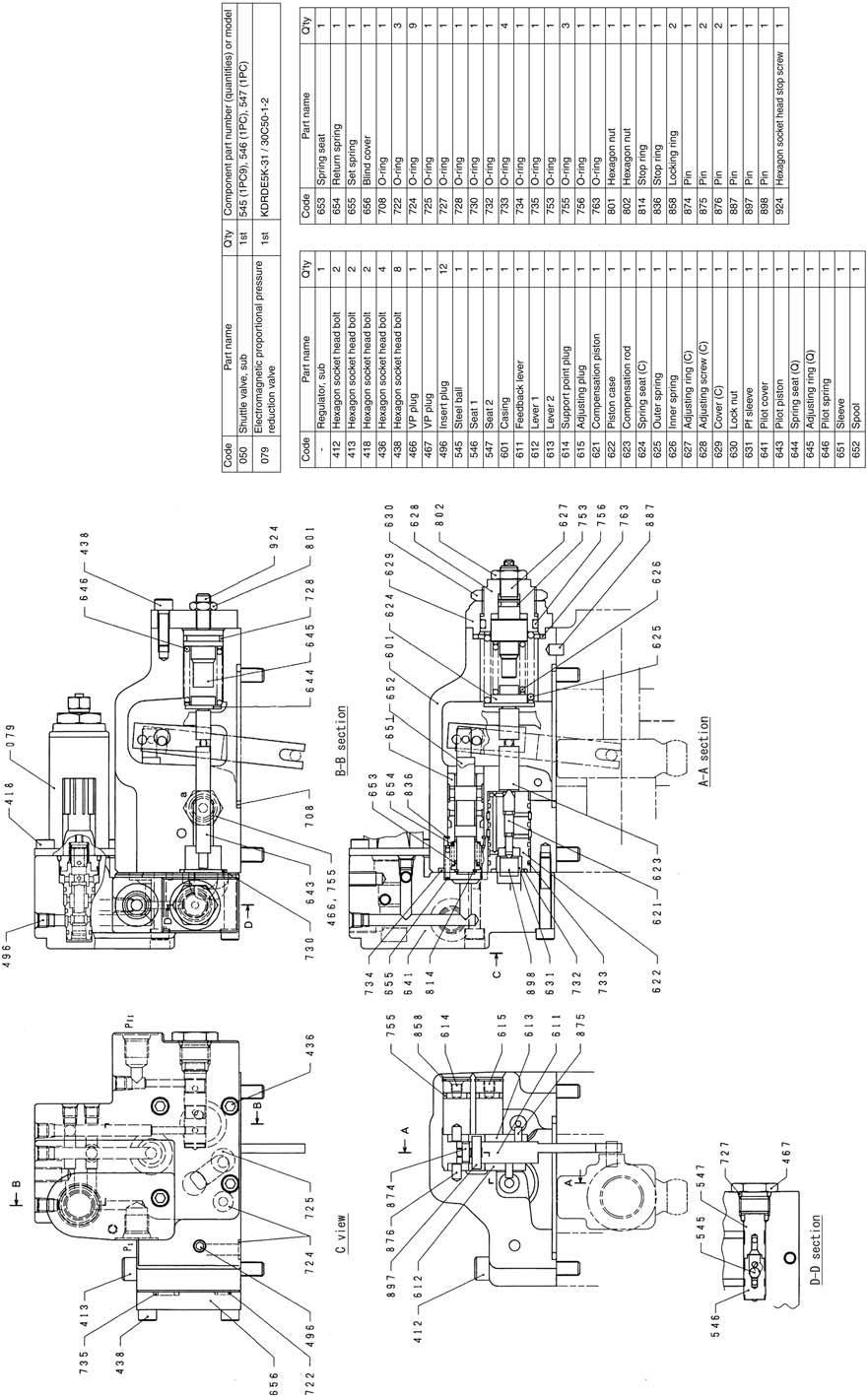

2.Disassembly Preparations [1] These regulators comprise small precision parts, so disassembly and assembly operations are somewhat complex. [2] The pressure-flow settings of the front side regulator and rear side regulator differ, so mark the regulators when disassembling to differentiate between the drive side and the driven side. [3] When disassembling the regulators, read the disassembly procedure thoroughly before following the sequence below. The numbers in parentheses after the part names are the codes indicated in "Attached diagram 1. Front-side regulator assembly cross-section diagram (KR3G-9Y04-HV)" and "Attached diagram 2. Rear-side regulator assembly cross-section diagram (KR3G-9X04-HV)".

3.Disassembly Procedure [1] Select a location for disassembly. •Select a clean location. •Place a rubber plate or cloth on the work platform so as not to damage the parts.

[2] Use cleaning oil to remove any debris or rust from the surface of the regulators.

[3] Remove the hexagon socket head bolts (438), and remove the covers (C) (629). •The covers (C) (629) are assembled with adjusting screws (C) (628), adjusting rings (C) (627), lock nuts (630), hexagon nuts (801) and (802), and hexagon socket head locking screws (924). Do not loosen these screws and nuts. Doing so changes the adjusted pressureflow setting.

[4] After removing the cover (C) (629) subassemblies, remove the outer springs (625), inner springs (626), and spring seatings (C) (624) from the compensation sections, and pull out the adjusting rings (Q) (645), pilot springs (646), and spring seatings (644) from the pilot sections. •The adjusting rings (Q) can be easily removed by pulling them out with an M4 bolt.

[5] Remove the hexagon socket head bolts (436), and remove the pilot covers (641).

After removing the pilot covers, remove the pins (898) and Pf sleeves (631) from the compensation sections and the set springs (655) from the pressure adjustment sections.

[6] Remove the stop rings (814), and remove the spring seatings (653), return springs (654), and sleeves (651). •The sleeves are assembled with retaining rings (836). •When removing the stop rings, the return springs fly out, so be careful not to lose these parts.

[7] Remove the locking rings (858), and remove the fulcrum plugs (614) and adjusting plugs (615). •The fulcrum plugs and adjusting plugs can be easily removed by pulling them out with an M6 bolt.

[8] Remove the levers 2 (613). Do not pull out the pins (875). •These can be easily removed by using a pair of tweezers.

[9] Pull out the pins (874), and remove the feedback levers (611). •Use a fine steel rod to push out the pins (874) (pin diameter φ4) from above without touching the levers 1 (612).

[10]Remove the levers 1 (612). Do not pull out the pins (875).

[11]Pull out the pilot pistons (643) and spools (652).

[12]Pull out the piston cases (622), compensation pistons (621), and compensation rods (623). •The piston cases can be removed by pushing out the compensation rods from the opposite side of the piston cases.

[13]Remove the hexagon socket head bolts (418), and remove the electromagnetic proportional pressure reducing valve (079) from the pilot cover (641). This completes the disassembly of the regulator main units. •This operation is only for the front-side regulator (KR3G-9Y04-HV). •Be careful not to damage the connector section of the electromagnetic proportional pressure reducing valve. (Caution) The component parts are small, so be very careful not to lose them.

4.Assembly Procedure

The assembly procedure is the reverse of the disassembly procedure. However, follow the precautions below. (1)Be sure to repair any parts damaged during disassembly, and prepare replacement parts in advance. (2)Any foreign matter entering the equipment can create a malfunction. Therefore, after thoroughly cleaning the equipment with cleaning oil, air blow the equipment, and perform assembly in a clean location. (3)Be sure to apply clean hydraulic oil to sliding sections before assembly. (4)As a rule, perform replacement for all O-rings and other seal parts. (5)Use a torque wrench to tighten all installation bolts and plugs to the torque specified in “Maintenance Standards”.

[1] Select a location for assembly. •Select a clean location. •Place a rubber plate or cloth on the work platform so as not to damage the parts.

[2] Install the compensation rods (623) into the compensation holes on the casings (601).

[3] Insert the pins (875) press fit in the levers 1 (612) into the grooves on the compensation rods (623), and install the levers 1 on the pins press fit in the casings (601).

[4] Install the spools (652) and sleeves (651) in the casing spool holes. •Check that the spools and sleeves slide smoothly in the casings without catching. •Be careful to assemble the spools in the correct direction.

[5] Install the feedback levers (611), and insert the pins (874) in alignment with the pin holes on the feedback levers. •Assembly is easier if the pins are inserted into the feedback levers in advance. •Be careful to assemble the feedback levers in the correct direction.

[6] Install the pilot pistons (643) into the pilot holes on the casings (601). •Check that the pilot pistons (643) slide smoothly without catching.

[7] Insert the pins (875) press fit in the levers 2 (613) into the grooves on the pilot pistons (643), and assemble the levers 2.

[8] Assemble the fulcrum plugs (614) and install the locking rings (858) so that the pins (875) press fit in the fulcrum plugs (614) are inserted into the pin holes on the levers 2 (613).

[9] Insert the adjusting plugs (615), and install the locking rings (858). •Be careful to insert the fulcrum plugs (614) and adjusting plugs (615) into the correct holes. •At this time, check that the backlash from the movement of the feedback levers (611) is not too great and that the feedback levers do not catch on anything.

[10]Install the return springs (654) and spring seatings (653) into the spool holes, and install the stop rings (814).

[11]Install the set springs (655) into the spool holes, and install the compensation pistons (621), piston cases (622), Pf sleeves (631), and pins (622) into the compensation holes. •Check that the Pf sleeves and pins move smoothly.

[12]Install the electromagnetic proportional pressure reducing valve (079) in the pilot cover (641), and tighten the hexagon socket head bolts (418).

Tightening torque: 6.9 N•m •This operation is only for the front-side regulator (KR3G-9Y04-HV). •Be careful not to damage the connector section of the electromagnetic proportional pressure reducing valve.

[13]Install the pilot covers (641), and tighten the hexagon socket head bolts (436).

Tightening torque: 12 N•m

[14]Install the spring seatings (Q) (644), pilot springs (646), and adjusting rings (Q) (645) into the pilot holes, and install the spring seatings (Q) (624), inner springs (626), and outer springs (625) into the compensation holes. •Be careful to install the spring seatings (Q) in the correct direction.

[15]Assemble the covers (C) (629) set with the adjusting screws (C) (628), adjusting rings (C) (627), lock nuts (630) ,hexagon nuts (801) and (802), hexagon socket head locking screws (924), and tighten the hexagon socket head bolts (438).

Tightening torque: 12 N•m

This completes the assembly of the regulator main units.